Spaceflight electronic welding spot defect detection method based on improved Tiny-YOLOv3 network

A detection method and point defect technology, applied in biological neural network models, image analysis, image enhancement, etc., can solve problems such as difficulty in finding internal cracks and holes in solder joints, detection results vary from person to person, and difficulty in eliminating potential safety hazards. Achieve rapid and intelligent classification detection, facilitate popularization and application, and improve detection accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0054] The experimental computing platform is as follows: CPU is Intel(R) Core(TM) i7-8750H@2.2GHz; GPU is NVIDIA2070M; memory is 16GB; operating system is win10; the deep learning framework is Keras architecture based on tensorflow background.

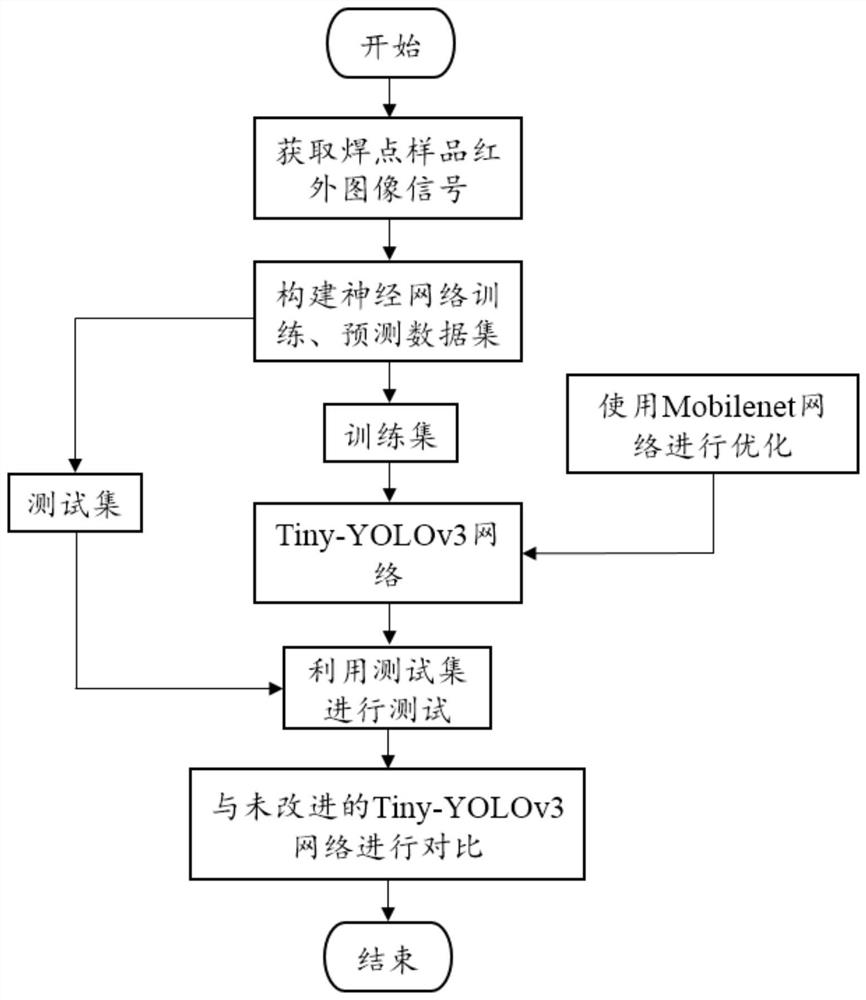

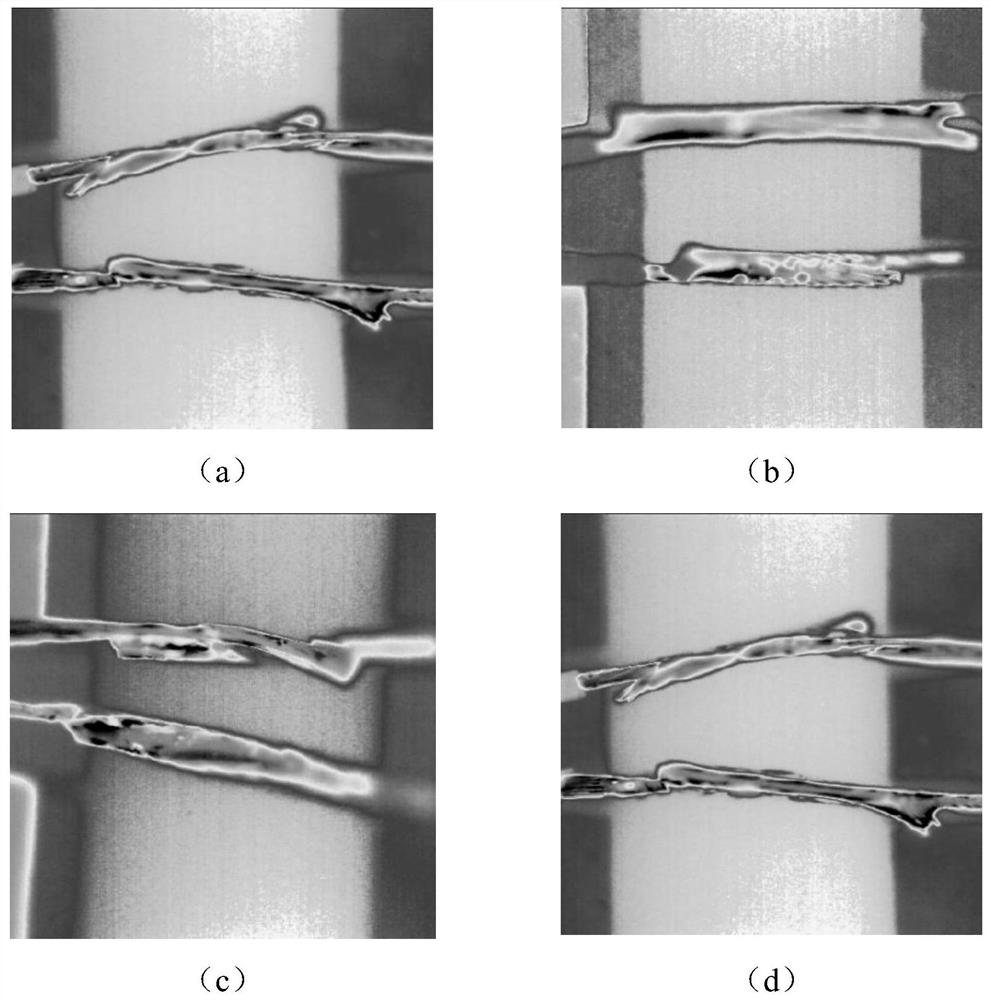

[0055] The obtained 383 infrared image samples of solder joints were cropped to obtain 383 infrared images of solder joints with a size of 416×416 pixels. Some images are as follows: figure 2 shown. Using the LabelImg image annotation software to label the positions and sizes of the three types of defects in the infrared images of solder joints, 383 xml format files containing the defect information of infrared images of solder joints were generated after labeling. The obtained xml format file is randomly divided into the training data set and the testing data set of the neural network according to the ratio of 9:1. The data set includes a total of 1274 objects of three types of defects: holes, breaches, and notches. . Using the Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com