Ultrasonic testing method used for composite material foaming structures

A foam structure and composite material technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of difficulty in detecting defects at the interface of foam bonding, low detection efficiency, and difficulty in determining defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

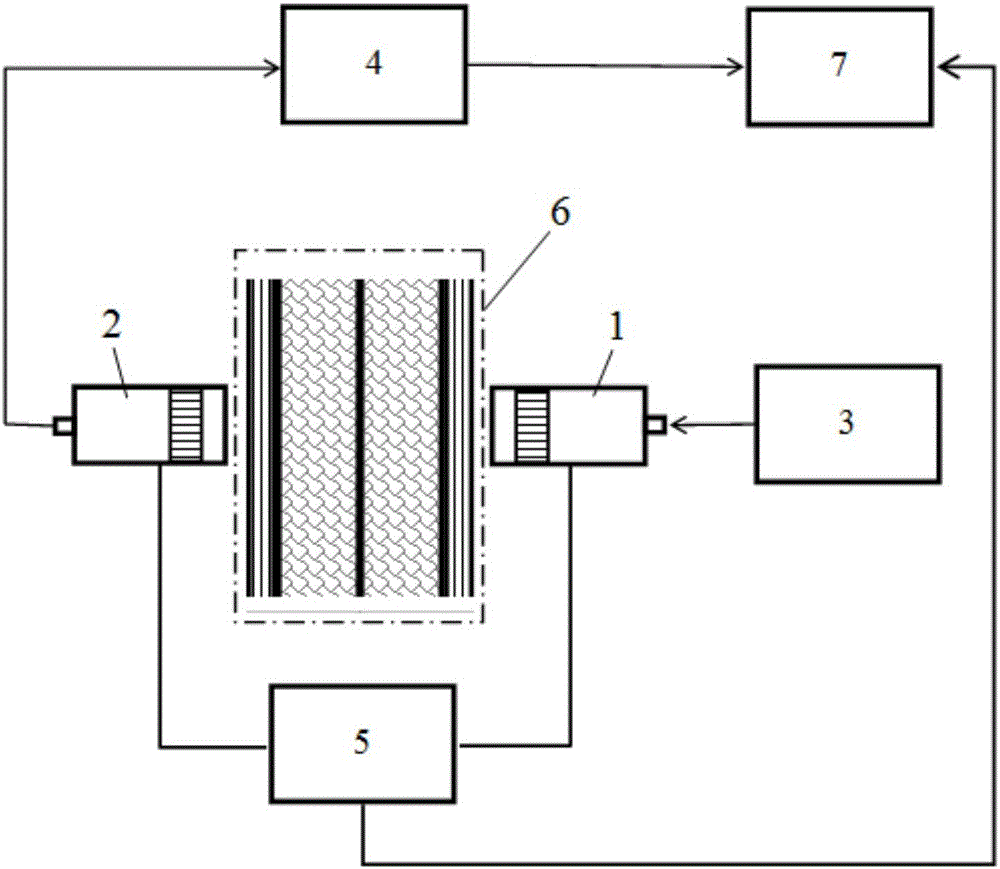

[0142] Choose the UPowr-1, UPower-2 and MUT-1 ultrasonic testing equipment produced by AVIC Composite Materials Co., Ltd. and the FJ-1 high-resolution ultrasonic transducer and high-energy transducer, respectively adopt water film coupling and high viscosity coupling The agent has carried out a series of practical testing applications on the overall foam structure of various composite materials. Among them, the size of the composite foam structure ranges from 100×500mm to 500×5000mm, and the thickness of the foam ranges from 20mm to 100mm.

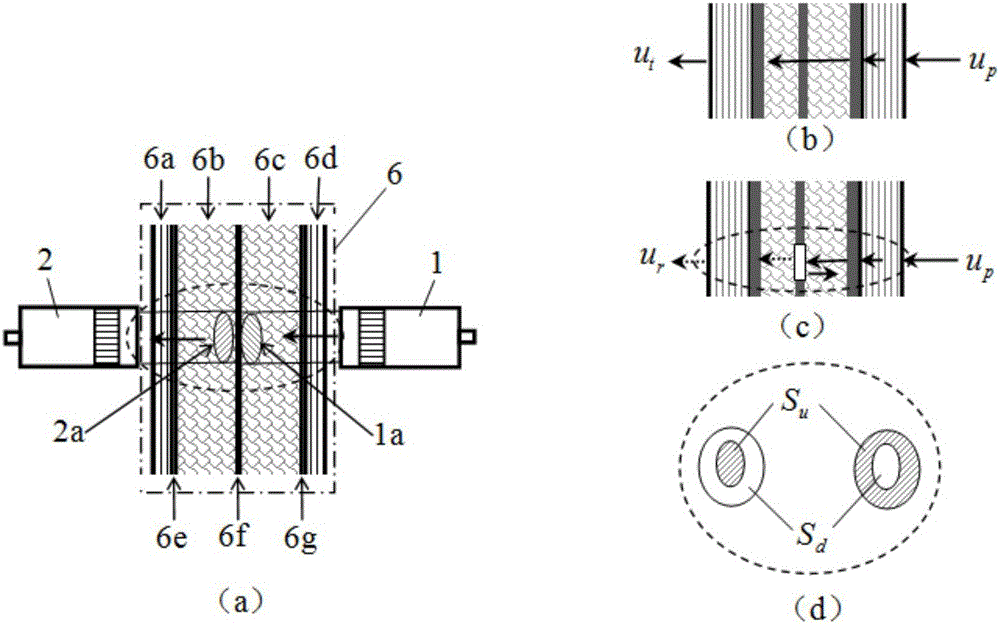

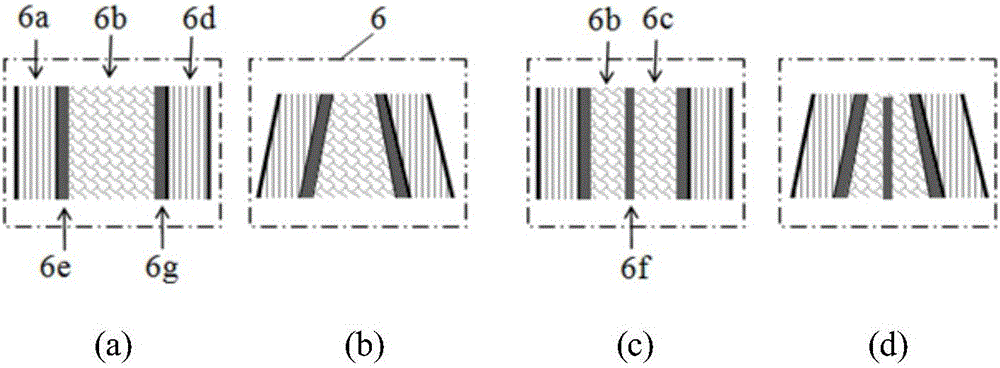

[0143] Detection of Integral Foam Structure of Composite Materials

[0144] Place the overall foam structure of the composite material to be tested on the workbench, select the frequency of the transducer to be 1 MHz, and use MUT-1 ultrasonic testing equipment for detection, by moving the transmitting transducer 1 located on both sides of the overall foam structure of the composite material to be tested and receiving transducer 2, and ensu...

Embodiment 2

[0149] Choose the UPowr-1, UPower-2 and MUT-1 ultrasonic testing equipment produced by AVIC Composite Materials Co., Ltd. and the FJ-1 high-resolution ultrasonic transducer and high-energy transducer, respectively adopt water film coupling and high viscosity coupling The agent has carried out a series of practical testing applications on a variety of composite multilayer foam structures. Among them, the size of the composite multilayer foam structure ranges from 200×500mm to 500×5000mm, and the foam consists of two layers of foam glued together by adhesives. Made, the thickness of the foam ranges from 10mm-80mm,

[0150] Inspection of Multilayer Foam Structure of Composite Materials

[0151]Place the multi-layer foam structure of the composite material to be tested on the workbench, select the frequency of the transducer to be 0.5MHz, and use the MUT-1 ultrasonic testing equipment for detection. Transducer 1 and receiving transducer 2, and ensure that the transmitting transdu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com