Crown cap surface defect online detection method based on image processing

A technology of image processing and detection methods, applied in the field of image processing, can solve the problems of detection and classification of multi-type defects on the surface of crown caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to better understand the content of the patent of the present invention, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

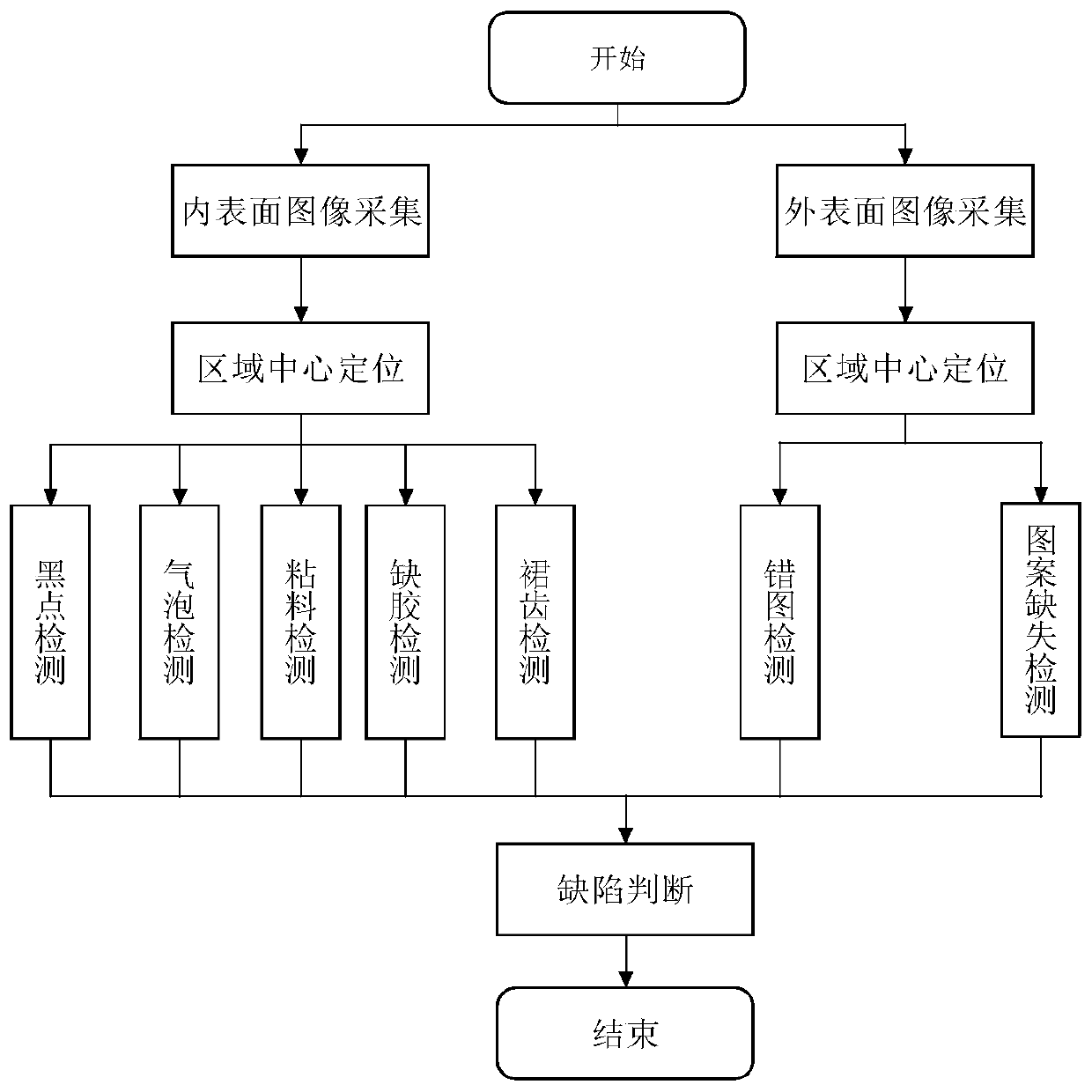

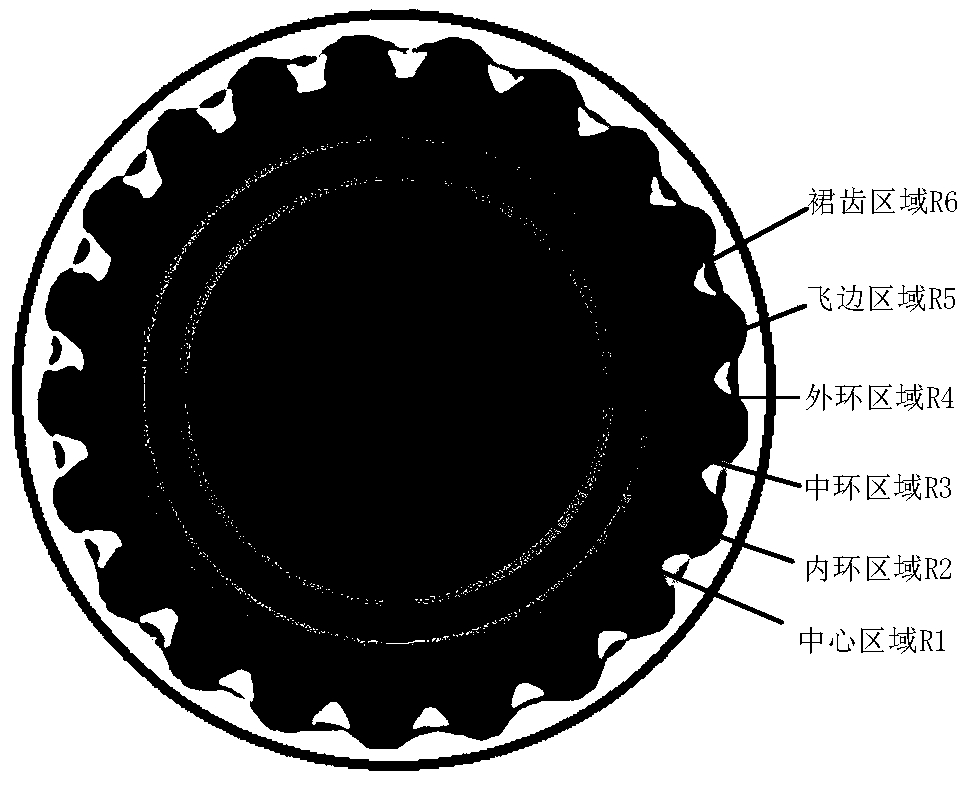

[0081] Such as figure 1 As shown, the surface defect detection process of the crown cover includes two parts: inner surface inspection and outer surface inspection. The inner surface inspection includes inner surface image acquisition, area center positioning and black spots, flash lack of glue, inner and outer ring bubbles, sticky materials, skirt teeth Detection of defect types such as deformity and missing. The external surface detection includes external surface image acquisition, regional center positioning and pattern missing, wrong image and other defect types detection. The internal and external surface defect detection is divided into two stations at the same time, and each has independent image acquisition. and processing system, a method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com