Part defect detection method and device, medium and computer program product

A defect detection and parts technology, applied in the field of image processing, can solve problems such as low detection accuracy, and achieve the effect of improving the overall vision, improving the accuracy of defect detection, and improving reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present application, not to limit the present application.

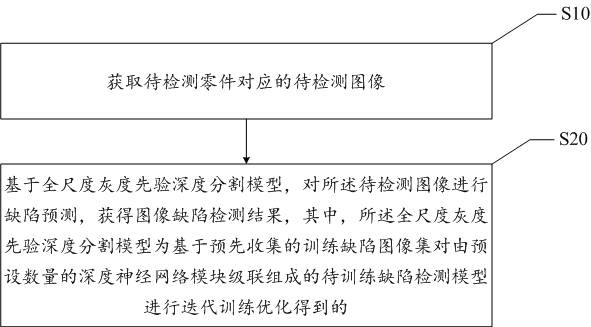

[0023] The embodiment of the present application provides a part defect detection method. In the first embodiment of the part defect detection method of the present application, refer to figure 1 , the part defect detection method includes:

[0024] Step S10, acquiring the image to be inspected corresponding to the part to be inspected;

[0025] In this embodiment, it should be noted that the image to be inspected is an X-ray image of the part to be inspected, wherein the X-ray image of the part to be inspected includes an X-ray image of an automobile steering knuckle and an X-ray image of an industrial casting Image and other images, the X-ray image of the automobile steering knuckle is a single-channel grayscale image, and the X-ray image of the automobile steering knuckle has relatively few types of defects, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com