Hydraulic support used for roadway temporary support and erecting and use method of hydraulic support

A hydraulic support and temporary support technology, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of insufficient distance to the roof, easily damaged roof, high labor intensity, etc., and achieve a safe working environment for employees Reliable, improved engineering quality, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

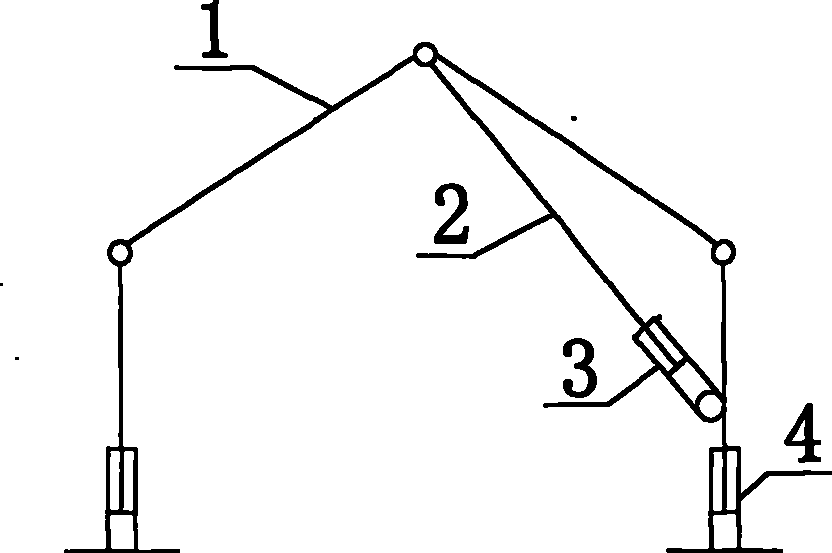

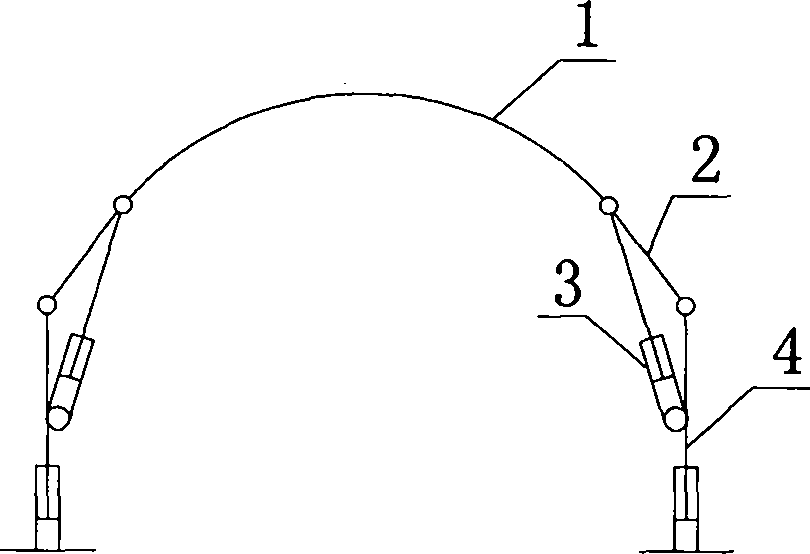

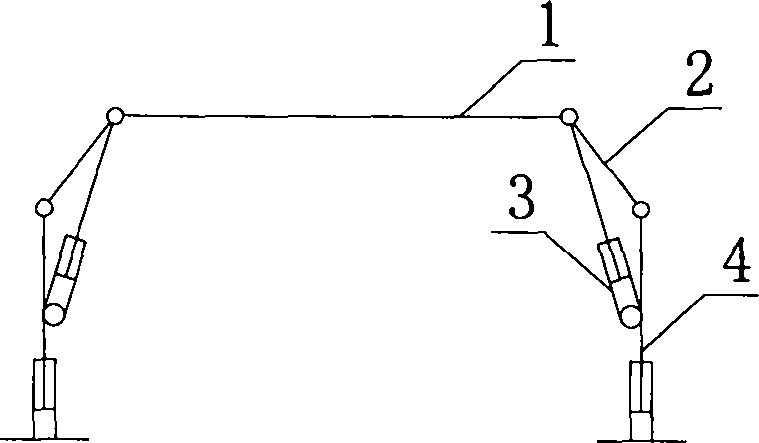

[0044] The hydraulic support mainly includes a top beam (1), an angle beam (2), a telescopic side support (4), and an ultra-statically indefinite balance oil cylinder (3); the top beam and the angle beam, and the angle beam and the telescopic support are hinged , One end of the super-static balance cylinder is hinged on the telescopic side support, and the other end is hinged on the top beam. Both the telescopic side support and the super-static balance cylinder are retractable, so as to realize the lifting and folding of the hydraulic support.

[0045] The super-static balance oil cylinder (3) is equipped with a two-way valve that communicates and closes on both sides. help body.

[0046] The telescoping side support (4) can be any kind of mode that can realize this support up and down stretching including hydraulic oil cylinder, telescoping wall etc.

[0047] According to the form of the roadway, the shape of the top beam of the hydraulic support is adapted to the top secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com