Synthetic method for high-purity iron phosphate and doped metallic element thereof

A technology of high-purity iron phosphate and metal elements, which is applied in the direction of electrical components, active material electrodes, battery electrodes, etc., can solve the problems of hindering lithium extraction/intercalation, lithium content reduction, environmental pollution, etc., and reduce the cost of reaction equipment and control Requirements, reduce waste water discharge, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) With ferrous oxalate (purity 99%) as iron source, phosphoric acid (purity 85%) as phosphorus source, according to molar ratio: n(Fe):n(P)=1:1.01 ratio, weigh oxalate Iron 87.80g, phosphoric acid 69.86g, polyethylene glycol is 0.02wt% of iron source;

[0029] (2) Dissolve phosphoric acid in 2L of distilled water, transfer it into a 3L reaction kettle, add polyethylene glycol, stir at 60rpm for 5min, and heat to 60°C in a water bath;

[0030] (3) Slowly add ferrous oxalate, and adjust the stirring speed to 300rpm;

[0031] (4) react for 3h until the precipitate turns white;

[0032] (5) Aging for 1 hour after the completion of the reaction, washing with distilled water until the pH value = 6.5, filtering and drying the precipitate at 120°C for 4 hours to obtain white ferric phosphate hydrate (FePO 4 2H 2 O).

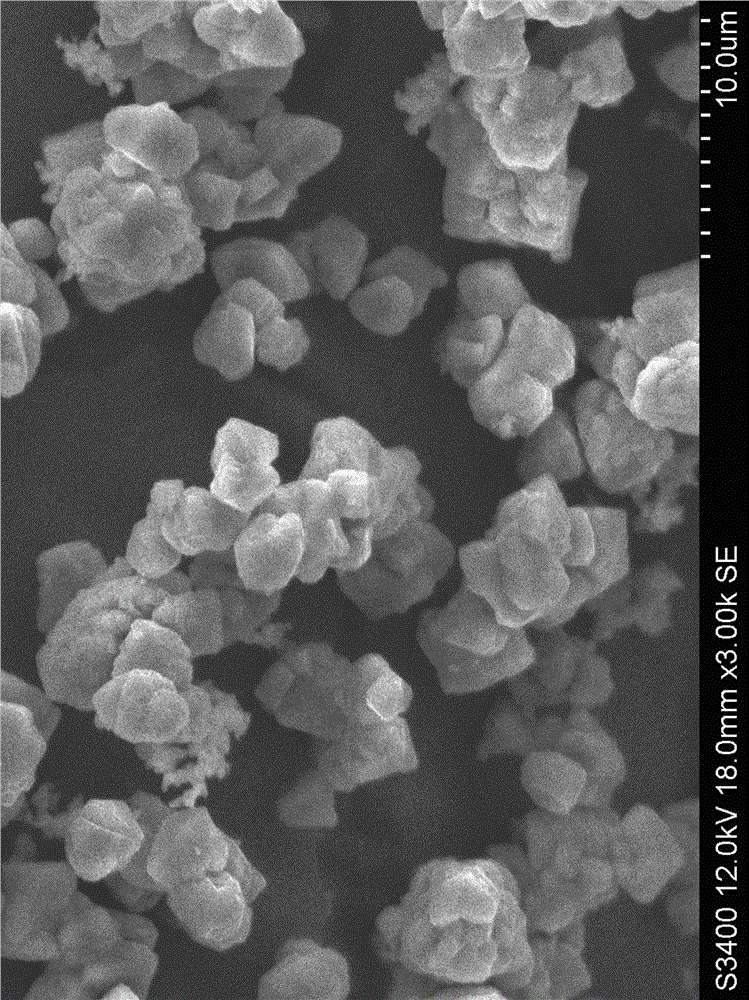

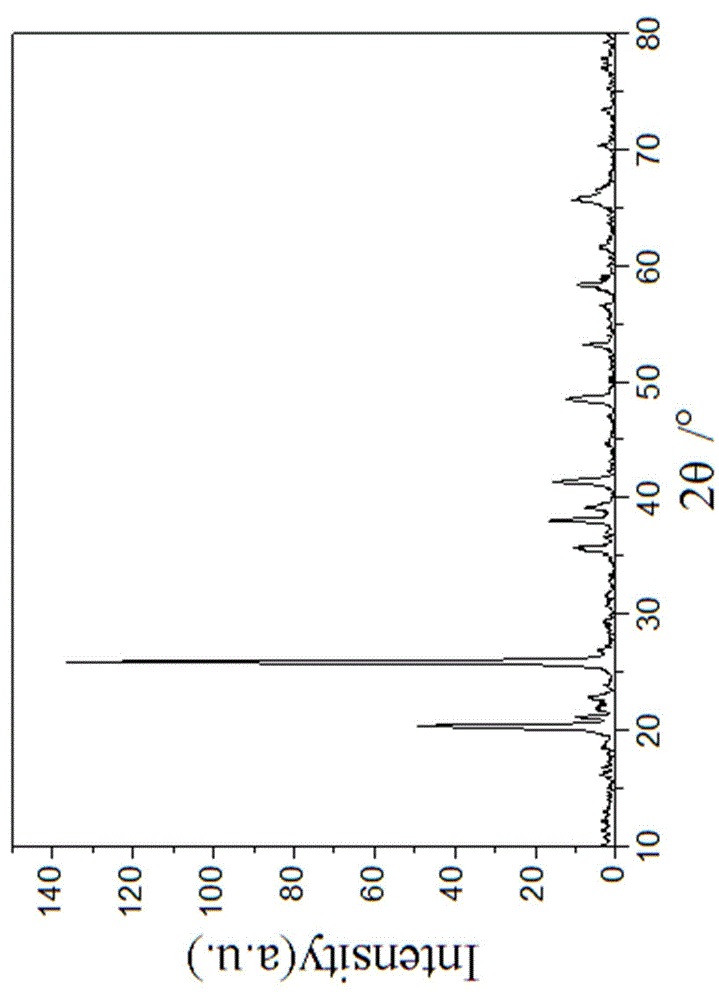

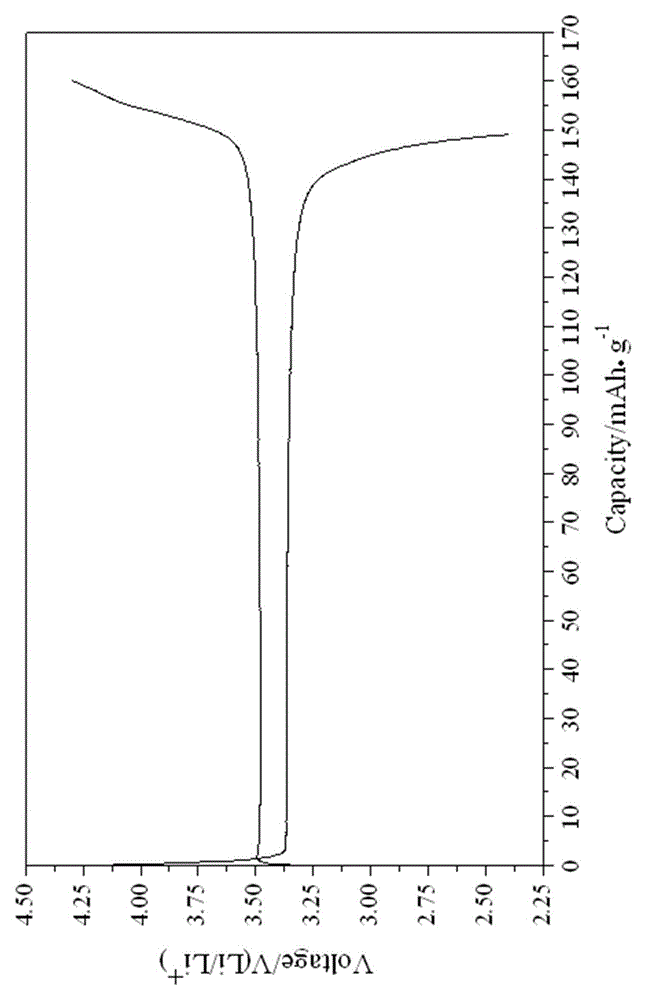

[0033] The particle size of the obtained water and iron phosphate is 2~5μm (such as figure 1 shown), with a purity of 99.5%; the synthesized FePO 4 2H 2 ...

Embodiment 2

[0035] (1) With ferric oxide (purity 99%) as iron source, phosphoric acid (purity 85%) as phosphorus source, according to molar ratio: n(Fe):n(P)=1:1.02 ratio, weigh three Ferric oxide 48.73g, phosphoric acid 70.55g, polyvinylpyrrolidone is 0.05wt% of iron source;

[0036] (2) Dissolve phosphoric acid in 2L of distilled water, transfer it into a 3L reaction kettle, add polyvinylpyrrolidone, stir at 60rpm for 5min, and heat to 80°C in a water bath;

[0037] (3) Slowly add ferrous oxalate, and adjust the stirring speed to 1000rpm;

[0038] (4) After 2 hours of reaction, when the solution is gray-green, add 20ml H 2 o 2 , the precipitate turned yellow-white, and continued to stir for 2 hours;

[0039] (5) Aging for 2 hours after the completion of the reaction, then washing with distilled water until the pH value = 6.5, filtering and drying the precipitate at 110°C for 5 hours to obtain yellow-white ferric phosphate hydrate (FePO 4 2H 2 (2), the purity is 99.5%;

[0040] Usi...

Embodiment 3

[0042] (1) Using ferrous oxalate (purity 99%) as iron source, phosphoric acid (purity 85%) as phosphorus source, prepared by doping manganese dioxide Molar ratio: n(Fe):n(P):n(Mn )=0.97:1.01:0.03 ratio, take ferrous oxalate 85.16g, phosphoric acid 70.55g, manganese dioxide 1.60g, polyvinylpyrrolidone is 0.03wt% of iron source;

[0043] (2) Fully mix manganese dioxide and ferrous oxalate with a ball mill at a speed of 200 rpm for 1 hour;

[0044] (3) Dissolve phosphoric acid in 2.5L of distilled water and move it into a 4L reaction kettle, add polyvinylpyrrolidone, stir at 60rpm for 5min, heat in a water bath to 60°C; slowly add ferrous oxalate and dioxide A mixture of manganese, and adjust the stirring speed to 1500rpm;

[0045] (4) After reacting for 2 hours, add 20ml H 2 o 2 , the precipitate turned yellow-white, and the stirring was continued for 6 hours;

[0046] (5) Aging for 6 hours after the completion of the reaction, then washing with distilled water to pH = 7.0, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com