Full-polyester sanded cloth paperless digital direct spray printing process

A technology of digital direct injection and printing technology, applied in the field of printing, can solve problems such as irreplaceable mainstream methods, pollution, staining, etc., achieve obvious economic and social benefits, solve pollution problems, and increase color depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

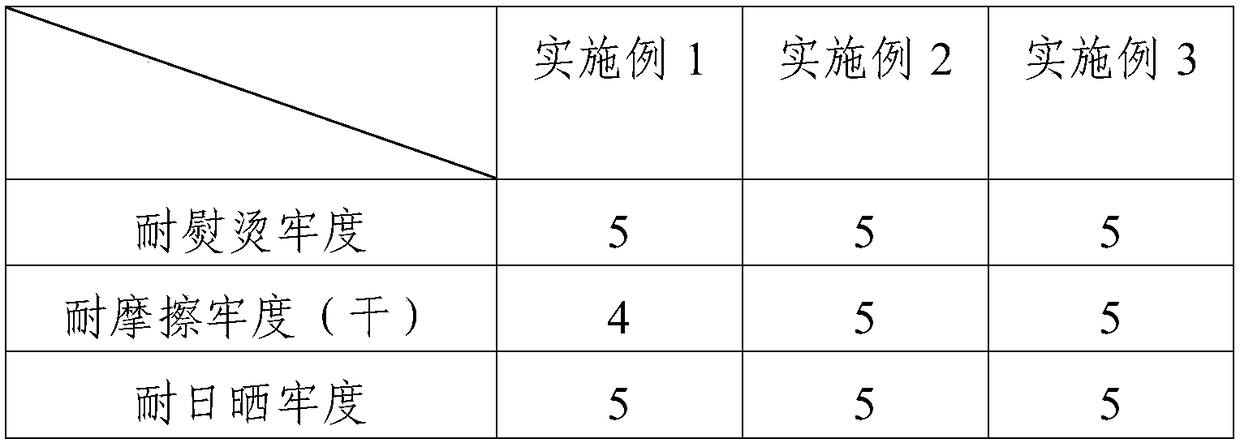

Embodiment 1

[0029] A paperless digital direct-injection printing process for all-polyester brushed cloth, comprising the following steps:

[0030] (1) Prepare sizing slurry: the sizing slurry includes the following components in weight percent: modified starch 2-5%, formic acid 1-3%, nanopowder 1-4%, sodium dihydrogen phosphate 0.2-0.8 %, the rest is water;

[0031] (2) padding and sizing: dipping and rolling the whole polyester brushed cloth twice in the prepared slurry, and the liquid rolling rate is 60%;

[0032] (3) One-time drying: For one-time drying, first heat up to 85°C for 2 minutes, then heat up to 125°C for 20 minutes, and finally heat up to 165°C for 1 minute;

[0033] (4) Digital inkjet printing: Make an inkjet printing model through computer digital drawing, and then use a digital color printing machine to directly spray the drawn pattern on the above-mentioned all-polyester brushed cloth with high-temperature dispersion ink. The ambient temperature during printing is 22-3...

Embodiment 2

[0038] A paperless digital direct-injection printing process for all-polyester brushed cloth, comprising the following steps:

[0039] (1) Prepare sizing slurry: the sizing slurry includes the following components in weight percentage: 4% sodium alginate, 1% acetic acid, 3% nanometer powder, 0.6% acetic acid, 2% Proxel GXL, and the rest is water;

[0040] (2) padding and sizing: dipping and rolling the whole polyester brushed cloth twice in the prepared slurry, and the rolling rate is 58%;

[0041] (3) One-time drying: For one-time drying, first heat up to 82°C for 2 minutes, then heat up to 120°C for 25 minutes, and finally heat up to 160°C for 1 minute;

[0042] (4) Digital inkjet printing: Make an inkjet printing model through computer digital drawing, and then use a digital color printing machine to directly spray the drawn pattern on the above-mentioned all-polyester brushed cloth with high-temperature dispersion ink. The ambient temperature during printing is 22-30°C. T...

Embodiment 3

[0047] A paperless digital direct-injection printing process for all-polyester brushed cloth, comprising the following steps:

[0048] (1) Prepare sizing slurry: the sizing slurry includes the following components in weight percentage: 2% methyl cellulose, 1% benzenesulfonic acid, 2% nanometer powder, 0.4% tartaric acid, 3% BIT-20, and the rest are water;

[0049] (2) padding and sizing: dipping and rolling the whole polyester brushed cloth twice in the prepared slurry, and the liquid rolling rate is 65%;

[0050] (3) One-time drying: For one-time drying, first heat up to 80°C for 2 minutes, then heat up to 130°C for 15 minutes, and finally heat up to 160°C for 1 minute;

[0051] (4) Digital inkjet printing: Make an inkjet printing model through computer digital drawing, and then use a digital color printing machine to directly spray the drawn pattern on the above-mentioned all-polyester brushed cloth with high-temperature dispersion ink. The ambient temperature during printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com