Patents

Literature

118results about How to "Improve defect detection accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

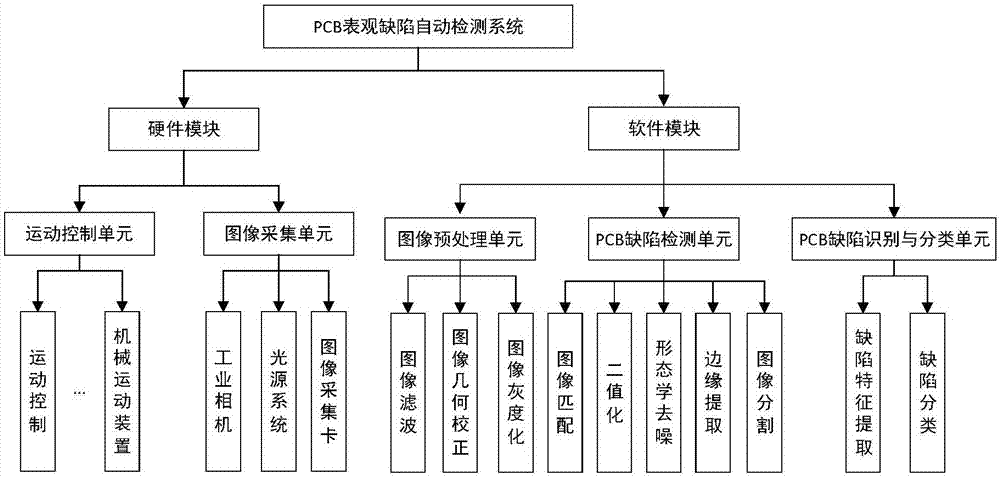

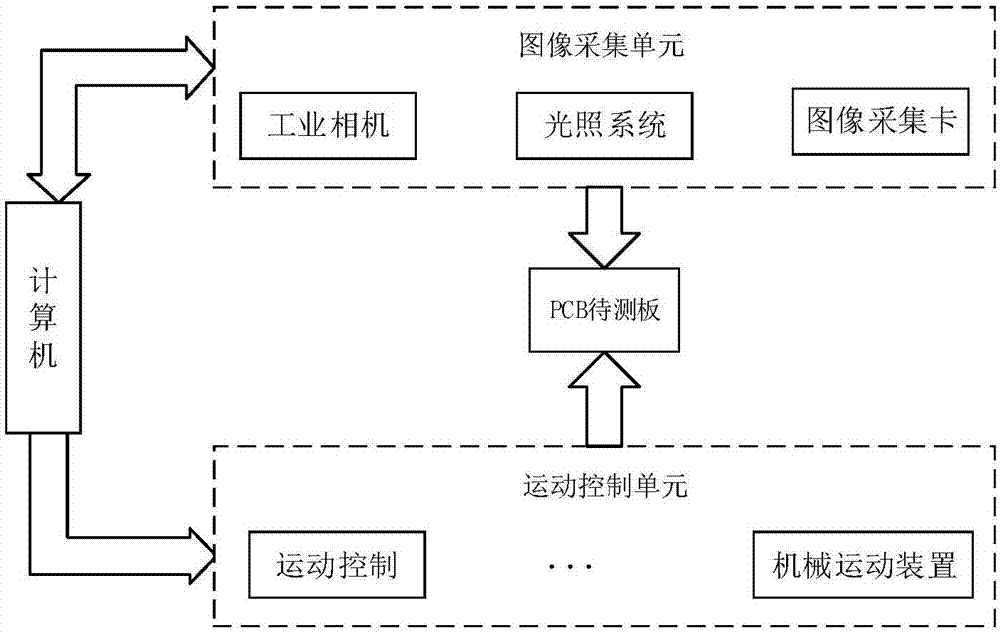

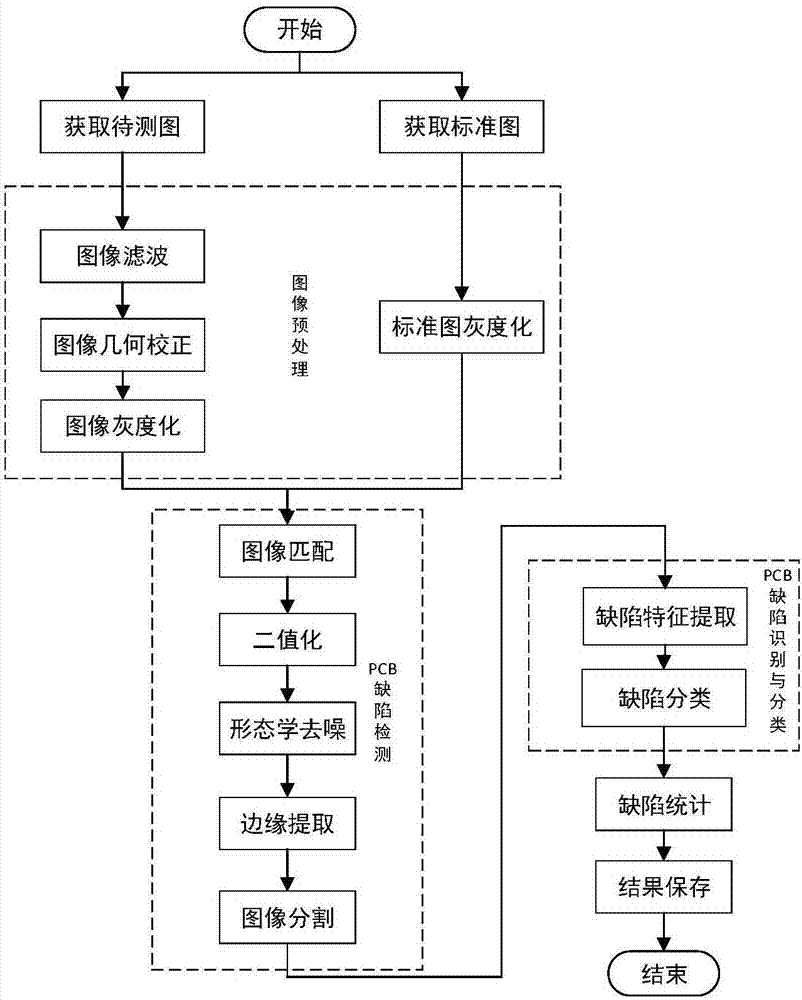

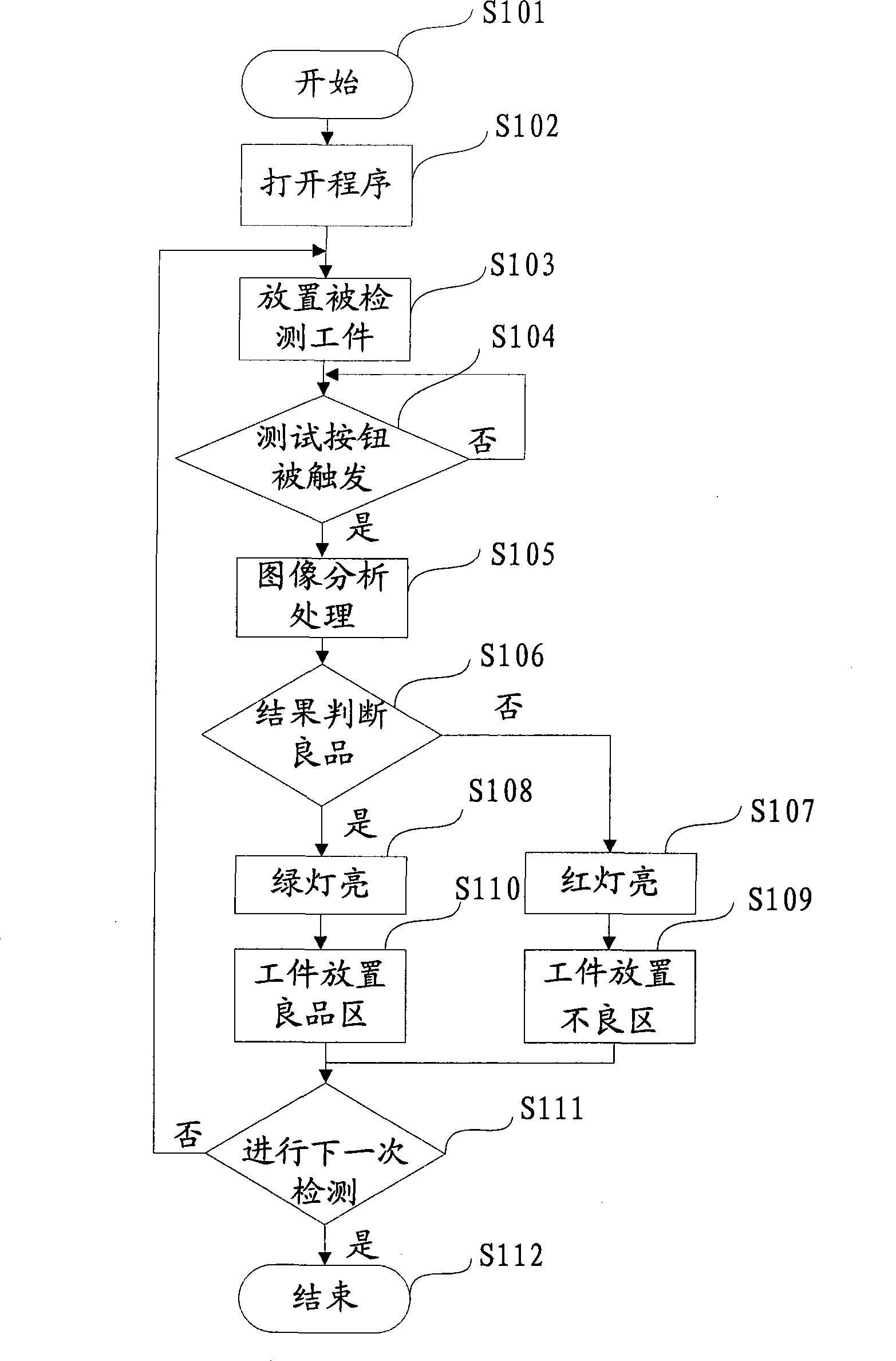

PCB apparent defect automatic detection system and method based on image

InactiveCN107389701AImprove detection efficiencyReduce false detection rateImage enhancementImage analysisMovement controlAutomatic testing

The invention provides a PCB apparent defect automatic detection system and method based on an image and aims at solving the problems that detection efficiency is low and misjudgment rate is high. The method comprises the following steps: firstly transmitting a to-be-detected PCB to a specified position by virtue of a motion control unit; acquiring an image of the to-be-detected PCB by utilizing image acquisition equipment such as an image acquisition card and an industrial camera; then sequentially carrying out a series of operation such as image preprocessing, PCB defect detection and PCB defect identification and classification on the acquired image, so that PCB defect automatic detection is completed; and finally realizing real-time automatic sorting of an unqualified PCB and timely reporting a defect position and a defect analysis result to an operator. The system and method which are provided by the invention can automatically detect the PCB defect and identify the defect type to a great extent, and false detection rate is reduced, so that enterprise cost is reduced, and the system and method which are provided by the invention have stronger practicability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

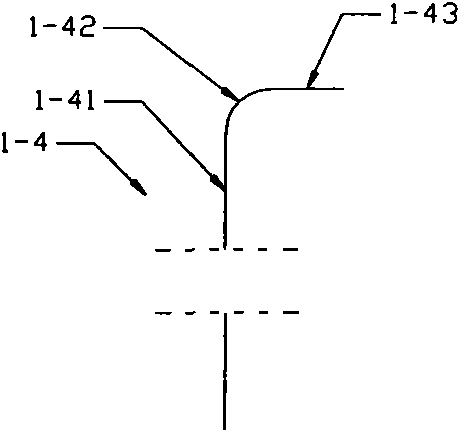

Oil and gas pipeline intelligent internal detection device based on multi-module combined location

ActiveCN103470959AReduce resistancePrevent pulling outPipeline systemsSpeed control systemElectromagnetic pulse

The invention discloses an oil and gas pipeline intelligent internal detection device based on multi-module combined location. The device comprises an internal detector arranged inside an oil and gas pipeline and a floor marker arranged outside the oil and gas pipeline. The internal detector comprises a driving system, a magnetic leakage detecting system, a speed control system, a distance measuring system and a low frequency emitting system, wherein the driving system, the magnetic leakage detection system, the speed control system, the distance measuring system and the low frequency emitting system are relatively fixedly connected together; the floor marker at least comprises a low frequency receiving system; the low frequency emitting system is used for sending detection results obtained by the magnetic leakage detection system out of the oil and gas pipeline; the low frequency receiving system is used for receiving low frequency electromagnetic pulse signals transmitted by the low frequency emitting system. The oil and gas pipeline intelligent internal detection device based on the multi-module combined location can timely obtain the detection data of the pipeline detector and analyze the detection data and accordingly rapidly determine the defect conditions of the pipeline.

Owner:BEIJING APC PETROCHEM TECH

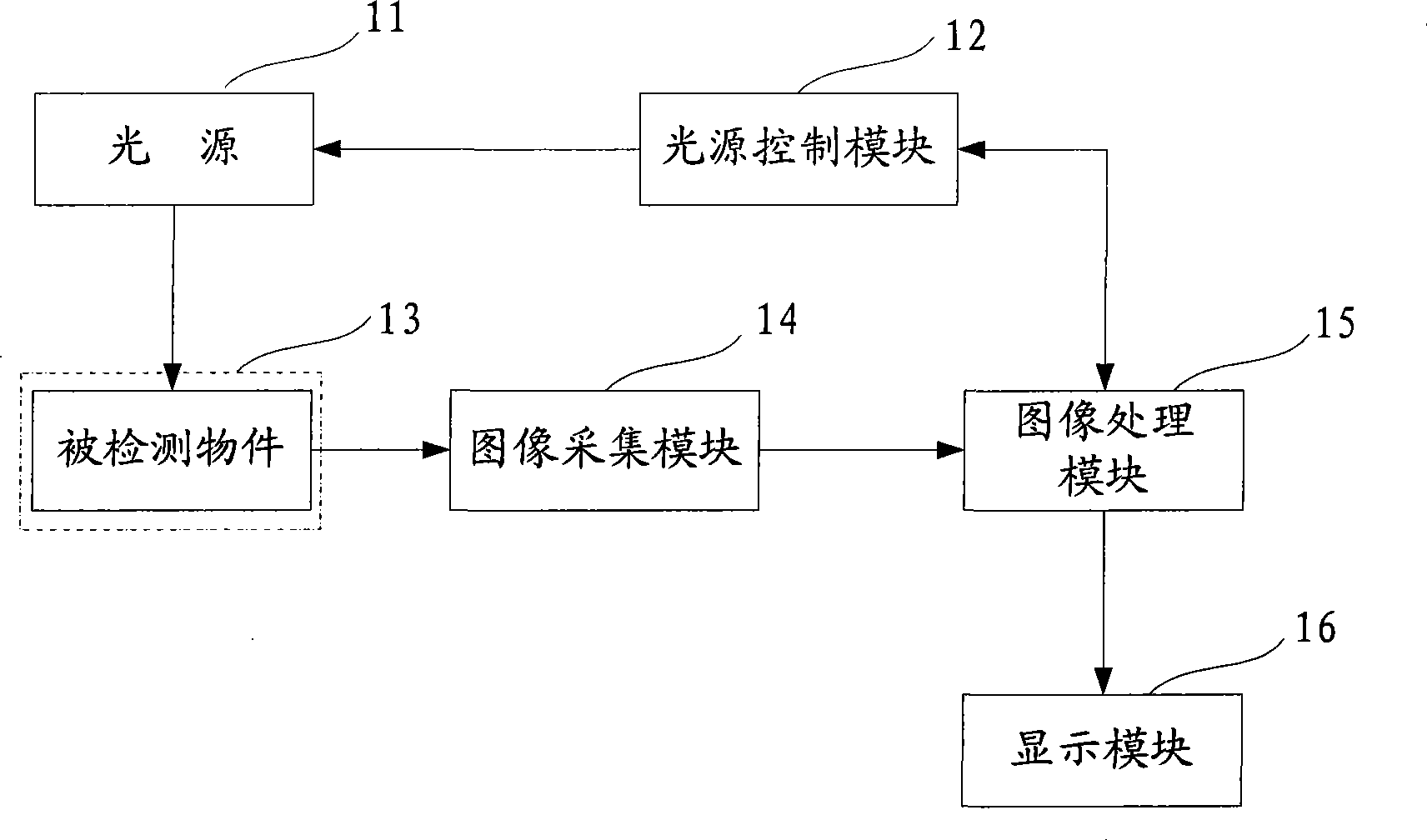

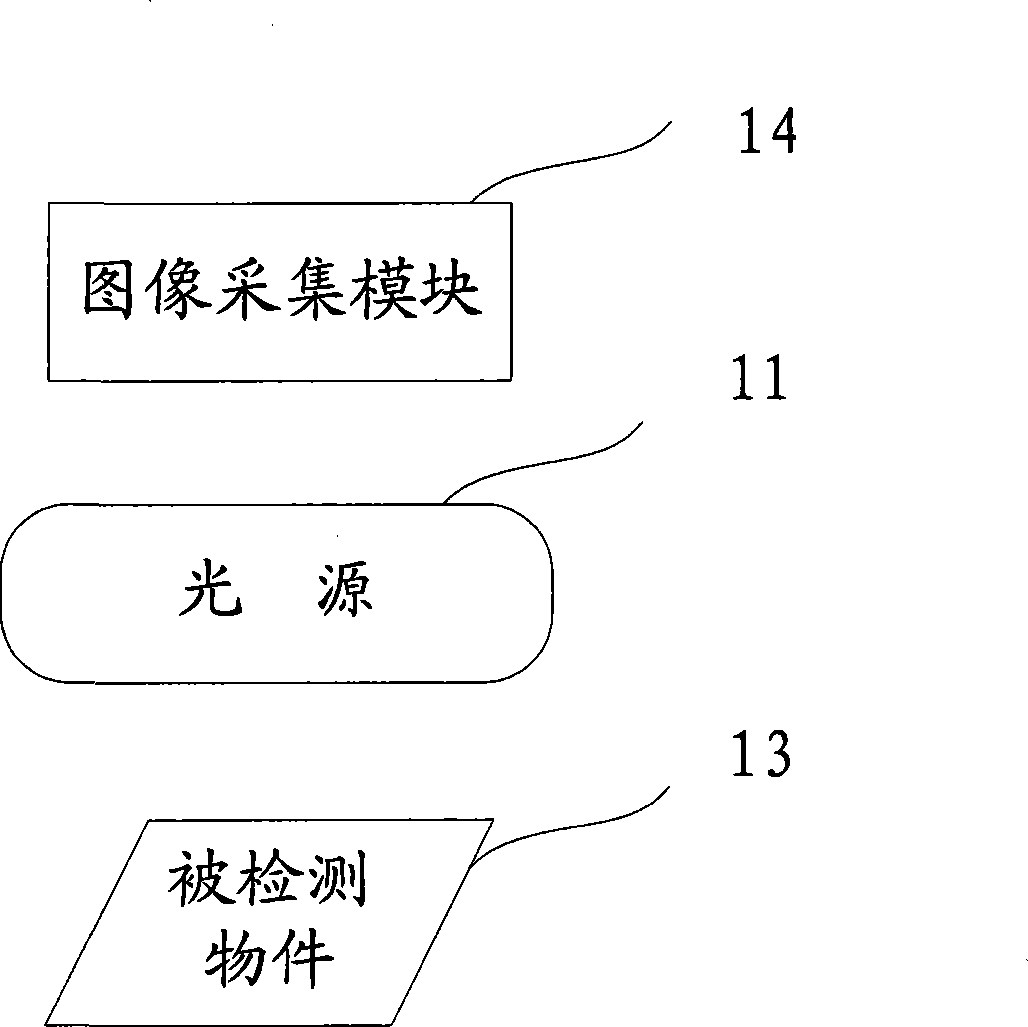

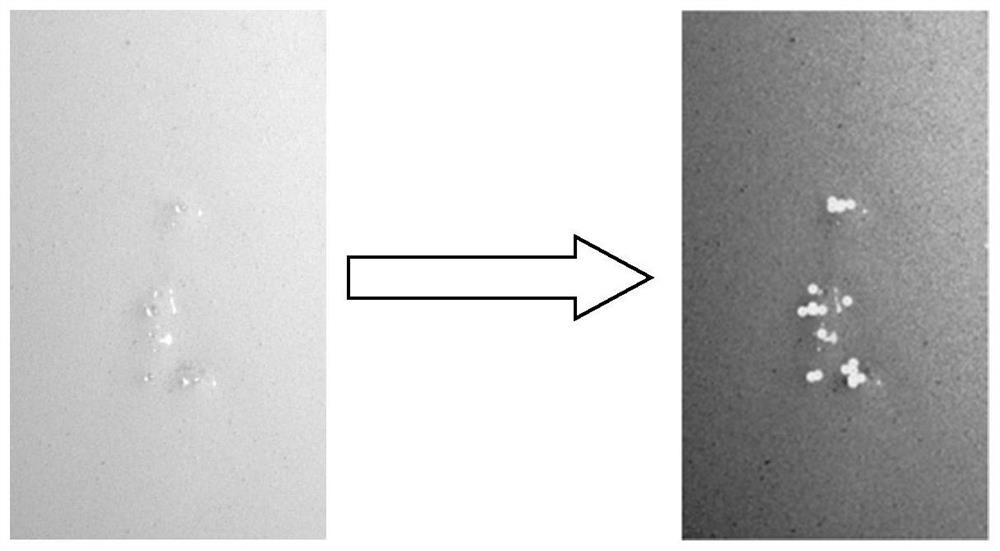

Surface flaw detecting method and device

InactiveCN101419176AAvoid human interferenceImprove defect detection accuracyImage enhancementOptically investigating flaws/contaminationPattern recognitionComputer vision

The invention provides a method for detecting surface blemish, which comprises the following steps: acquiring an image of an object to be detected; generating a binary image through binary treatment according to the acquired image of the object to be detected; filtering possible blemish particles for the image subjected to the binary treatment; and comparing grey mean value of a blemish with the grey mean value of an image blemish area before the binary treatment to determine the blemish. The invention also provides a device for detecting surface blemish. The device has better practicability and accuracy, and is easy to popularize.

Owner:BYD CO LTD

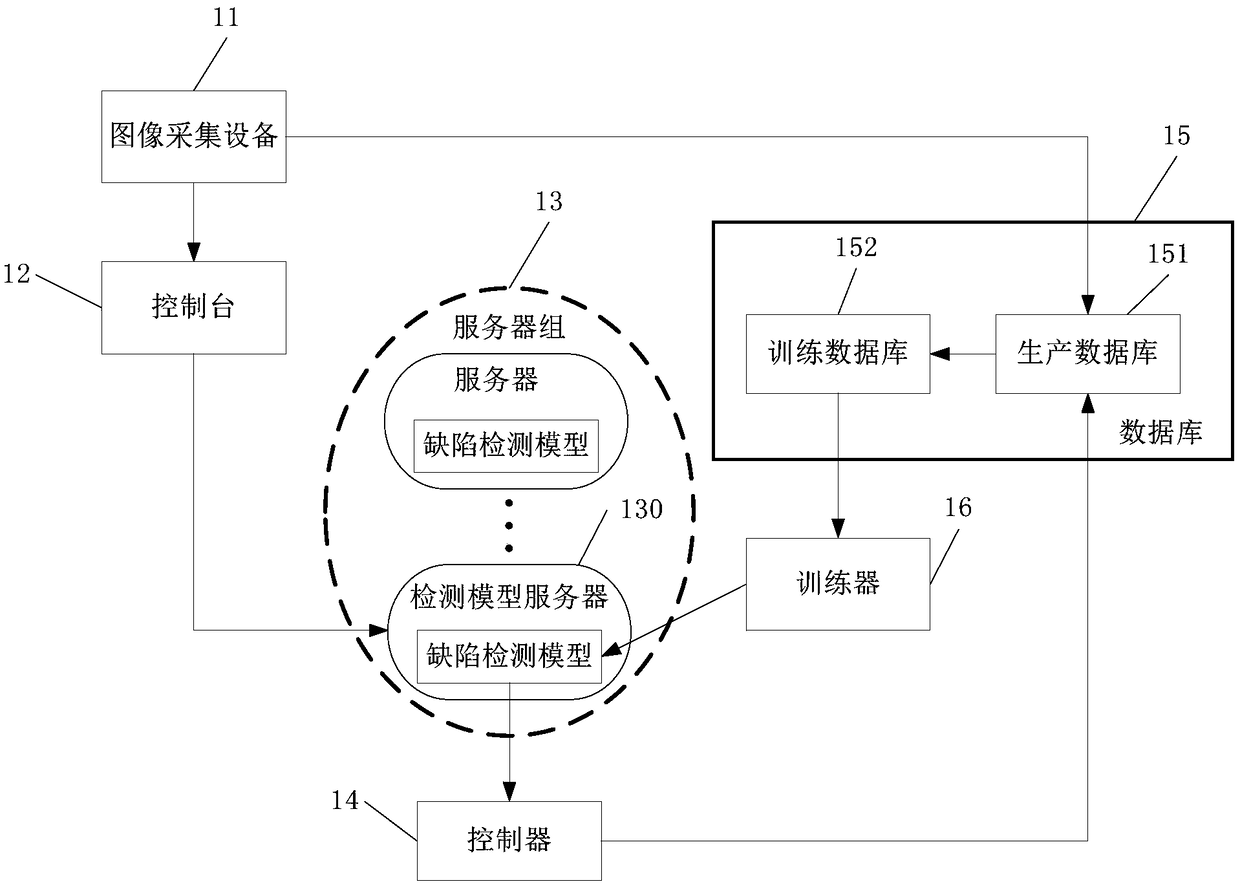

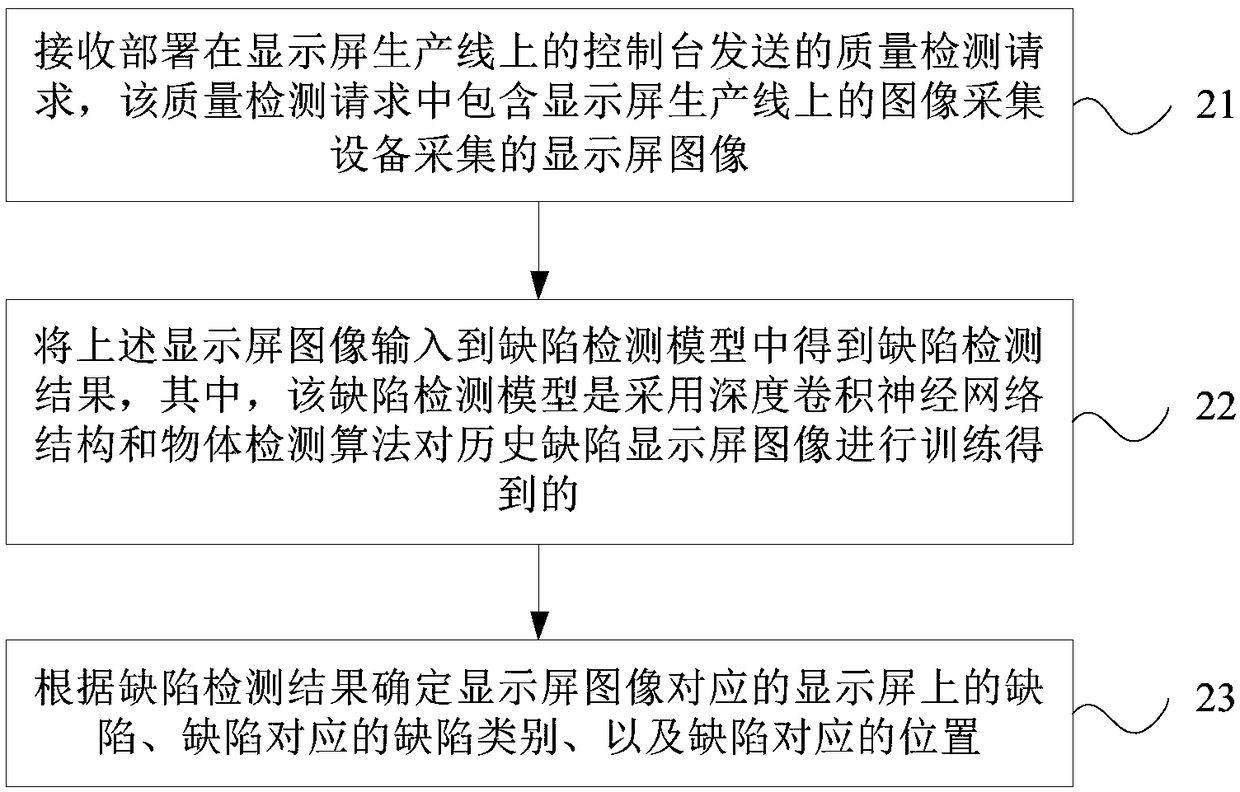

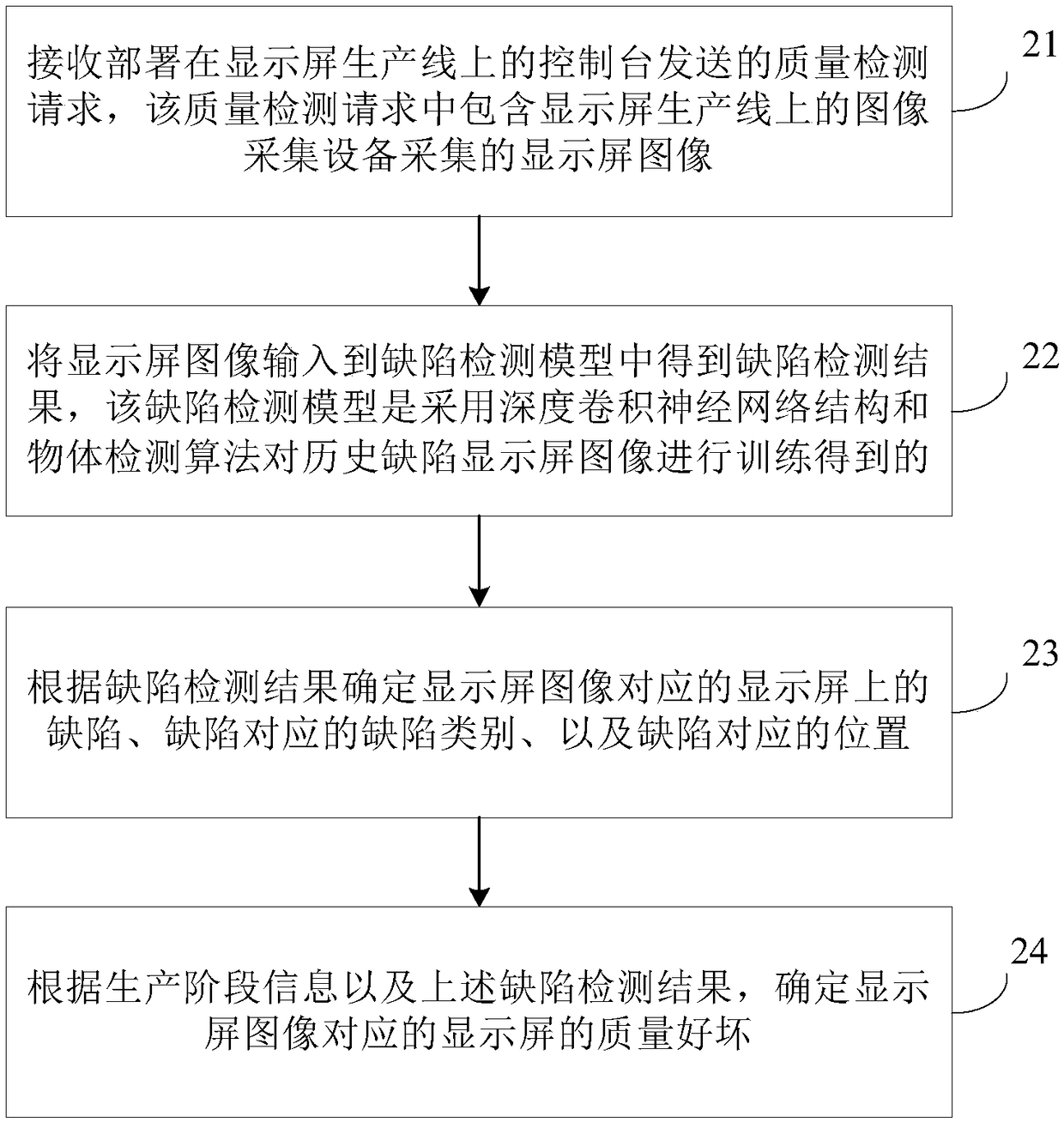

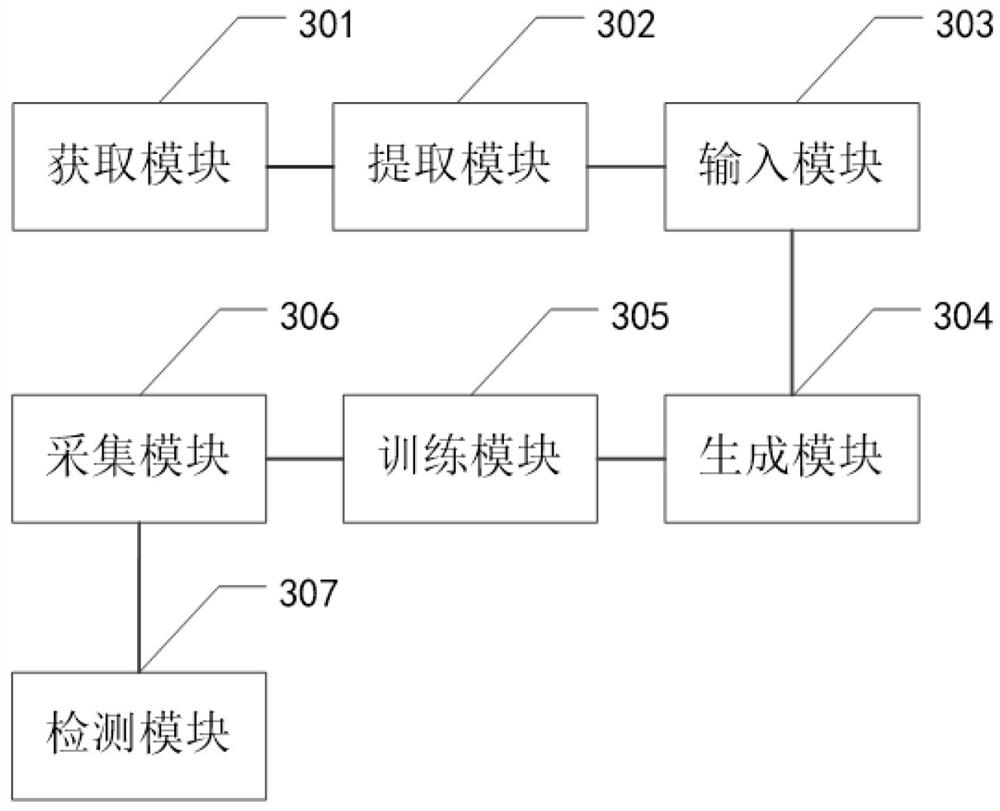

Display screen quality detecting method and device, electronic equipment and storage medium

PendingCN108846841AImprove defect detection accuracyHigh business expansion capabilityImage enhancementImage analysisProduction lineNetwork structure

The invention provides a display screen quality detecting method and device, electronic equipment and a storage medium. The method comprises the steps of receiving a quality detecting request from a console deployed on a display screen production line, wherein the quality detecting request includes a display screen image acquired by an image acquisition device on the display screen production line; inputting the display screen image into a defect detection model to obtain a defect detection result, wherein the defect detection model is obtained by training a historical defect display screen image by a depth convolution neural network structure and an object detection algorithm; and according to the defect detection result, determining defects on the display screen corresponding to the defect image, the defect category corresponding to the defects, and the locations corresponding to the defects. The technical scheme has the advantages of high defect detection accuracy, good system performance and high service expansion ability.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

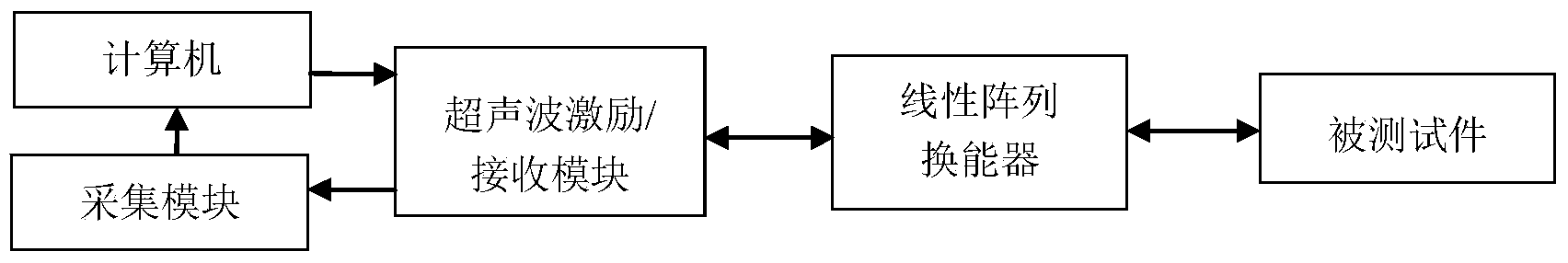

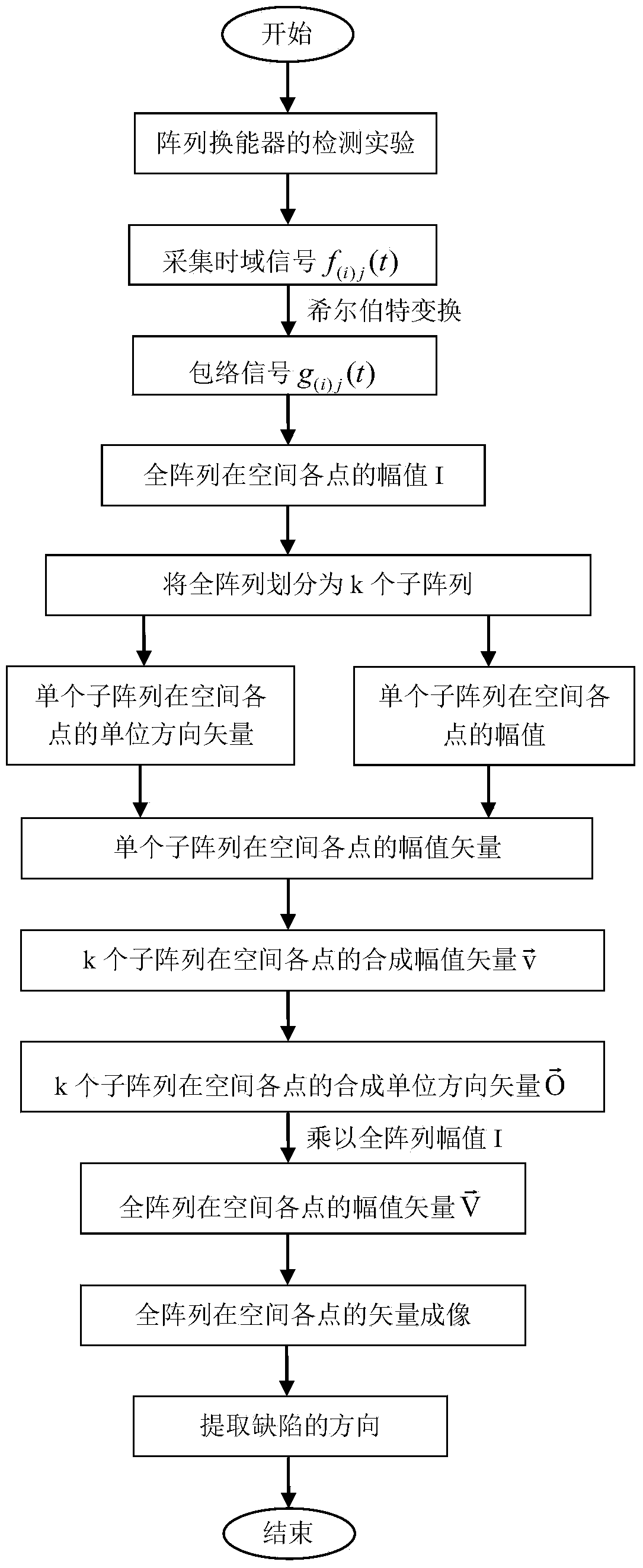

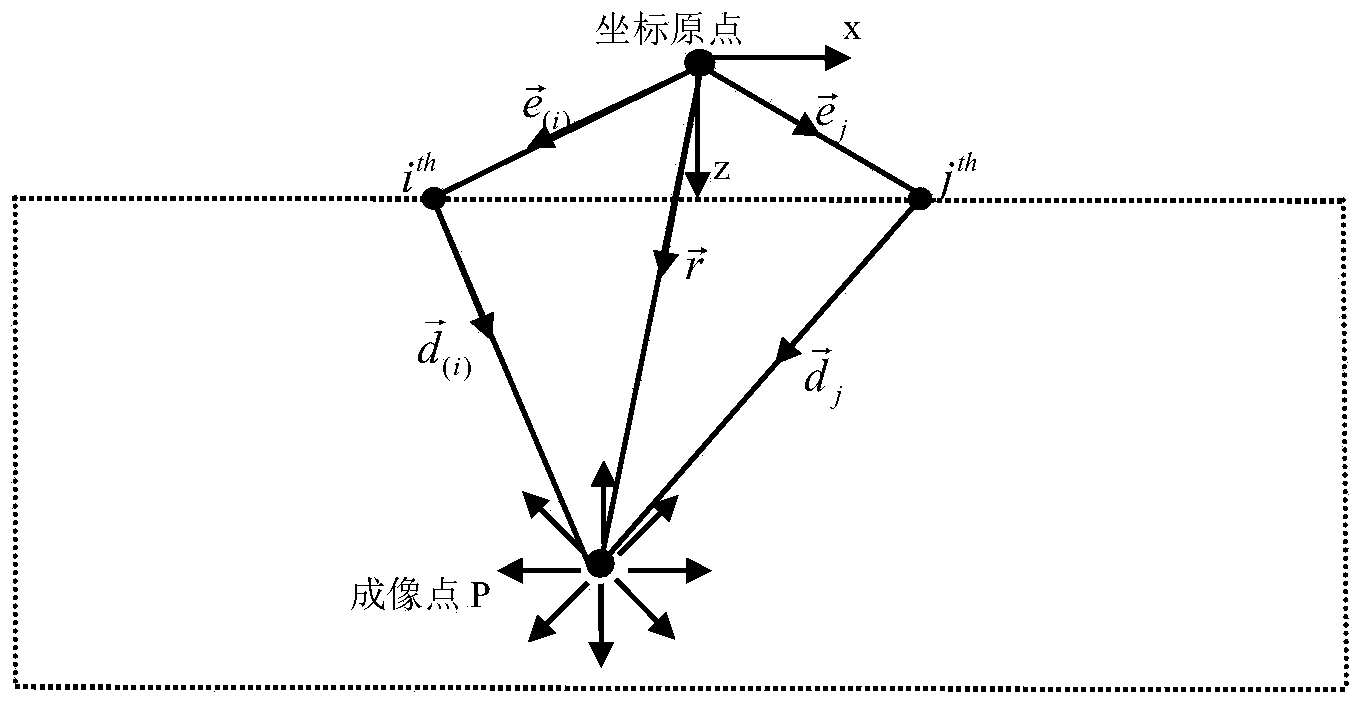

Orientation identification method of ultrasonic array crack defects based on vector full-focusing imaging

InactiveCN103969337AImprove detection abilityImprove defect detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationTransducer

The invention relates to an orientation identification method of ultrasonic array crack defects based on vector full-focusing imaging, and belongs to the field of nondestructive testing. According to the method, vector full-focusing treatment is performed on signals received by a transducer array so as to obtain a global vector diagram, the positions of the defects are determined by the strongest energy of reflected signals at the defects, then local vector diagrams of the defects are extracted according to the positions of the defects, and finally the directions of the vectors are determined by utilizing the directions of vectors in the local vector diagrams. According to the principle of vector full-focusing imaging, a plurality of sub-arrays are constructed in the transducer array, the unit direction vector at any imaging point is calculated through the sub-arrays, and echo amplitude after compensation at any imaging point to the transducer array is vectorized by utilizing the unit direction vector, so that amplitude vector at any imaging point is obtained.

Owner:BEIJING UNIV OF TECH

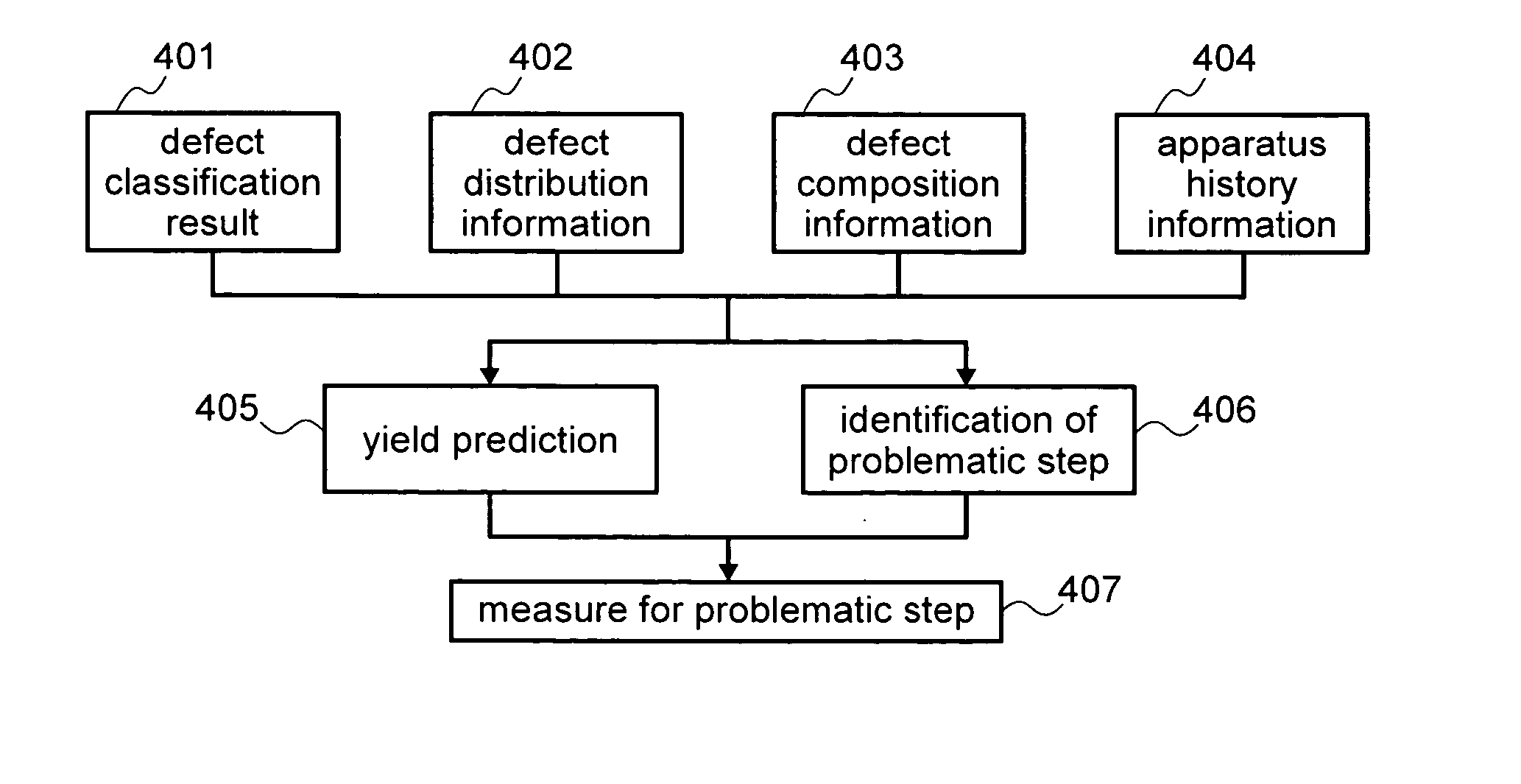

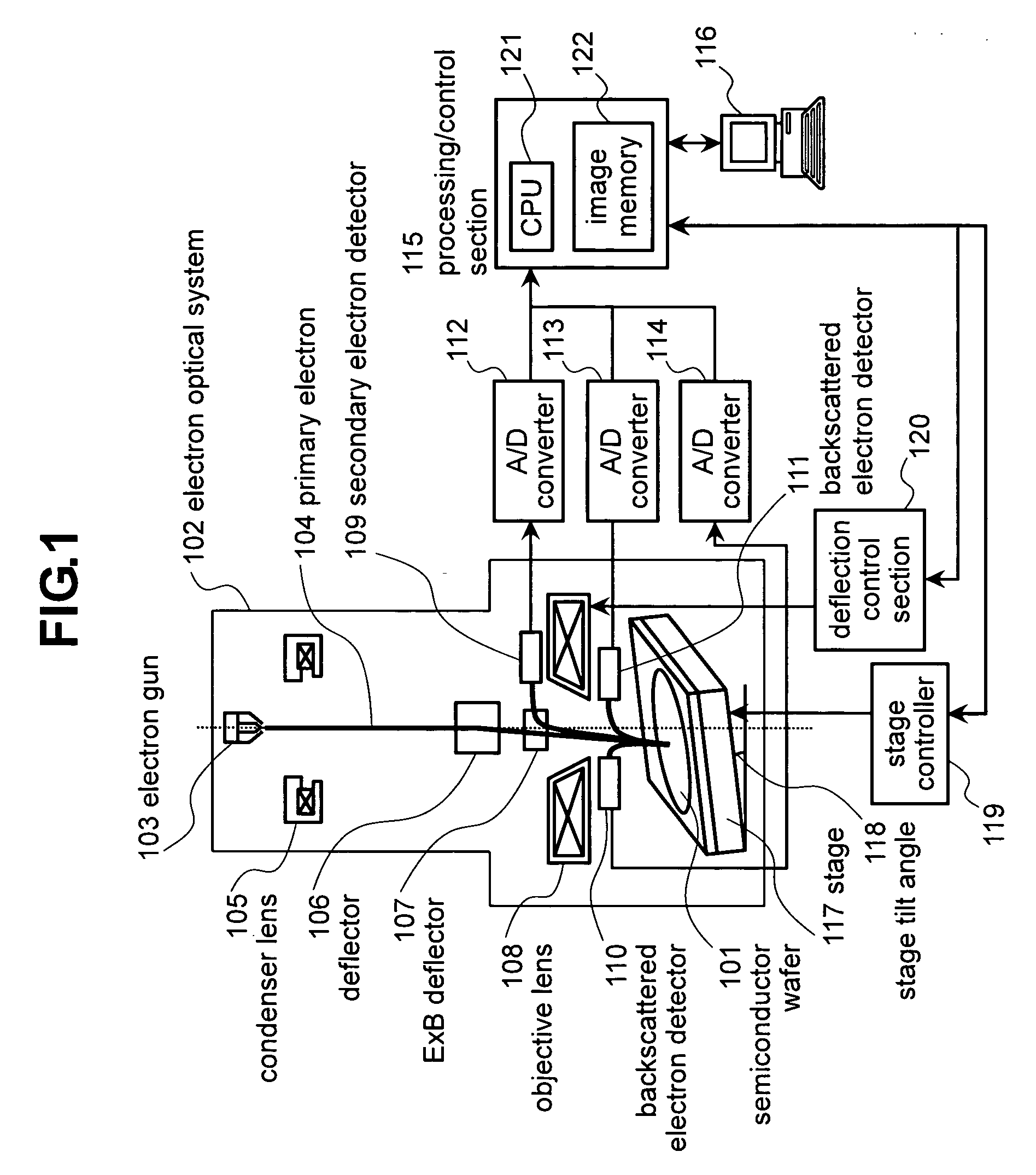

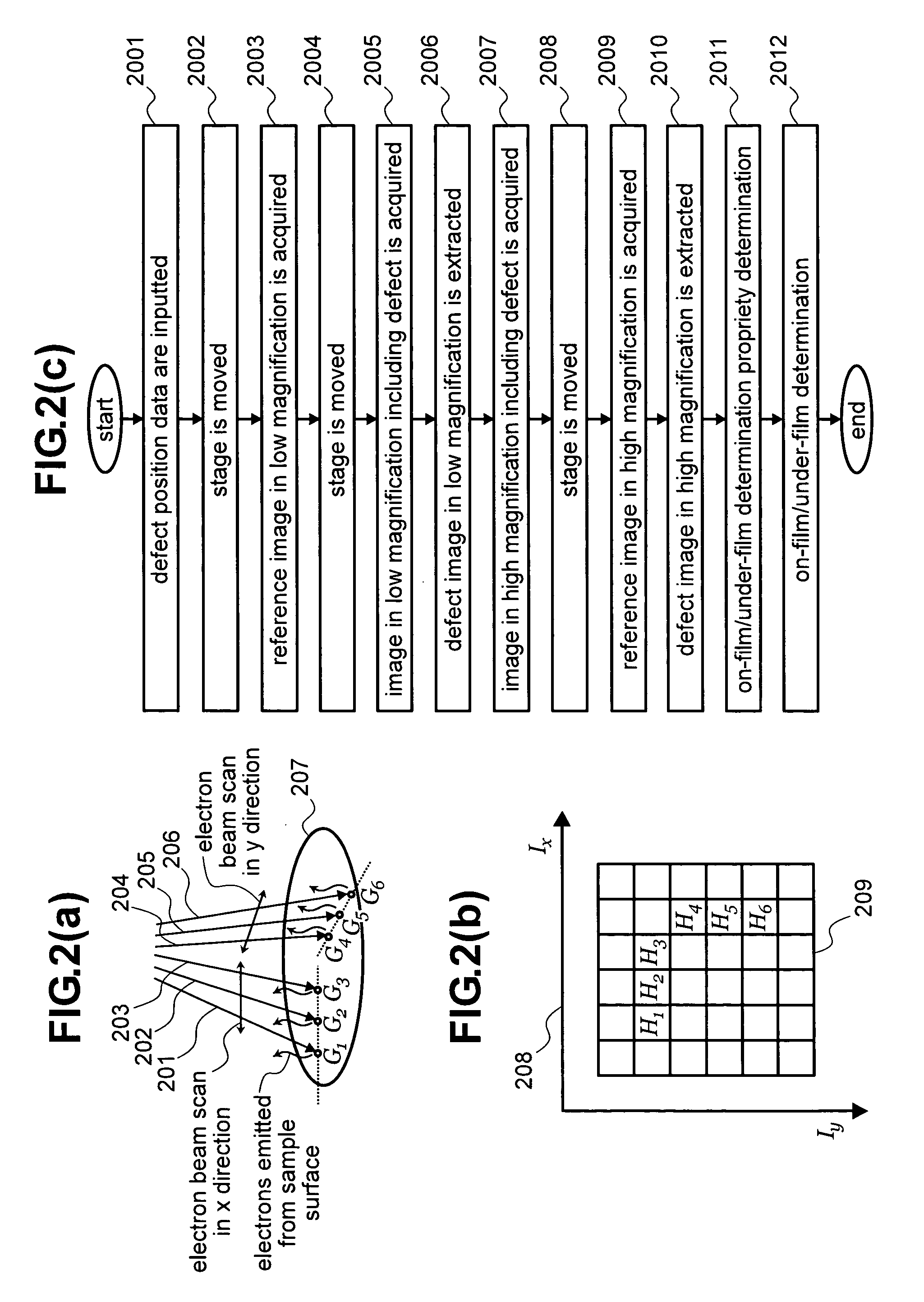

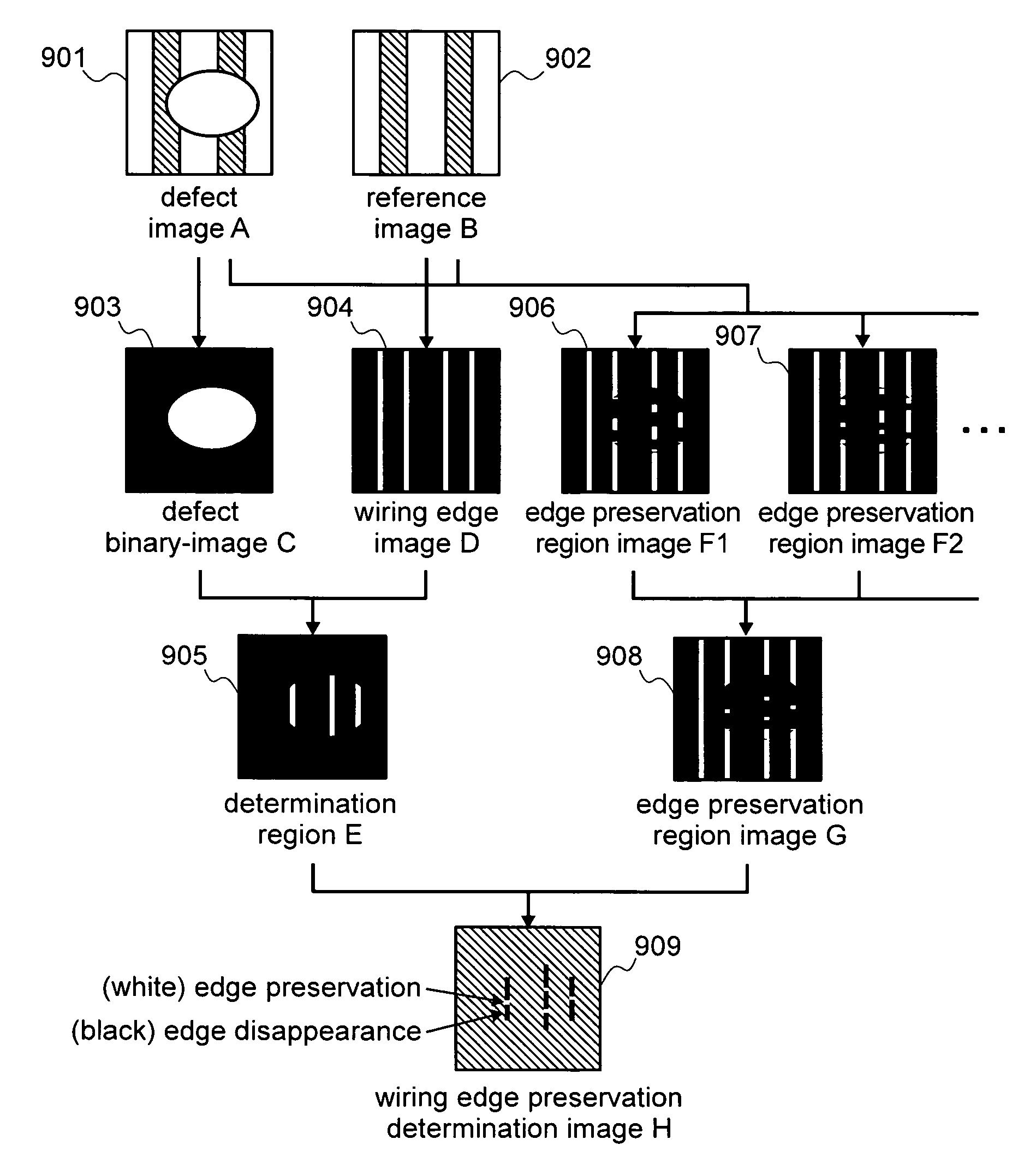

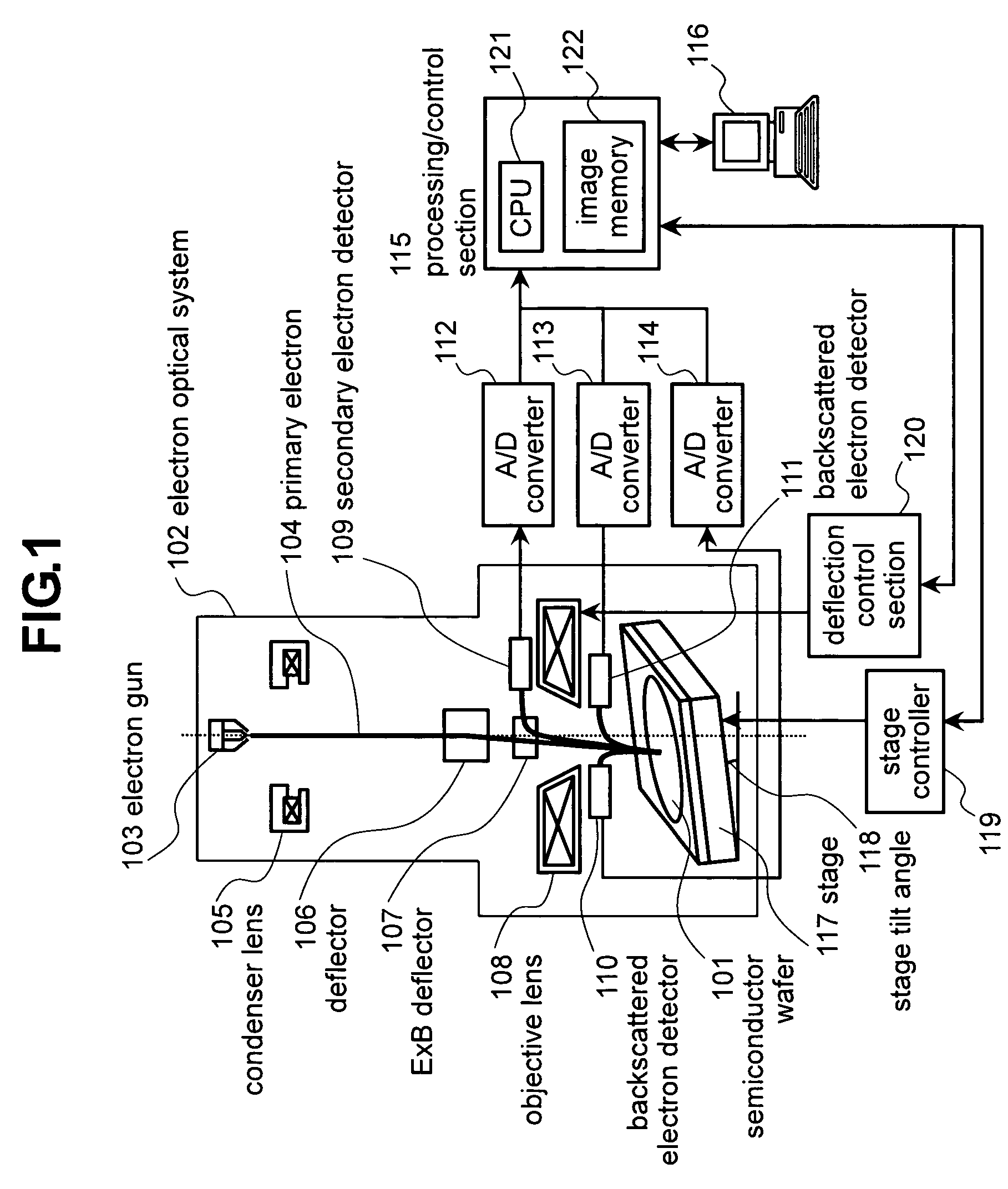

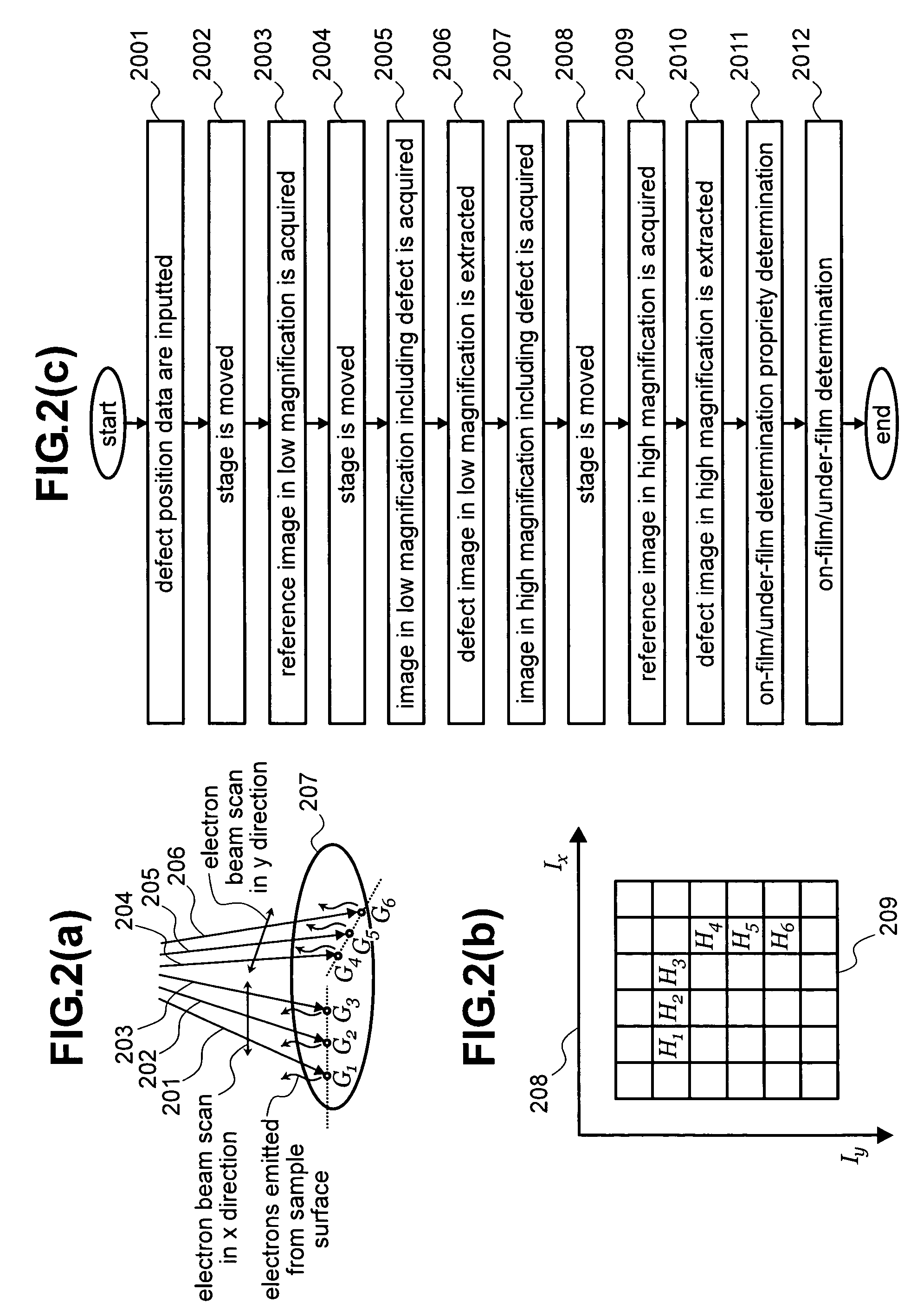

Method and apparatus of reviewing defects on a semiconductor device

ActiveUS20070145270A1Highly versatileReliable handlingMaterial analysis using wave/particle radiationElectric discharge tubesDevice materialClassification methods

To realize reliable on-film / under-film defect classification (classification into 3 classes of on-film, under-film, and determination-disabled) with determination propriety determination, an on-film / under-film defect classification method and a method of narrowing a range of defect generation timing are given, the methods being robust to 4 variation factors, wherein an edge of a boundary line between a line pattern region and a base region is focused, and whether the edge is preserved between defect and reference images in a defective region is determined, thereby an on-film or under-film defect can be identified. Furthermore, a range of the defect generation timing can be narrowed based on an identification result of the on-film or under-film defect, and information of a defect classification class (defect type) such as particle defect or pattern defect as necessary.

Owner:HITACHI HIGH-TECH CORP

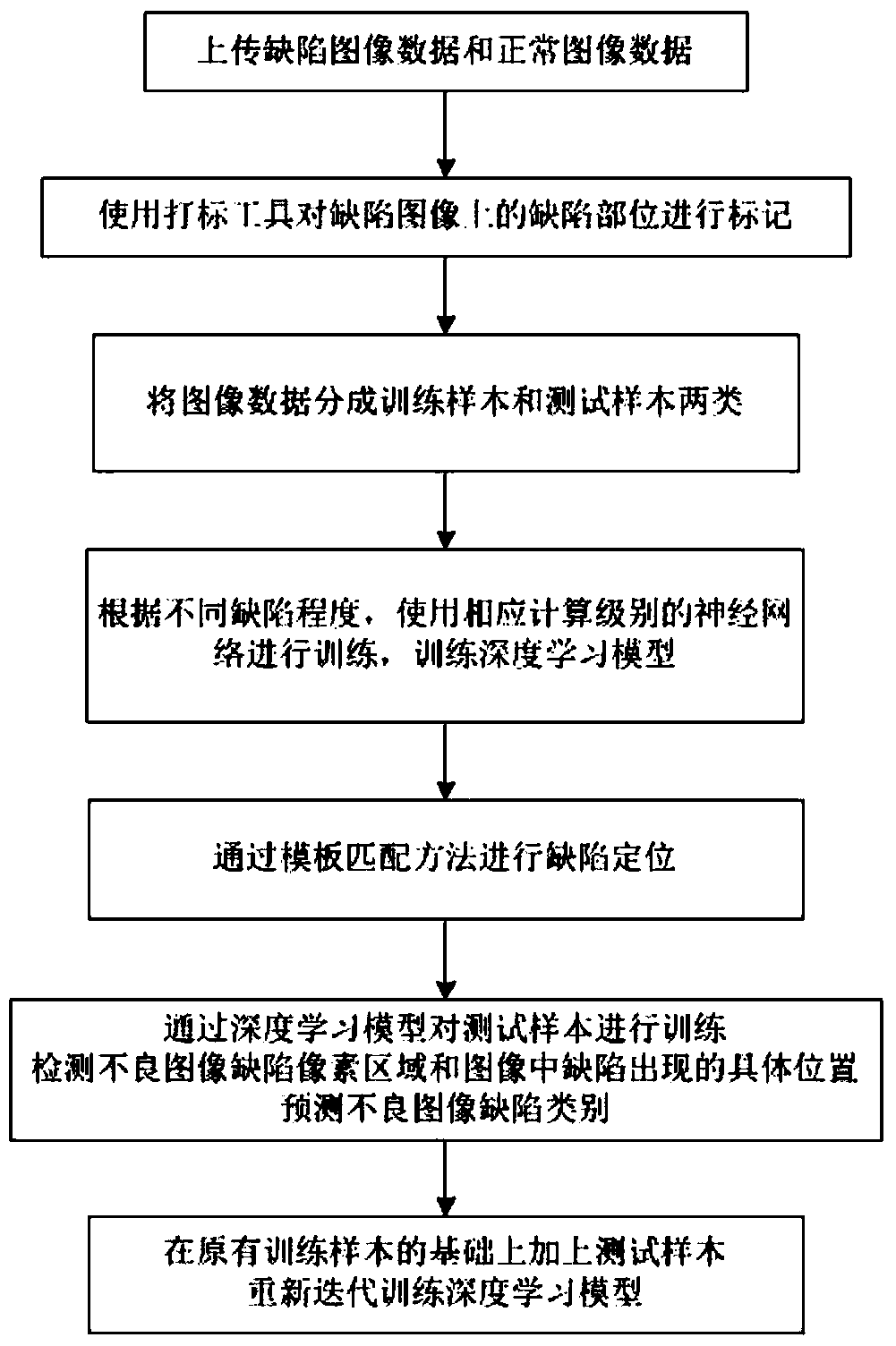

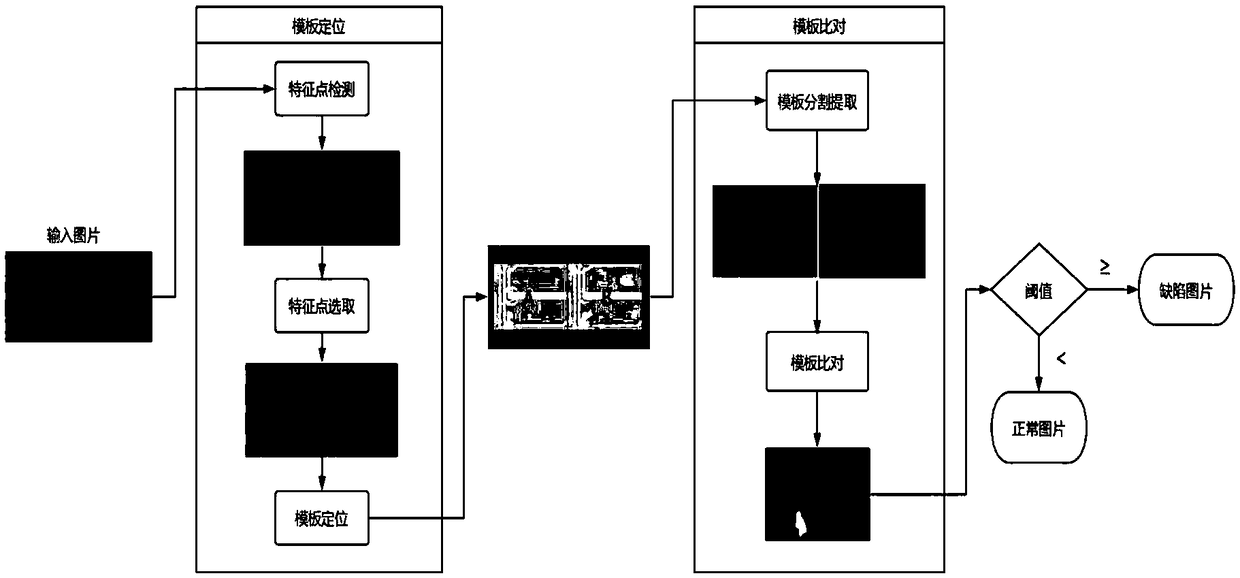

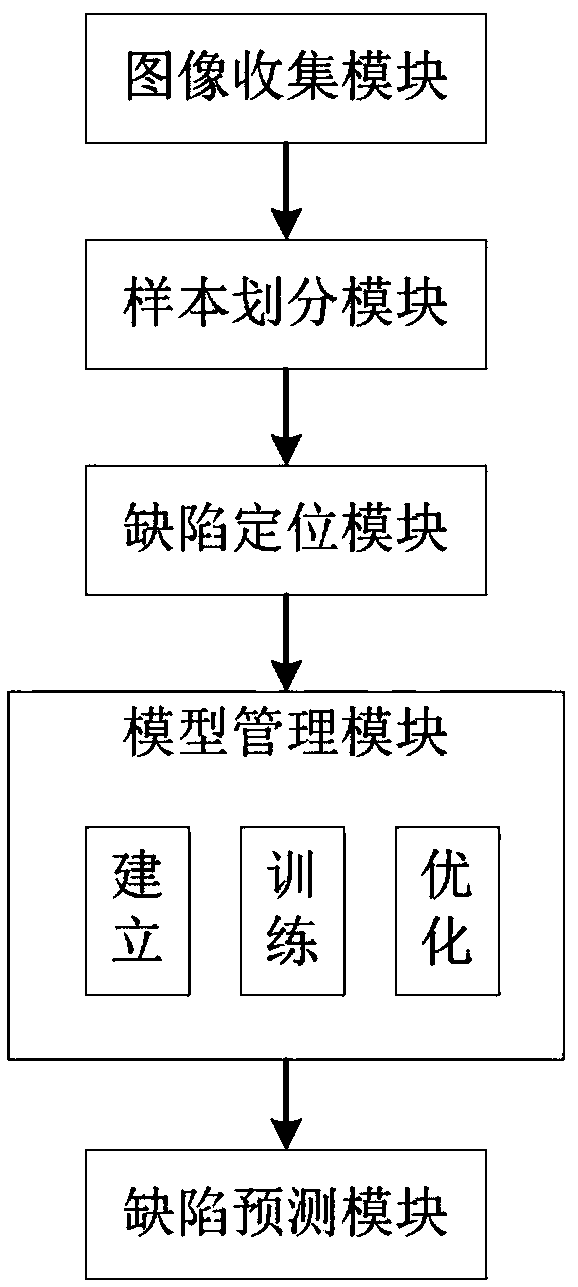

A method and system for detect defects in defective image

InactiveCN109472769AImprove the level of automated detectionImprove detection accuracyImage enhancementImage analysisComputer visionNetwork model

The invention discloses a defect detection method and a system of a defective image. Through a depth learning method, a depth convolution neural network model is constructed to analyze the deep logical relationship between defect factors in the bad image, the defect relationship between parts and parts, and the defect classification between parts and the whole, thereby realizing defect classification. The invention can effectively realize defect position detection and defect class prediction, has high precision and accurate classification, and has better detection effect on small targets. It can optimize the detection accuracy and reduce the missed detection.

Owner:CHENGDU UNION BIG DATA TECH CO LTD

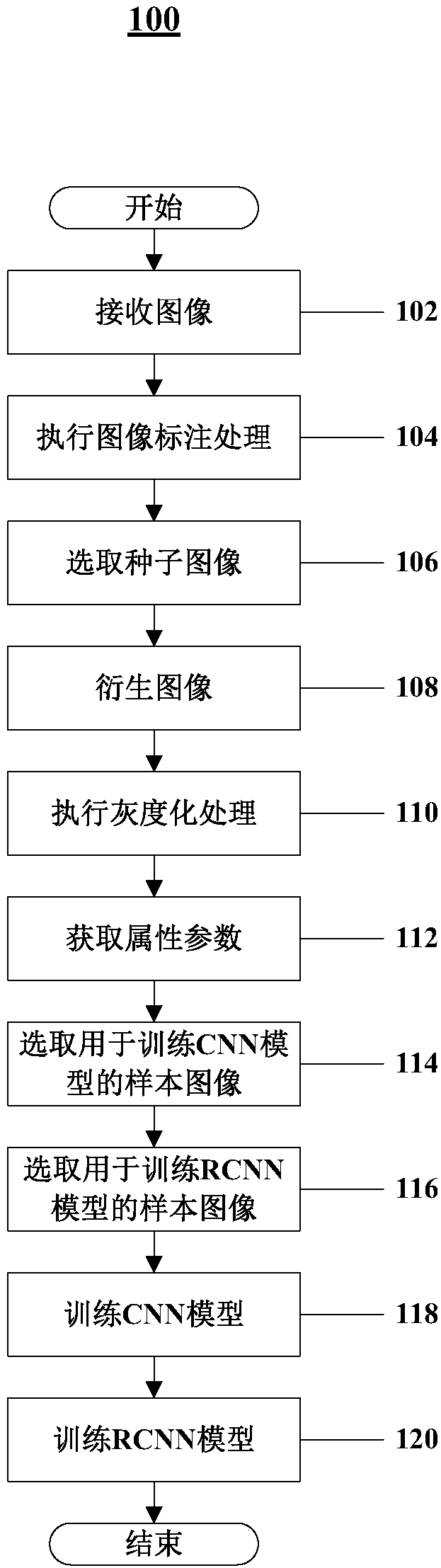

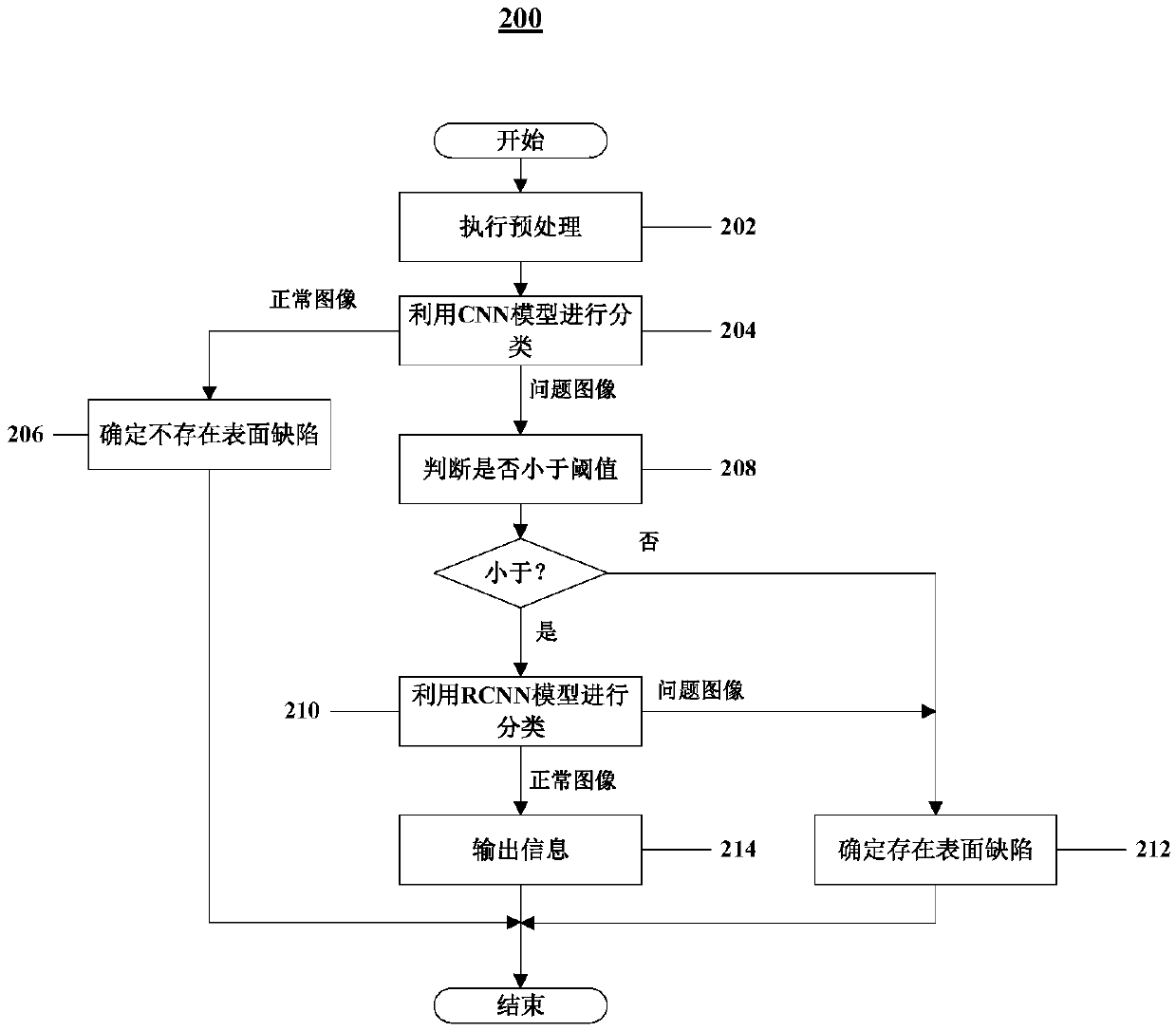

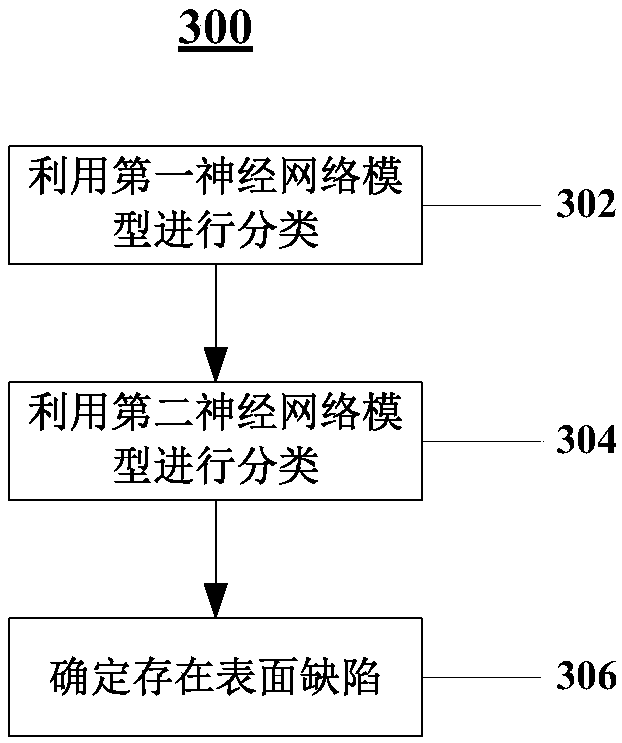

Method of defect detection, device and equipment

InactiveCN108038843ANo fatigueImprove defect detection accuracyImage enhancementImage analysisPattern recognitionNetwork model

The invention relates to a method of defect detection, device and equipment. The method comprises steps: in the case of detecting whether a surface defect exists in an electronic product included in aspecified image, a first well-trained neural network model is used to classify the specified image, wherein the first neural network model is used for detecting whether the image belongs to a problematic image or a normal image; if the first neural network model classifies the specified image to the problematic image and the given reliability value of the specific image belonging to the problematic image is smaller than a reliability threshold, a second well-trained neural network model is used to classify the specified image, wherein the second neural network model is used for detecting whether the image belongs to a problematic image or a normal image; and if the second neural network model classifies the specified image to the problematic image, the surface defect is determined to exist in the electronic product included in the specified image. The method, the device and the equipment can improve the defect detection accuracy in a condition of consuming no manpower basically.

Owner:INTEL PROD CHENGDU CO LTD +1

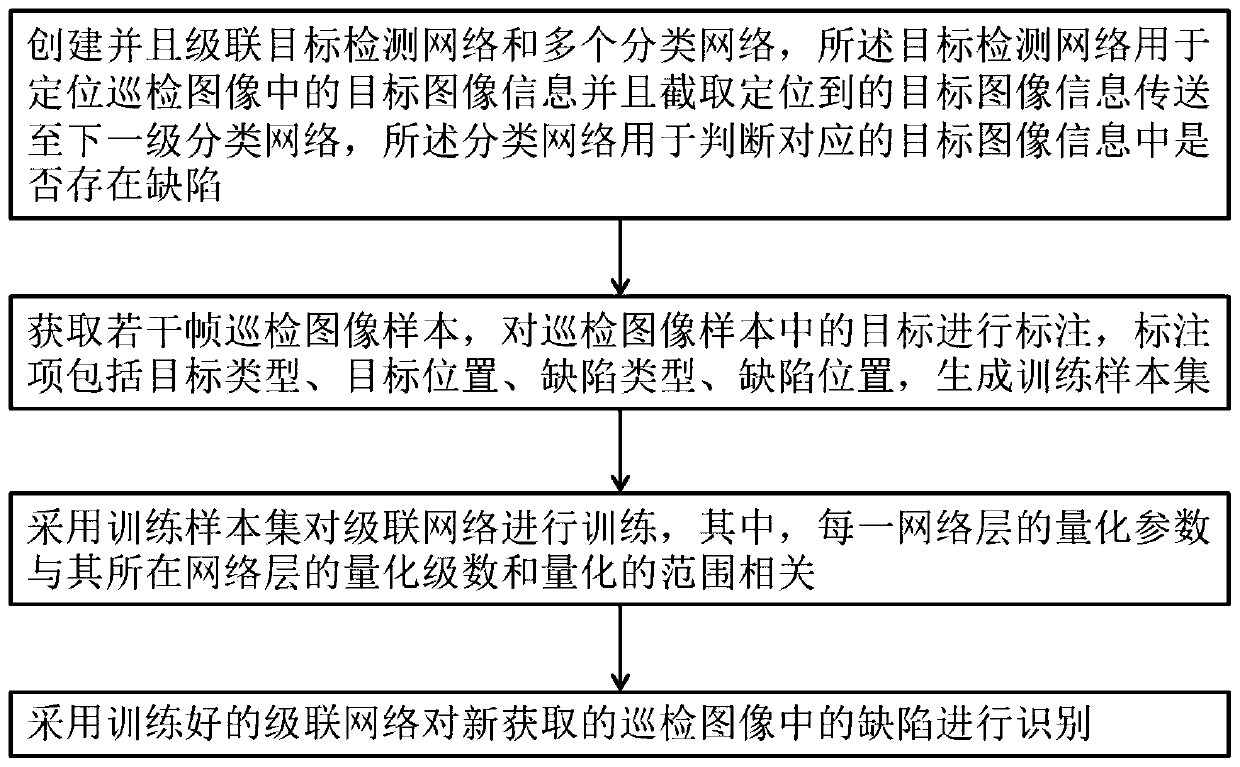

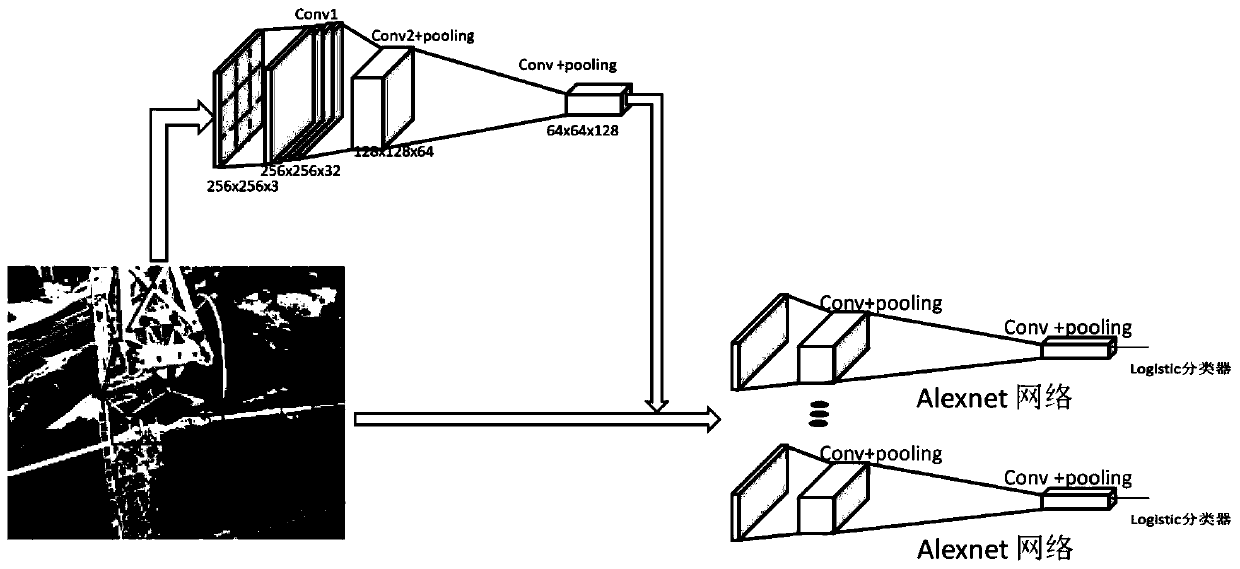

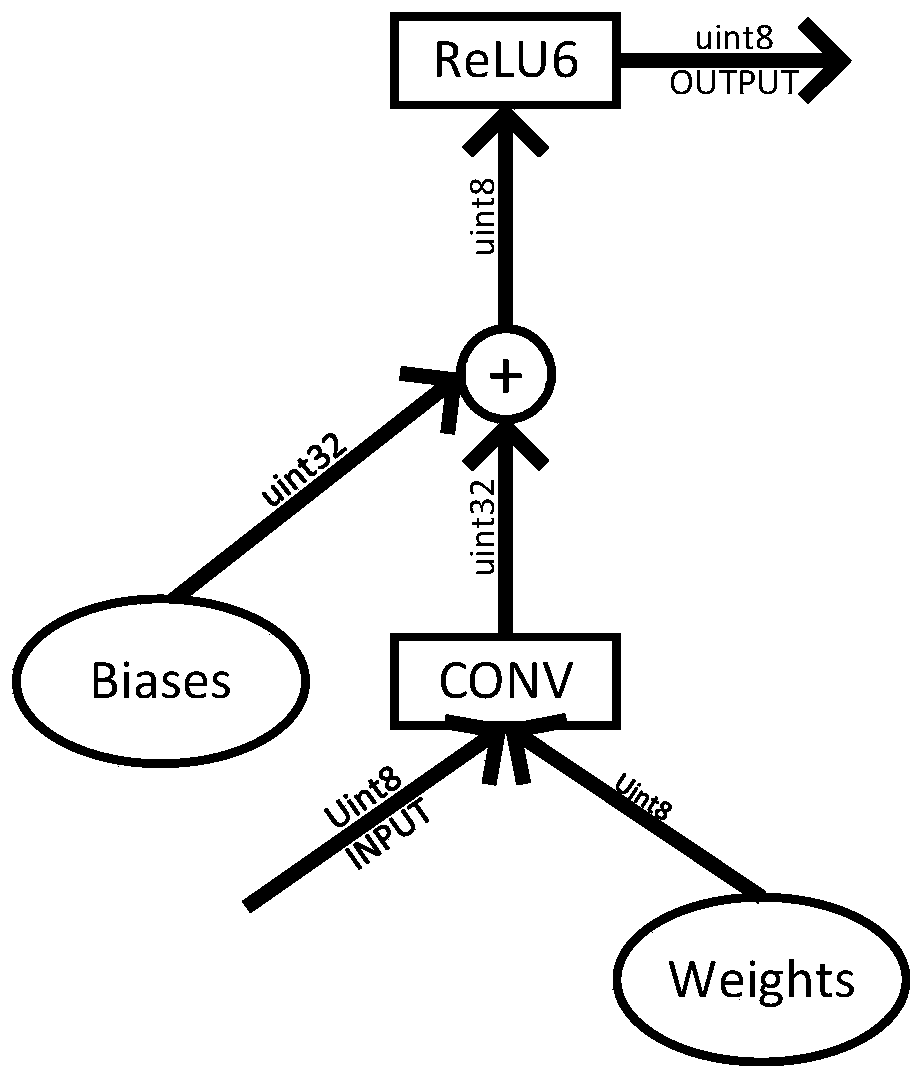

Electric power inspection image defect identification method and system, and electric power inspection unmanned aerial vehicle

PendingCN110796107APreserve precisionQuantify fitImage analysisScene recognitionPower gridUncrewed vehicle

The invention discloses an electric power inspection image defect identification method. The method comprises the following steps: creating and cascading a target detection network and a plurality ofclassification networks; obtaining a plurality of frames of inspection image samples, labeling targets in the inspection image samples, and generating a training sample set; adopting a training sampleset to train a cascade network, wherein the quantization parameter of each network layer is related to the quantization stage number and the quantization range of the network layer where the networklayer is located; and identifying defects in the newly acquired inspection image by adopting the trained cascade network. According to the invention, an effective FPGA airborne identification system is provided for operation and maintenance of a power grid tower and an overhead line, and a corresponding quantization function can ensure that different channels of different network layers can be properly quantified, so that the precision of the network is reserved to the maximum extent; through cascading the target detection network and the classification network, the defect detection accuracy is greatly improved, and the unmanned aerial vehicle routing inspection of the power grid truly realizes automatic identification.

Owner:南京北旨智能科技有限公司 +1

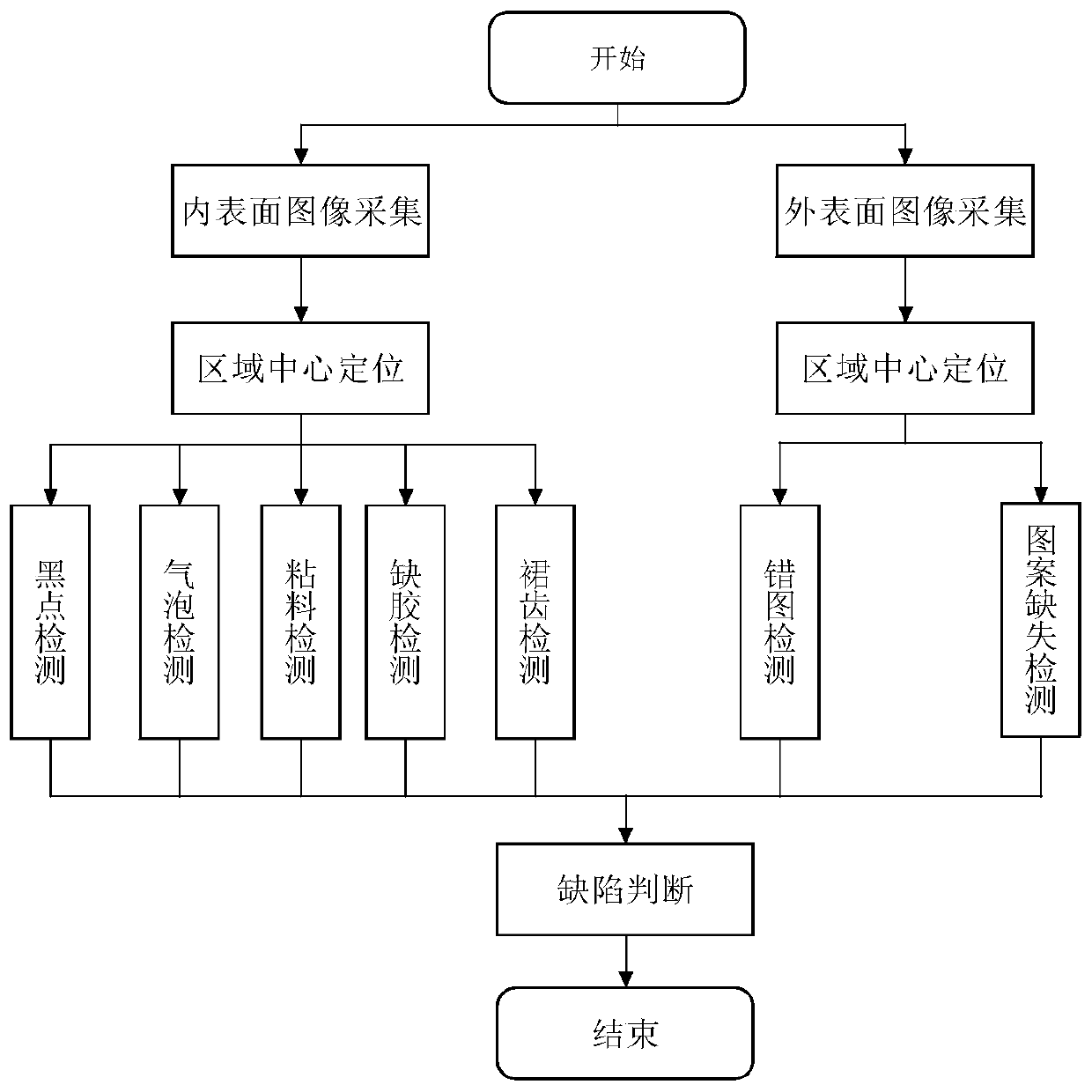

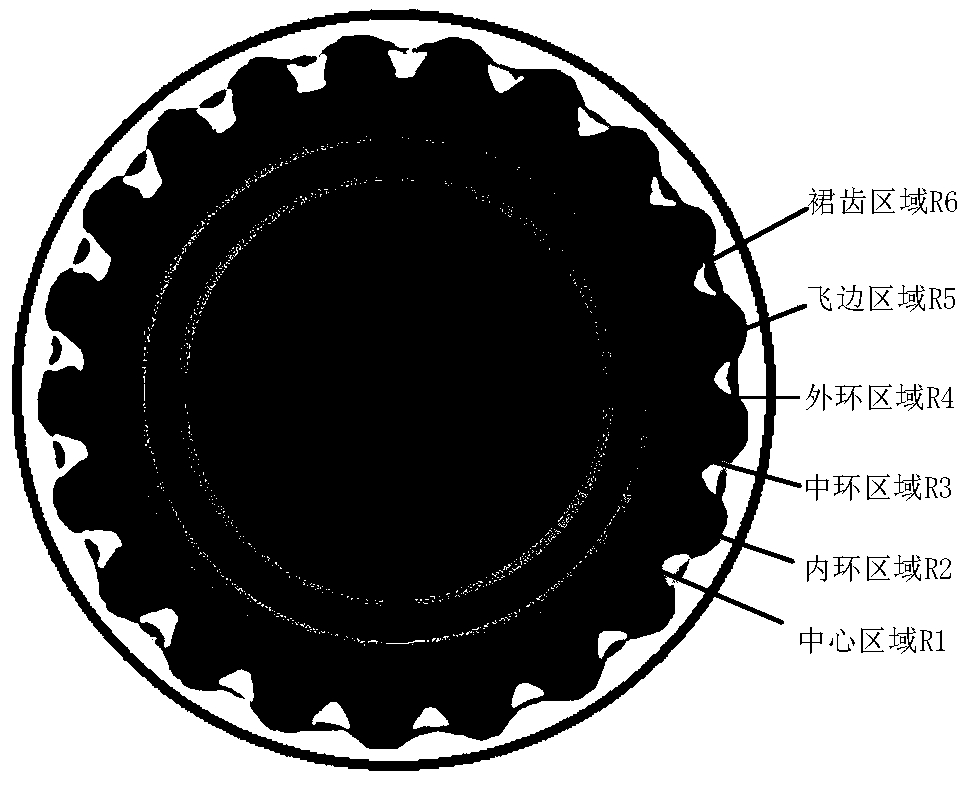

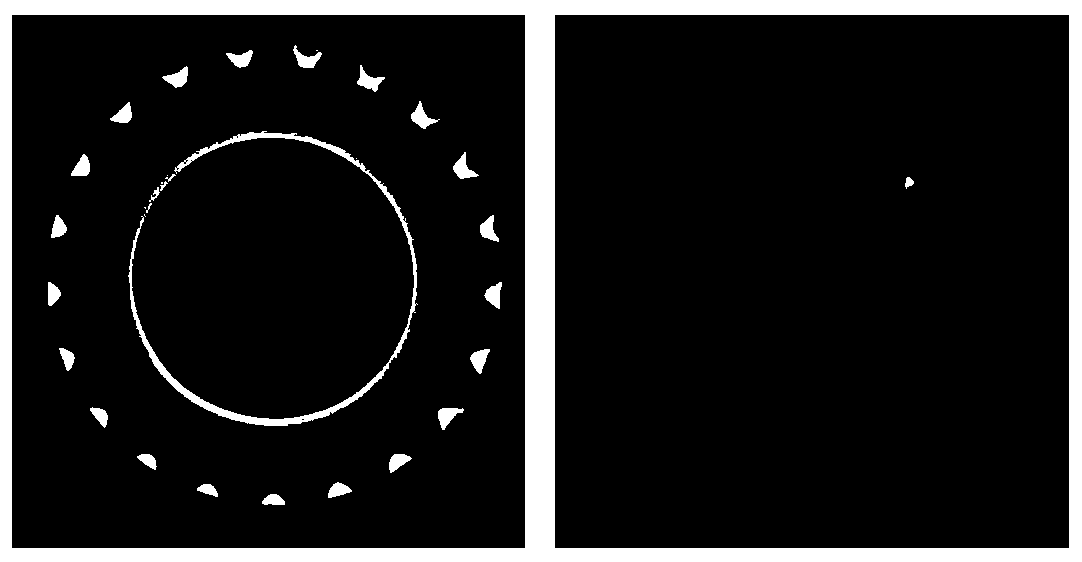

Crown cap surface defect online detection method based on image processing

ActiveCN110220917AEasy to detectImprove defect detection accuracyOptically investigating flaws/contaminationSurface patternTemplate matching

The invention discloses a crown cap surface defect online detection method based on image processing, and belongs to the technical field of image processing. The method comprises the following steps:acquiring a crown cap inner surface image, and implementing central positioning and region extraction by using an image segmentation technology; implementing bottle cap inner surface defect detectionby using image processing algorithms such as threshold segmentation, morphological processing, connected region feature analysis and region comparison; establishing a crown cap outer surface pattern template offline by adopting an automatic training learning algorithm; and acquiring a crown cap outer surface image, and finishing bottle cap outer surface defect detection by using feature template matching, affine transformation and regional comparison. The method can be used for rapidly detecting various crown cap surface defects online, can detect 300 bottle caps in one minute, has the advantages of high defect detection accuracy, high robustness and the like, and can be attached to a crown cap production line to realize defect detection and type differentiation of crown caps.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

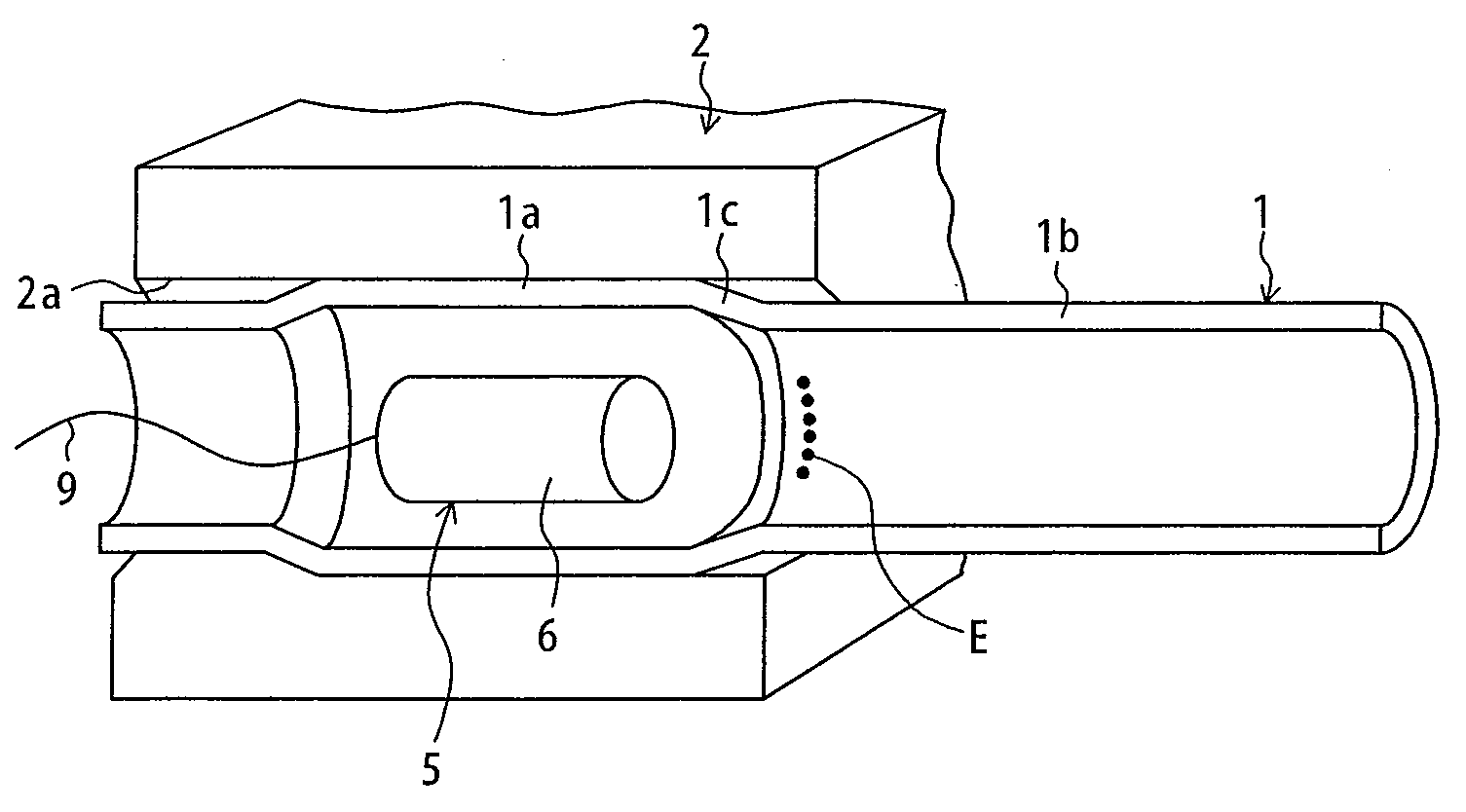

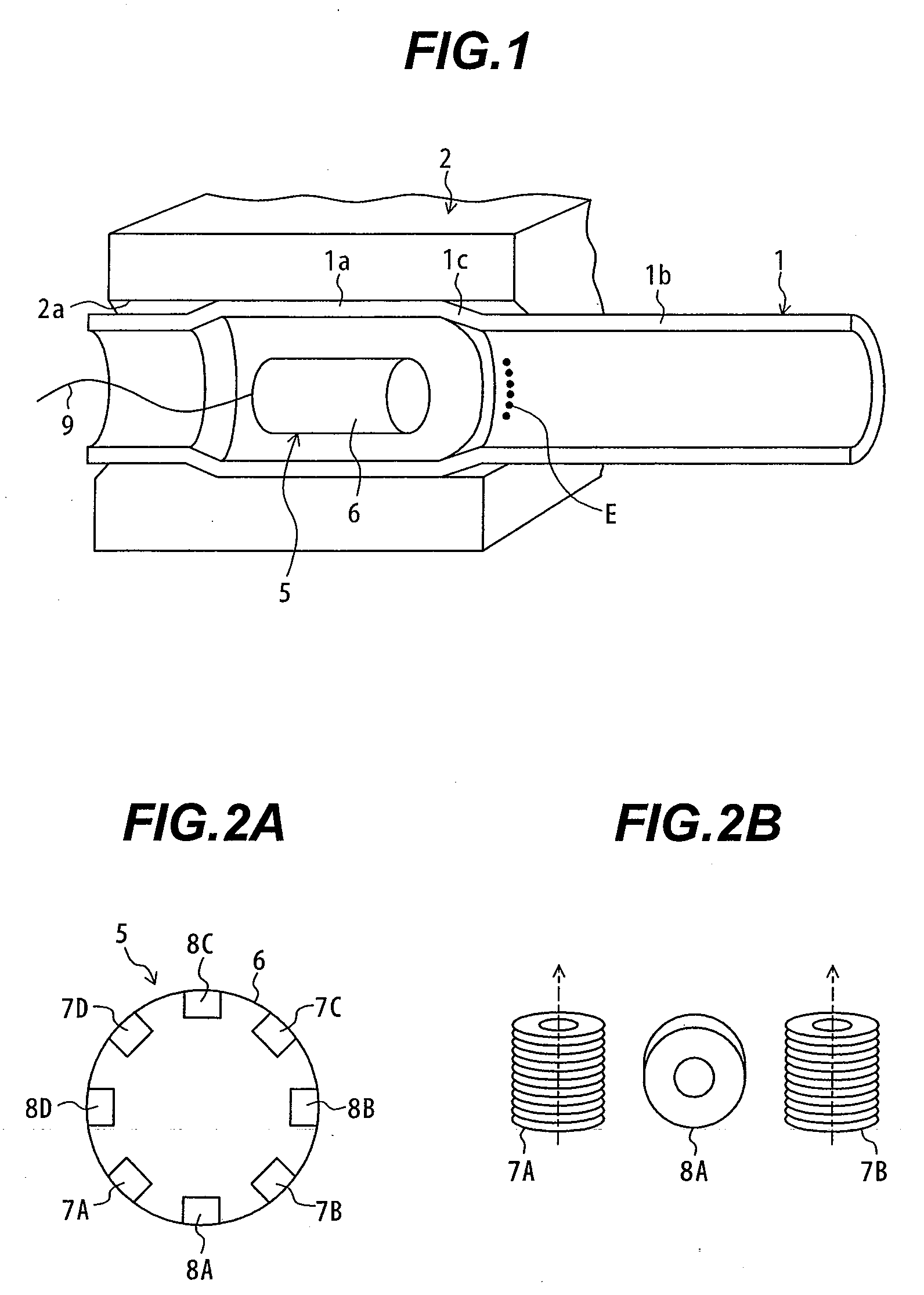

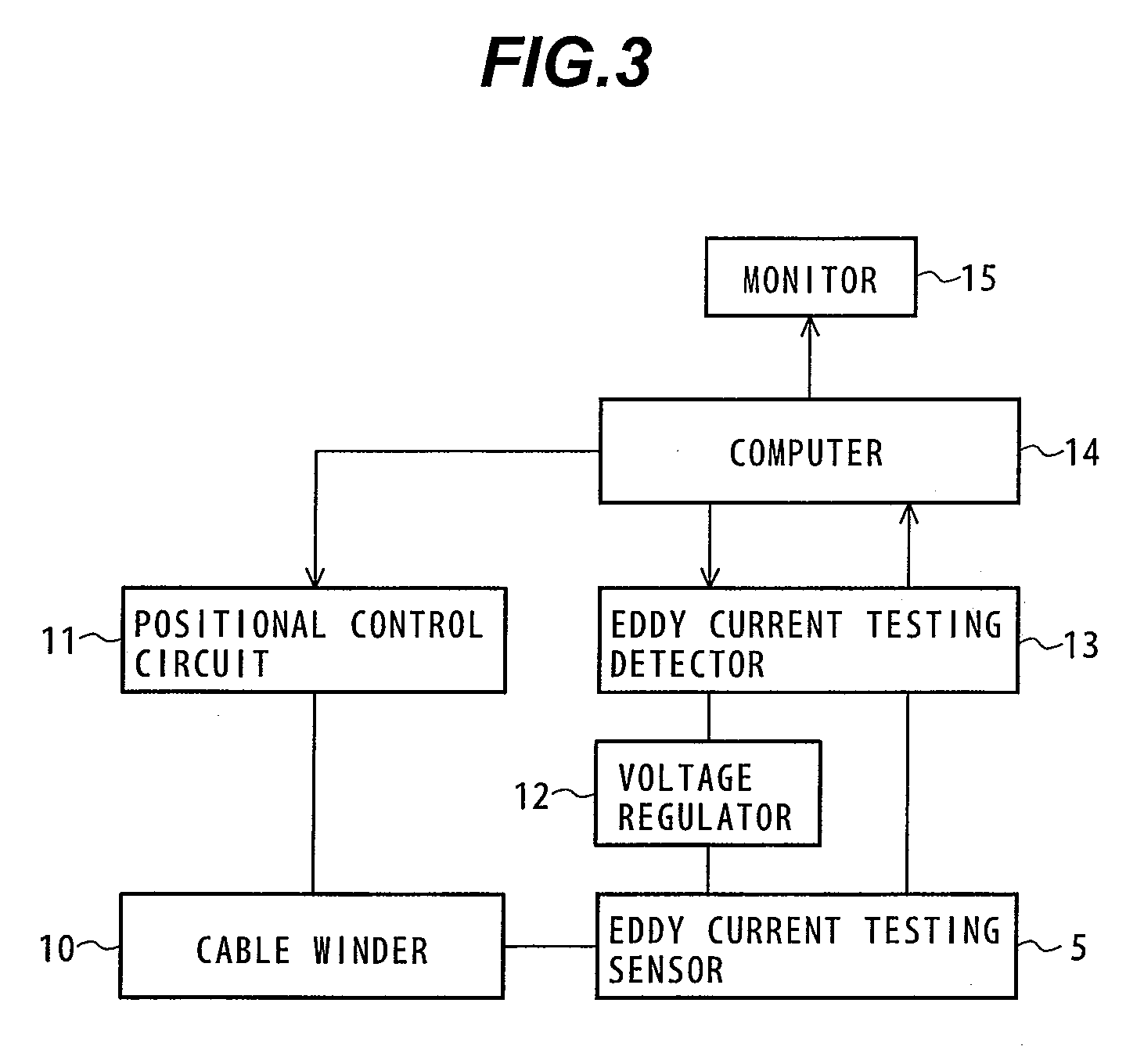

Eddy current testing method and eddy current testing apparatus

InactiveUS20090102473A1Small amountHigh positioning accuracyMaterial magnetic variablesVoltage regulationEngineering

The present invention provides an eddy current testing method and an eddy current testing apparatus that can reduce detection noise to increase the SN ratio thus improving the defect detection accuracy.An eddy current testing sensor includes a pair of excitation coils and a detection coil disposed therebetween. For example, a voltage regulator applies voltages having different amplitudes to the pair of excitation coils so as to reduce detection noise caused by a deformed portion of a heat exchanger tube and a tube plate in a detection signal of the detection coil. Alternatively, for example, an eddy current testing detector applies a first excitation frequency f1, at which tube material noise is reduced to negligible an amplitude, and a second excitation frequency f2, which is higher than the first excitation frequency f1, to the eddy current testing sensor. The phase and gain of a measurement waveform with the second excitation frequency f2 are adjusted and then a differential waveform of the first and second excitation frequencies f1 and f2 is obtained based on an induction voltage detected by the detection coil so as to cancel out tube expansion noise.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

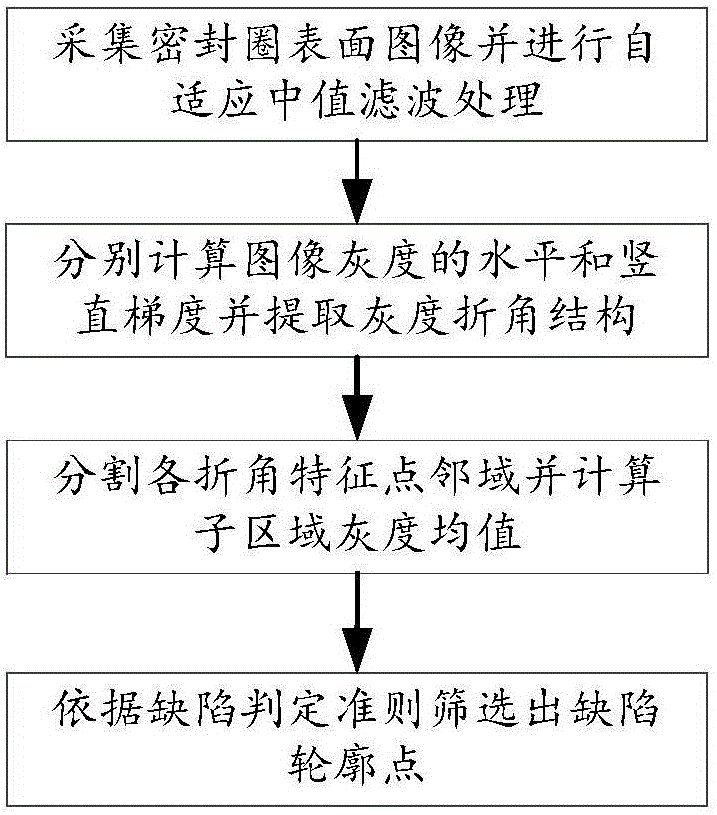

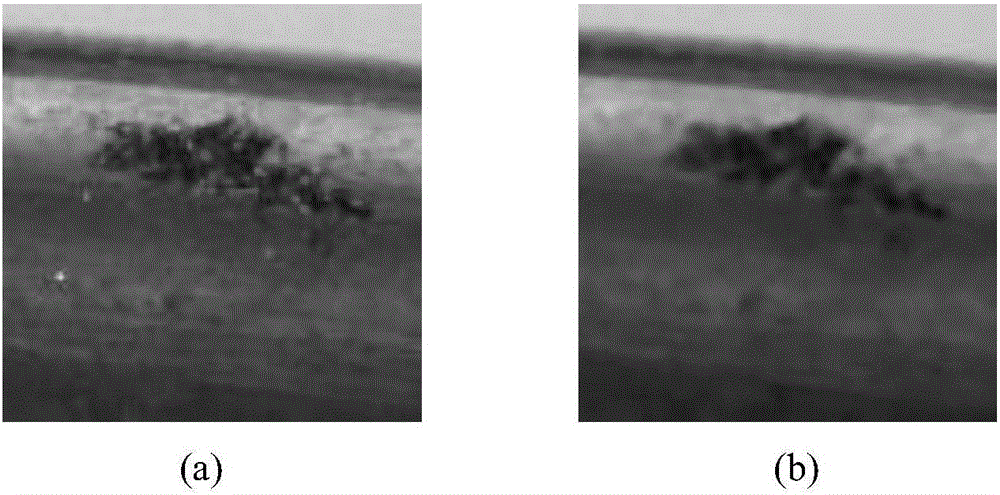

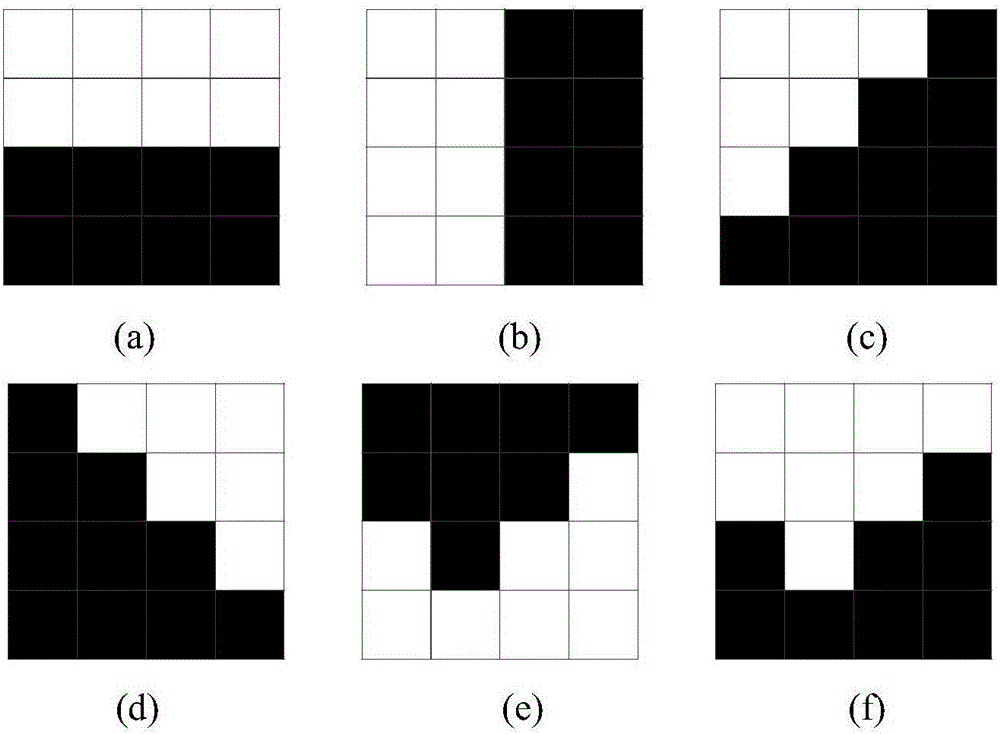

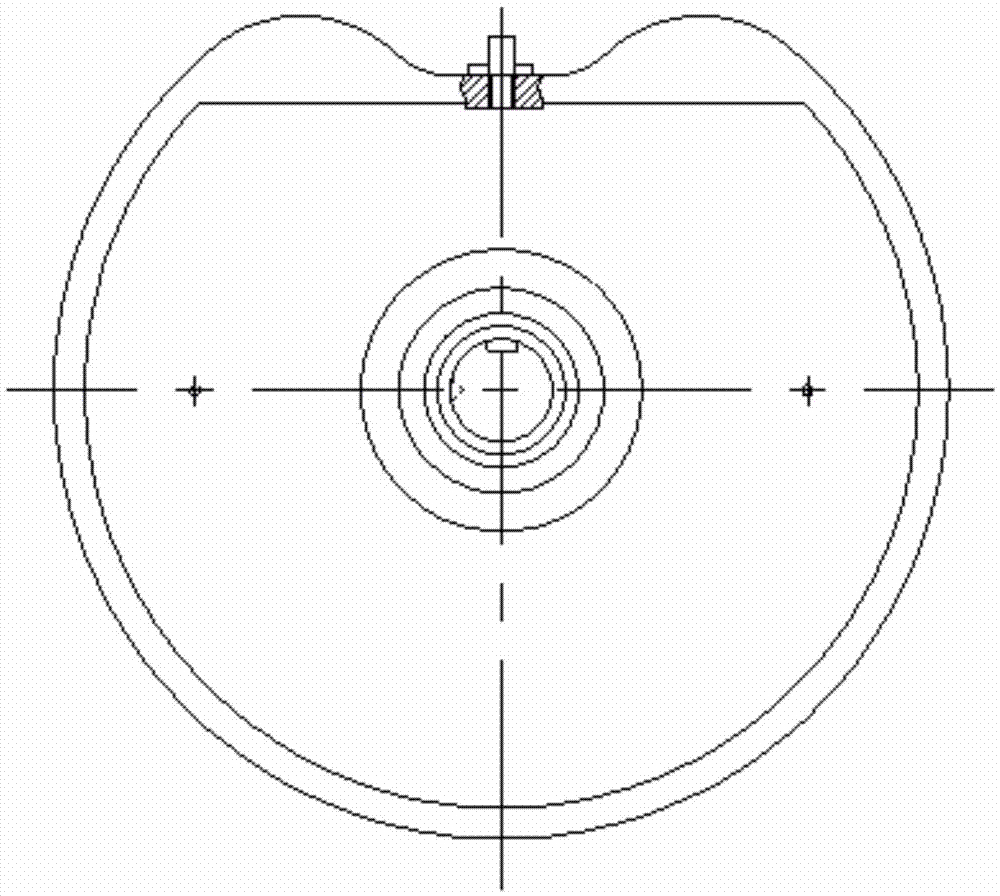

Sealing ring surface defect detection method based on machine vision

InactiveCN105784713AStrong stickImprove defect detection accuracyOptically investigating flaws/contaminationSelf adaptiveGray level

The invention discloses a sealing ring surface defect detection method based on machine vision. The sealing ring surface defect detection method comprises the following steps: firstly, acquiring images of the surface of a sealing ring, and performing self-adaptive median filtering treatment on the acquired images; subsequently, calculating a gray level gradient and a vertical gradient of the images, and extracting gray bevel structures in the images according to the gray level gradient and the vertical gradient; partitioning different bevel characteristic point neighborhoods, and calculating a gray level mean of the partitioned neighborhoods; finally, by taking functions for describing the gray level difference degree of the partitioned neighborhoods as defect judgment principles, screening out defect outline points, and detecting the defects of the surface of the sealing ring. According to the forming reason of the defects of the surface of the sealing ring, inherent differences of defect outlines and appearance outline of the sealing ring can be analyzed and verified on the images, various types of defects, including recesses, rill marks, impurities, trimming and over-cutting defects, on the surface of the sealing ring can be detected, and the method has the advantages of high defect detection accuracy, good algorithm robustness and the like.

Owner:NANJING UNIV OF SCI & TECH

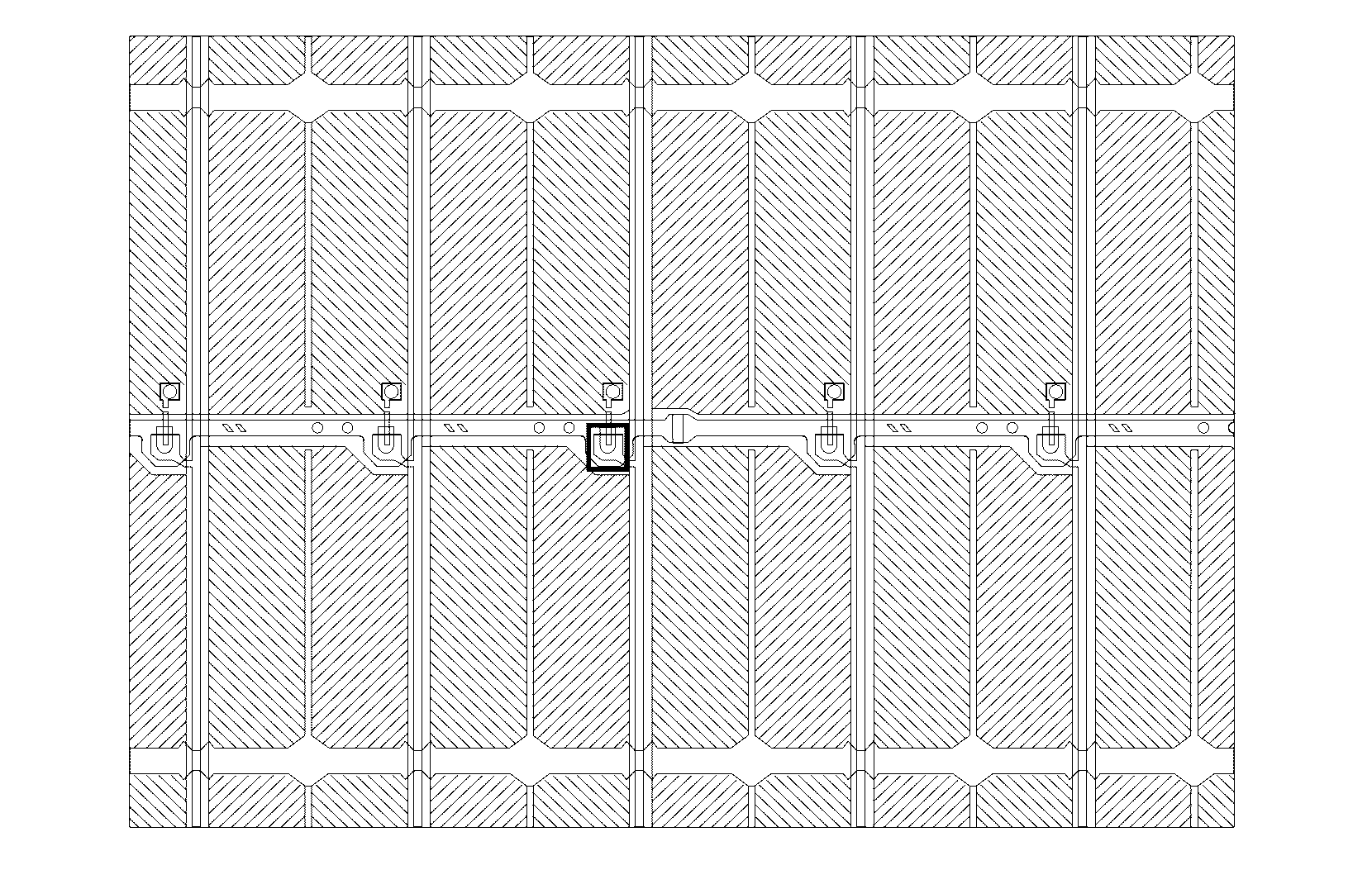

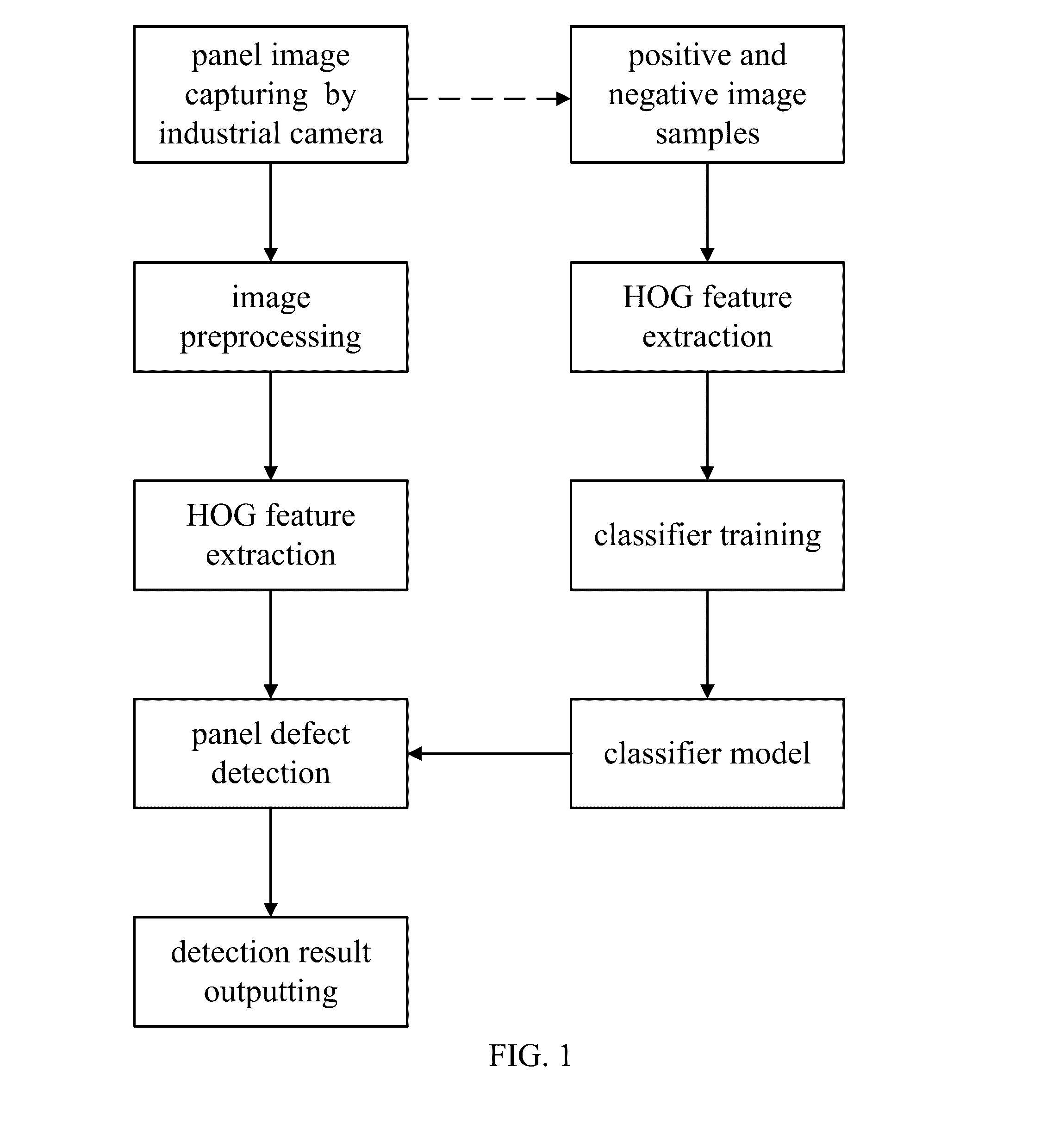

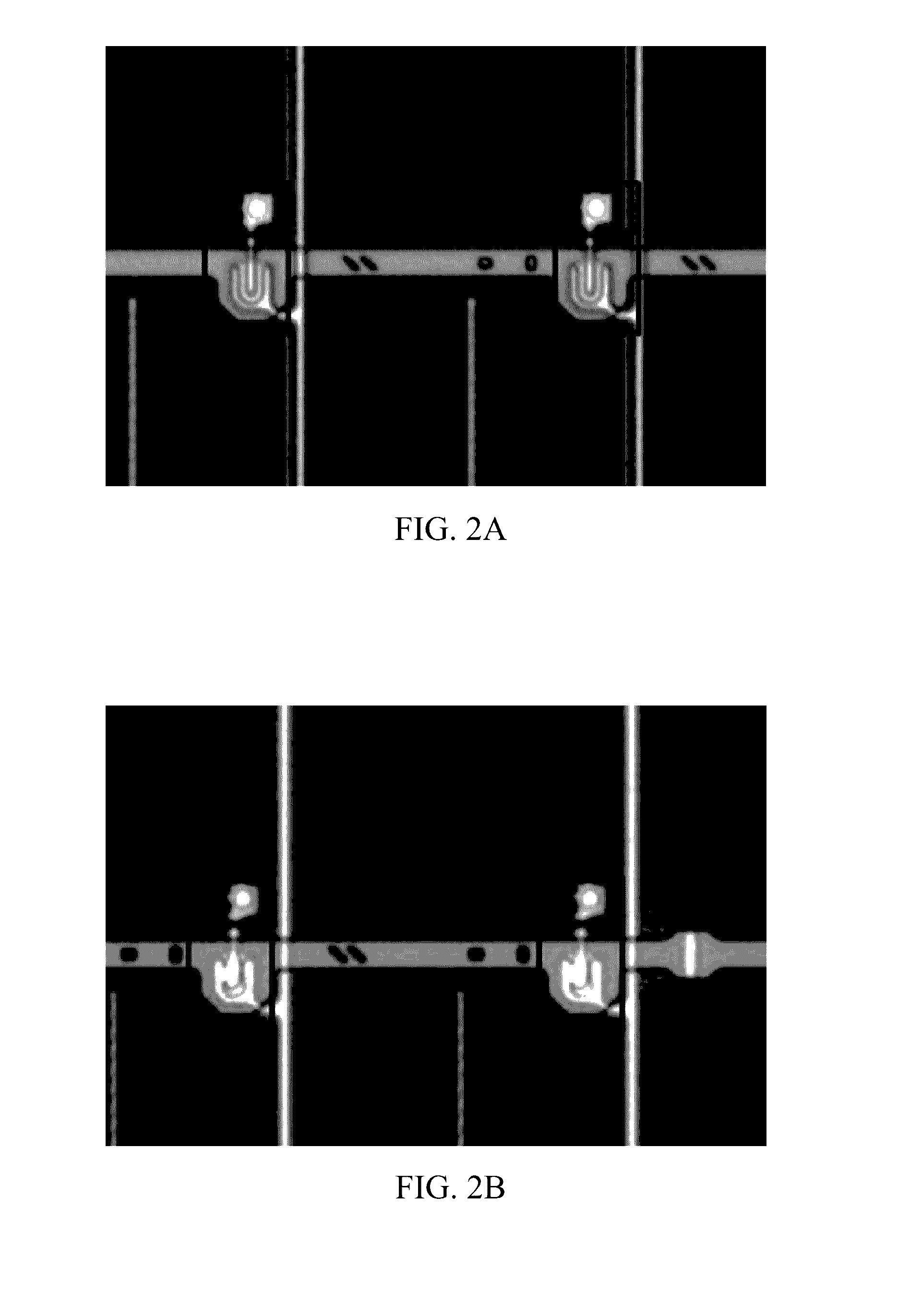

Defect detection method for display panel based on histogram of oriented gradient

ActiveUS20160364849A1Improve defect detection accuracyImprove accuracyImage enhancementImage analysisImaging FeatureHistogram of oriented gradients

In order to detect defects in display panels by an automatic way accurately and quickly, the present invention proposes a method combining image feature extraction and classifier model. It calculates the histograms of oriented gradient (HOG) of images of the display panel collected by an industrial camera of a detection apparatus as feature vectors. Then use them as input samples to train the classifier model to recognize the defects of the display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

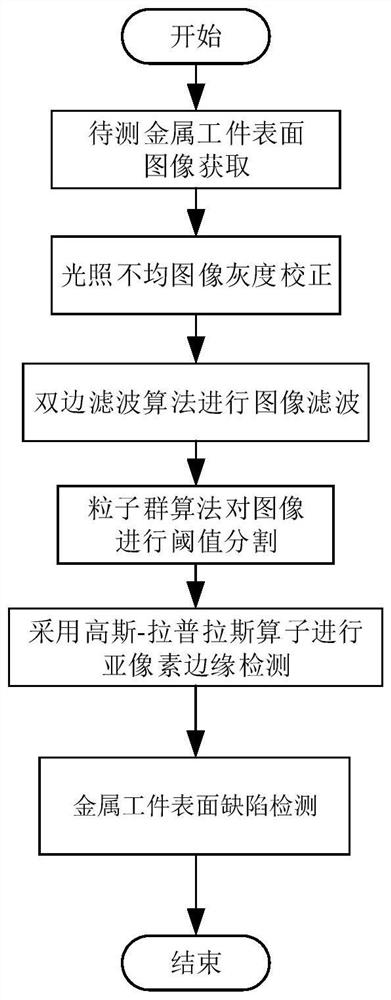

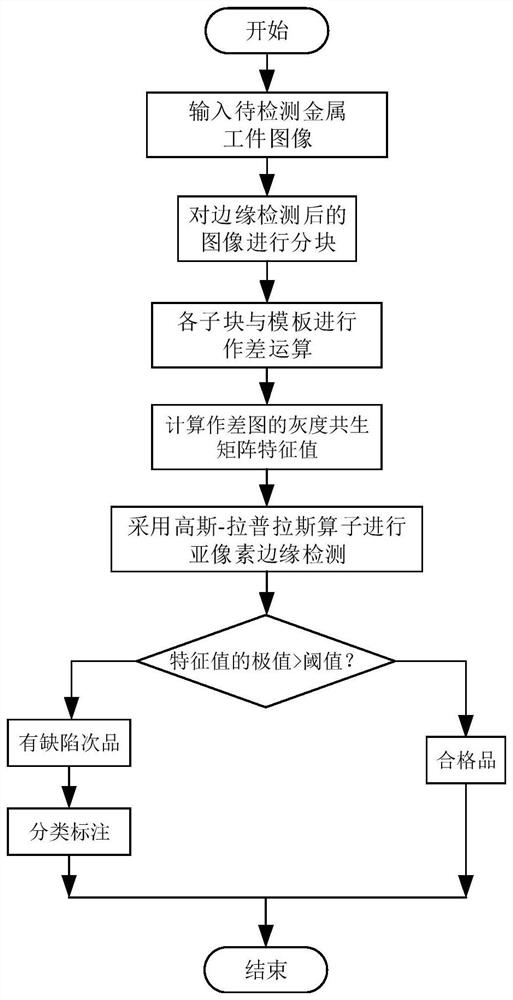

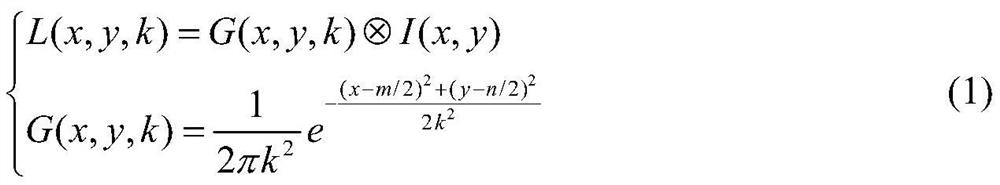

Metal workpiece surface defect image detection method

InactiveCN112330628AImprove defect detection accuracyPromote the development of visual automatic inspection technologyImage enhancementImage analysisFeature extractionMachine vision

The invention discloses a metal workpiece surface defect image detection method. The method comprises the steps of: firstly, collecting a surface image of a metal workpiece through professional imaging equipment, and then enabling the collected image to be subjected to image early-stage preprocessing including the steps of uneven illumination image gray scale correction, image filtering, image threshold segmentation and the like; further performing feature extraction and analysis on the preprocessed image, and introducing a sub-pixel edge detection algorithm to perform edge detection on the metal workpiece; and finally, carrying out template matching on the template image and the measurement image by adopting a gray-level co-occurrence matrix algorithm so as to carry out defect detection on the surface of the metal workpiece. According to the metal workpiece surface defect image detection method provided by the invention, the traditional manual visual inspection is replaced by an automatic detection technology based on machine vision, the production efficiency is improved, the labor cost is reduced, the metal workpiece defect detection precision is improved by adopting a sub-pixeledge detection algorithm, and the production quality is optimized.

Owner:NANTONG SAMER PRECISION EQUIP CO LTD

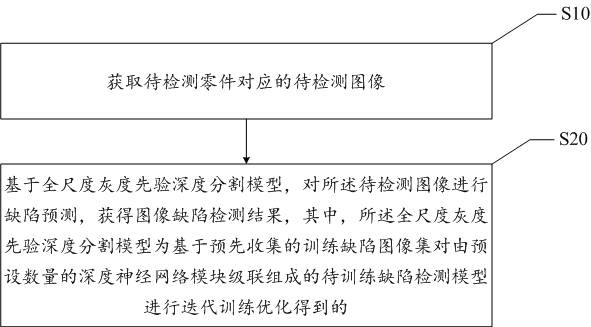

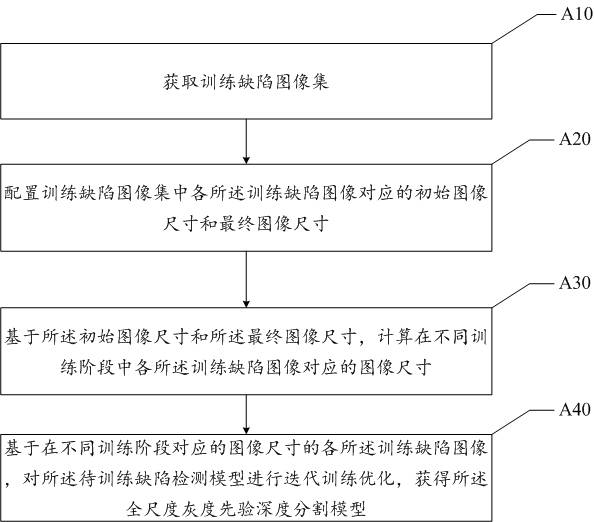

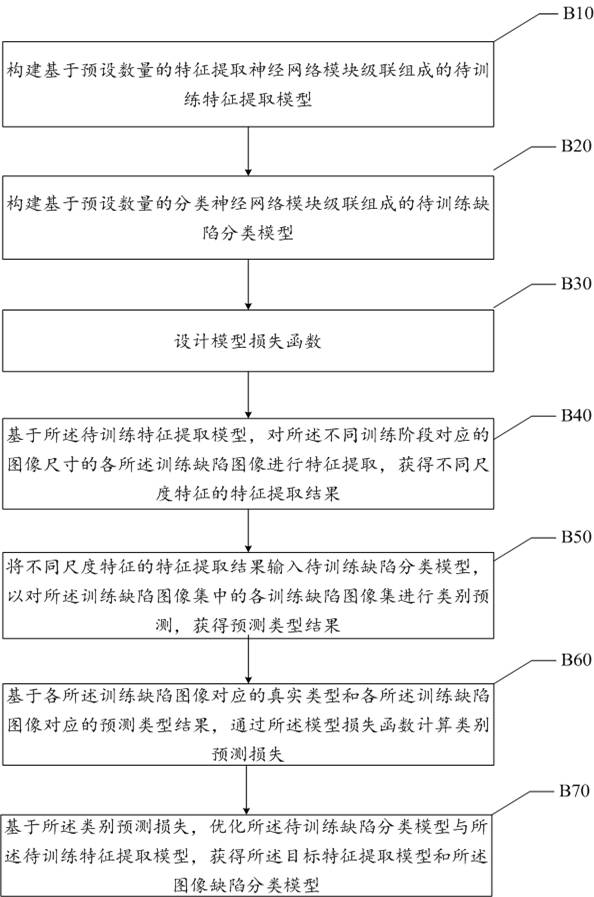

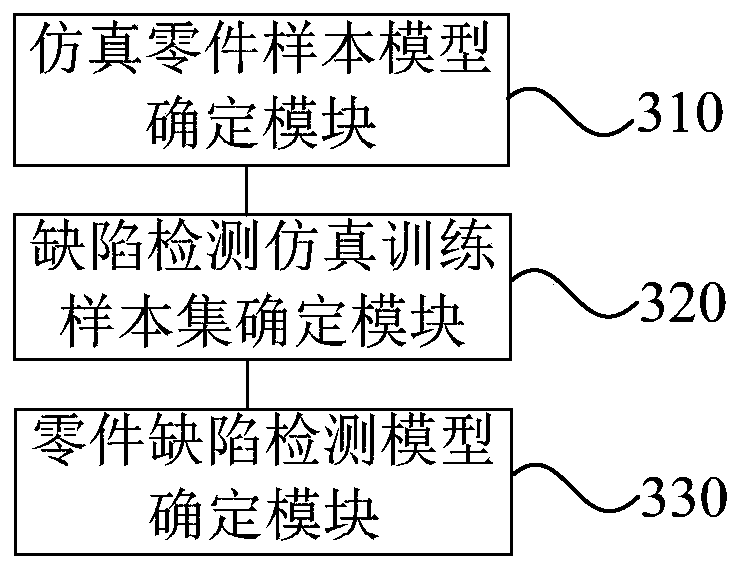

Part defect detection method and device, medium and computer program product

ActiveCN113421263AImprove defect detection accuracyImprove reliabilityImage enhancementImage analysisAlgorithmEngineering

The invention discloses a part defect detection method and device, a medium and a computer program product. The part defect detection method comprises the steps of obtaining a to-be-detected image corresponding to a to-be-detected part, carrying out the defect prediction of the to-be-detected image based on a full-scale gray scale prior depth segmentation model, and obtaining an image defect detection result. The full-scale gray scale prior depth segmentation model is obtained by performing iterative training optimization on a to-be-trained defect detection model formed by cascading a preset number of deep neural network modules based on a pre-collected training defect image set. The technical problem that the defect detection accuracy of parts is low is solved.

Owner:深圳市信润富联数字科技有限公司

Method and apparatus of reviewing defects on a semiconductor device

ActiveUS7764826B2Narrowing range of generationEasy to detectMaterial analysis using wave/particle radiationElectric discharge tubesReference imageClassification methods

To realize reliable on-film / under-film defect classification (classification into 3 classes of on-film, under-film, and determination-disabled) with determination propriety determination, an on-film / under-film defect classification method and a method of narrowing a range of defect generation timing are given, the methods being robust to 4 variation factors, wherein an edge of a boundary line between a line pattern region and a base region is focused, and whether the edge is preserved between defect and reference images in a defective region is determined, thereby an on-film or under-film defect can be identified. Furthermore, a range of the defect generation timing can be narrowed based on an identification result of the on-film or under-film defect, and information of a defect classification class (defect type) such as particle defect or pattern defect as necessary.

Owner:HITACHI HIGH-TECH CORP

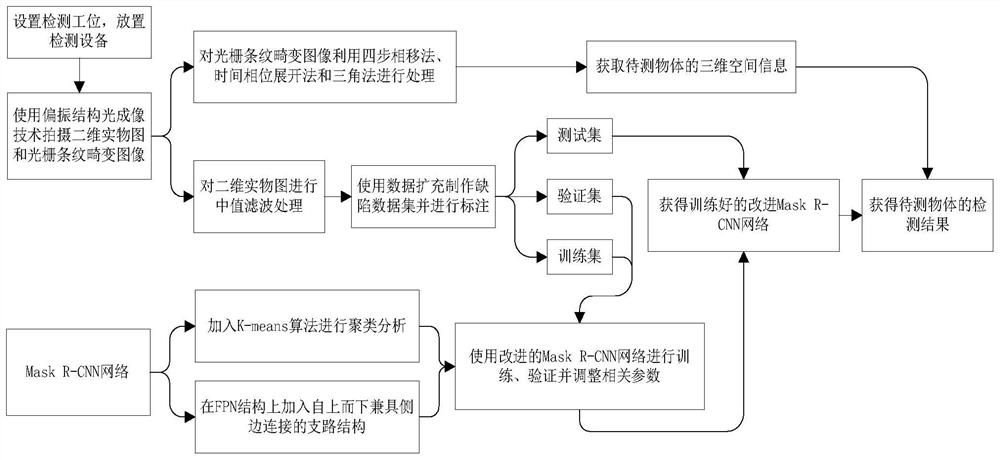

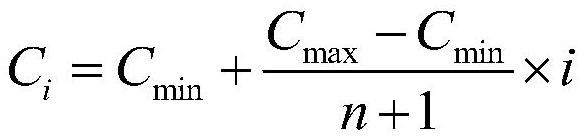

Defect detection method based on polarization structured light imaging and improved Mask R-CNN

ActiveCN112116576AFully integratedImprove defect detection accuracyImage enhancementImage analysisAlgorithmImage resolution

In order to solve the problems of imperfect surface defect detection information, low precision, low efficiency and the like, the invention provides a defect detection method based on a polarization structured light imaging technology and an improved Mask RCNN. The method comprises the following steps: firstly, combining polarization processing with structured light three-dimensional imaging to obtain a high-definition two-dimensional physical graph and three-dimensional space information of an object; performing median filtering processing on the two-dimensional physical graph; secondly, on the basis of a Mask RCNN target recognition method, adding a K-means algorithm to carry out clustering analysis on a training set, adding branches with side edge connection from top to bottom to an original FPN structure, and combining lower-layer high-resolution features and upper-layer high-resolution features to generate a new feature map; detecting an image with defects by utilizing the improved Mask RCNN network, and classifying, positioning and segmenting the defects; finally, obtaining a series of information such as the type, position, length, width, depth and area of the defect throughdata arrangement, achieving quantification of defect data, and the object surface defect detection precision and efficiency are effectively improved.

Owner:AIR FORCE UNIV PLA

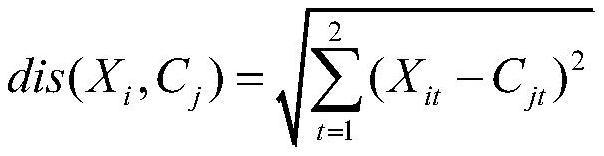

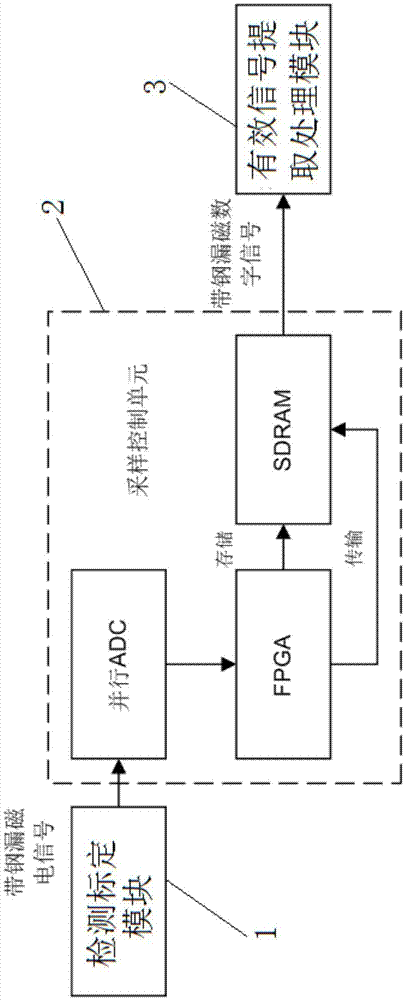

Background noise removal device and method for magnetic flux leakage detection and calibration

ActiveCN106959336AImprove signal-to-noise ratioImprove accuracyMaterial magnetic variablesSignal-to-noise ratio (imaging)Background noise

The invention discloses a background noise removal device and a background noise removal method for magnetic flux leakage detection and calibration. The device comprises a detection and calibration module, a sampling control module and an effective signal extracting and processing module, wherein the sampling control module is electrically connected with the detection and calibration module and transmits a detection signal to the effective signal extracting and processing module; and the effective signal extracting and processing module is used for preprocessing the collected signal, rejecting gap interference data and separating effective data from original data so as to guarantee that the signal entering a signal processing system is an effective signal in which a periodic interference signal is rejected. According to the background noise removal device, a background magnetic field in a calibration roll used in a flux leakage detection signal is eliminated, noise signals are removed, and effective flux leakage detection signals are extracted, so that the signal to noise ratio of internal defect magnetic flux leakage can be greatly increased, and the defect detection accuracy rate can be increased.

Owner:BAOSHAN IRON & STEEL CO LTD

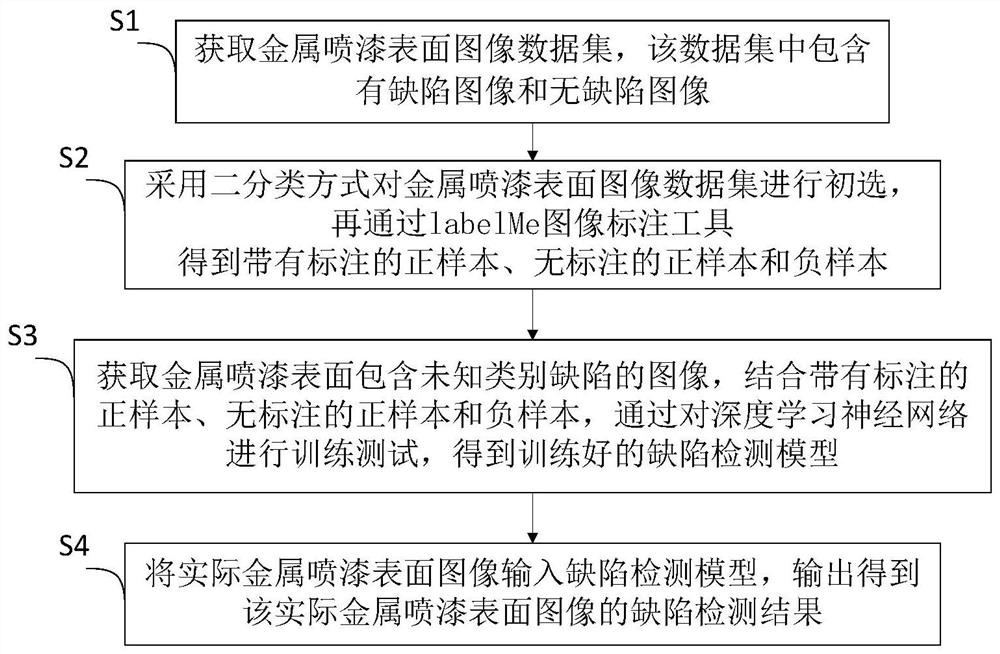

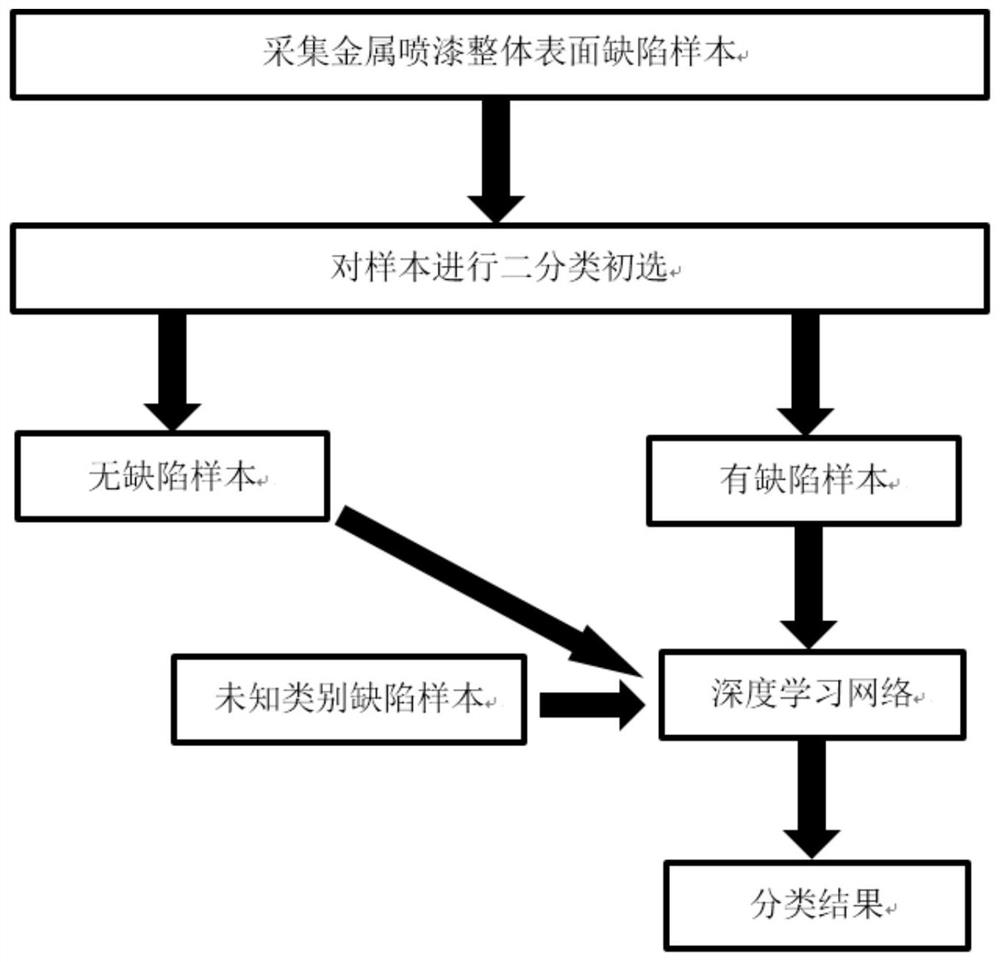

Metal paint spraying surface defect detection method

PendingCN111798419AReduce workloadGuaranteed reliabilityImage enhancementImage analysisComputer visionData set

The invention relates to a metal paint spraying surface defect detection method. The method comprises the steps of acquiring a metal paint spraying surface image data set containing defect images anddefect-free images; carrying out primary selection on the metal paint spraying surface image data set by adopting a binary classification mode to obtain a positive sample with a label, a positive sample without a label and a negative sample without a label; acquiring an image containing unknown types of defects on the surface of metal paint spraying, and performing training test on a deep learningneural network in combination with a sample obtained by binary classification primary selection to obtain a defect detection model; and inputting the actual metal paint spraying surface image into the defect detection model, and outputting a defect detection result of the actual metal paint spraying surface image. Compared with the prior art, the method has the advantages that early-stage samplescreening and labeling can be accurately and quickly carried out by combining blob block detection and the deep learning neural network, and meanwhile, the neural network is trained by utilizing the defect images of unknown types, so that the metal paint spraying surface defects can be quickly, accurately and comprehensively detected by the method.

Owner:SHANGHAI UNIV OF ENG SCI

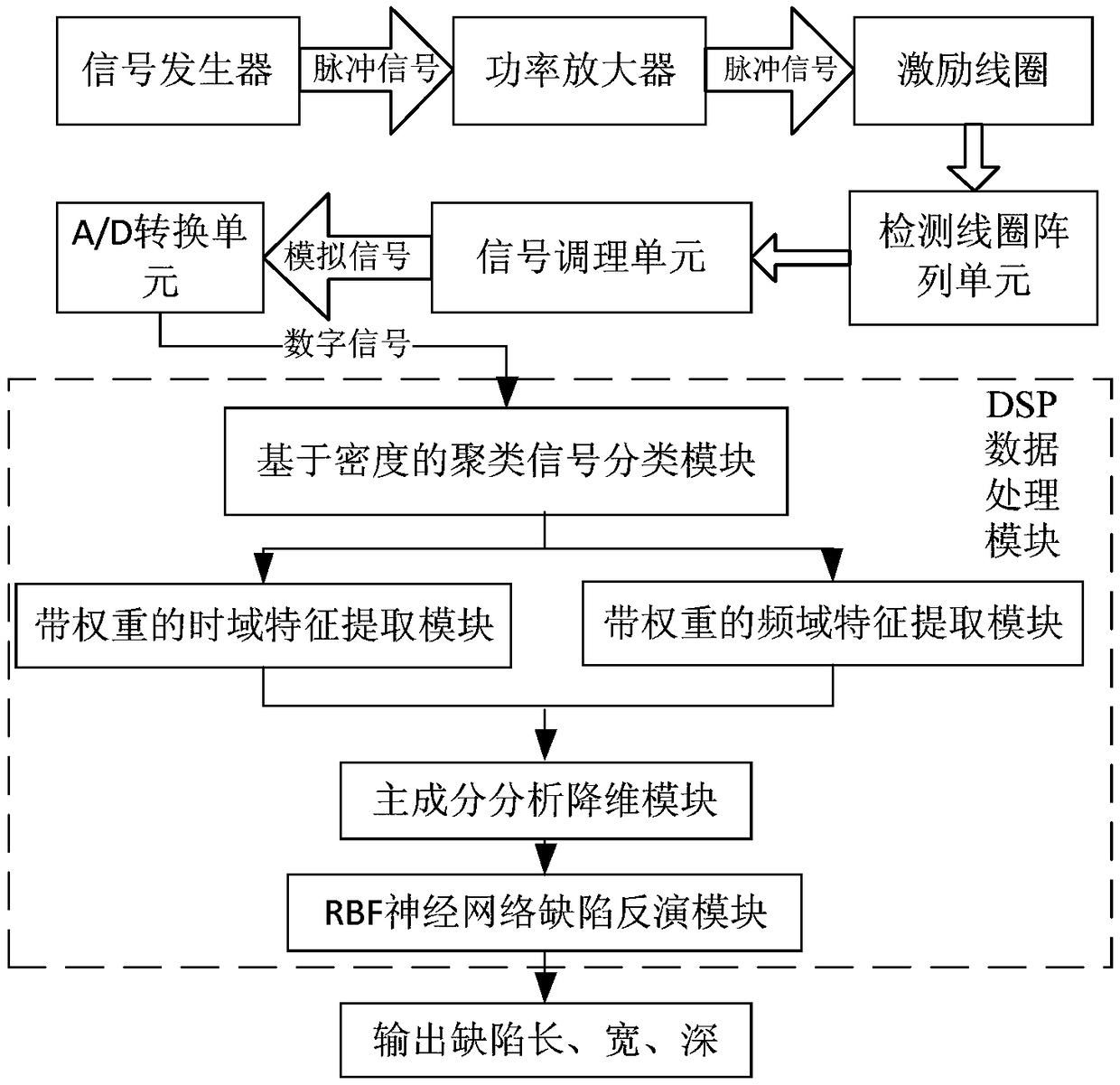

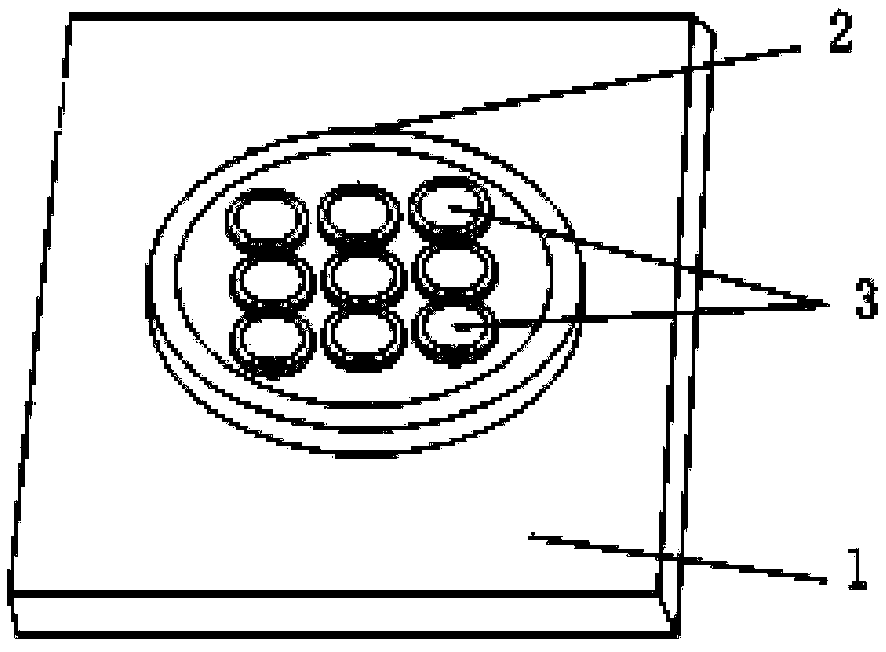

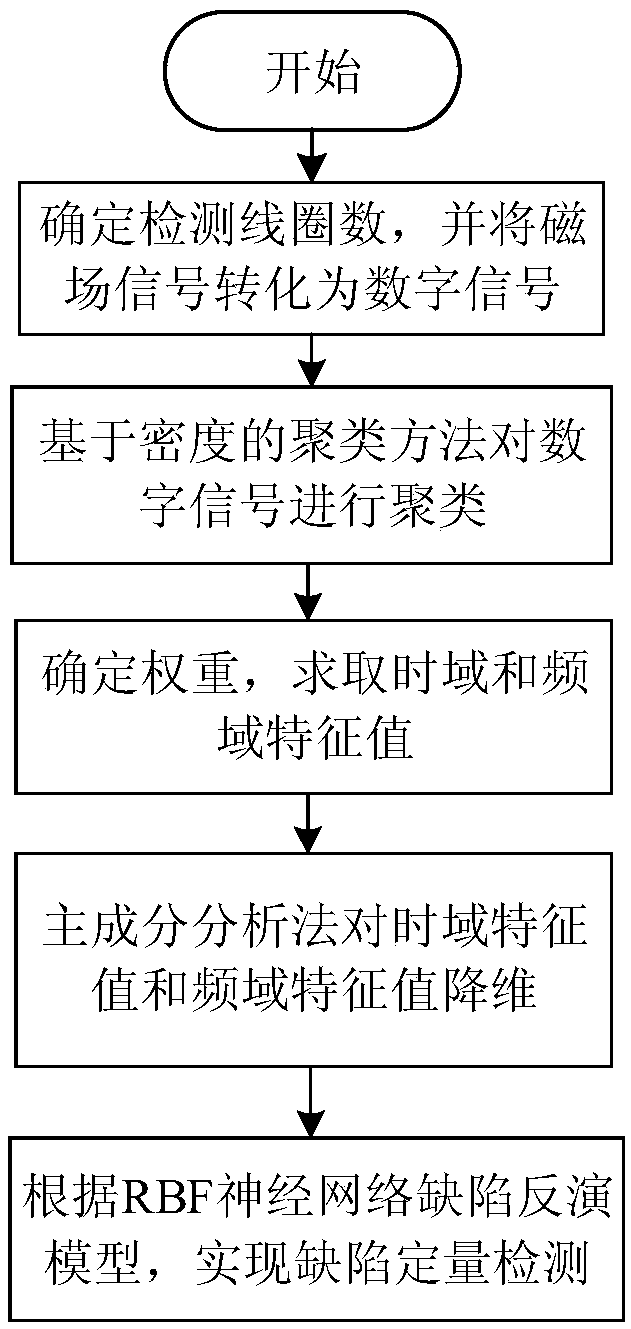

Defect detecting device and method based on pulsed eddy current array

ActiveCN109142514ALittle changeRealize quantitative detectionUsing electrical meansElectric/magnetic depth measurementTime domainNon destructive

The invention provides a defect detecting device and method based on a pulsed eddy current array, and relates to the technical field of non-destructive testing. The defect detecting method comprises the following course that a signal generator produces a periodic pulse signal, after being amplified by a power amplification machine, the periodic pulse signal is applied to two ends of an exciting coil; a test coil array unit acquires a magnetic field signal above a piece to be tested, and transports the magnetic field signal to a signal conditioning unit; the signal conditioning unit is used forperforming filtering and amplifying on the signal, and transporting the treated signal to an A / D converting unit; and finally, the signal is transported to a DSP data processing module to seek dimension information of defects. According to the defect detecting device disclosed by the invention, clustering treatment and equalizing treatment are performed on detection array data, so that the influence of inclination or lifting-off of the detection array coil on defect detection is effectively restrained; a structure that a coil is used for exciting, and an array is formed by a plurality of testcoils is adopted, so that the interference of a magnetic field is reduced, and comprehensive defect information detection is also realized; and the time domain characteristic quantity and the frequency domain characteristic quantity are combined, so that the defect detecting accuracy is improved.

Owner:NORTHEASTERN UNIV

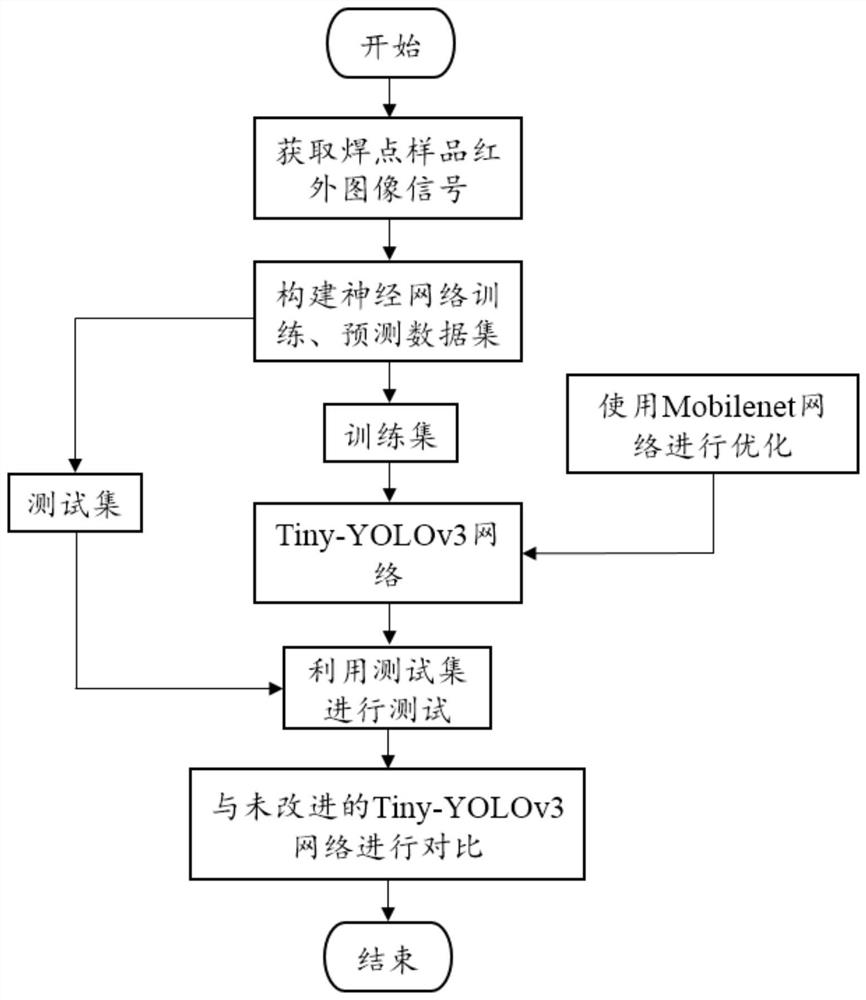

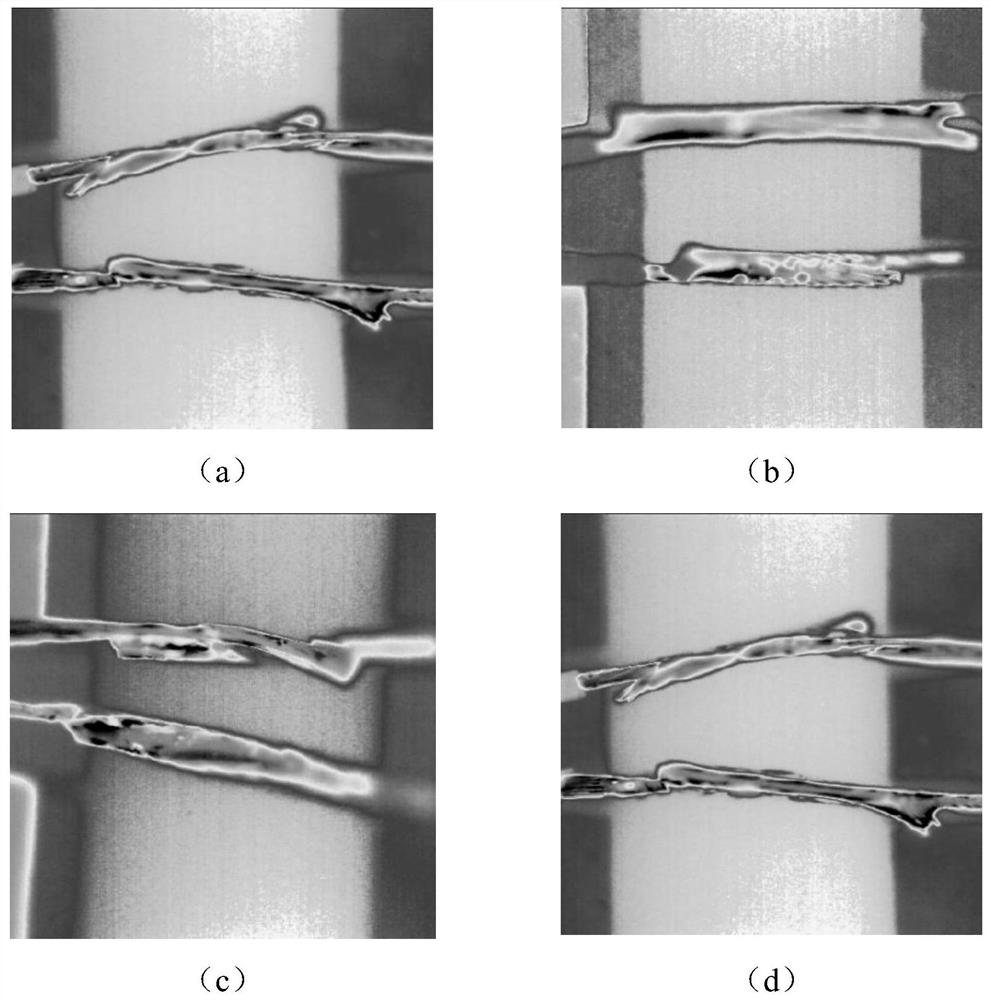

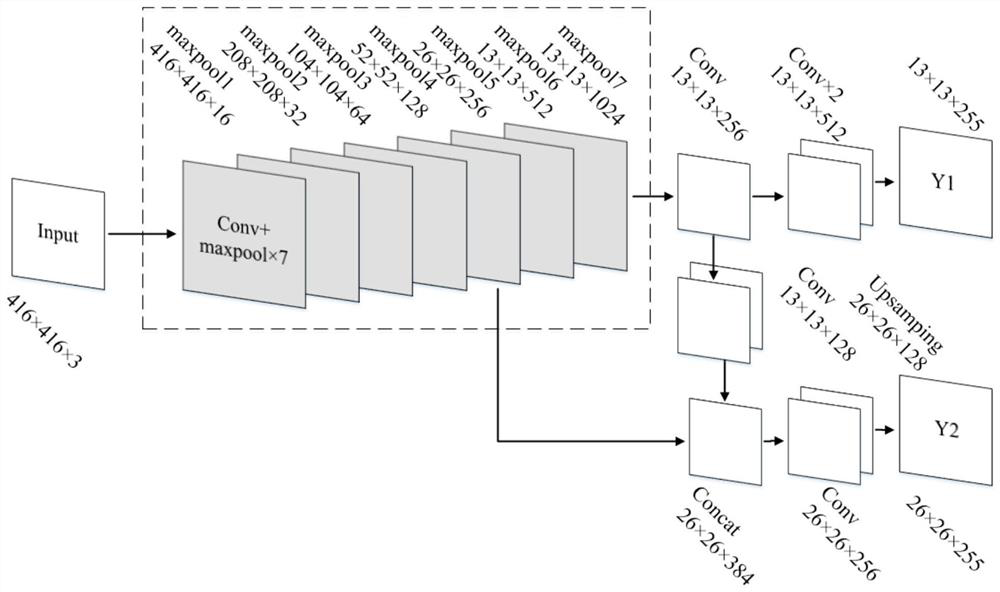

Spaceflight electronic welding spot defect detection method based on improved Tiny-YOLOv3 network

PendingCN111986187AImprove detection efficiencyImprove detection accuracyImage enhancementImage analysisData setEngineering

The invention belongs to the related technical field of defect detection and discloses a spaceflight electronic welding spot defect detection method based on an improved Tiny-YOLOv3 network. The detection method comprises the following steps of (1) enhancing a network layer for feature extraction in Tiny_YOLOv3 by using a Mobileet network, replacing seven convolution and maximum pooling network layers in a Tiny _ YOLOv3 backbone network by using a lightweight network Mobileet to obtain an improved Tiny_YOLOv3 network; (2) inputting a welding spot infrared image with a known defect type into the improved Tiny_YOLOv3 network as a training data set of a sample so as to train and learn the improved Tiny_YOLOv3 network, thereby obtaining an improved Tiny _ YOLOv3 network model; and (3) inputting the infrared image of the welding spot sample to be detected into the improved Tiny_YOLOv3 network model so as to complete the detection of the welding spot defects. The spaceflight electronic welding spot defect detection method effectively improves spaceflight electronic welding spot defect detection accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH +1

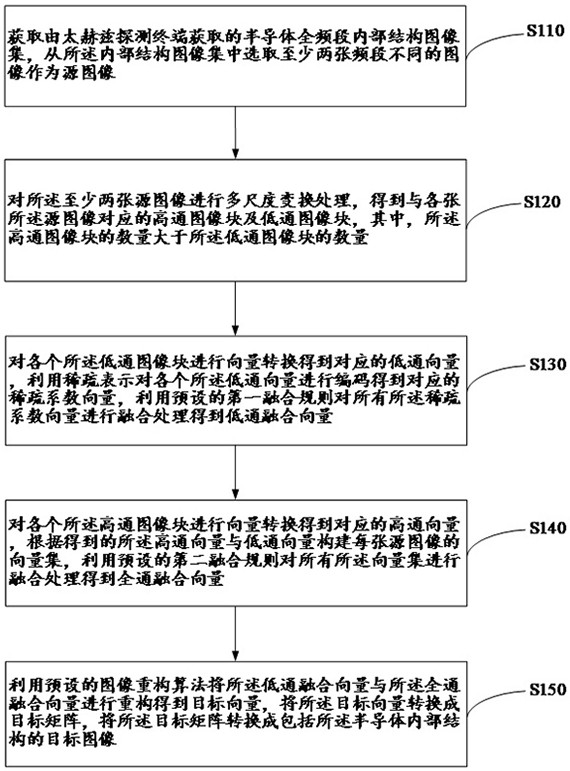

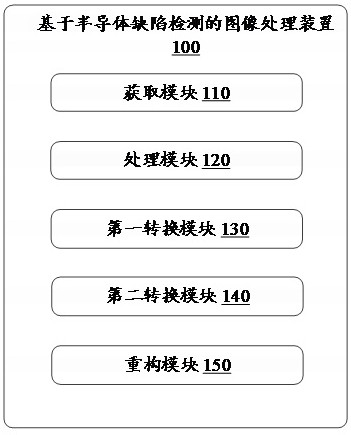

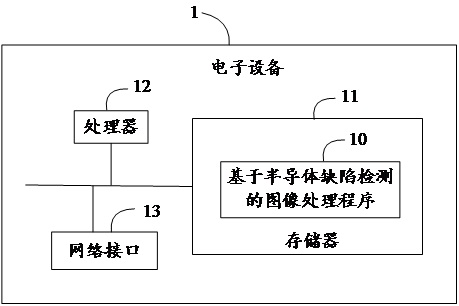

Image processing method and device based on semiconductor defect detection, equipment and medium

InactiveCN111968119AImprove defect detection accuracyImprove clarityImage enhancementImage analysisPattern recognitionImaging processing

The invention relates to the field of data processing, and provides an image processing method and device based on semiconductor defect detection, equipment and a medium. The method comprises the steps: acquiring a semiconductor full-band internal structure image set, and selecting images with different frequency bands from the internal structure image set to serve as source images; processing thesource image to obtain a high-pass image block and a low-pass image block, converting the low-pass image block to obtain a low-pass vector, encoding the low-pass vector to obtain corresponding sparsecoefficient vectors, and performing fusion processing on all the sparse coefficient vectors to obtain a low-pass fusion vector; converting the high-pass image block to obtain a high-pass vector, constructing a vector set of each source image according to the high-pass vector and the low-pass vector, and performing fusion processing on all the vector sets to obtain an all-pass fusion vector; reconstructing the low-pass fusion vector and the all-pass fusion vector to obtain a target vector, and converting the target vector into a target image. The definition of semiconductor imaging can be improved, and therefore the semiconductor defect detection precision is improved.

Owner:JIHUA LAB

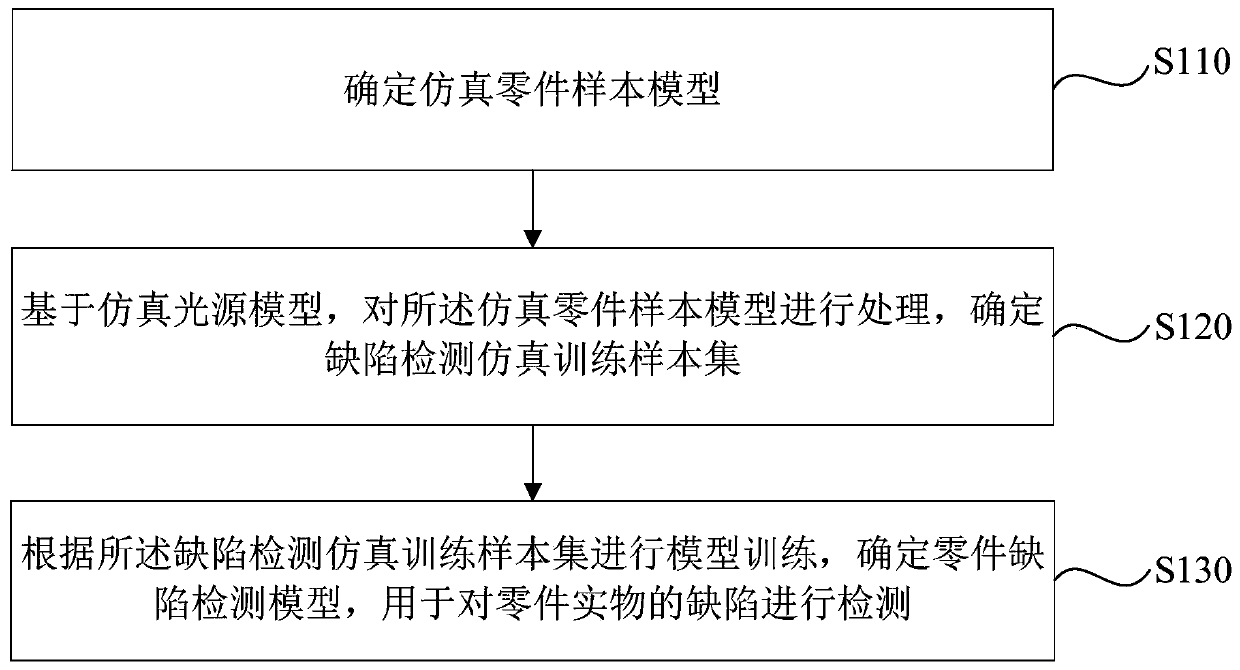

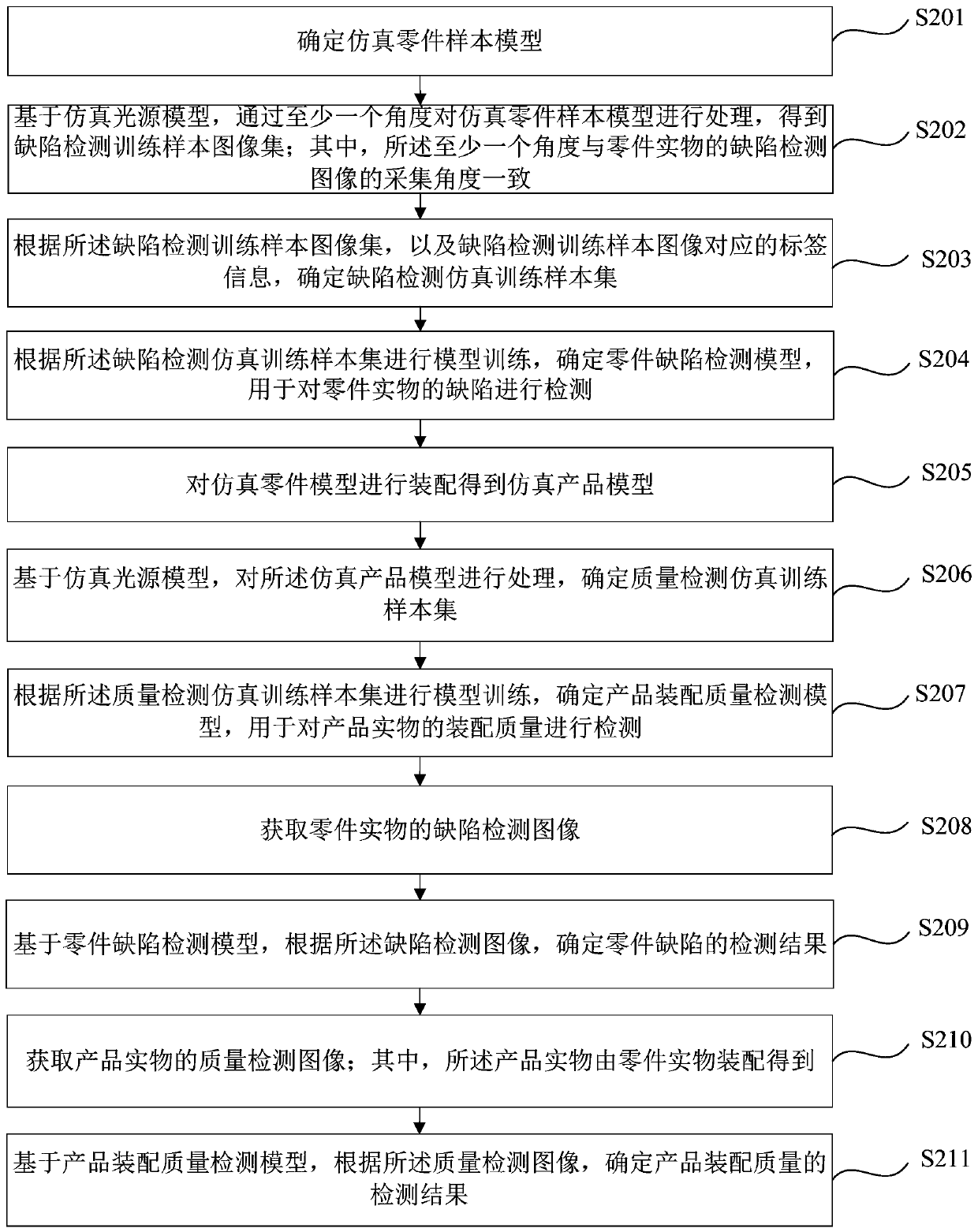

Part defect detection method, device and equipment and storage medium

PendingCN111428374AImprove defect detection accuracyImprove performanceImage enhancementImage analysisAlgorithmSimulation training

The embodiment of the invention discloses a part defect detection method, device and equipment and a storage medium. The method comprises the following steps: determining a simulation part sample model; processing the simulation part sample model based on a simulation light source model, and determining a defect detection simulation training sample set; and performing model training according to the defect detection simulation training sample set, and determining a part defect detection model for detecting defects of a part entity. The embodiment of the invention provides the method and the device, the defects of the parts can be detected. According to the method, the problem of poor performance of an assembly quality detection model obtained through training due to the fact that enough and high-quality training data is difficult to obtain when part defect detection is carried out is solved, so that the high-precision training data is obtained to obtain the high-performance quality detection model in time before part defect detection is carried out, and the effect of improving the part defect detection accuracy is achieved.

Owner:WLZ SMART QUALITY UNIT

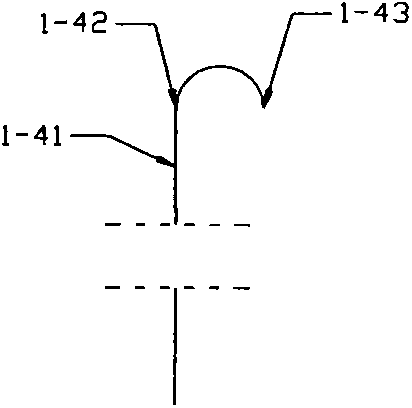

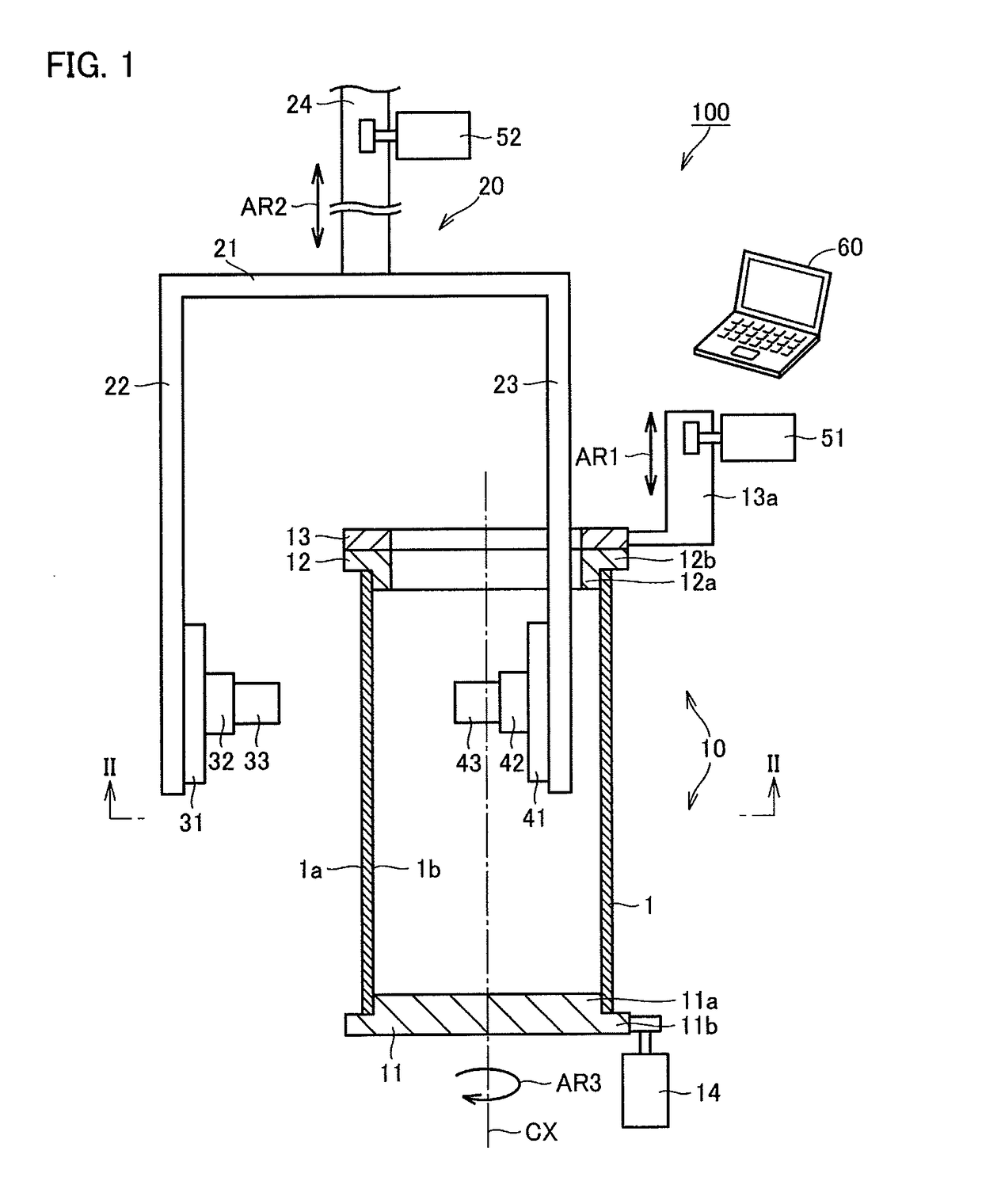

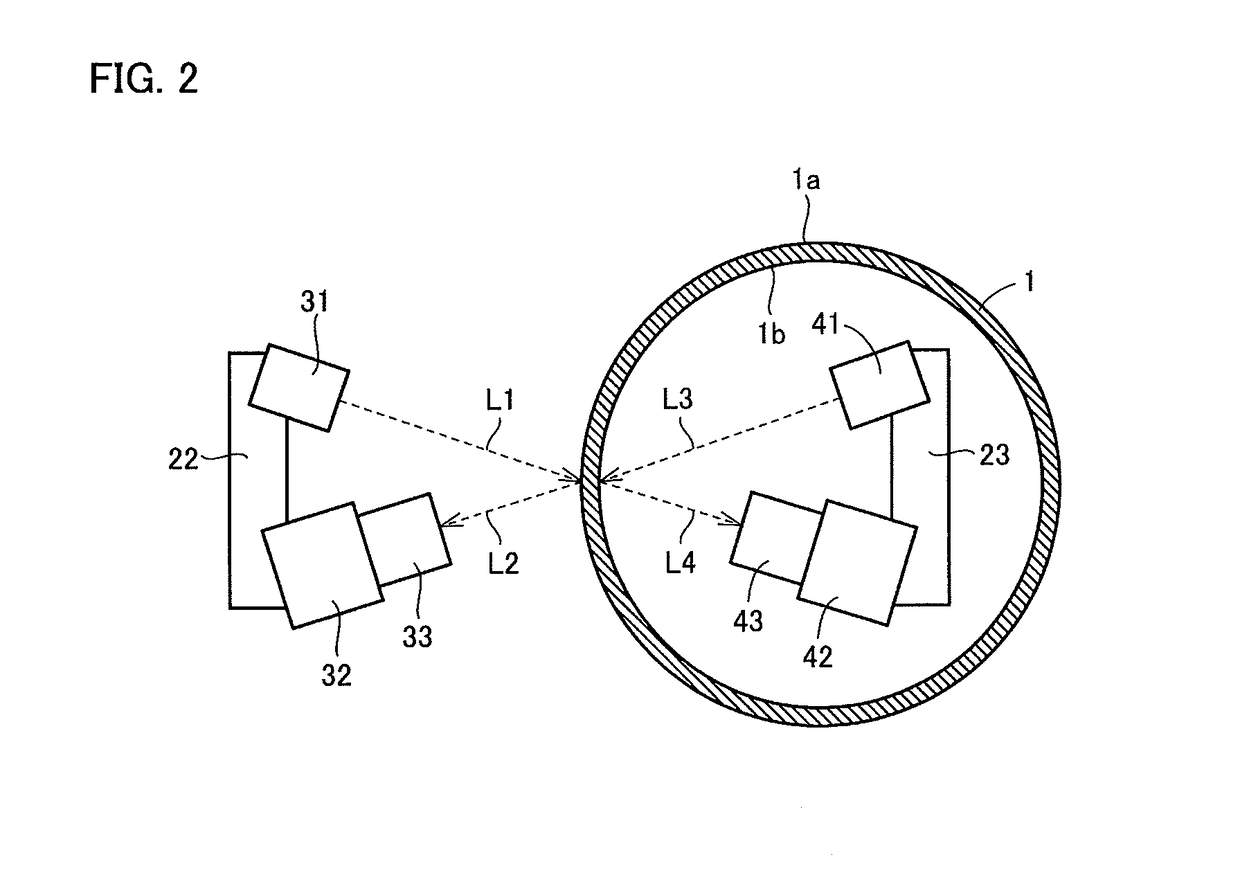

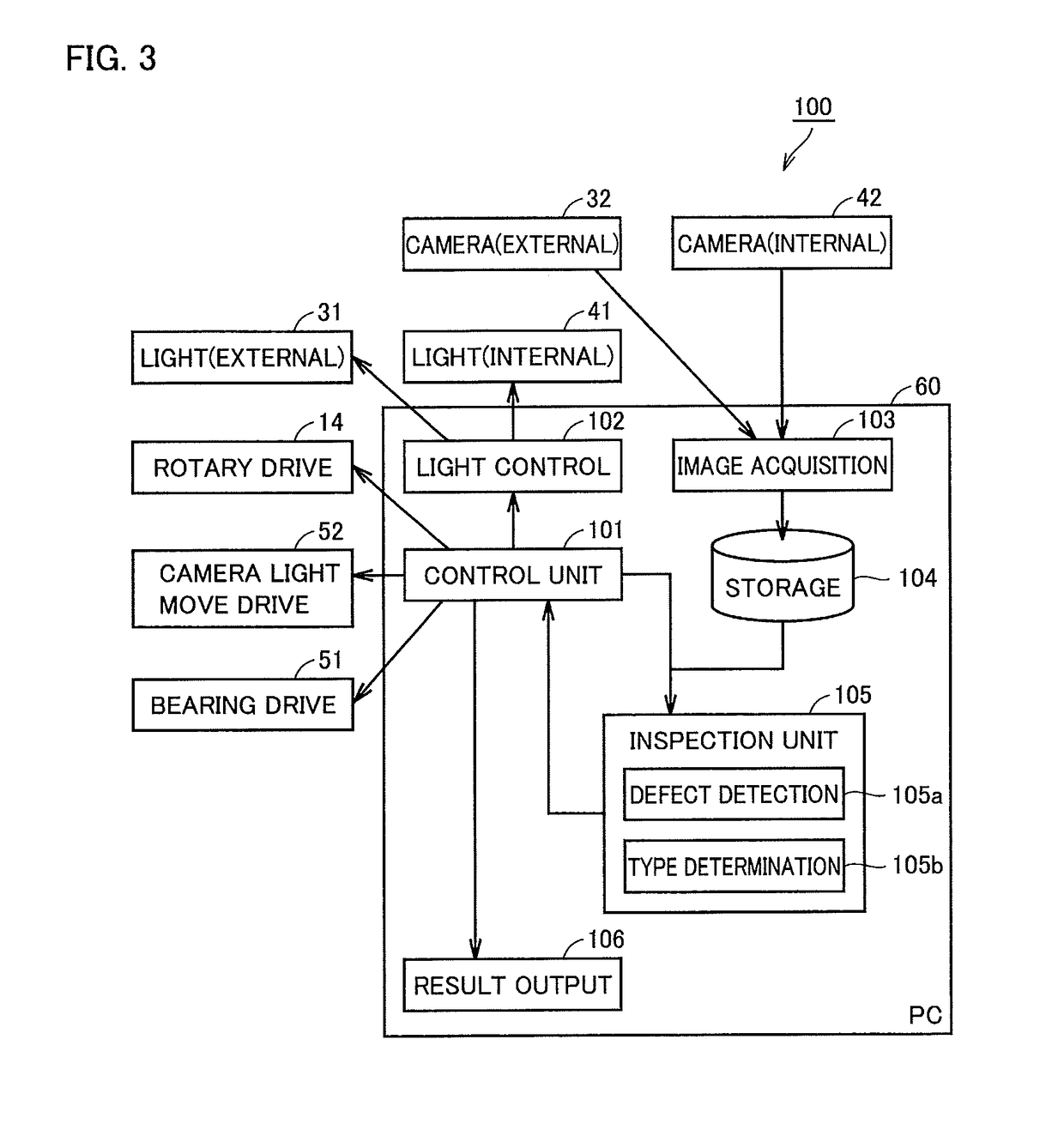

Defect inspection apparatus for tubular product such as intermediate transfer belt

InactiveUS20180357757A1Improve defect detection accuracyImage enhancementImage analysisEngineeringLight source

A defect inspection apparatus comprises a light source that irradiates the outer surface of the intermediate transfer belt, a first line camera for receiving the light from the outer surface and transmitting a signal based on the received light, a light source that irradiates the inner surface of the intermediate transfer belt, and a second line camera that receives the light from the inner surface and transmits a signal based on the received light. Based on the signal received from the first line camera, the defect inspection apparatus creates an outer surface image of the outer surface. Based on the signal received from the second line camera, the defect inspection apparatus creates an inner surface image of the inner surface. Based on the outer surface image and the inner surface image, the defect inspection apparatus detects defects contained in the intermediate transfer belt.

Owner:KONICA MINOLTA INC

Defect detection method and device, electronic equipment and computer readable storage medium

ActiveCN113379680AImprove defect detection accuracyImage enhancementImage analysisComputer graphics (images)Engineering

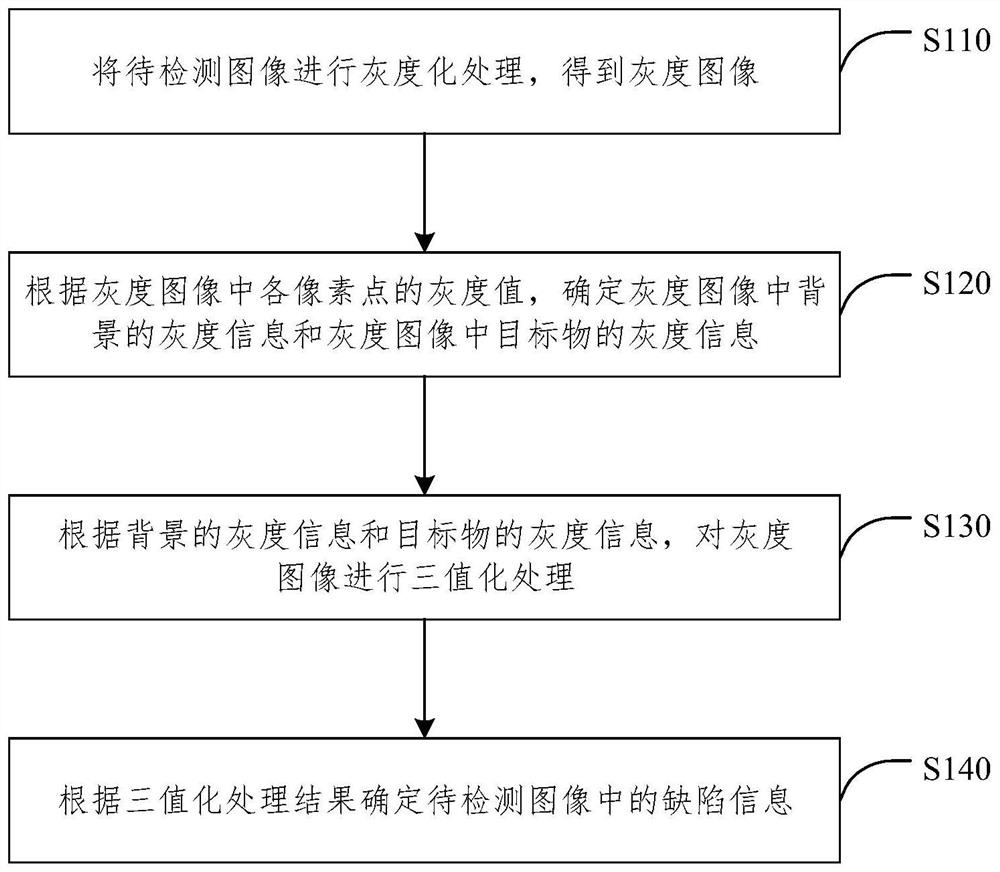

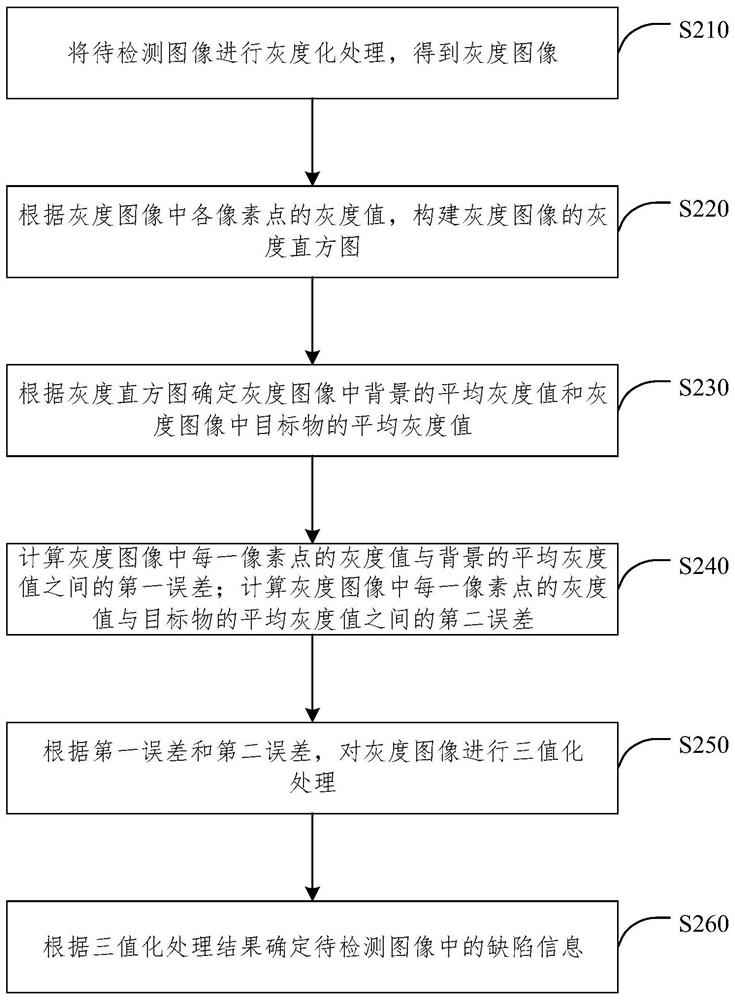

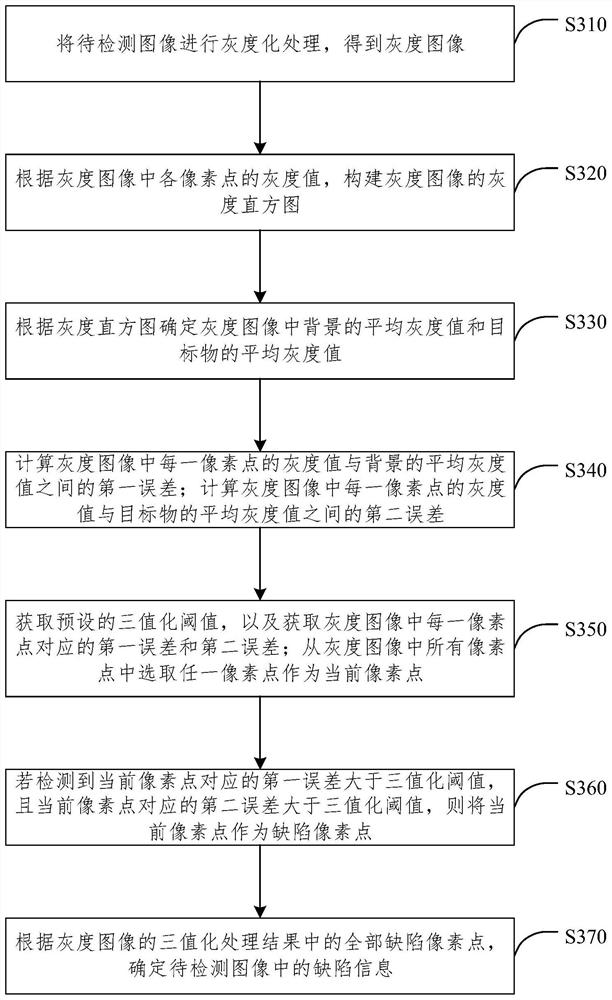

The invention relates to a defect detection method and device, electronic equipment and a computer readable storage medium. The method comprises the following steps: carrying out graying processing on a to-be-detected image to obtain a grayscale image; determining gray scale information of a background in the gray scale image and gray scale information of a target object in the gray scale image according to the gray scale value of each pixel point in the gray scale image; performing ternary processing on the grayscale image according to the grayscale information of the background and the grayscale information of the target object; and determining defect information in the to-be-detected image according to a ternary processing result. According to the embodiment of the invention, the defect detection precision of the image can be effectively improved.

Owner:SHANGHAI WINGTECH INFORMATION TECH CO LTD

Image grey value based mask optical defect detecting method

ActiveCN108037142AImprove defect detection accuracyEasy to detectOptically investigating flaws/contaminationCamera interfaceLightness

The invention discloses an image grey value based mask optical defect detecting method. The method includes steps: acquiring bright area data and dark area data of an actual image on a camera interface; adopting a camera flat field correction function for camera view field brightness correction of the actual image to guarantee value maintenance of grey values of a bright area and a dark area in aview field, and keeping uniform as far as possible; selecting a dark area on a calibration plate of the actual image, and calibrating a grey value to be V1; selecting a bright area on the calibrationplate of the actual image, and calibrating a grey value to be V2; recording the calibrated grey value V1 of the dark area and the calibrated grey value V2 of the bright area into a Recipe template toserve as subsequent mask detection parameters, and directly applying the subsequent mask detection parameters as grey values of standard image generation bitmap to keep uniformity of the grey values of the actual image and the grey values of a standard image as far as possible; after image registration, subjecting the actual image and the standard image to absolute subtraction operation to furtherjudge whether the actual image has defects or not. By adoption of the method, defect detection accuracy can be improved, and great detection effects are achieved.

Owner:江苏维普光电科技有限公司

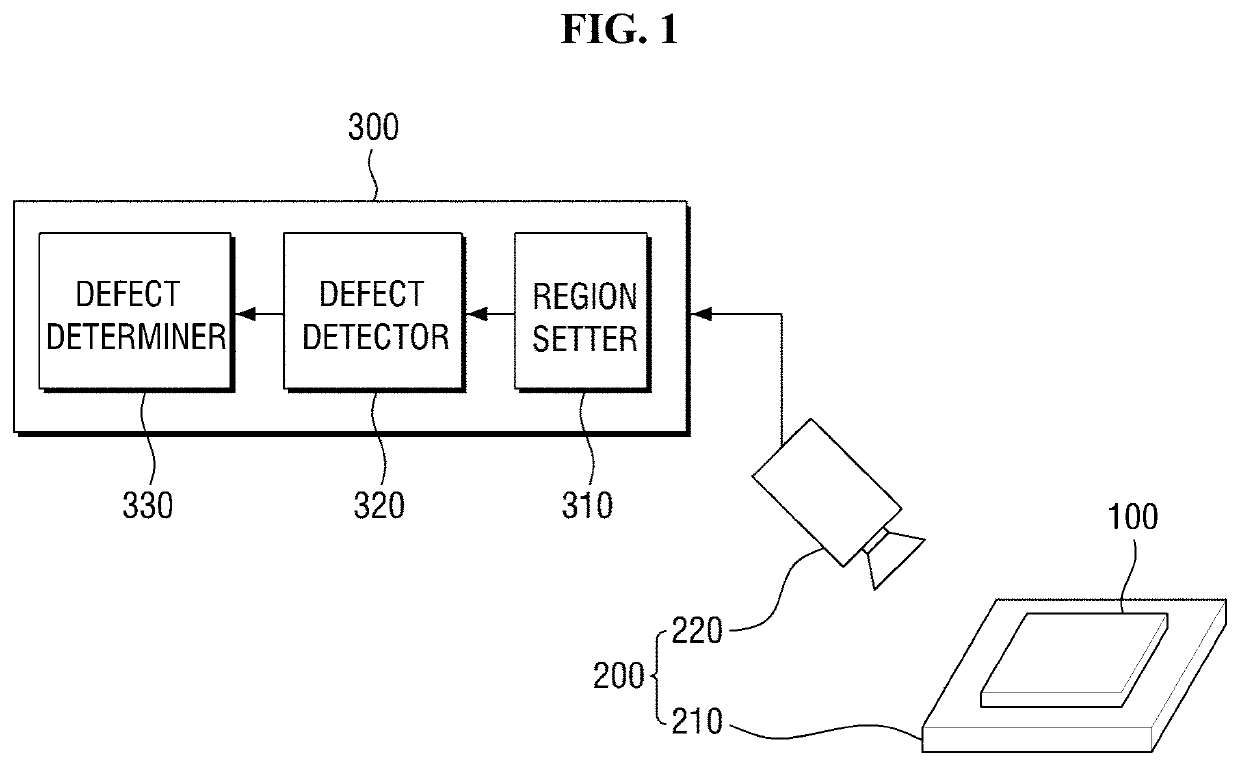

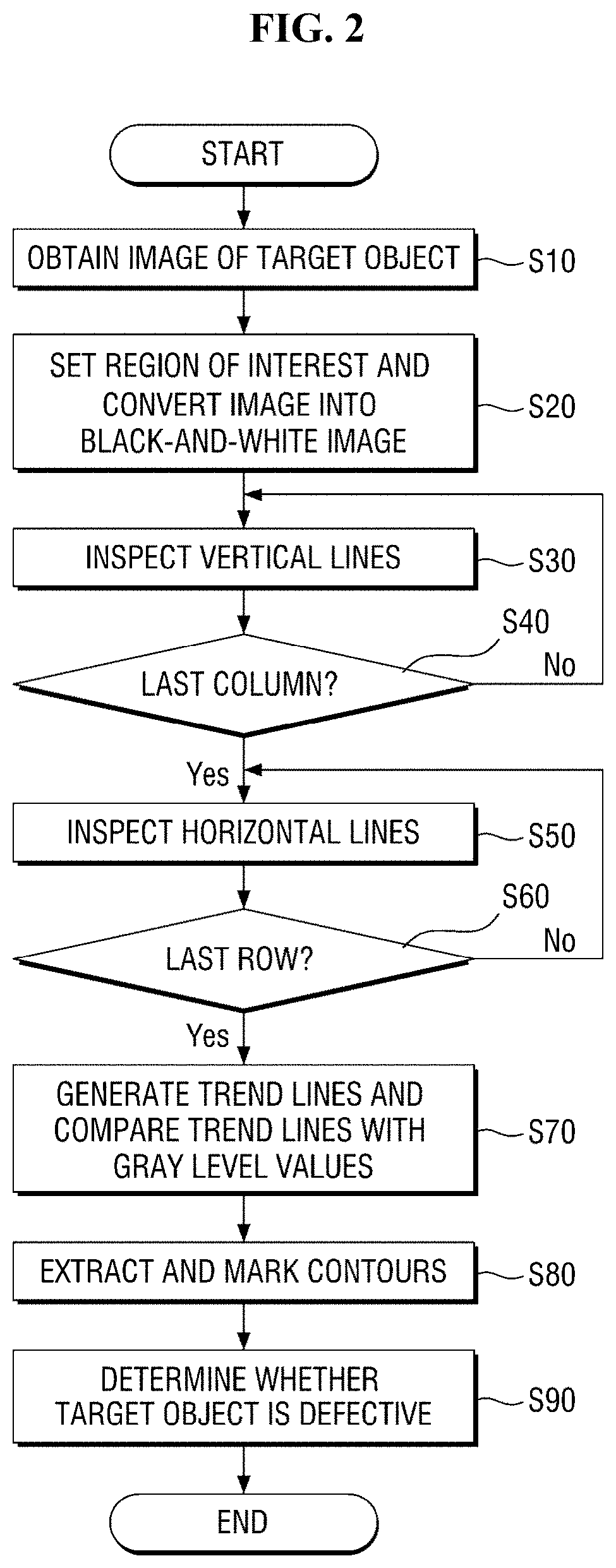

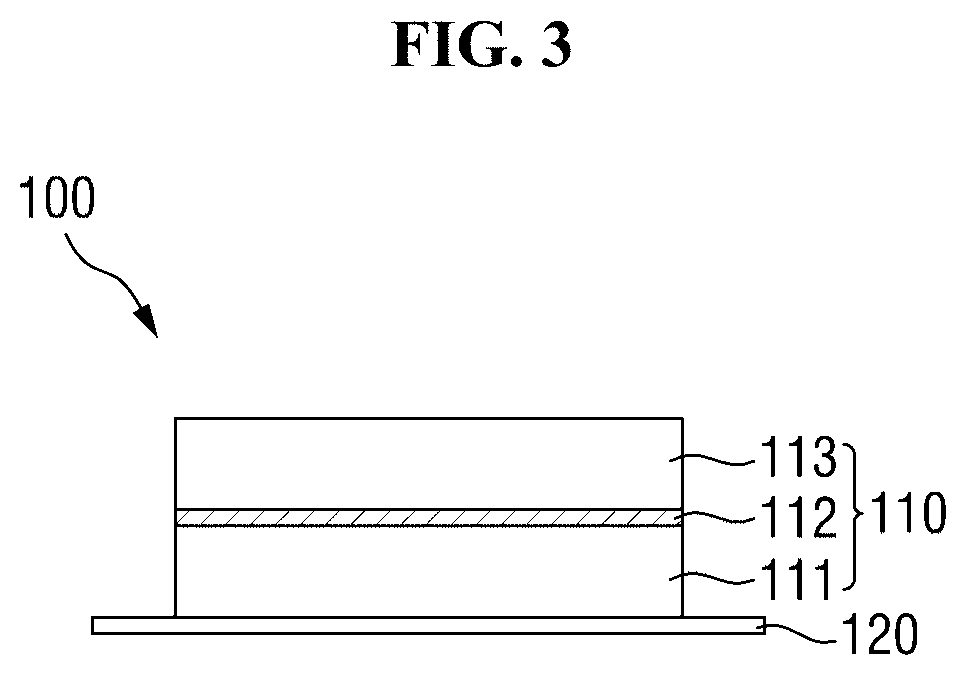

Defect detection apparatus and method

ActiveUS20190340739A1Increasing stain defect detection accuracyImprove defect detection accuracyImage enhancementImage analysisSetterGray level

A defect detection apparatus including a region setter which sets a region of interest in an image including a plurality of pixels, and a defect detector which divides the region of interest into a plurality of segments and generates a trend line for each of the segments based on gray level values of the pixels. Here, the defect detector detects a stain in the image by comparing the gray level values of the pixels with the trend line.

Owner:SAMSUNG DISPLAY CO LTD

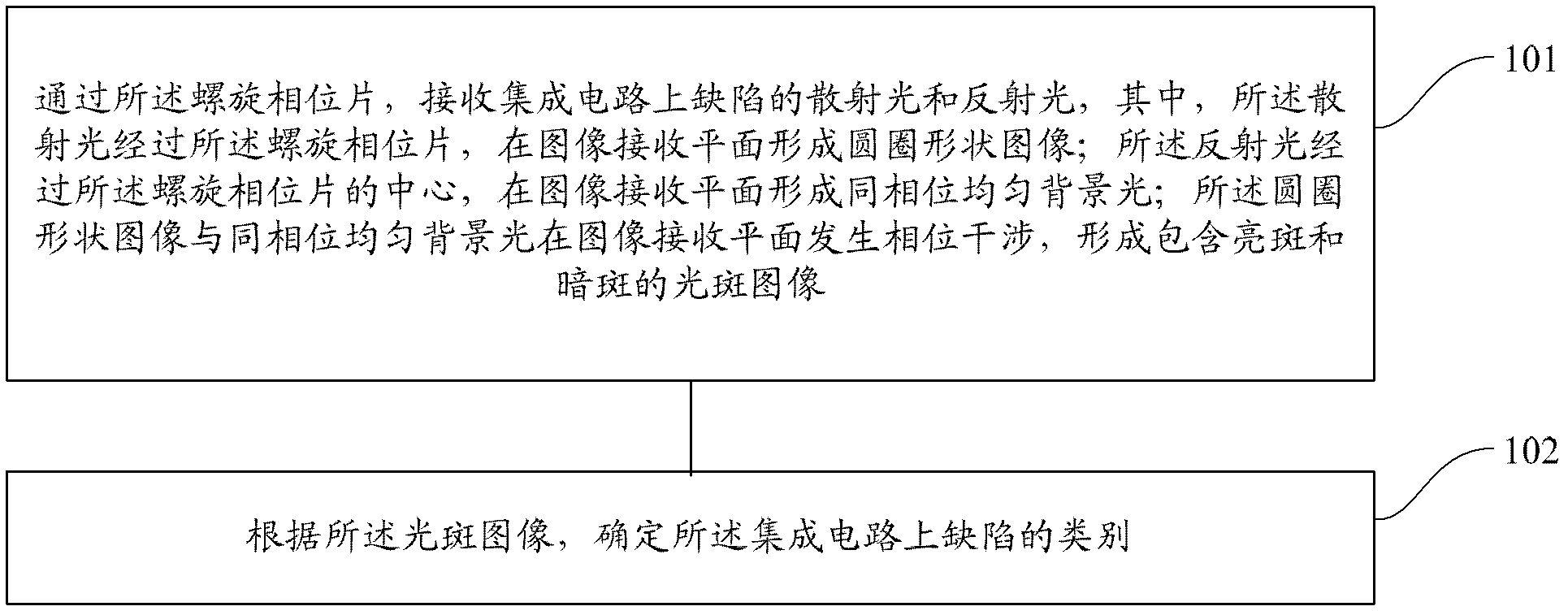

Integrated circuit defect optical detection method and device

ActiveCN103018202AImprove defect detection accuracyPhase-affecting property measurementsScattering properties measurementsDark spotBright spot

The embodiment of the invention discloses an integrated circuit defect optical detection method and an integrated circuit defect optical detection device. The method comprises the steps that: a spiral phase plate is arranged at a Fourier plane; through the spiral phase plate, scattered light and reflected light of the defect on the integrated circuit are received, wherein the scattered light passes through the spiral phase plate and forms a circle image on an image receiving plane, and the reflected light passes through the center of the spiral phase plate and forms same-phase uniform background light on the image receiving plane; the circle image and the same-phase uniform background light are subjected to phase interference on the image receiving plane, such that a spot image comprising bright spots and dark spots is formed; and the type of defect on the integrated circuit is determined according to the spot image. According to the embodiment of the invention, integrated circuit defect detection precision can be improved.

Owner:SKYVERSE TECH CO LTD

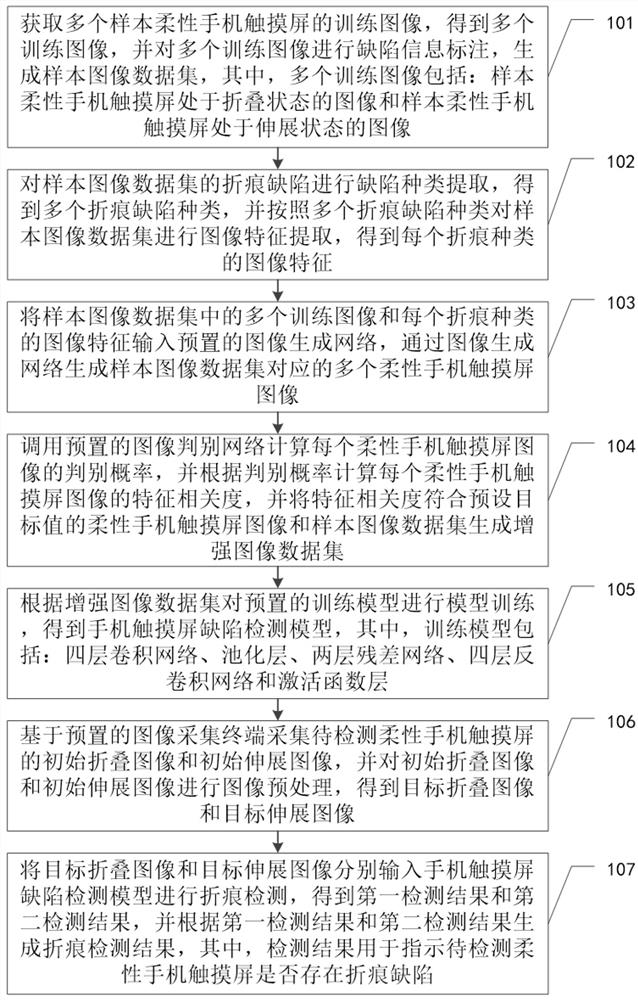

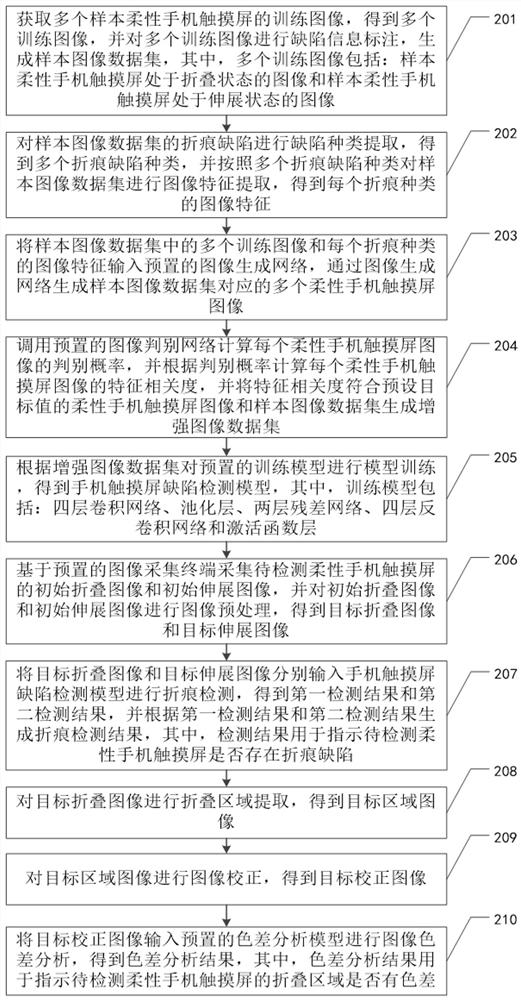

Defect detection method, device and equipment for mobile phone touch screen and storage medium

ActiveCN114862845AImprove defect detection accuracyEasy to identifyImage enhancementImage analysisData setComputer graphics (images)

The invention relates to the field of artificial intelligence, and discloses a defect detection method, device and equipment for a mobile phone touch screen and a storage medium, which are used for improving the defect detection accuracy of the flexible mobile phone touch screen. The method comprises the following steps: performing defect information labeling on a plurality of training images to generate a sample image data set; generating an enhanced image data set according to the sample image data set; performing model training on the training model according to the enhanced image data set to obtain a mobile phone touch screen defect detection model; the method comprises the following steps: acquiring an initial folding image and an initial stretching image of a to-be-detected flexible mobile phone touch screen, and carrying out image preprocessing on the initial folding image and the initial stretching image to obtain a target folding image and a target stretching image; and inputting the target folding image and the target stretching image into a mobile phone touch screen defect detection model for crease detection to obtain a crease detection result.

Owner:深圳市瑞桔电子有限公司

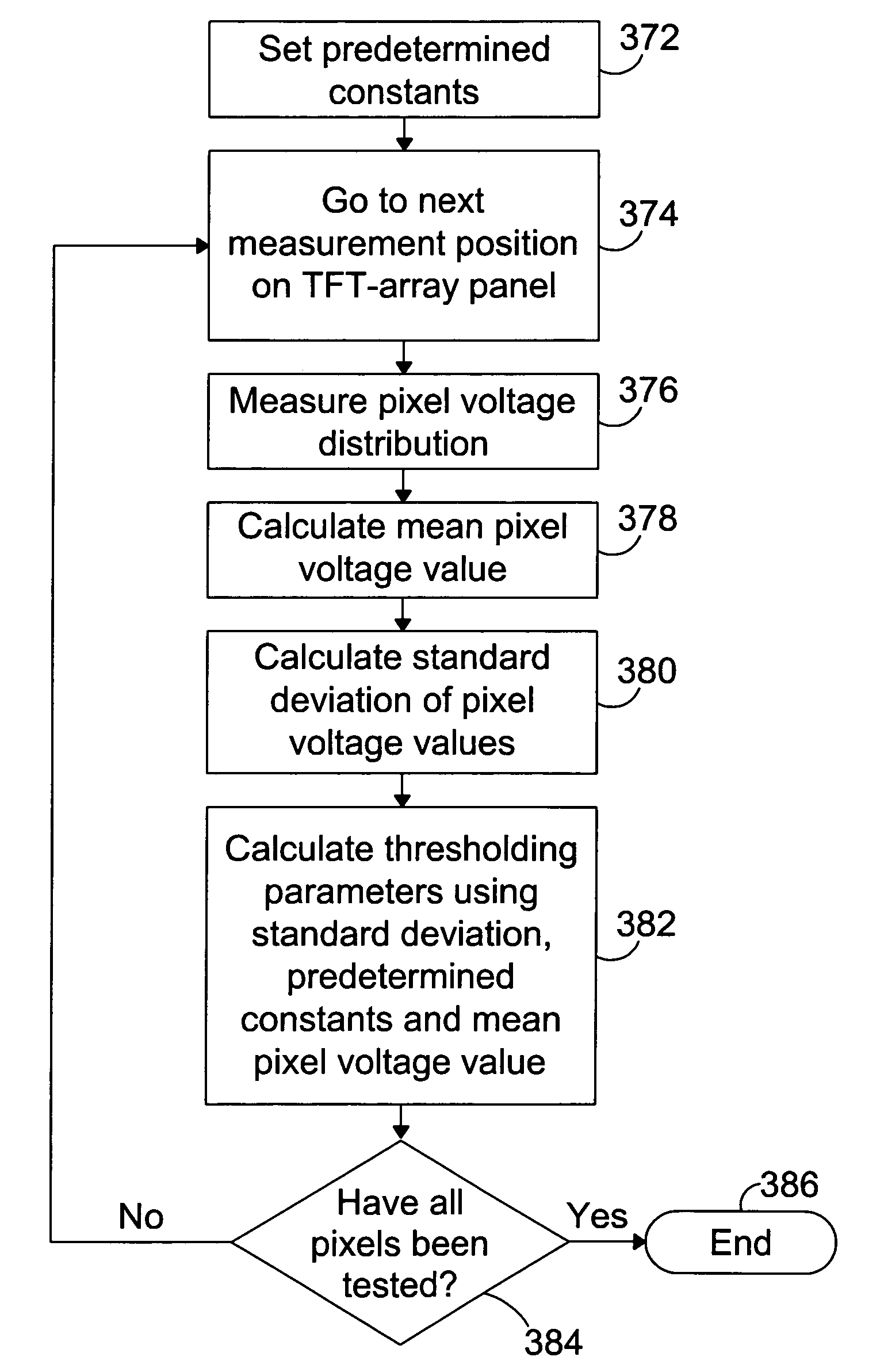

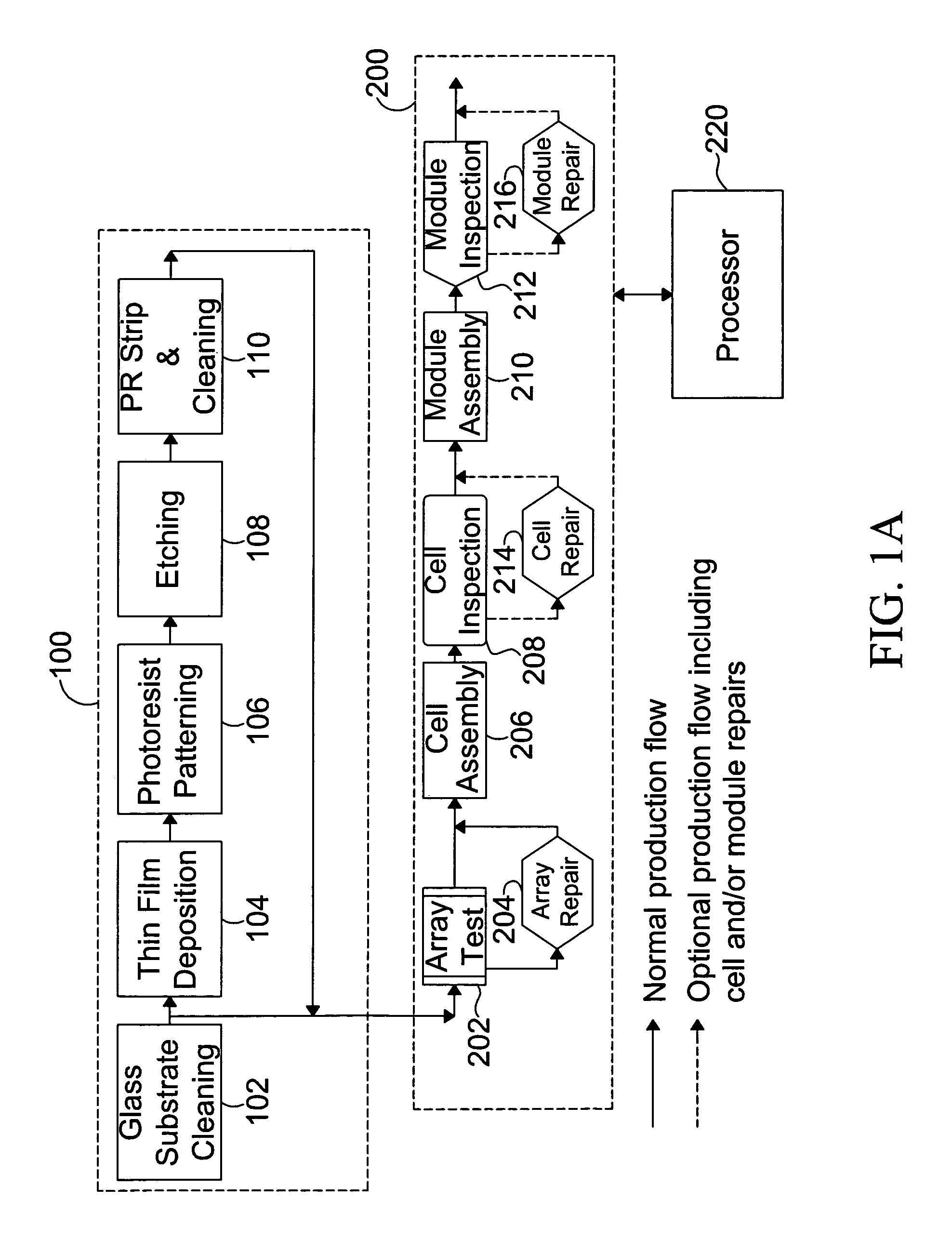

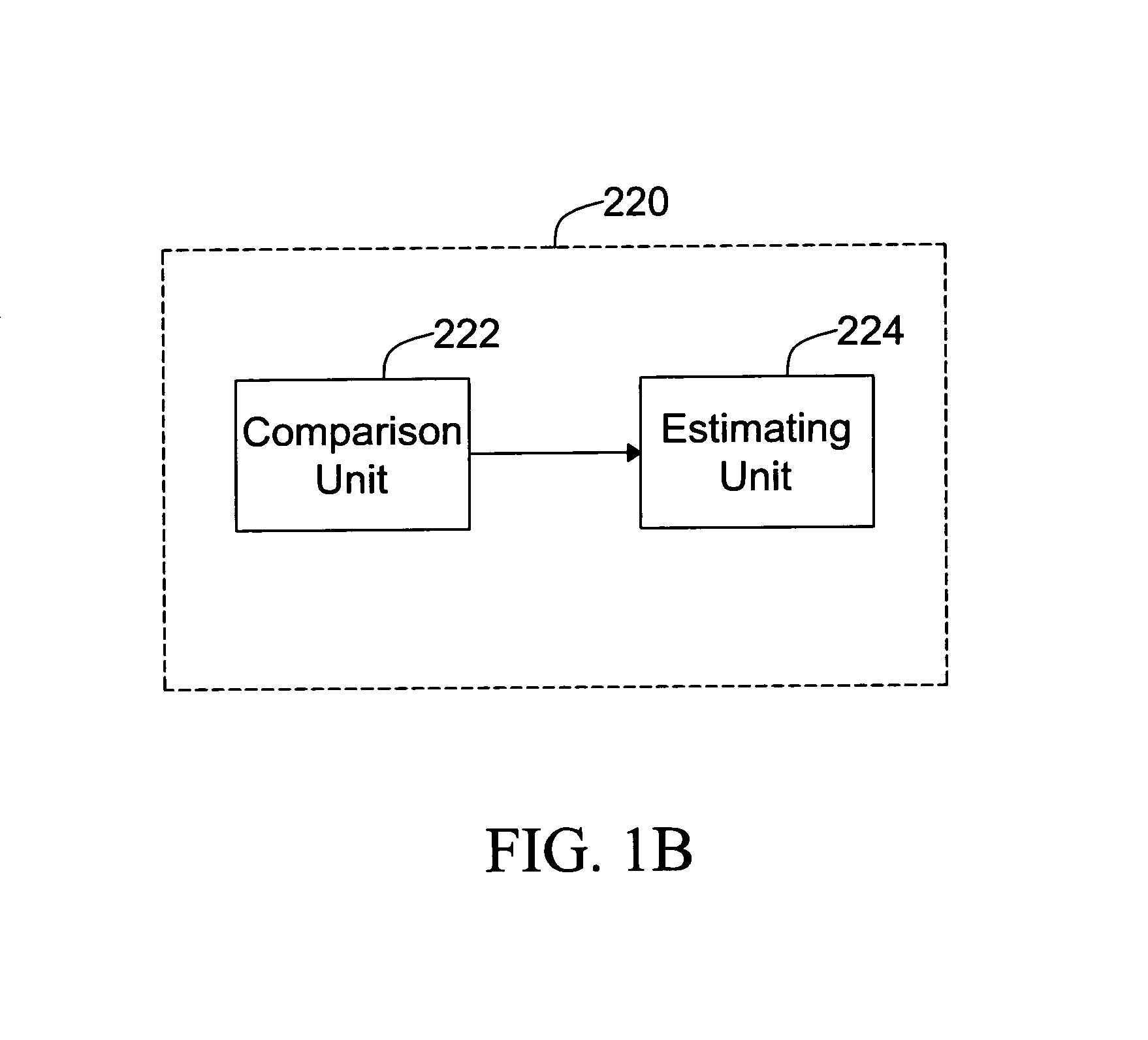

System and method for improving TFT-array manufacturing yields

InactiveUS7024338B2Improve defect detection accuracyShorten operation timeMaterial analysis by electric/magnetic meansTotal factory controlRestoration deviceHigh probability

A system and method for detecting defects in TFT-array panels is provided that improves defect detection accuracy by adjusting the thresholding parameters used to classify defective pixels when the number of defects reported by a TFT-array testing system exceeds a predetermined critical number. In a preferred embodiment, the thresholding parameters are adjusted until the number of reported defects is less than or equal to the predetermined critical number. The predetermined critical number represents a threshold number for determining if the number of reported defects is abnormally high. Reducing the number of reported defects to a number equal to or less than the predetermined critical number will decrease the operation time of the TFT-array repair equipment, because of the reduced number of potential defects it will be required to handle, and will also result in the TFT-array testing system reporting a smaller number of potential defects, with the potential defects that are reported having a higher probability of being real defects.

Owner:YIELDBOOST TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com