Textured mono-crystalline silicon solar battery, preparation method and preparation system thereof

A technology for solar cells and monocrystalline silicon, applied in the field of solar cells, can solve the problems of liquid level control, excessive etching, high requirements, etc., and achieve the effects of low cost, enhanced stability and high forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

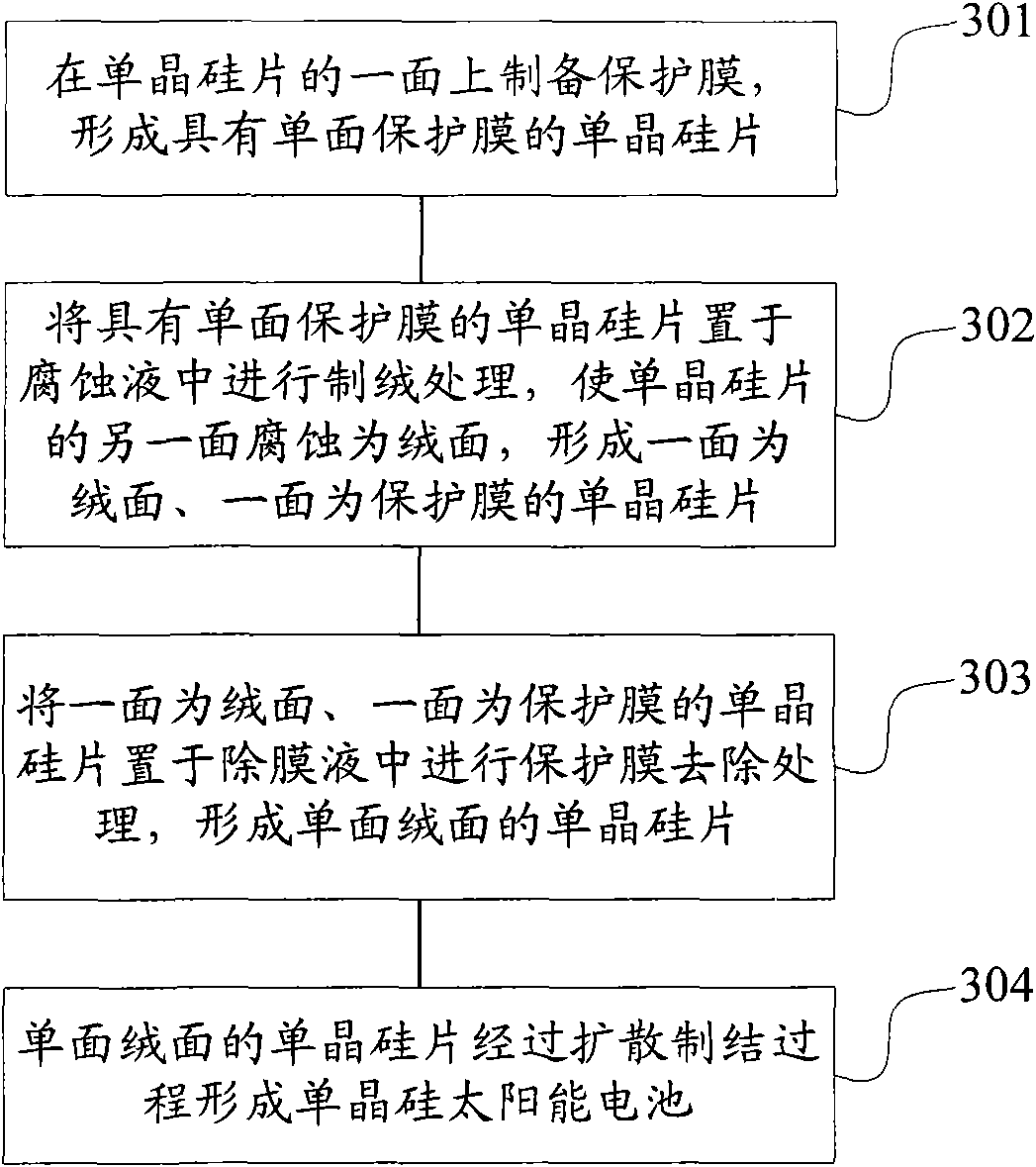

[0037] refer to image 3 , showing a flow chart of an embodiment of a method for preparing a textured monocrystalline silicon solar cell according to the present invention, which specifically includes the following steps:

[0038] Step 301, preparing a protective film on one side of the monocrystalline silicon wafer to form a monocrystalline silicon wafer with a single-sided protective film;

[0039] In order to obtain single-sided textured monocrystalline silicon solar cells, it is first necessary to prepare a protective film on one side of the monocrystalline silicon wafer to protect the monocrystalline silicon wafer from corrosion by the corrosive liquid in the texturing process. The preparation method of the protective film i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com