Method for correcting mask distribution pattern

A technology of layout drawing and mask, applied in photoengraving process of pattern surface, original for photomechanical processing, special data processing application, etc., can solve problems such as low pattern density and uneven etching, and achieve improved surface The effect of uniformity and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

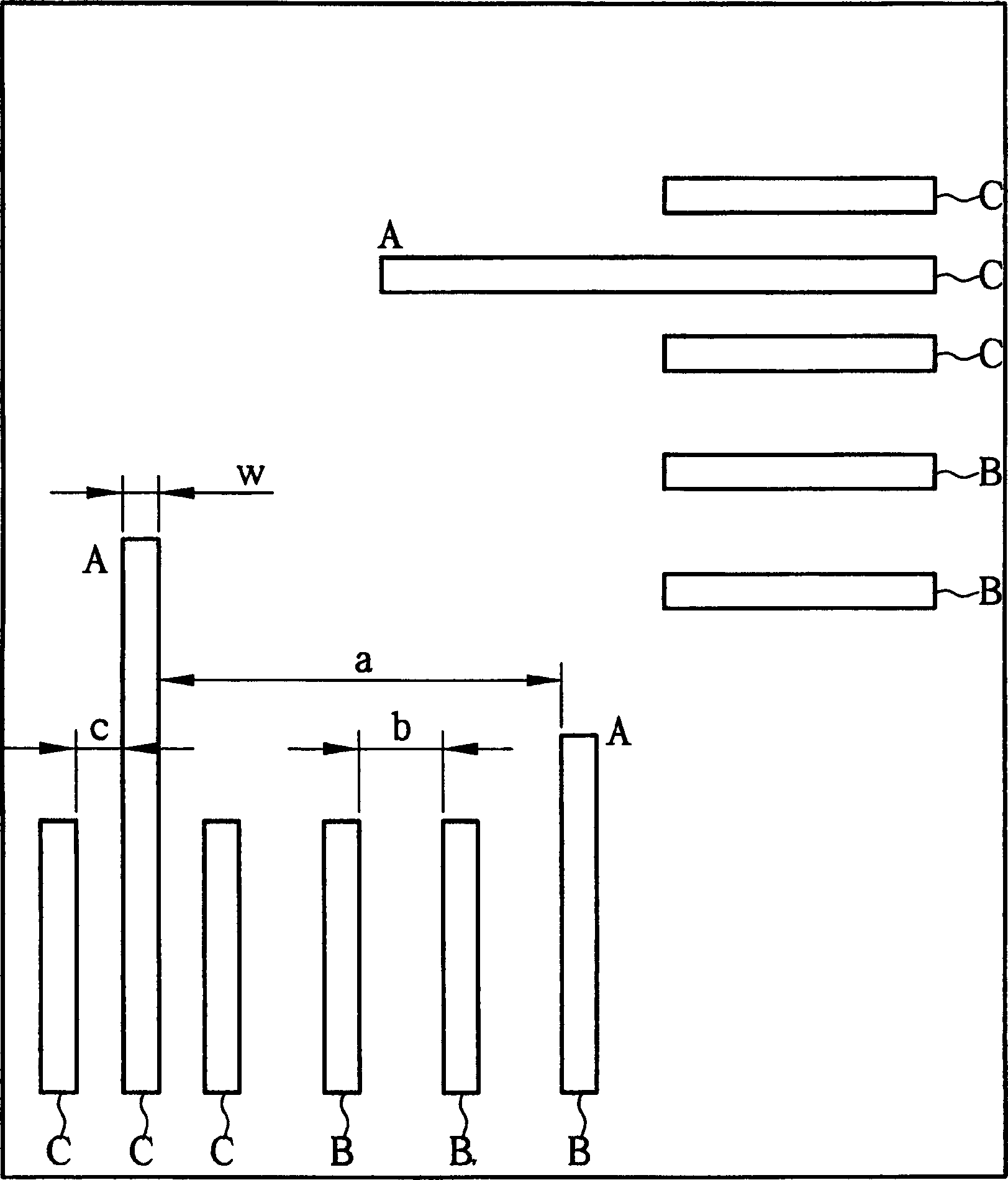

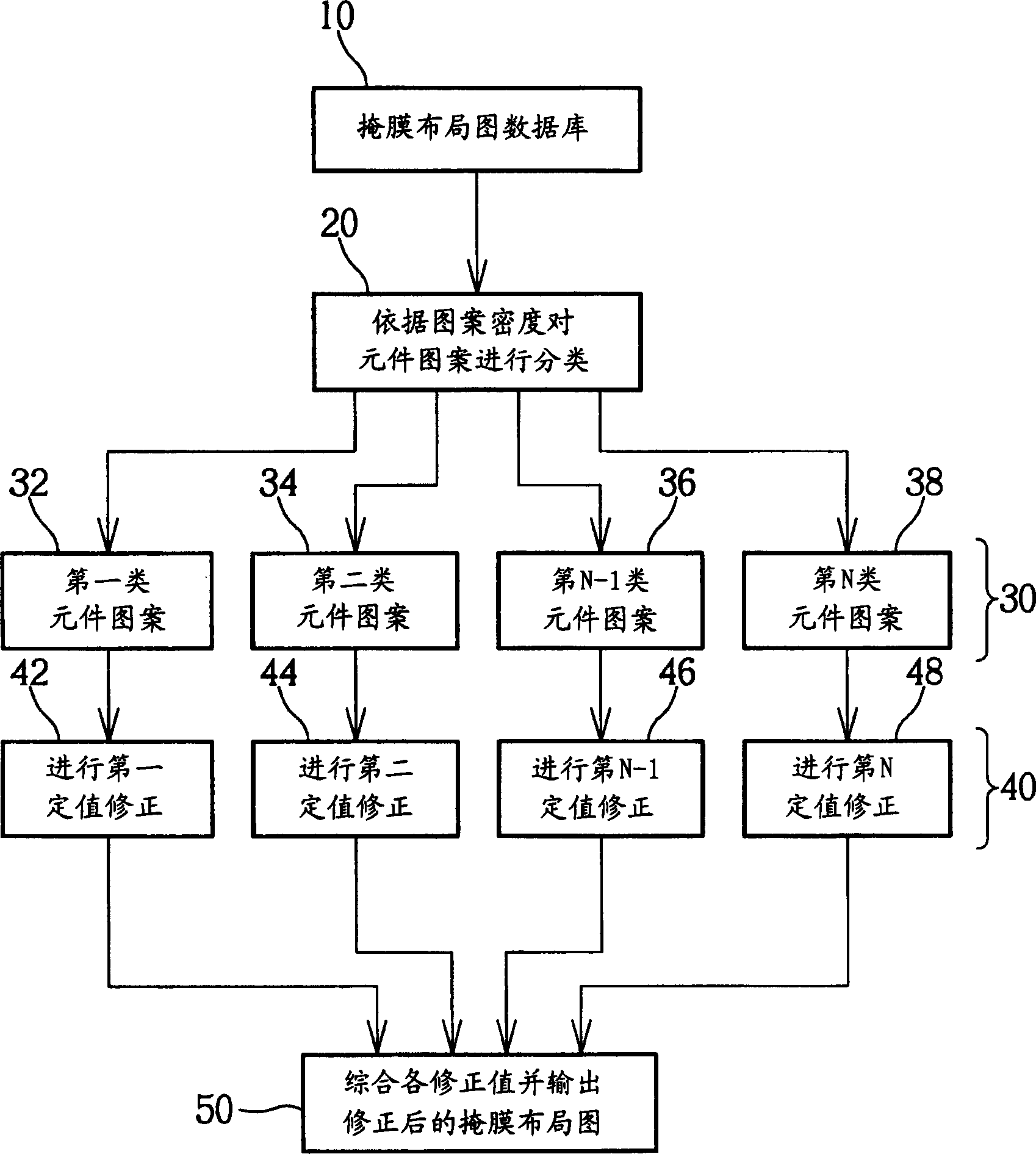

[0022] refer to image 3 , image 3 A flowchart of a method for correcting a mask layout to avoid microloading effects according to the present invention. Such as image 3 As shown, the method of the present invention first proceeds to step 10, providing a mask layout database. The mask layout diagram contains a plurality of (linear) element patterns, which are respectively used to define conductive regions in different regions on a single chip, such as word lines or bit lines in memory cell regions and logic circuit regions, etc. Component patterns for different circuit design requirements, or used to define component patterns on a multi-chip, and the database includes parameter data of each component pattern.

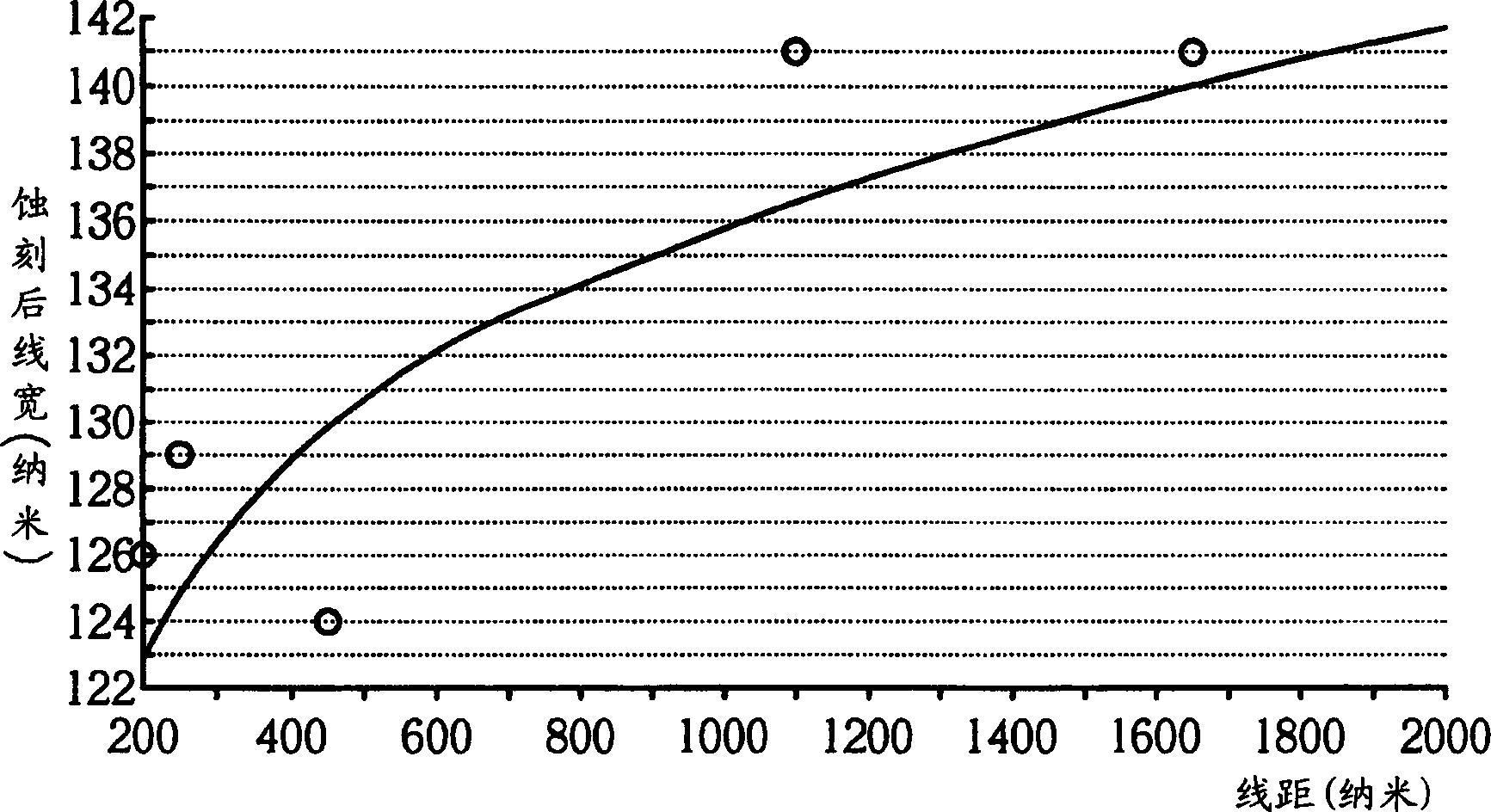

[0023] Since the micro-loading effect is caused by the pattern density difference between the various element patterns, the present invention then proceeds to step 20, provides a detection program, and classifies according to the pattern density of each element pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com