Sealing ring surface defect detection method based on machine vision

A technology of defect detection and machine vision, applied in the direction of optical defect/defect, instrument, measuring device, etc., to achieve the effect of high accuracy and strong algorithm robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

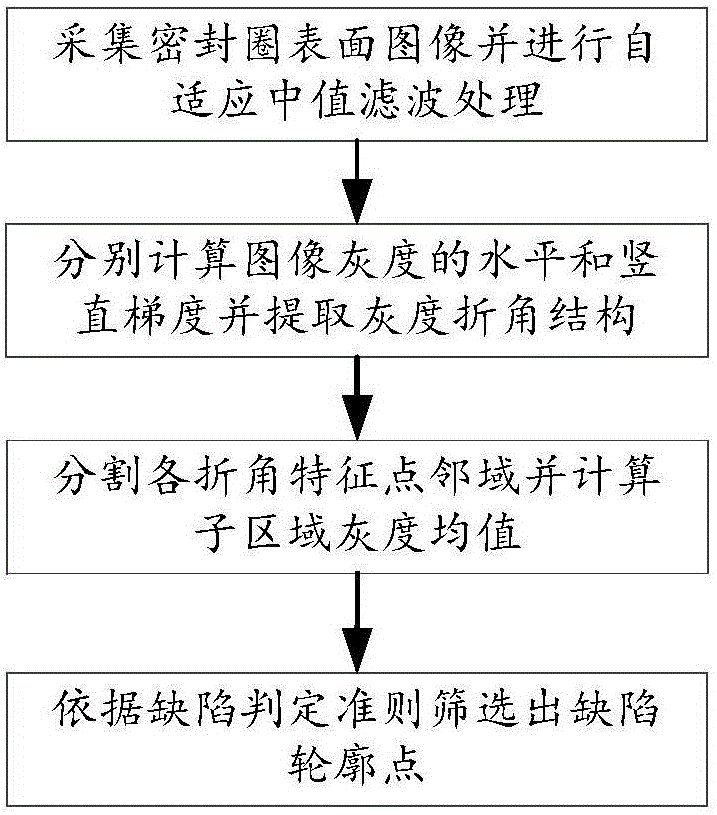

[0039] to combine Figure 1 to Figure 6 , a method for detecting surface defects of sealing rings based on machine vision, the method steps are as follows:

[0040] Step 1. Use the camera to collect the surface image of the sealing ring, and perform adaptive median filter processing on the collected image. The specific method is as follows:

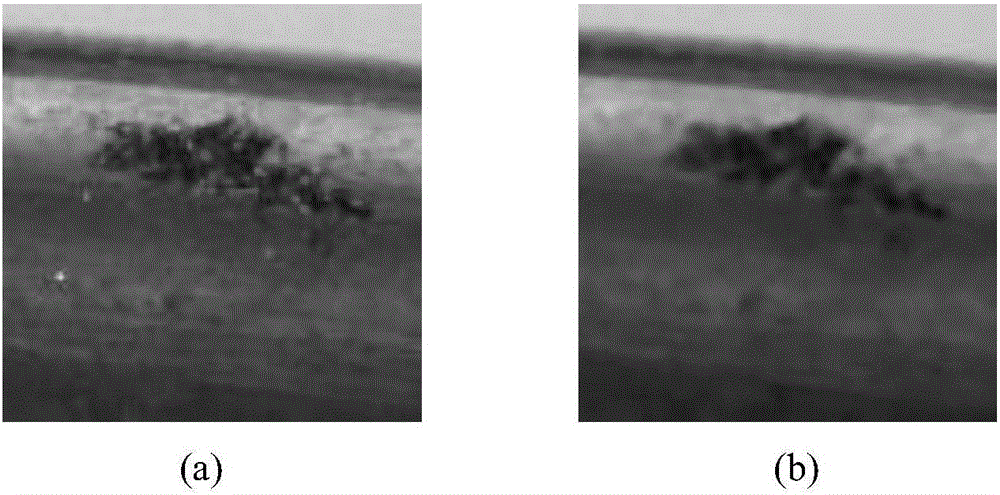

[0041] Place the sealing ring on a transparent glass platform, place a parallel light source above the sealing ring, and the camera is facing the sealing ring to collect the arc segment, turn on the parallel light source, the camera collects the surface image of the sealing ring, and performs adaptive median value on the collected image filter processing. In order to clearly observe the effect of filter processing, select a local area on the surface of the sealing ring such as figure 2 (a), the processing result of adaptive median filtering is as follows figure 2 (b) shown.

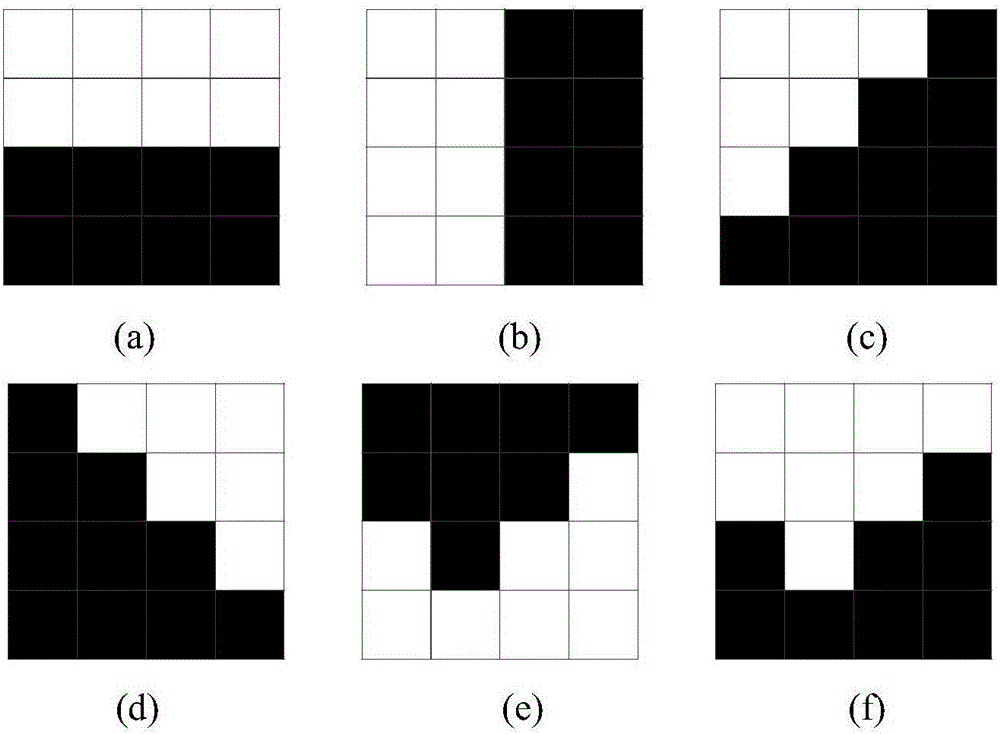

[0042] Step 2, use the Sobel template W for the image pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com