Orientation identification method of ultrasonic array crack defects based on vector full-focusing imaging

A direction recognition, ultrasonic array technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids and process the response signals of detection, which can solve problems such as inability to recognize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

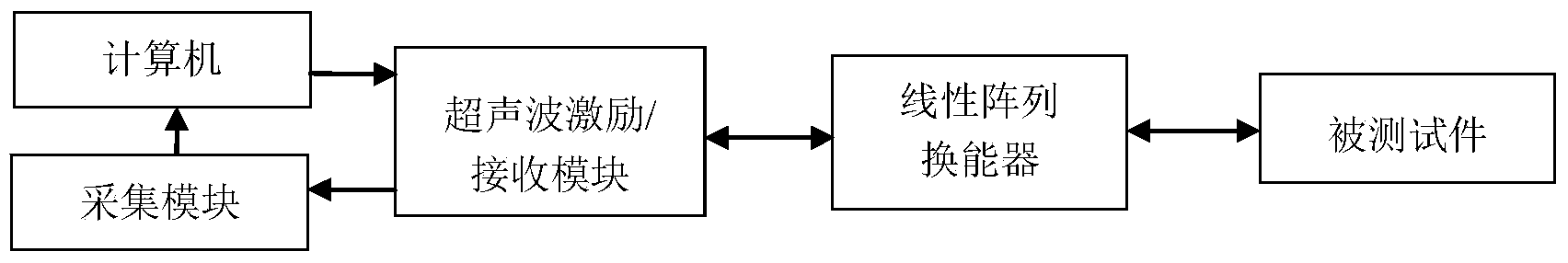

[0051] The detection instrument in this example is Multi2000 series phased array equipment, which includes ultrasonic excitation / reception module, acquisition module and phased array linear array transducer. The center frequency of the linear array transducer used in the experiment is f=5MHz, the total number of array elements is N=32, the width of a single array element is a=0.5mm, and the distance between the centers of two adjacent array elements is p=0.6mm. The propagating wave velocity in the component is c=5900m / s, then the wavelength The detection object is a round steel forging with a diameter of 300mm and a thickness of 40mm.

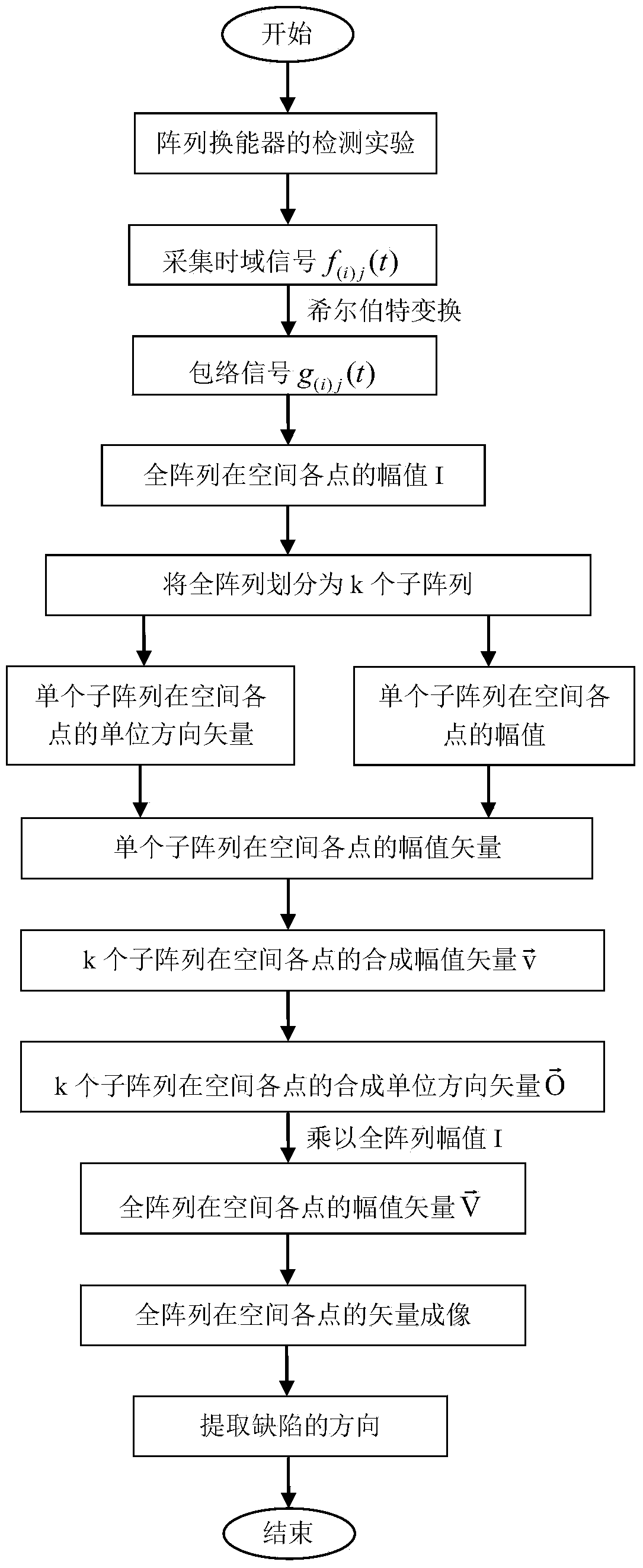

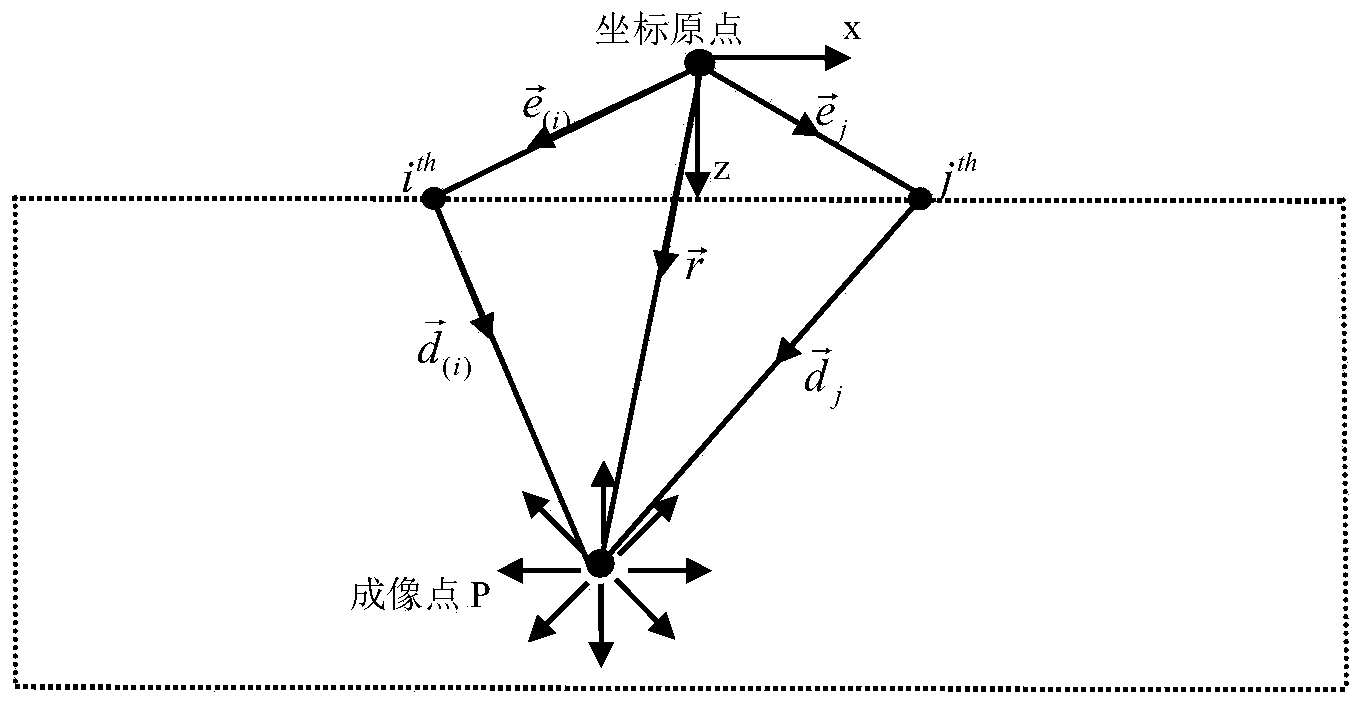

[0052] The specific steps of an ultrasonic array crack defect direction identification method based on vector total focus imaging proposed by the present invention are as follows:

[0053] Step 1: In such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com