Electric power inspection image defect identification method and system, and electric power inspection unmanned aerial vehicle

A defect identification and power inspection technology, applied in the field of artificial intelligence, can solve problems such as difficult creation, large amount of calculation of the identification system, heavy inspection tasks, etc., and achieve the effect of retaining accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

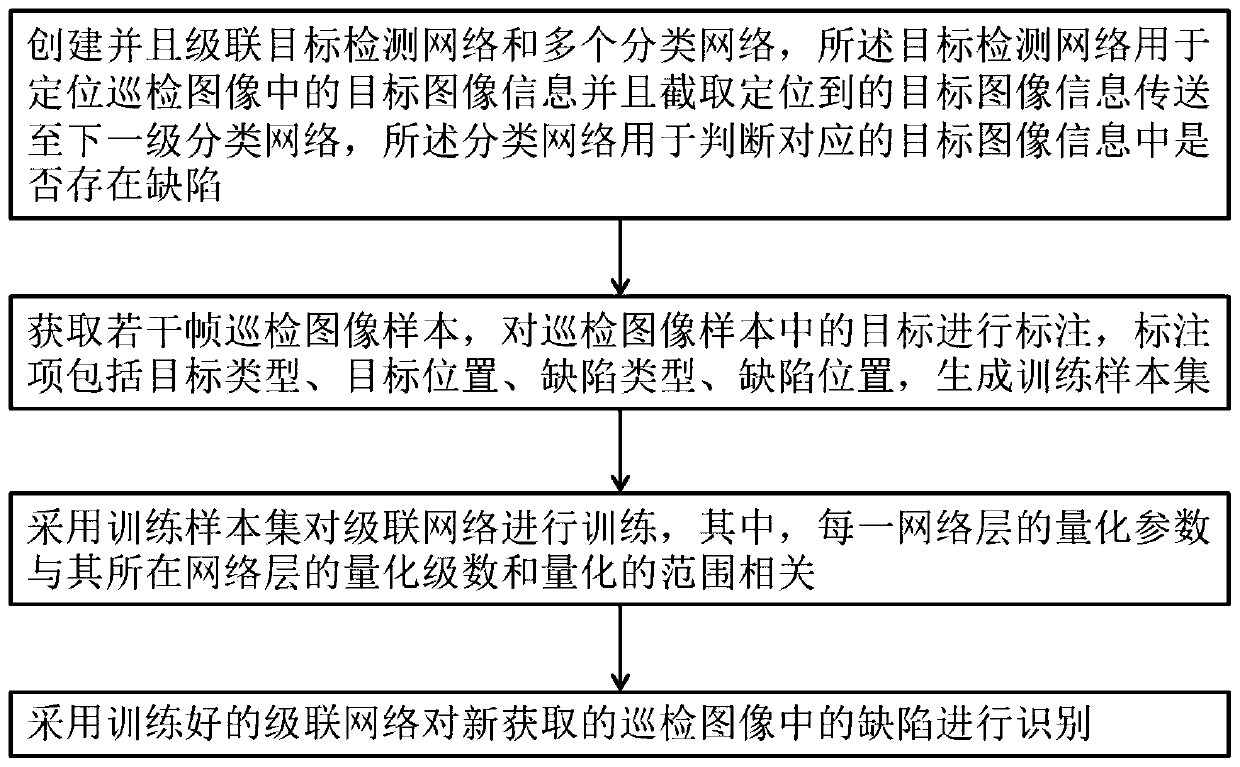

[0053] to combine figure 1 The object of the present invention is to provide a method for identifying defects in power inspection images, which can greatly improve the detection accuracy and enable automatic identification of UAV inspections in power grids.

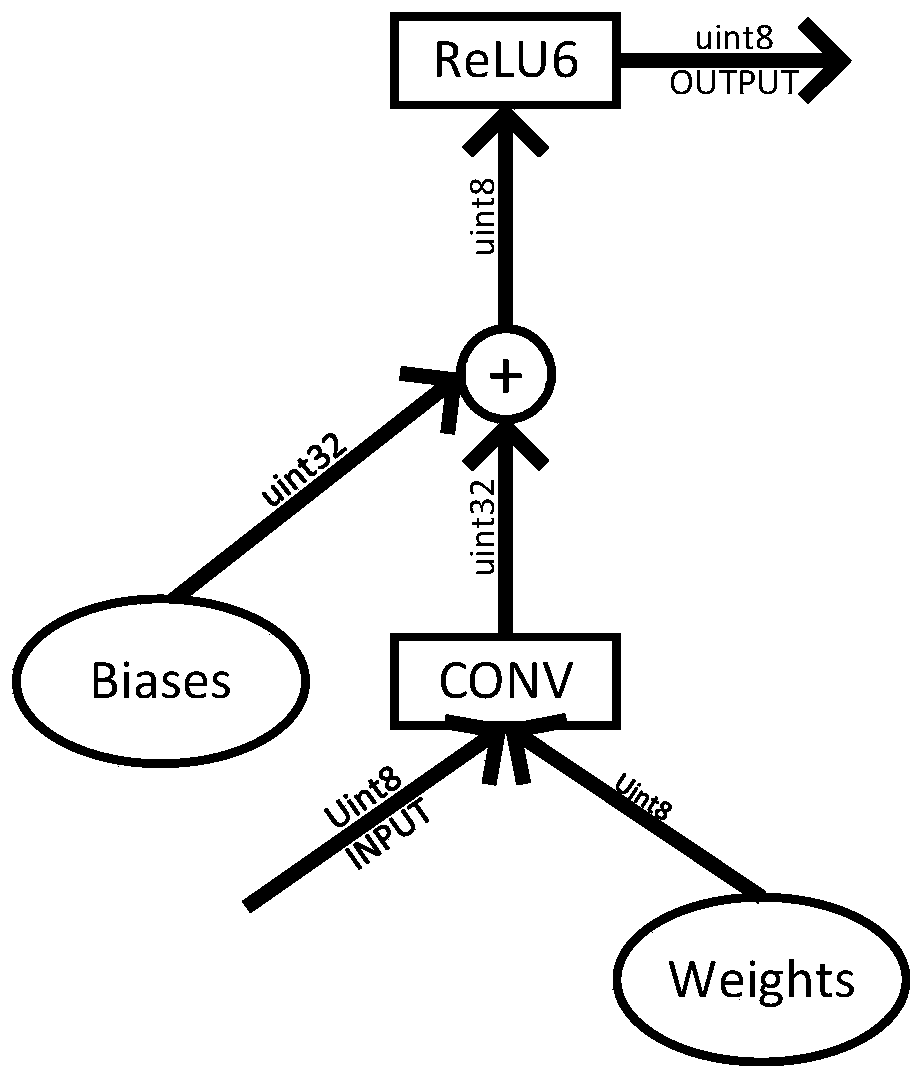

[0054] The method for identifying defects in power inspection images includes two parts: constructing a training data set and creating a cascaded network model.

[0055] Regarding the construction of the training data set, the initial training data set is composed of pictures collected by the approaching observation of the UAV, and then the final training data set is completed by manually marking the positions of the targets and defects.

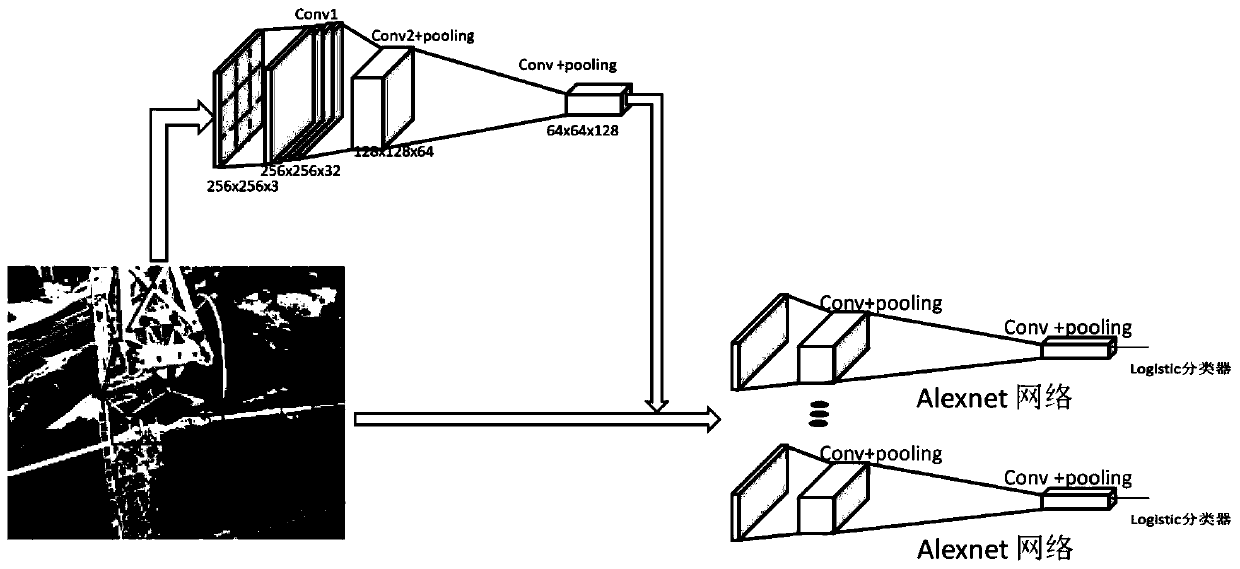

[0056] The working principle of the cascaded network model: the target detection network first locates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com