System for preparing indium phosphide crystals by utilizing indium-phosphorus mixture

An indium phosphide and mixture technology, which is applied in the field of synthesizing indium phosphide by using indium-phosphorus mixed balls, can solve the problems of increasing the contamination of materials and increasing the cost of material preparation, so as to reduce the cost of materials, reduce the pollution of materials, and improve the purity of crystals. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

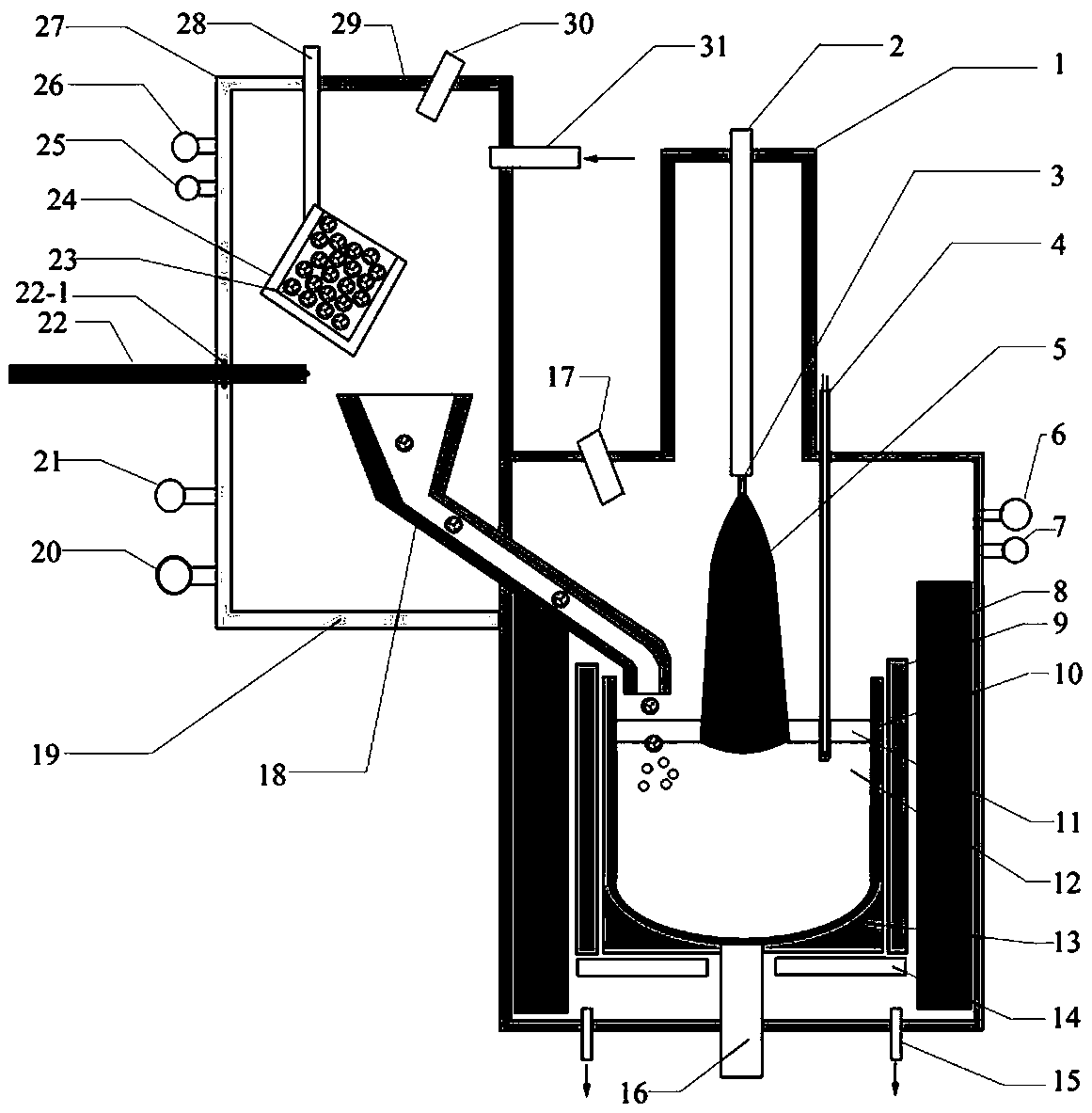

[0028] Embodiment 1, a system for preparing indium phosphide crystals using an indium-phosphorus mixture, including a vacuum system, a gas charging and deflation system, a temperature and pressure control system, an electrical control system, a cooling cycle system and a weighing system. These systems are commonly used basic systems in this field, especially single crystal furnaces for preparing indium phosphide crystals based on the in-situ synthesis method. These systems are basic configurations and will not be described here. In order to realize the preparation of indium phosphide crystals by using indium-phosphorus mixed balls, the present invention improves the furnace body.

[0029] see figure 1 , the furnace body is divided into synthetic growth chamber 1, feeding chamber 19 and charging chamber 27, charging chamber 27 and feeding chamber 19 are separated up and down by inserting plate 22, and a sealing ring I22-1 is set between inserting plate 22 and the furnace wall ...

Embodiment 2

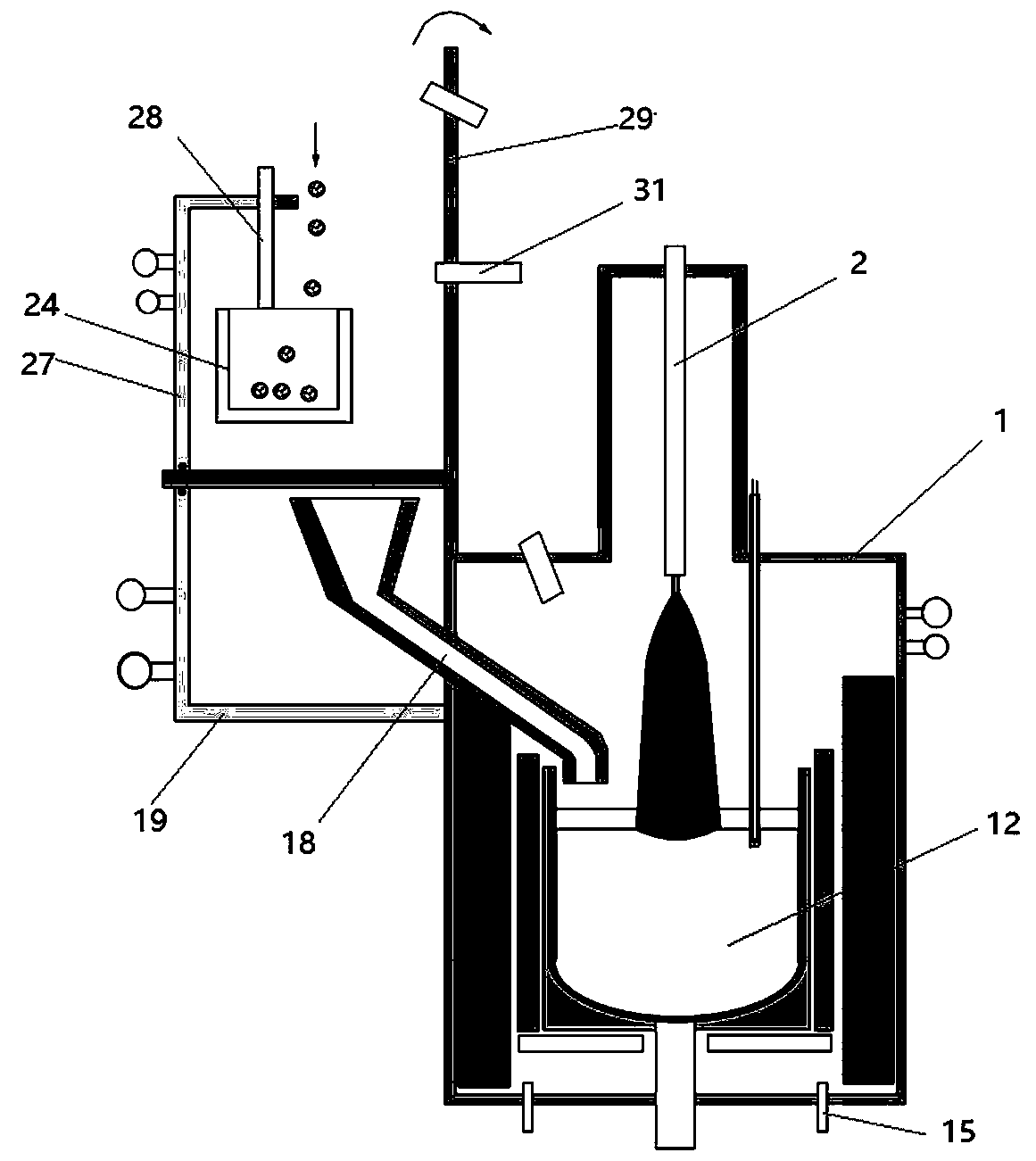

[0033] Embodiment two, see Figure 4 , the difference between this embodiment and Embodiment 1 is: in this embodiment, the feeding pipe 18 adopts a straight pipe, and the synthetic growth chamber 1 and the feeding chamber 19 are stacked in dislocation, so that the feeding pipe 18 passes into the crucible 10, and the first observation window 17 is located on the side wall of the synthetic growth chamber 1.

[0034] The steps of applying this system to prepare indium phosphide crystals are as follows:

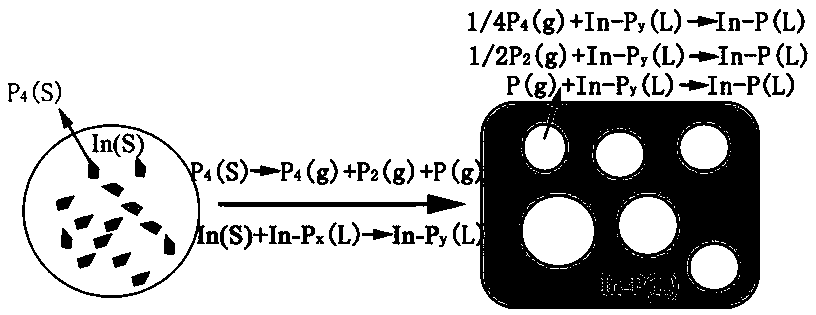

[0035] 1) Mix high-purity indium powder and high-purity phosphorus powder evenly at a mass ratio of 3.7: 1.0-1.5, and press them into spherical indium-phosphorus mixing balls 23 .

[0036] 2) Put the boron oxide powder mixed with indium phosphorus mixing balls 23 into the carrier 24 in the charging chamber 27 , and put the boron oxide block into the crucible 10 .

[0037] 3) Vacuum the entire system to 10-10 through the air inlet 31 -5 Pa, and inert gas below 156°C is charged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com