Metal paint spraying surface defect detection method

A defect detection, metal technology, applied in neural learning methods, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

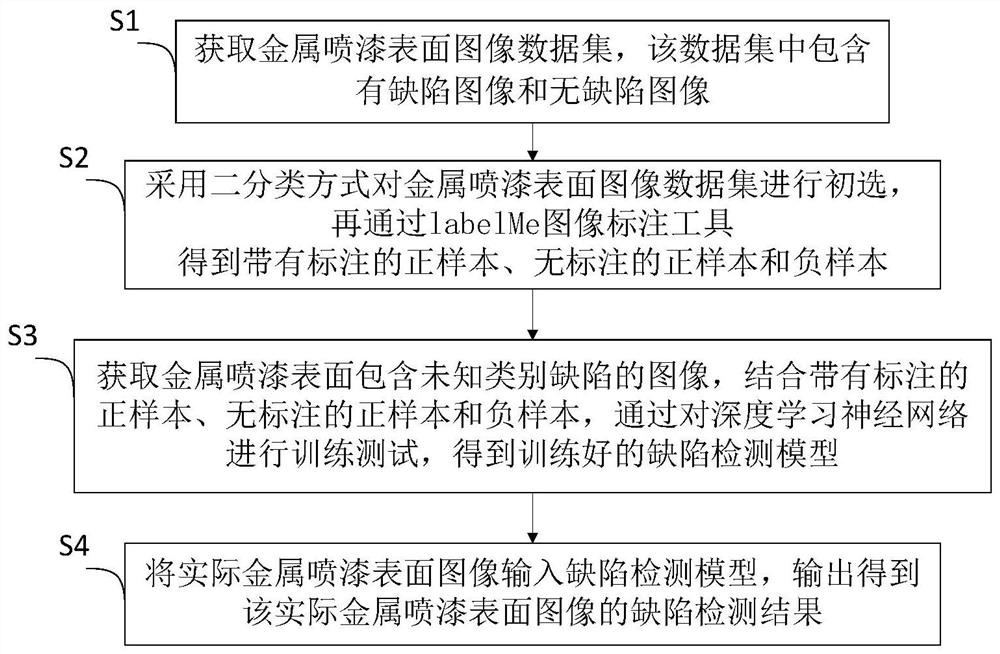

[0043] Such as figure 1 Shown, a kind of metal spray paint surface defect detection method, comprises the following steps:

[0044] S1. Obtain a metal spray paint surface image data set, which contains defective images and non-defective images;

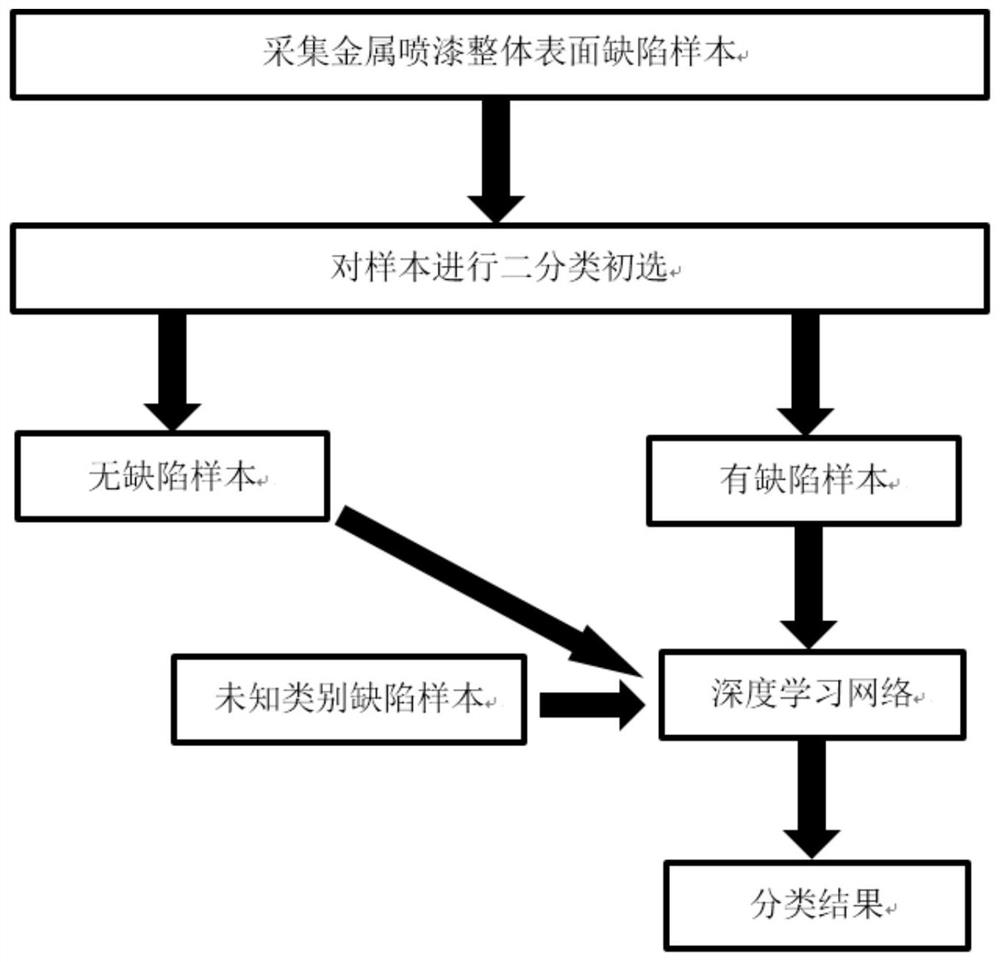

[0045] S2. Use the binary classification method to preliminarily select the metal spray paint surface image data set, and then use the LabelMe image labeling tool to obtain positive samples with labels, positive samples without labels, and negative samples. Among them, the positive samples are defective images, and the negative samples are The sample is a defect-free image;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com