Automatic cutting equipment

A fully automatic, cutting technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of large cutting error, low efficiency, impossible to process and cut EVA, etc., to ensure smooth and accurate. , Improve work efficiency, real-time controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

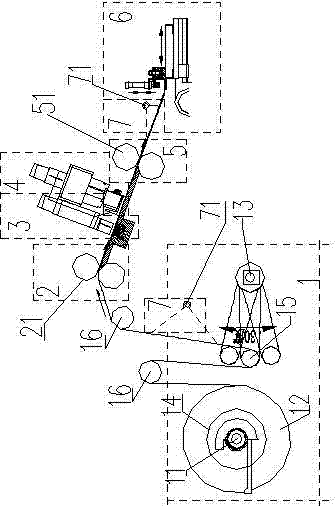

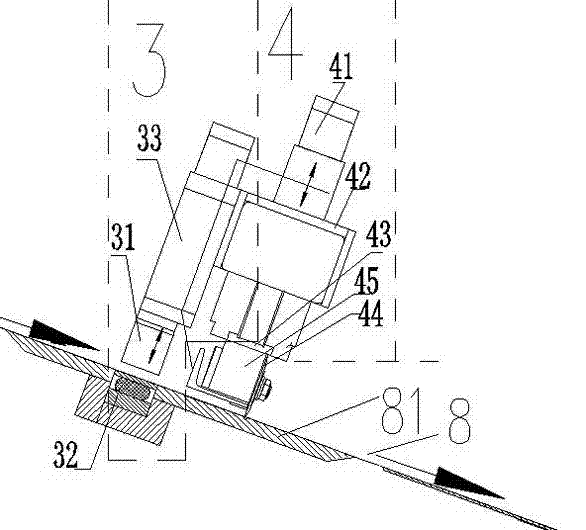

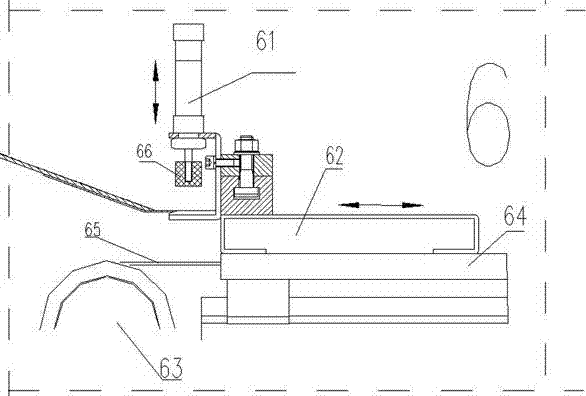

[0034] Such as figure 1 As shown, the equipment system of this embodiment includes a main control computer (not shown in the figure) in the cabinet and an automatic tension control discharge mechanism 1, a material delivery metering mechanism 2, an automatic punching mechanism 3, an automatic pressing Tight cutting mechanism 4, automatic feeding mechanism 5, automatic material stacking mechanism 6, described feeding metering mechanism, automatic punching mechanism, automatic pressing and cutting mechanism, automatic feeding mechanism are all installed on the transmission platform 8.

[0035] The automatic tension control discharge mechanism 1 includes (TPT or EVA) film reel 12, tension control rocker arm 15, two guide wheels 16, frequency conversion motor 14, air tension shaft 11, angular displacement sensor 13, film The reel is set on the air tension shaft, and the air tension shaft is connected with the output shaft of the frequency conversion speed regulation motor. The fre...

Embodiment 2

[0052] Embodiment 2 (optimized embodiment)

[0053] Such as Figure 4 As shown, the equipment system of this embodiment includes the main control computer (not shown in the figure) in the cabinet and the lifting device 9, the automatic tension control discharge mechanism 1, the feeding metering mechanism 2, the automatic cutting Mechanism 3, automatic compression and cutting mechanism 4, automatic material folding mechanism 6, the automatic cutting mechanism and automatic compression and cutting mechanism are installed on the cutting and cutting platform 8.

[0054] The automatic tension control discharge mechanism 1 is similar to embodiment 1, and also includes a film reel 12, a tension control rocker arm 15, two guide wheels 16, a frequency conversion speed regulating motor 14, an air tension shaft 11, and an angular displacement sensor 13, The film reel is set on the air tension shaft, and the air tension shaft is connected with the output shaft of the frequency conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com