PCB apparent defect automatic detection system and method based on image

An automatic detection and defect detection technology, applied in the field of defect detection, can solve the problems of low detection efficiency and accuracy of PCB boards, high price, and high false detection rate, and achieve the goal of reducing hardware control costs, reducing defect rates, and low false detection rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

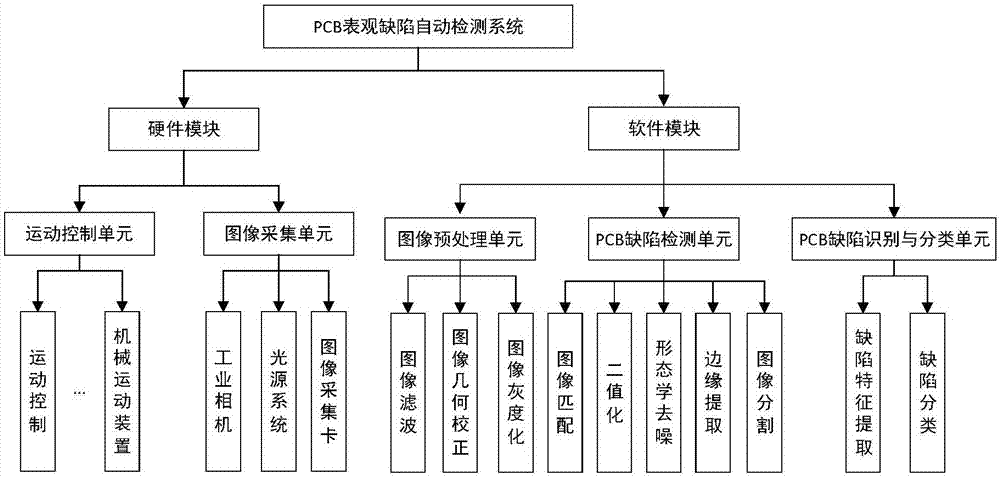

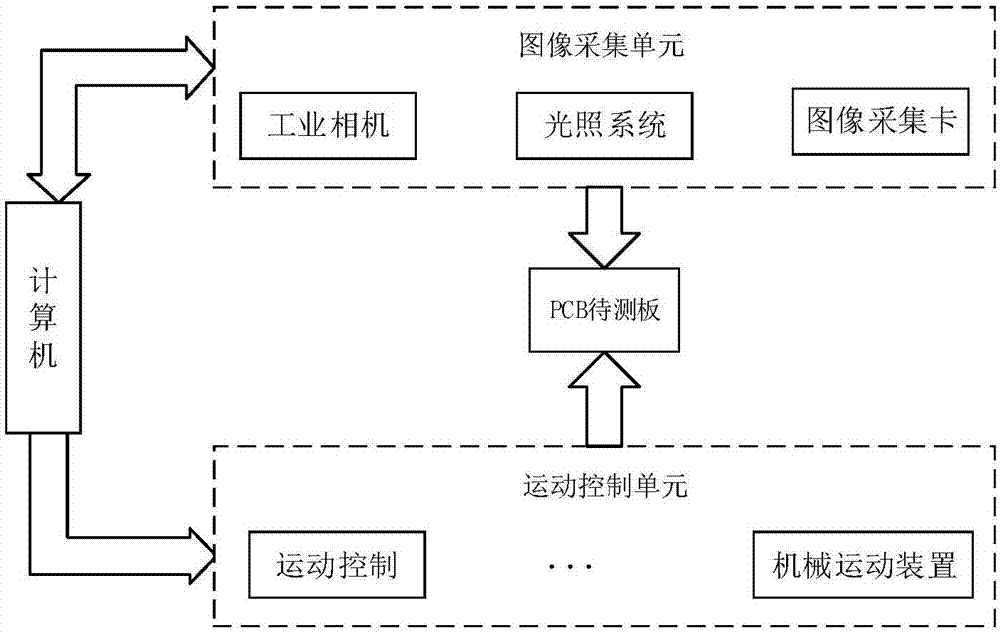

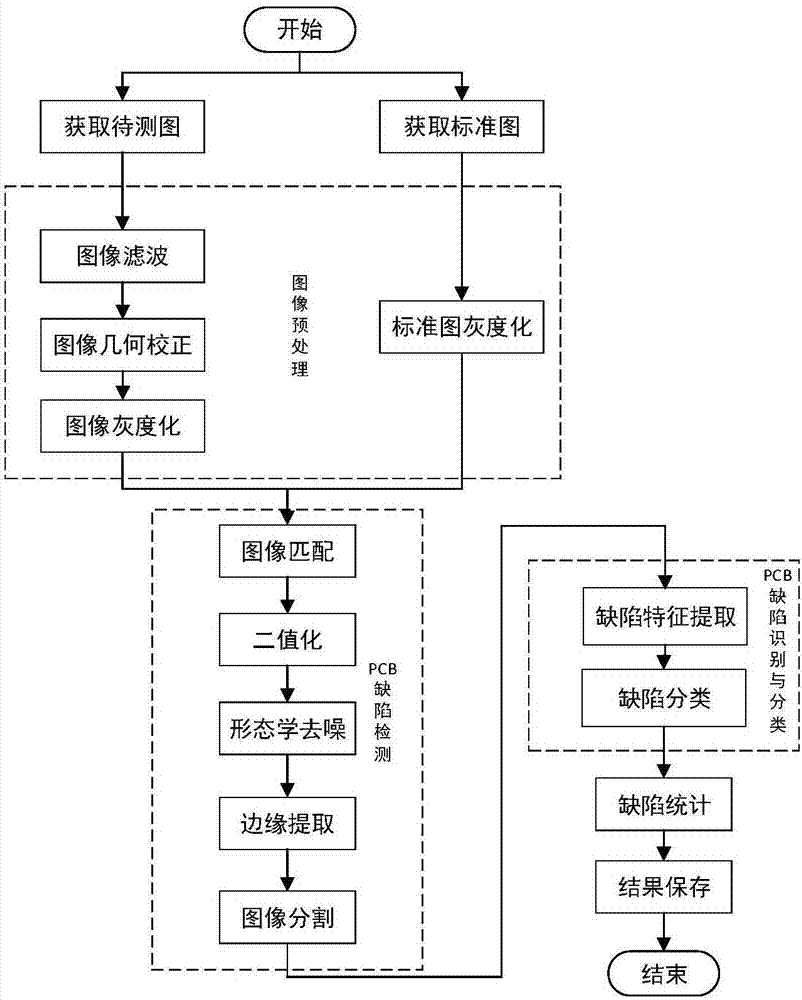

[0040] The image-based PCB apparent defect automatic detection system provided by the present invention includes a motion control unit, an image acquisition unit, an image preprocessing unit, a PCB defect detection unit, and a PCB defect identification and classification unit, wherein:

[0041] The motion control unit is used to transfer the PCB to be tested to the designated position of the image acquisition unit through the transfer device;

[0042] The image acquisition unit is used to obtain the PCB to-be-tested image and the PCB standard image by using the image acquisition card, the light source system and the industrial camera;

[0043] The image preprocessing unit is used to perform image filtering, image correction, and image grayscale preprocessing operations on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com