Die-cutting machine capable of efficiently manufacturing base table paper and using method of die-cutting machine

A high-efficiency, die-cutting machine technology, applied in metal processing and other directions, can solve the problems of low efficiency, inconvenient adjustment, difficulty in adapting to different specifications of paper, etc., and achieve the effect of improving die-cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

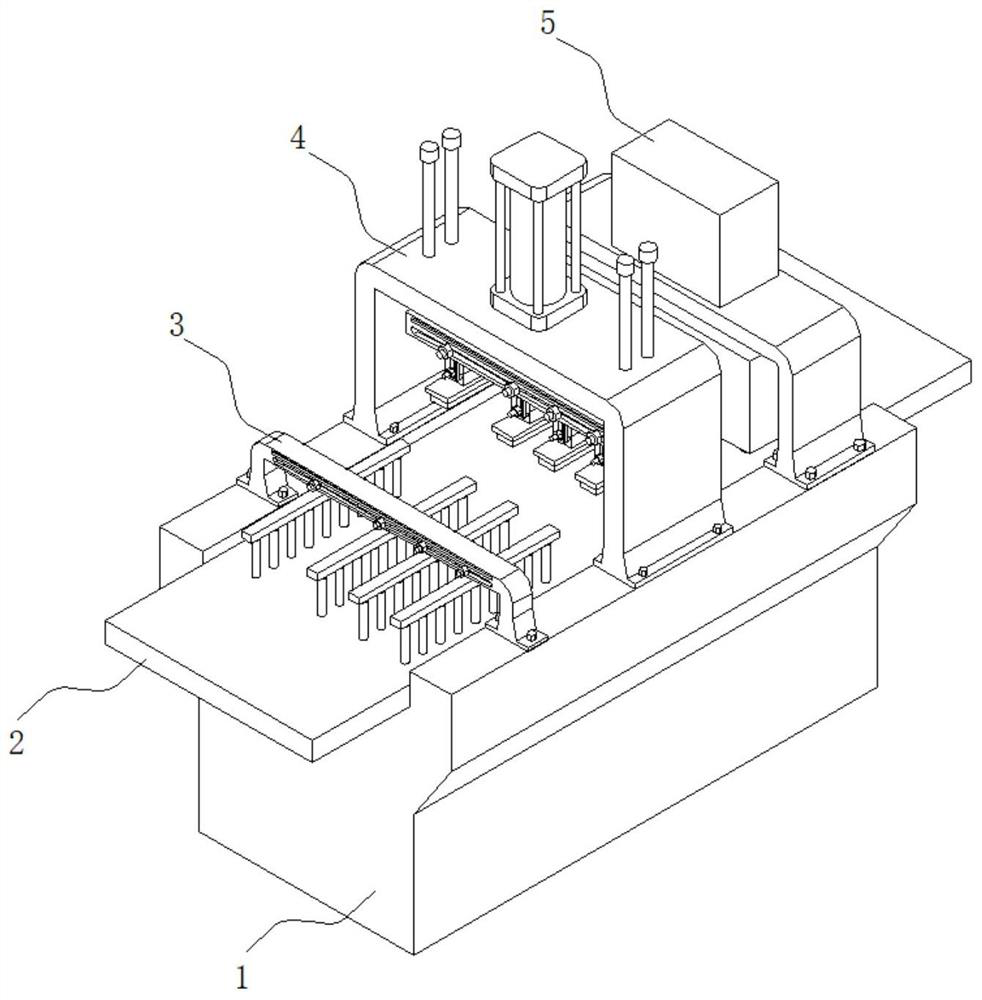

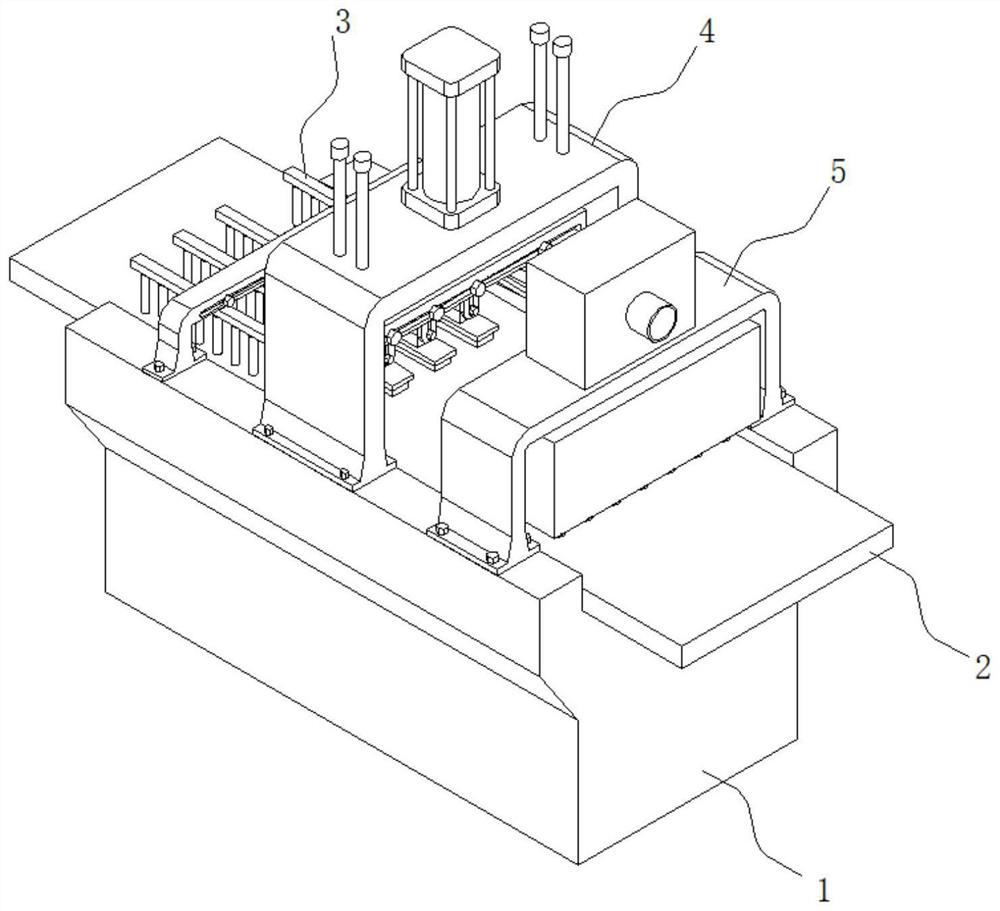

[0042] See Figure 1-2 As shown, the present invention is a die cutter that can make the base paper, including the frame 1, the positioning mechanism 3, the die cutting mechanism 4, and the exhausting mechanism 5, and the top groove of the rack 1 is provided. Table 2, the top of the frame 1 is provided with a positioning mechanism 3, a die cutting mechanism 4, and a waste mechanism 5 in the transfer direction of the frame.

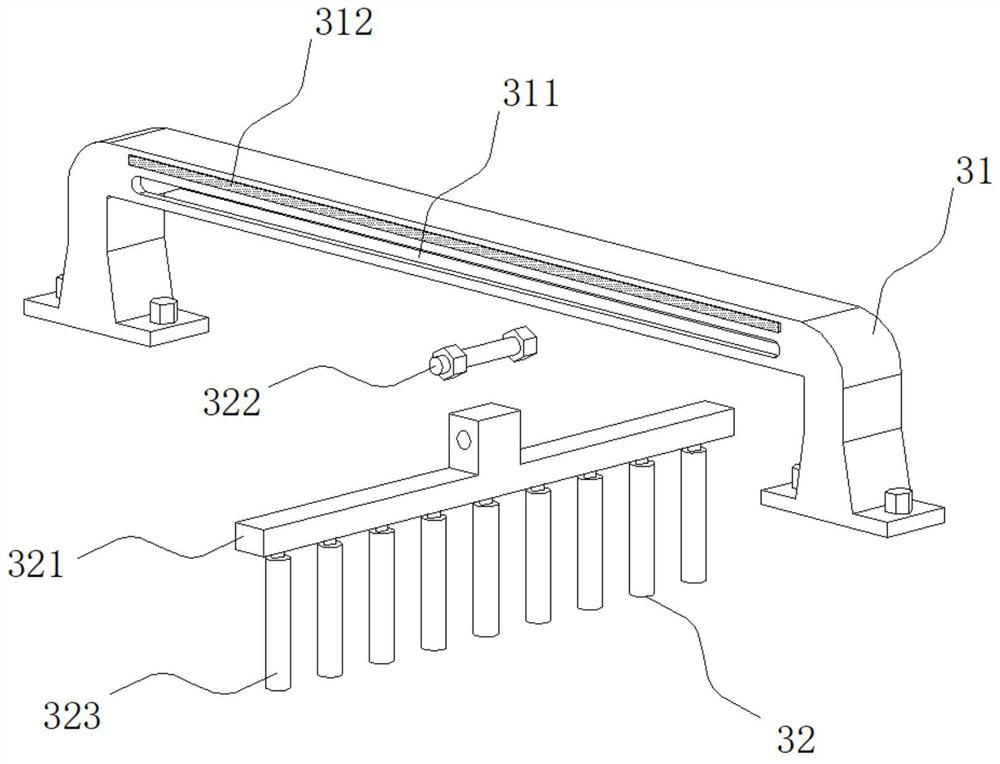

[0043] In which image 3 As shown, the positioning mechanism 3 includes positioning the gantry 31 and the positioning assembly 32, positioning the gantry 31 on the frame 1, and four positioning assemblies 32 are positioned on the beam of the gantry 31, and the positioning assembly 32 includes a T-rack 321. The first bolt 322 and the roller 323, the top of the T-rack 321 slides in conjunction with the beam bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com