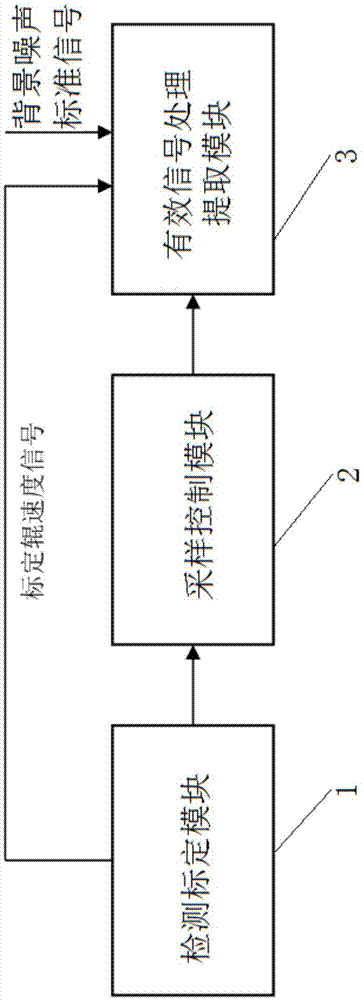

Background noise removal device and method for magnetic flux leakage detection and calibration

A background noise and magnetic flux leakage detection technology, applied in the direction of material magnetic variables, etc., can solve problems such as large background noise, and achieve the effect of improving the signal-to-noise ratio and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

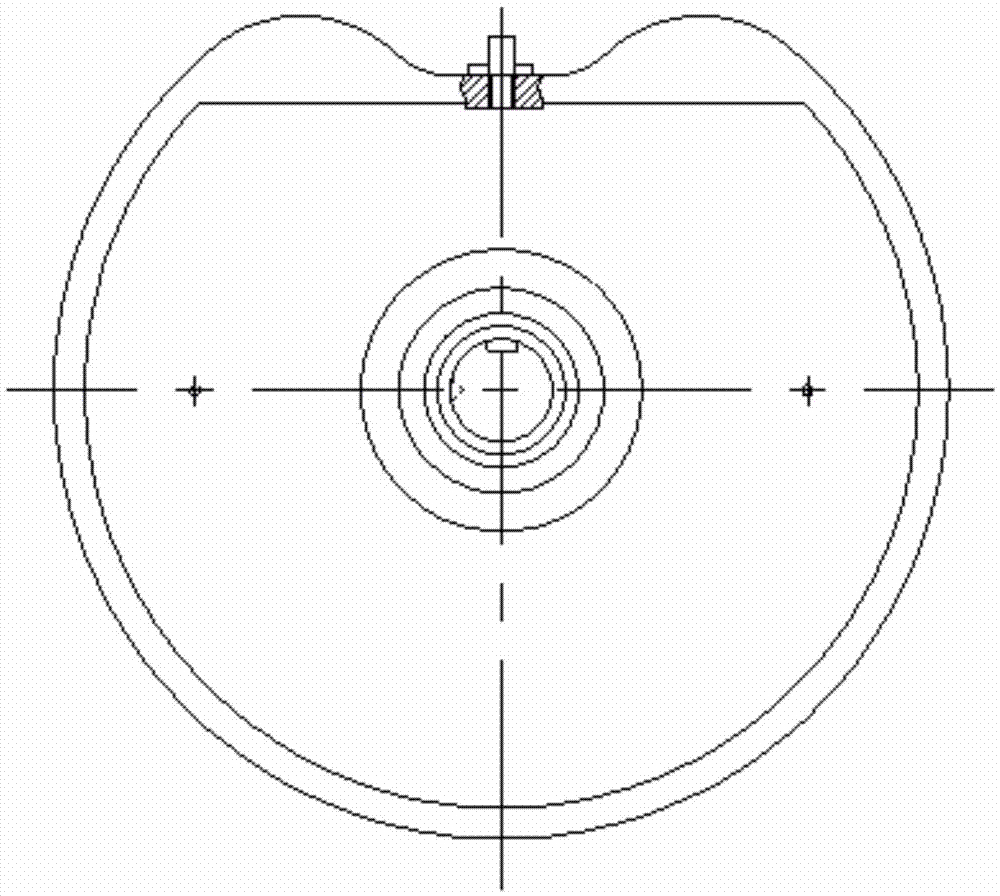

[0034] Such as Figure 6 As shown, the detection and calibration module 1 includes a detection probe 11 , a magnetization device 12 and a calibration roller 13 . A calibration roller 13 and a magnetizing device 12 are arranged successively along the advancing direction of the strip, and a detection probe 11 is arranged on the magnetization device 12, and the detection probe 11 converts the magnetic field signal into a voltage signal. As an embodiment of the present invention, the detection probe 11 may be a magnetic sensor.

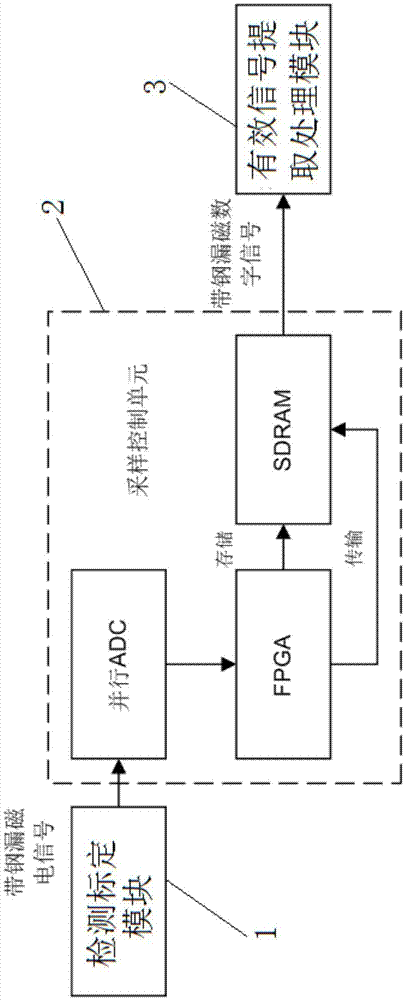

[0035] Such as image 3As shown, the sampling control module 2 includes a processing unit, an AD sampling circuit and a storage unit. The AD sampling circuit converts the voltage signal into a digital signal, and the processing unit temporarily stores the digital signal obtained by the AD sampling in the storage unit, and sends the signal in the storage unit.

[0036] As an embodiment of the present invention, the processing unit is an FPGA board, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com