Metal workpiece surface defect image detection method

A metal workpiece, image detection technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of low detection efficiency, difficult to judge the quality of mass-produced and processed products, and detect the subjective influence of workers, so as to optimize production. The effect of quality, improving production efficiency and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with the accompanying drawings.

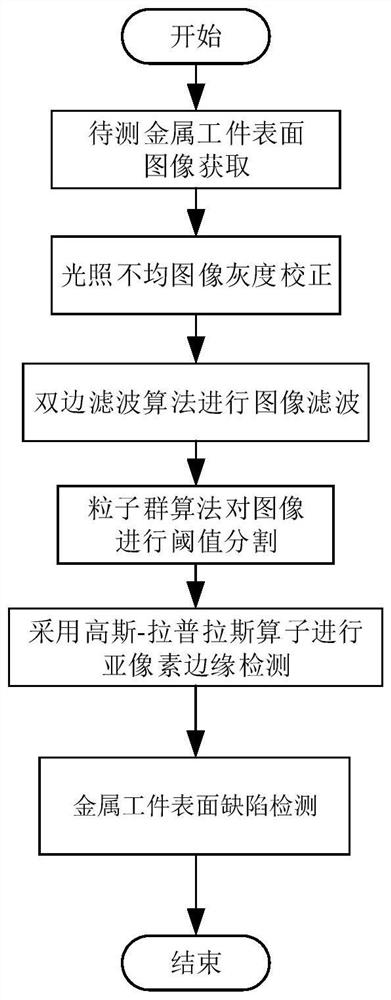

[0038] A flow chart of a metal workpiece surface defect image detection method is as follows figure 1 shown, including the following steps:

[0039] Step 1: Collect the surface image of the metal workpiece to be detected through professional imaging equipment;

[0040] Step 2: Perform pre-processing operations on the collected metal workpiece images; specific pre-processing operations on the collected metal workpiece images include the following steps:

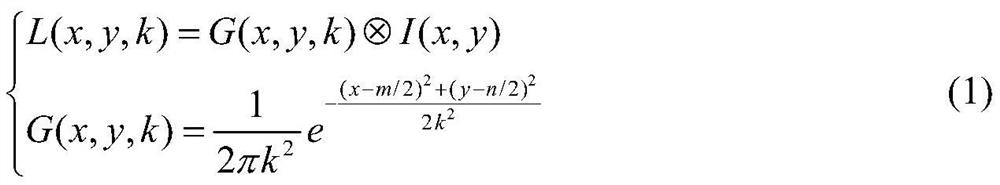

[0041] Step 2.1: Image grayscale correction for uneven illumination: first transform the image from the RGB channel to the HSV color space, and use formula (1) to estimate the illumination component L(x, y, k) in the image through the method based on the multi-scale Gaussian function :

[0042]

[0043] In the formula Represents convolution operation; (x, y) represents the pixel coordinates in the image; I(x, y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com