Patents

Literature

42results about How to "Improve die-cutting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

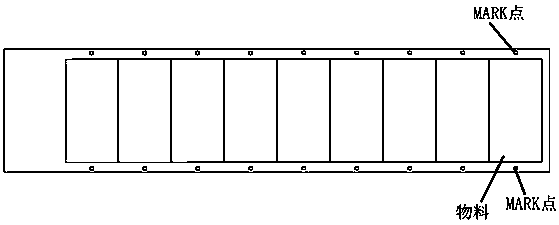

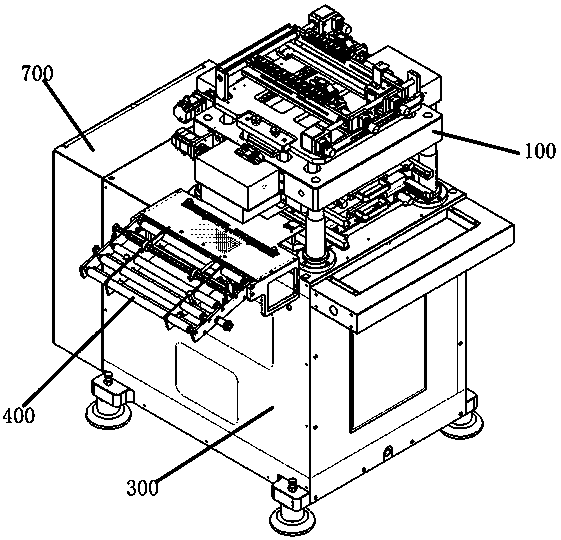

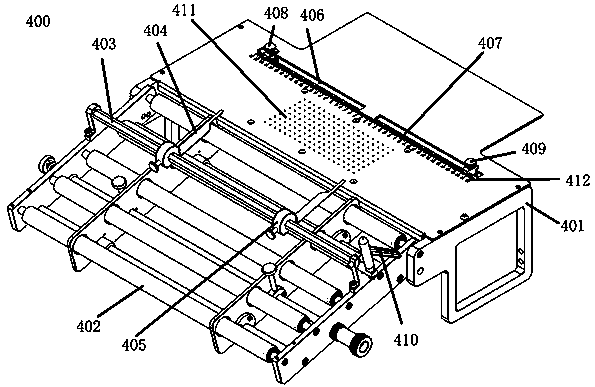

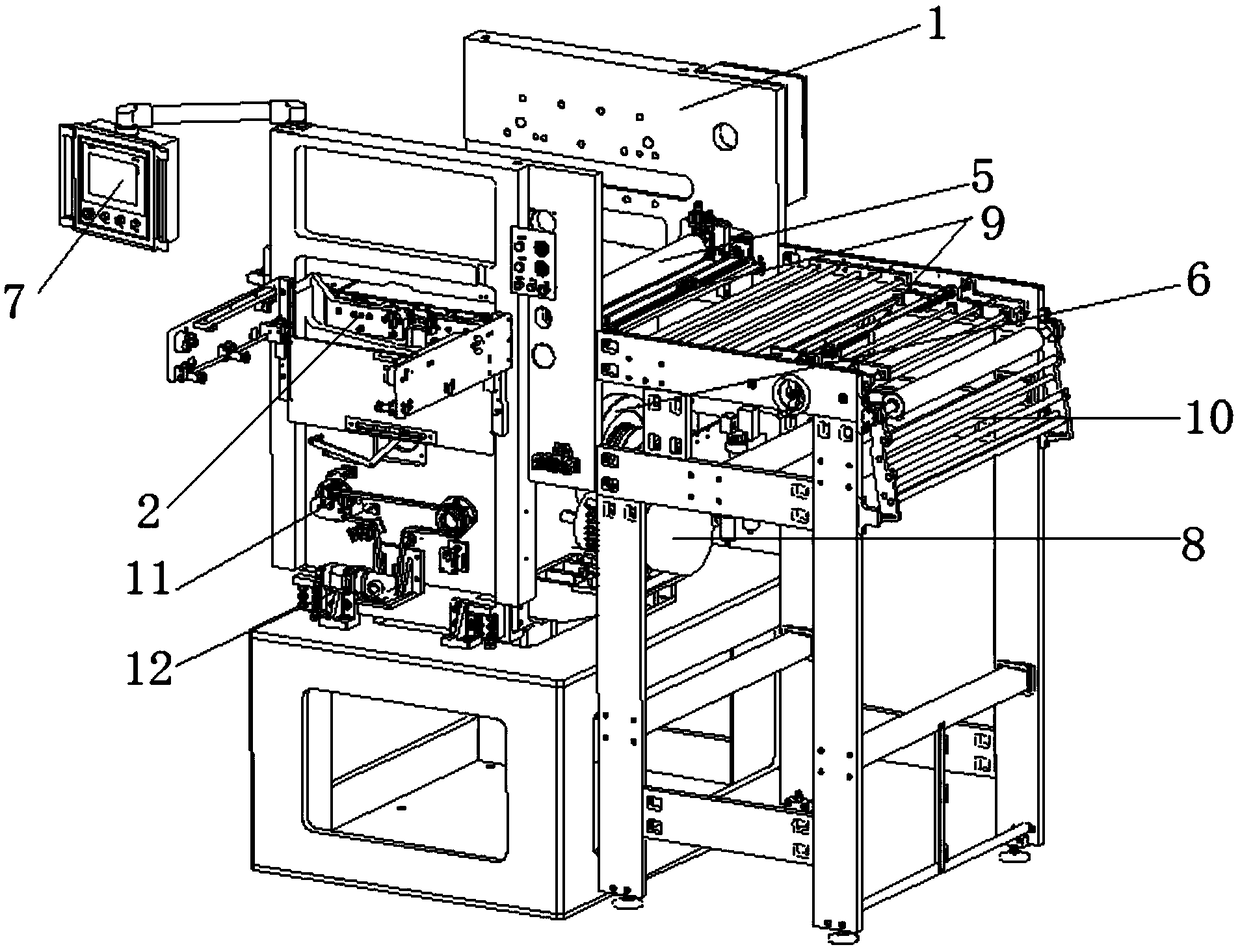

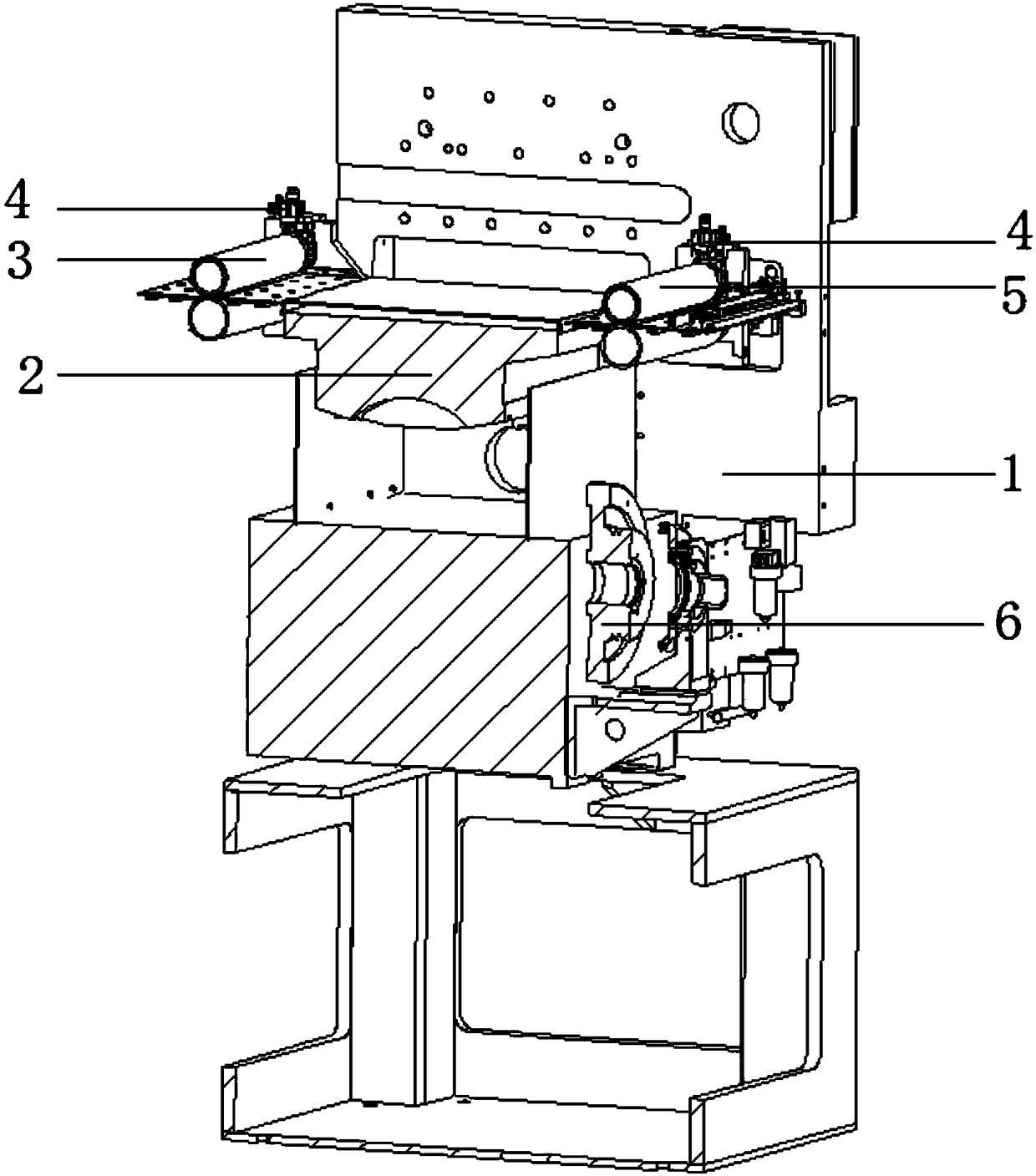

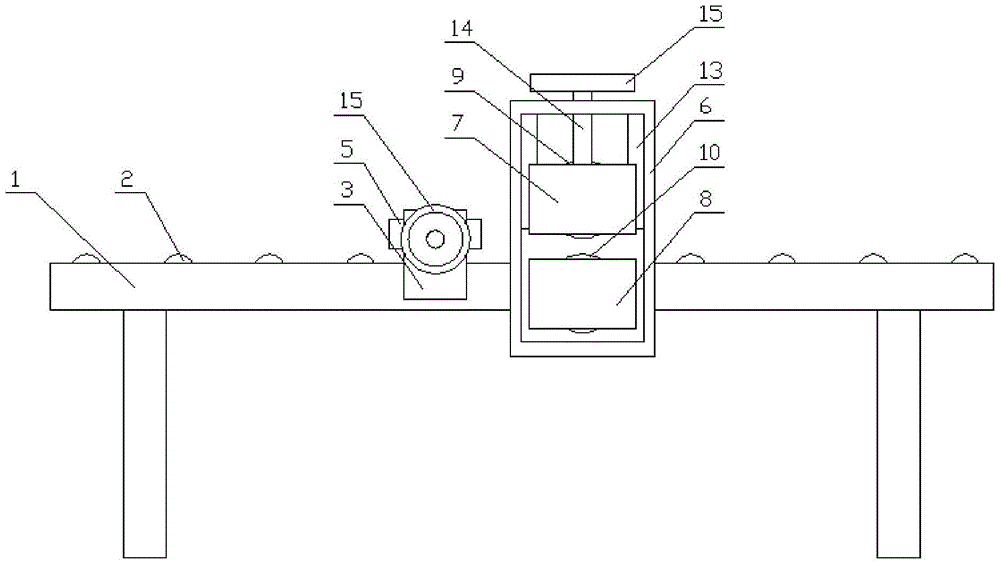

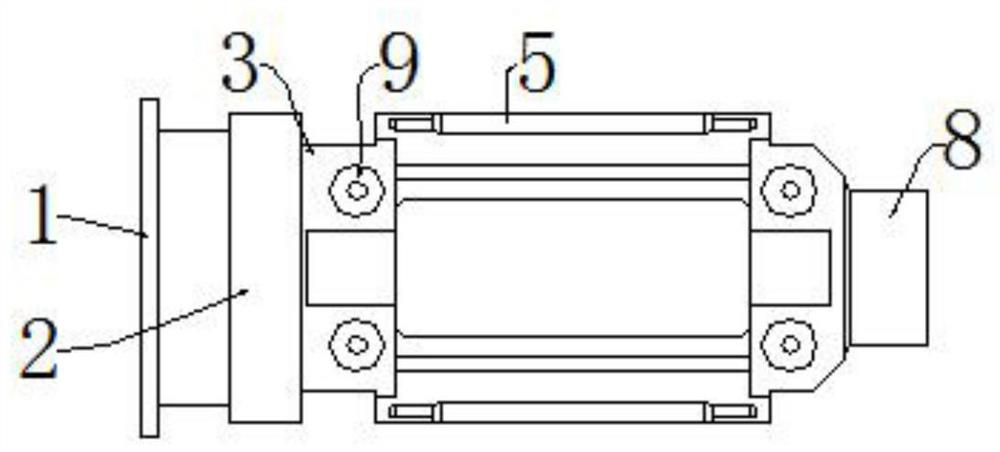

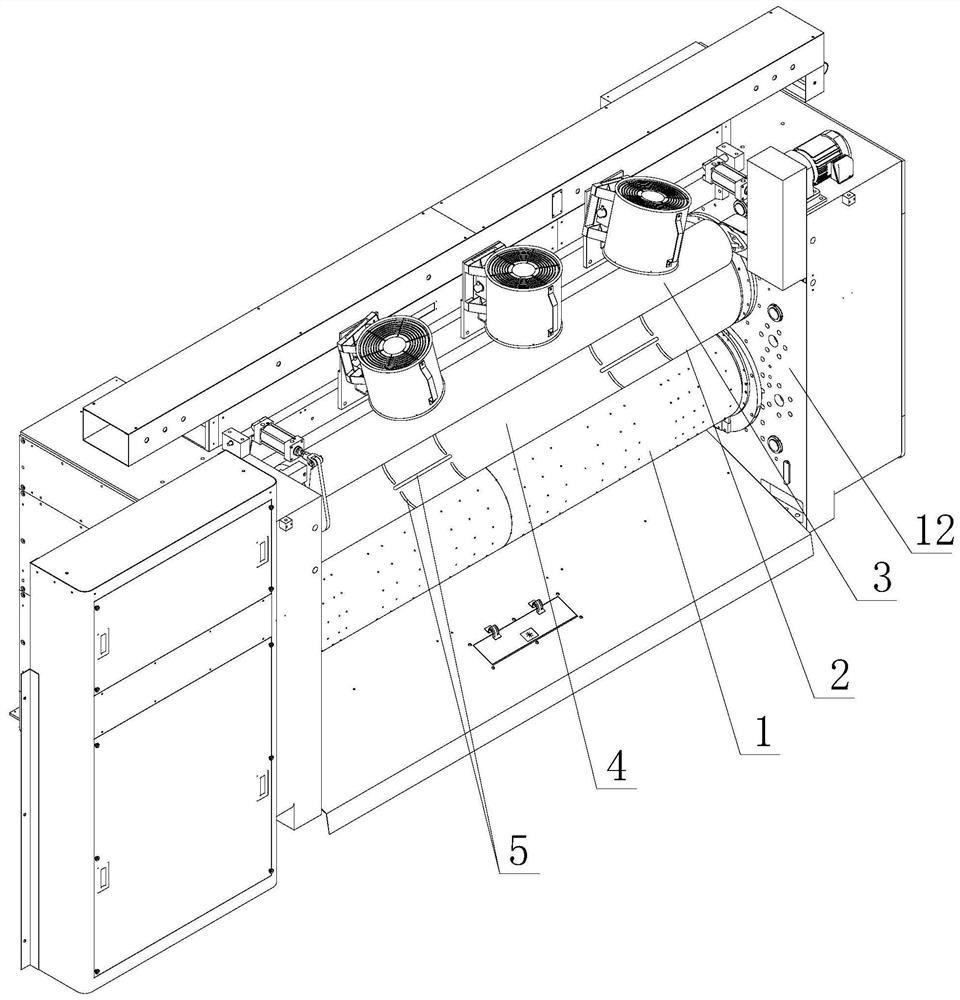

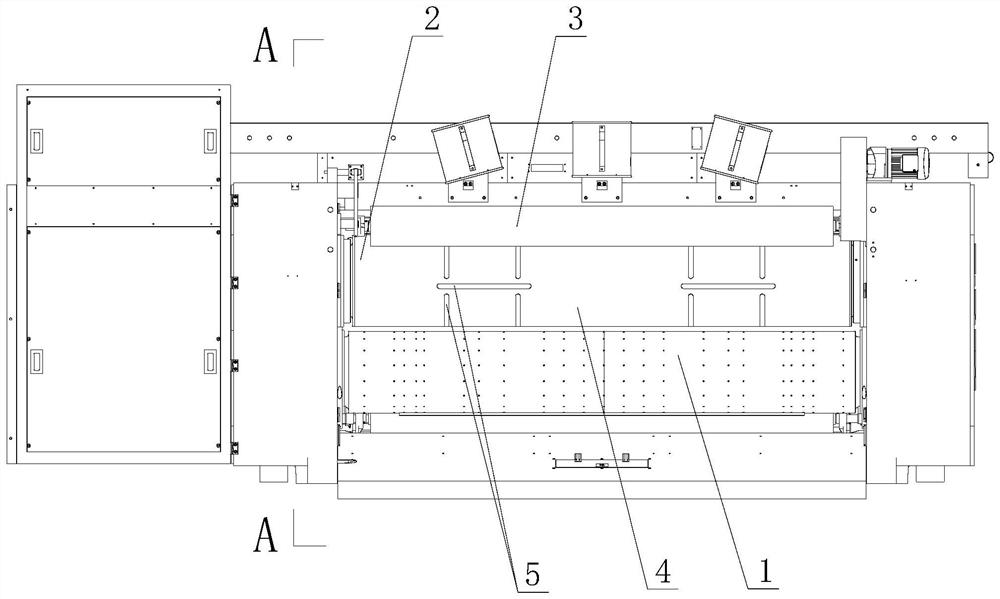

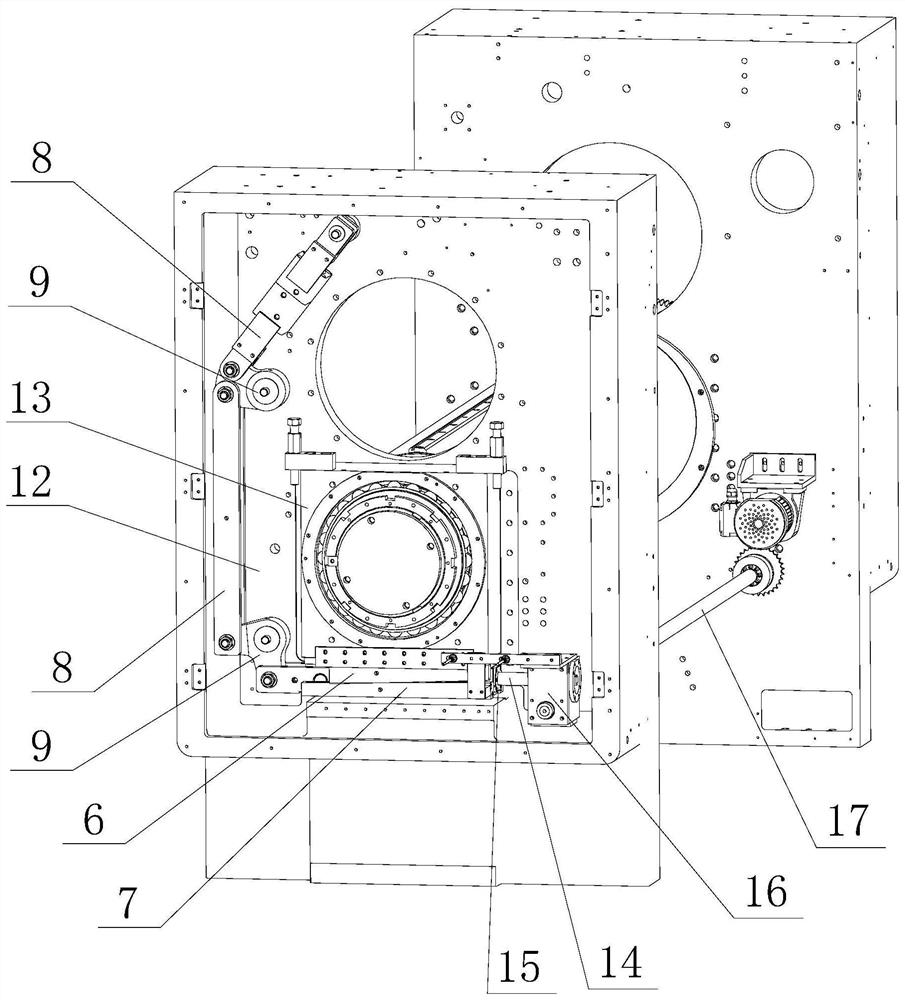

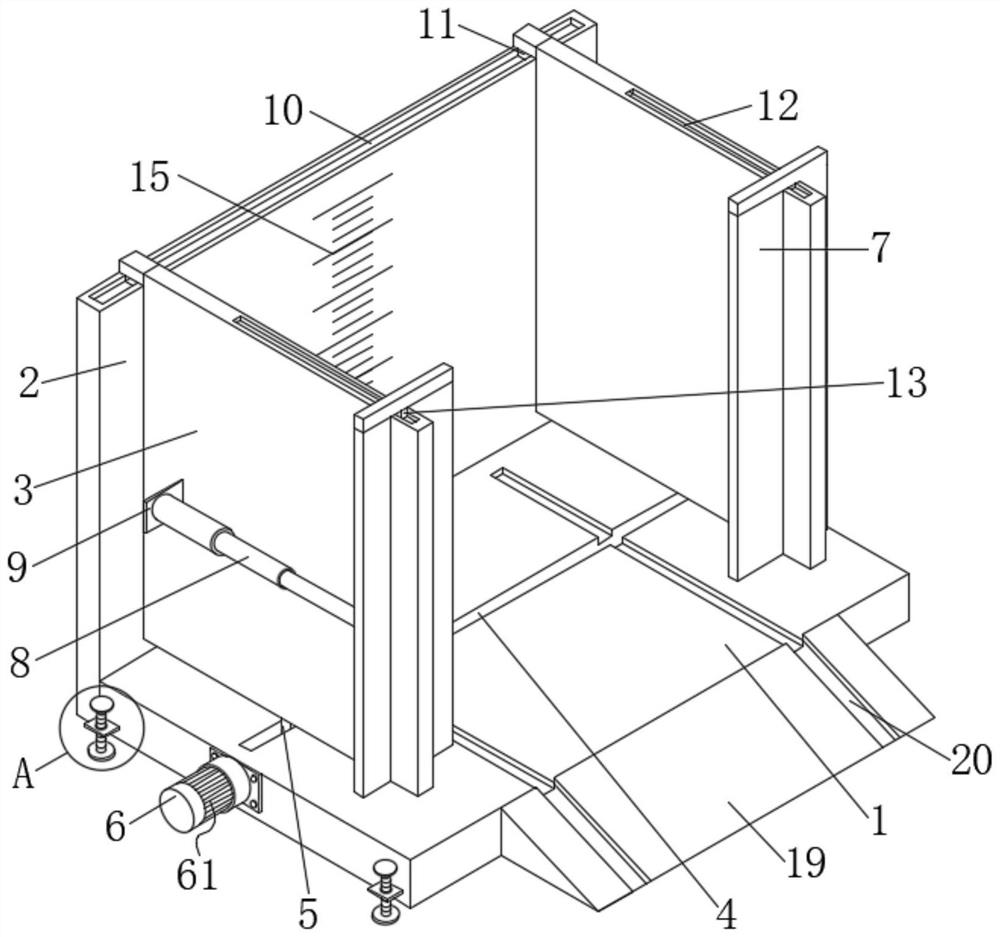

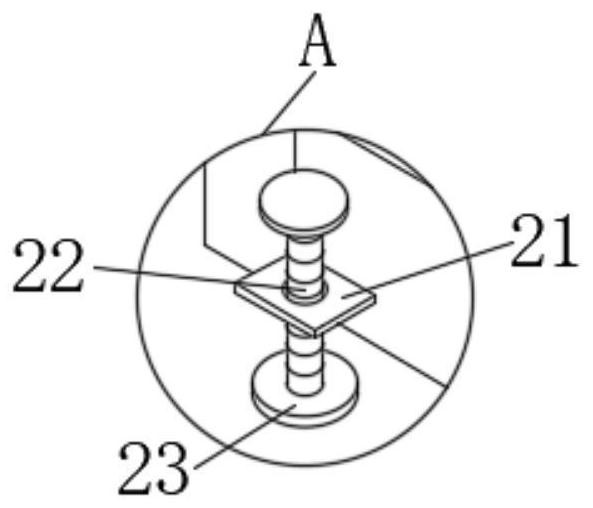

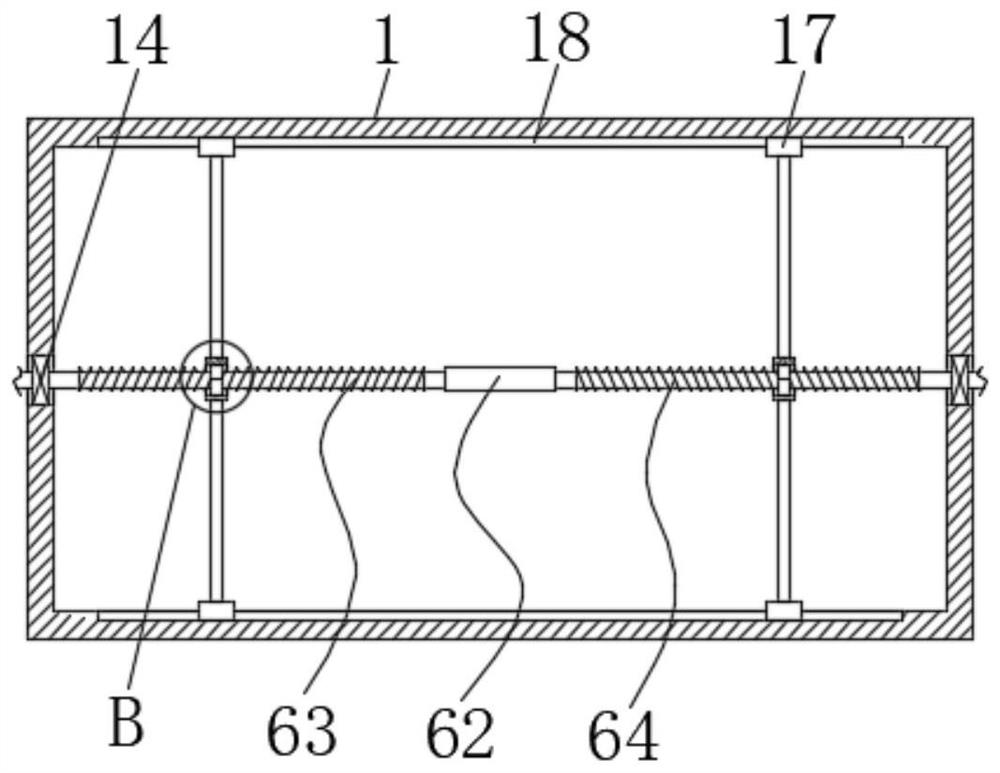

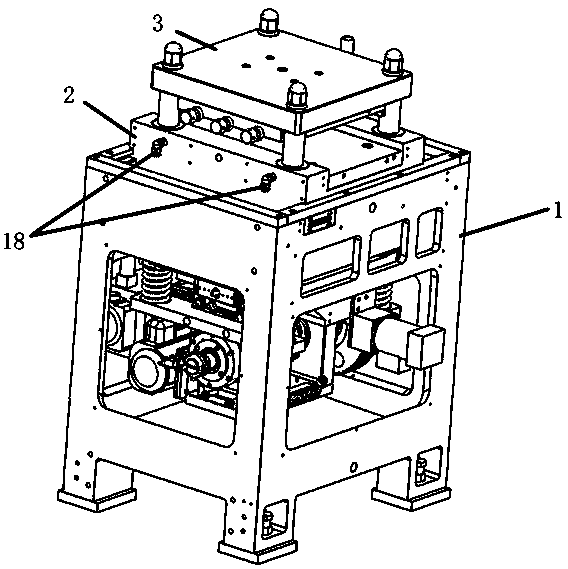

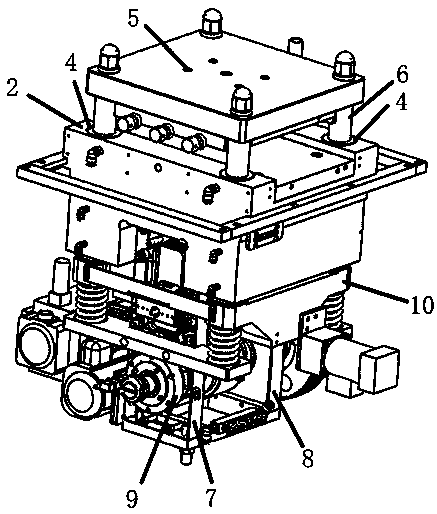

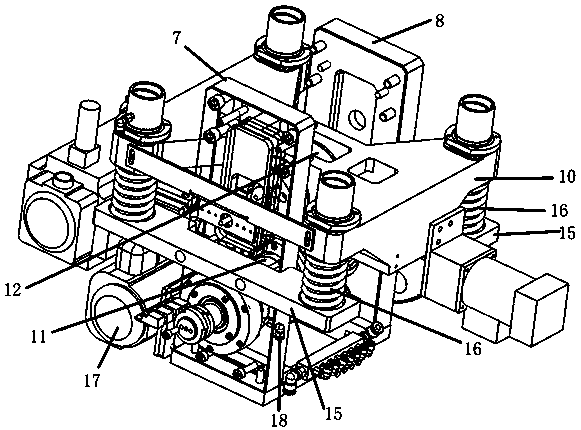

CCD automatic positioning die cutting machine

PendingCN110696093AImprove die-cutting accuracyImprove die-cutting efficiencyMetal working apparatusMachineDie cutting

The invention provides a CCD automatic positioning die cutting machine, and belongs to the field of die cutting equipment. The CCD automatic positioning die cutting machine comprises a die cutting main machine for providing stamping power, a control box for centralized control, a feeding mechanism for feeding materials and a positioning adjusting mechanism for die cutting horizontal adjusting automatic positioning. The control box is mounted behind the die cutting main machine, the adjusting mechanism is mounted on the die cutting main machine, and the feeding mechanism is mounted on the sideportion of the die cutting main machine. Compared with the prior art, adjusting in the horizontal direction can be carried out under the condition without halts, meanwhile, the die cutting precision and the die cutting efficiency are improved, it is not needed to worry about the situation that the die cutting position is wrong due to material staggering, and the CCD automatic positioning die cutting machine has the beneficial effects that the die cutting precision and the die cutting efficiency are higher.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

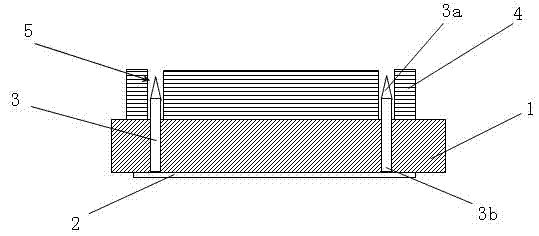

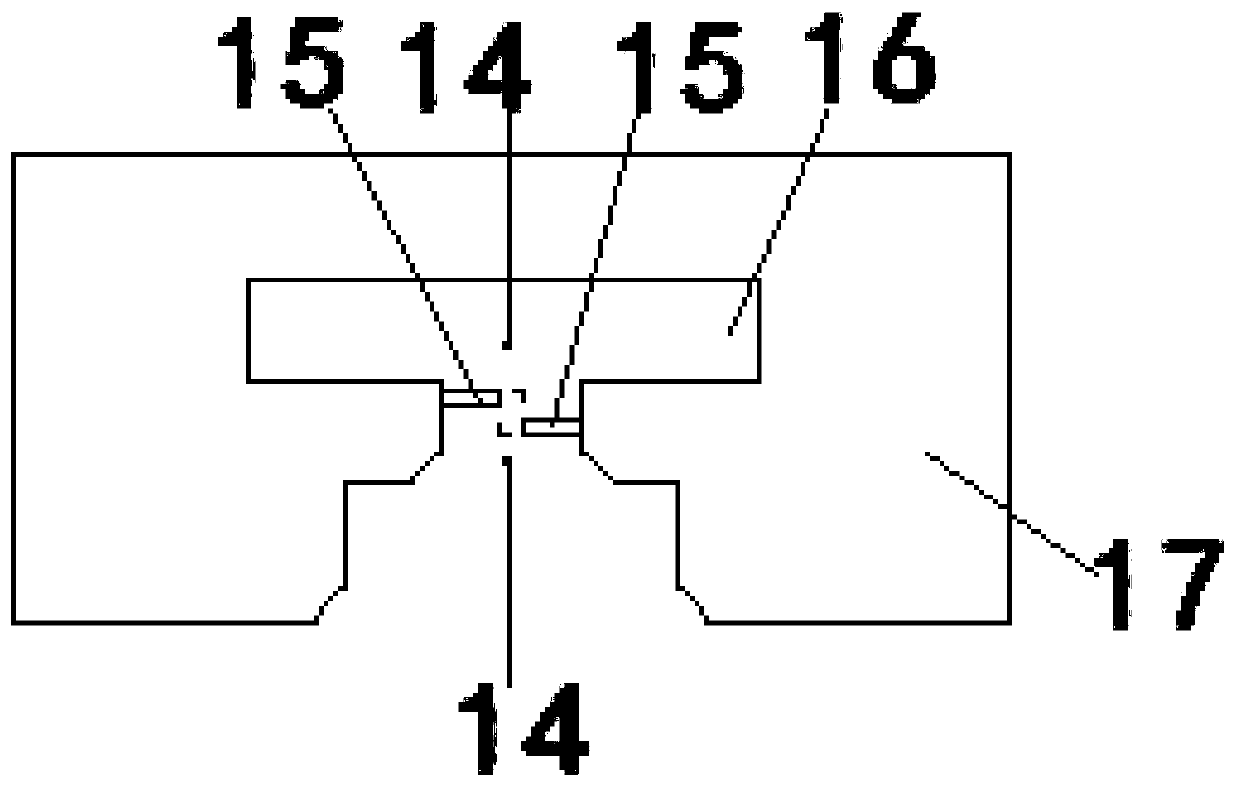

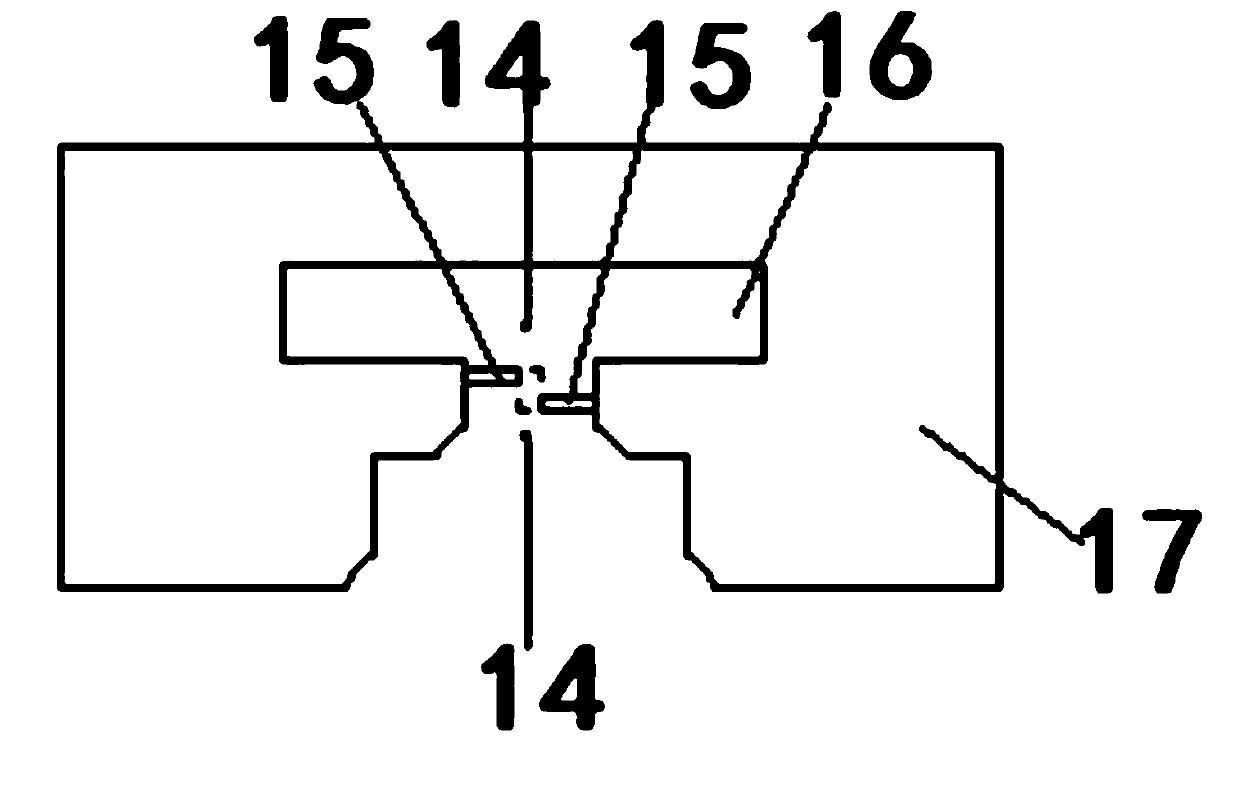

Mold cutting tool and manufacture method thereof

InactiveCN102172925AImprove die-cutting accuracyGuaranteed die-cutting accuracyMetal working apparatusEngineeringUltimate tensile strength

The invention discloses a mold cutting tool comprising a bottom plate and a cutting tool body, wherein the bottom plate is made of a metal material and is provided with a cutting tool containing gap, and the cutting tool ridge of the cutting tool body is fixed in the cutting tool containing gap. In the manufacture method of the mold cutting tool, the bottom plate made of the metal material is adopted, the cutting tool containing gap is machined on the bottom plate so as to intensify the strength of the bottom plate, and the cutting tool body and the bottom plate can be more stably and tightly combined. When the mold cutting tool is stressed when being used, the cutting tool containing gap has small possibility of widening because of deformation, thereby increasing the stability of the cutting tool body under the working state, improving the mold cutting precision of the mold cutting tool so as to prolong the service life of the mold cutting tool, reducing links of filling up the cutting tool, supplementing the cutting tool, changing the cutting tool and the like in the operation process, and improving working efficiency. Meanwhile, because the mold cutting tool is combined by machining by steps, machining cost and machining complexity are far lower than those of the integral machining of a graver or a etching knife, and thus production cost is lowered while mold cutting precision is guaranteed in the use process.

Owner:天津普瑞特产品标识有限公司

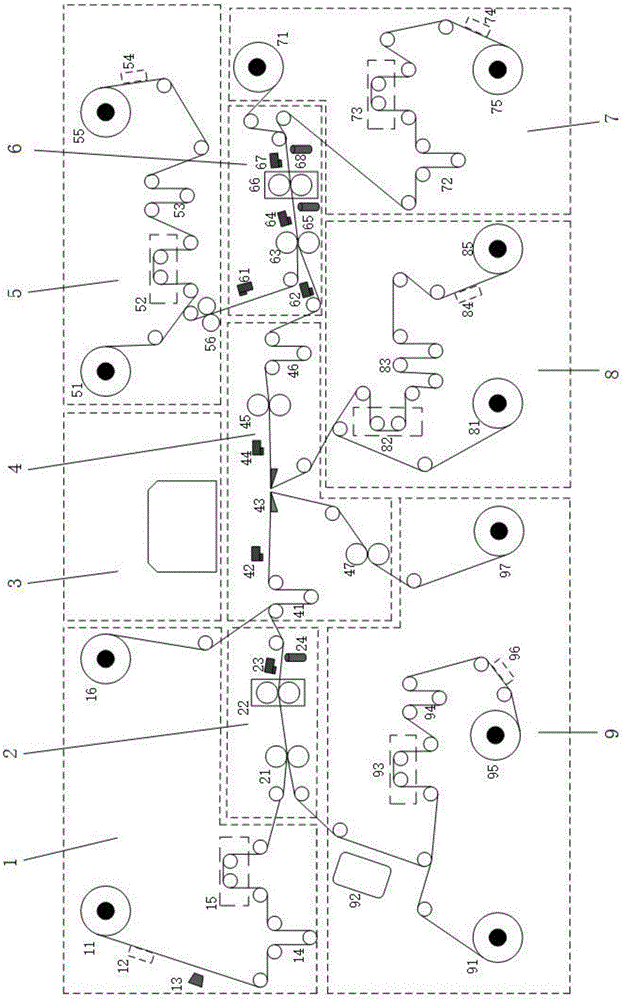

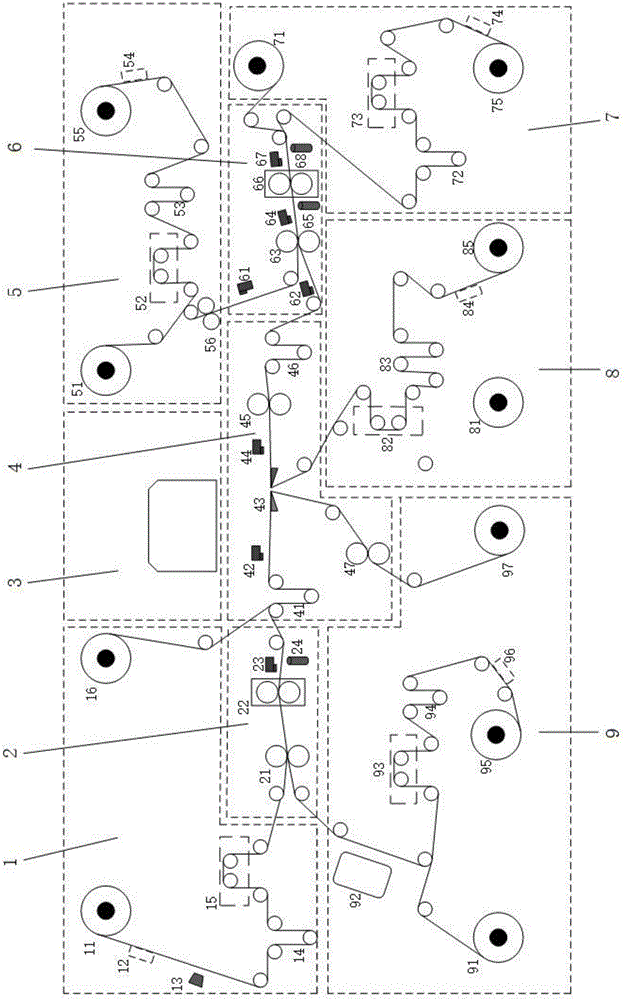

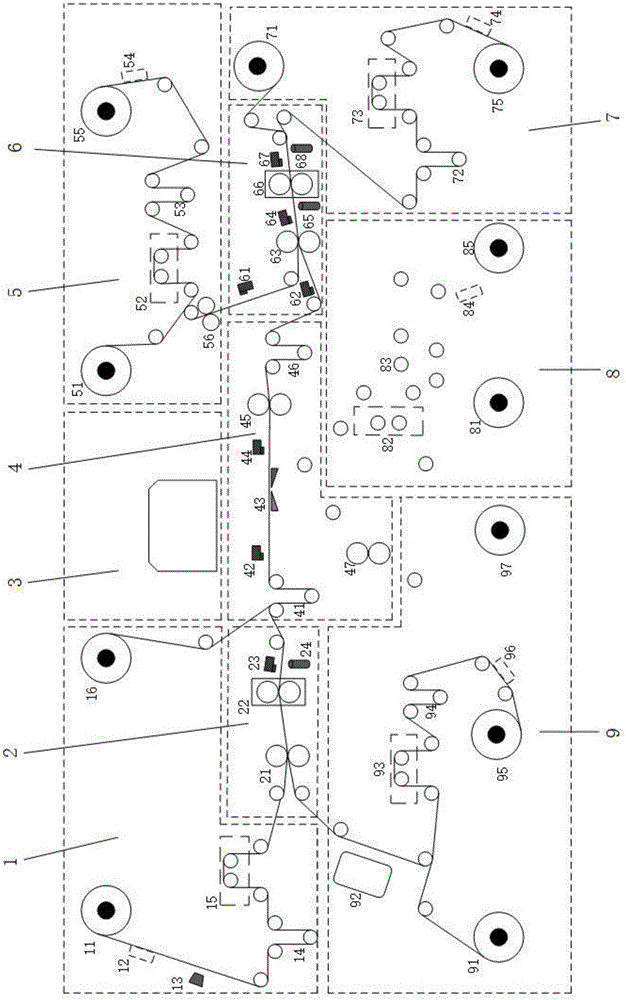

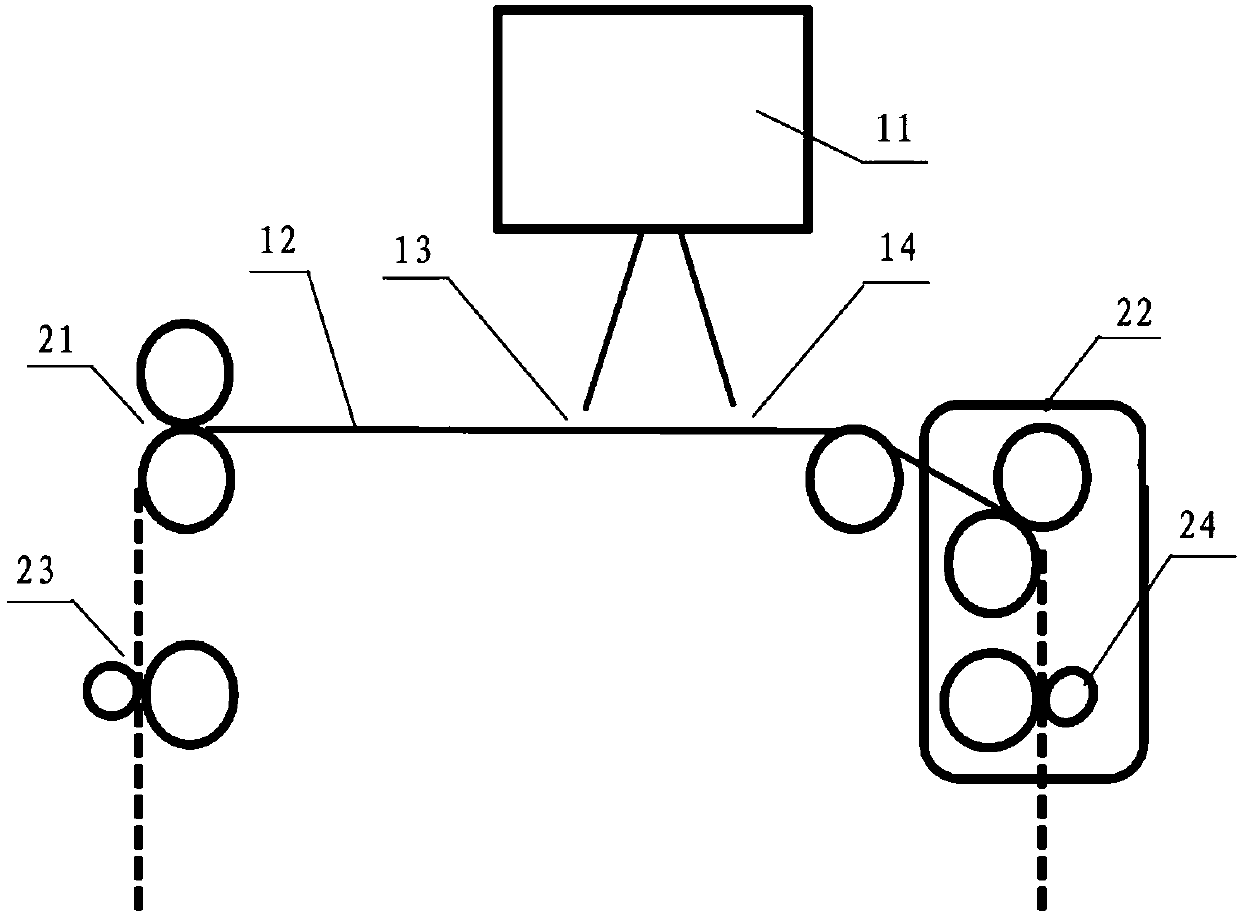

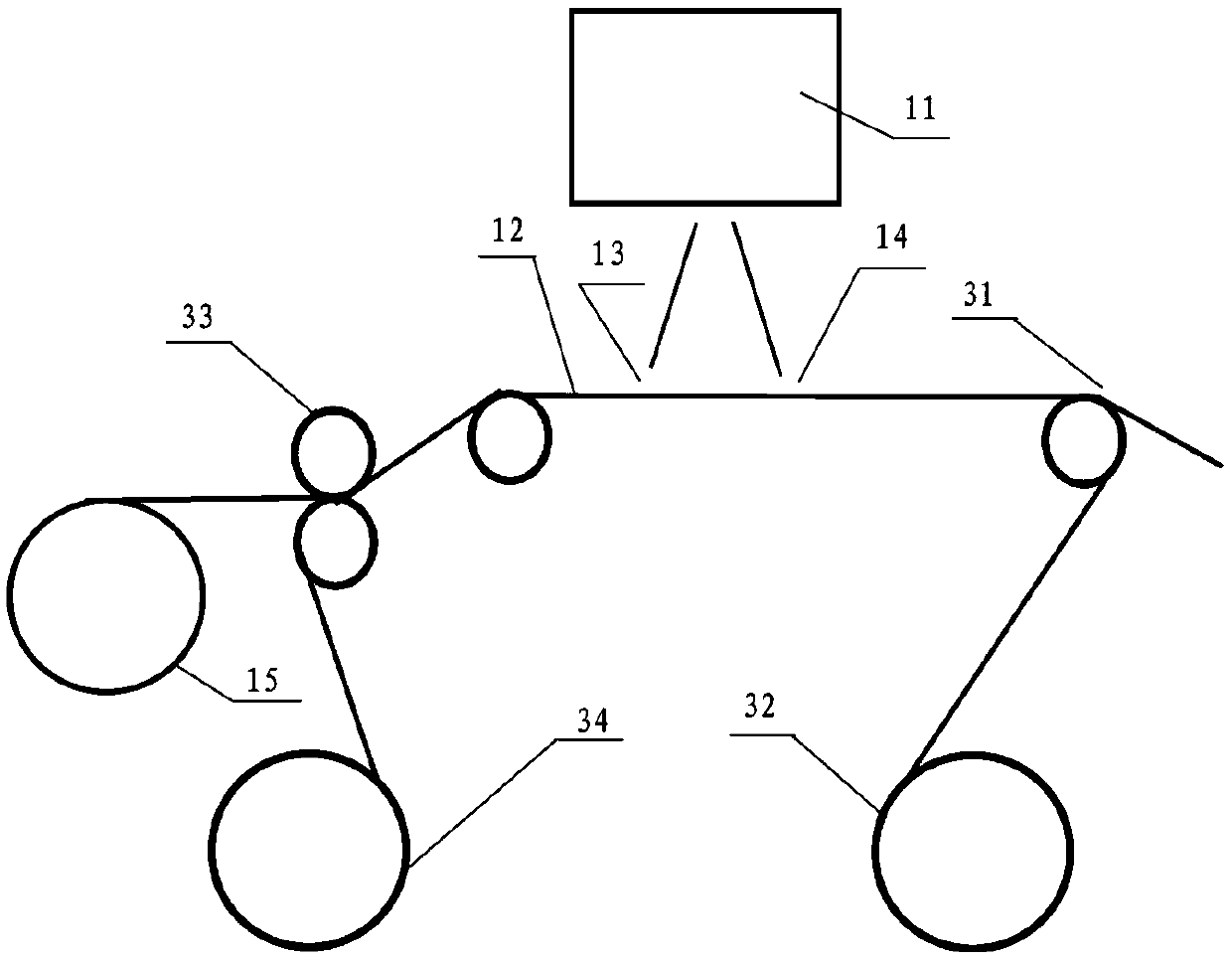

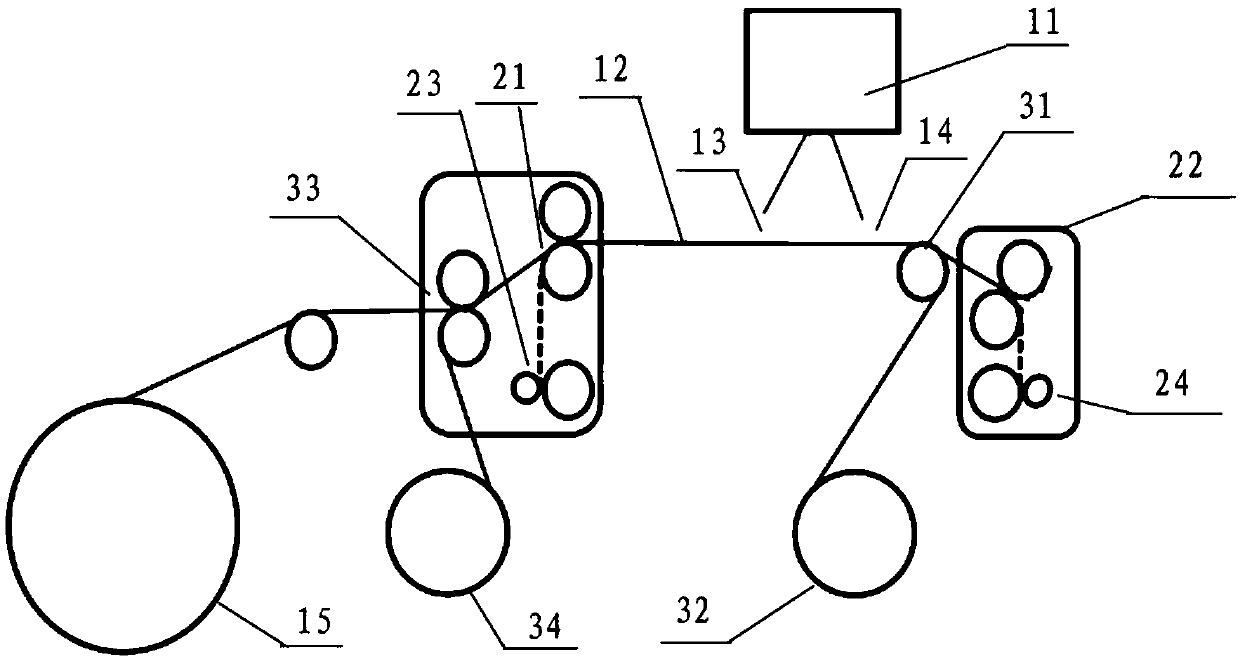

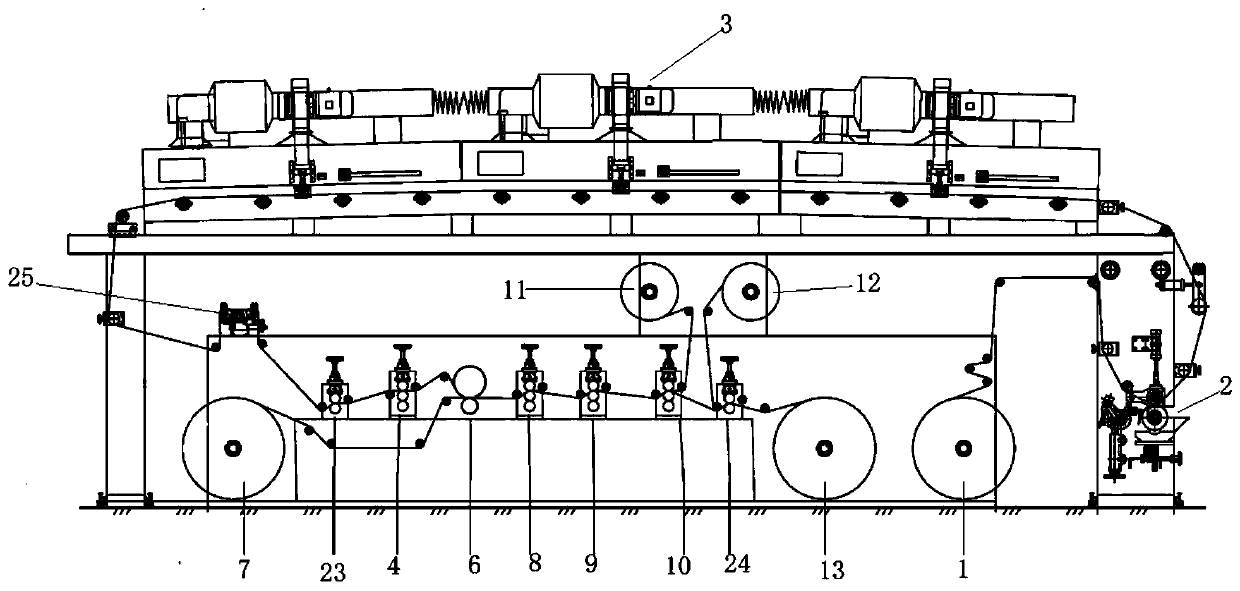

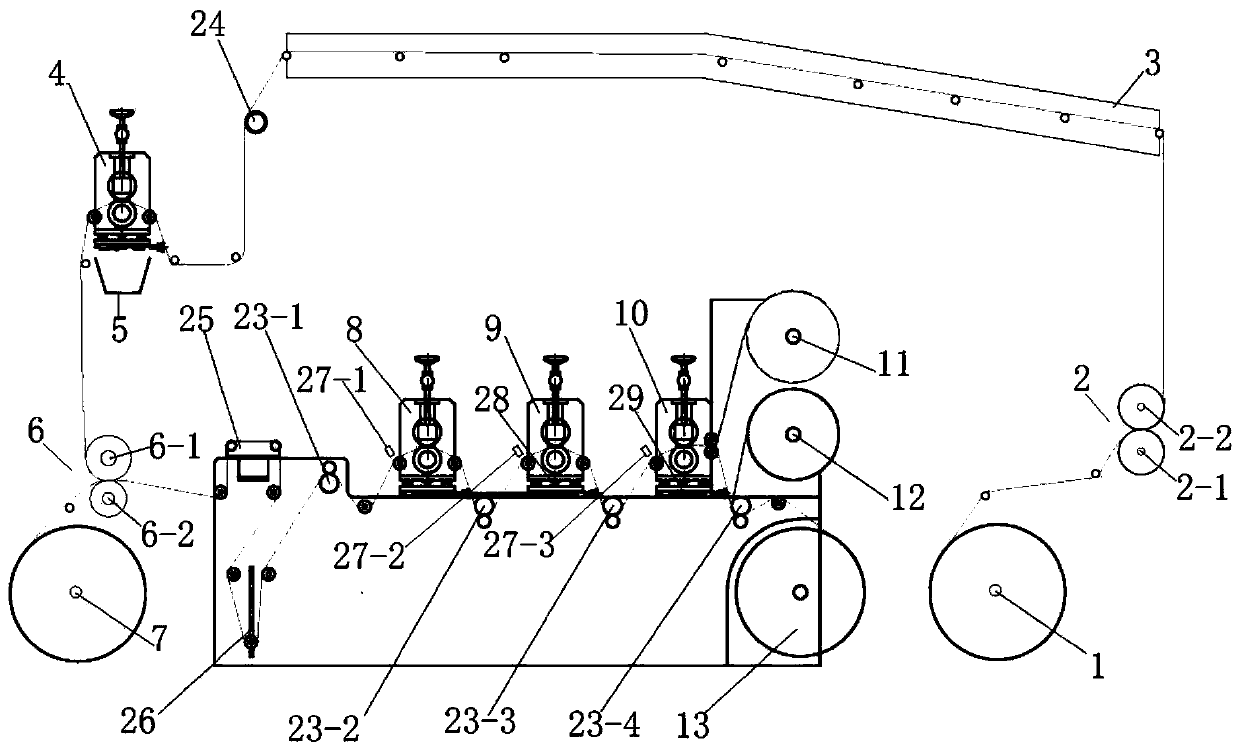

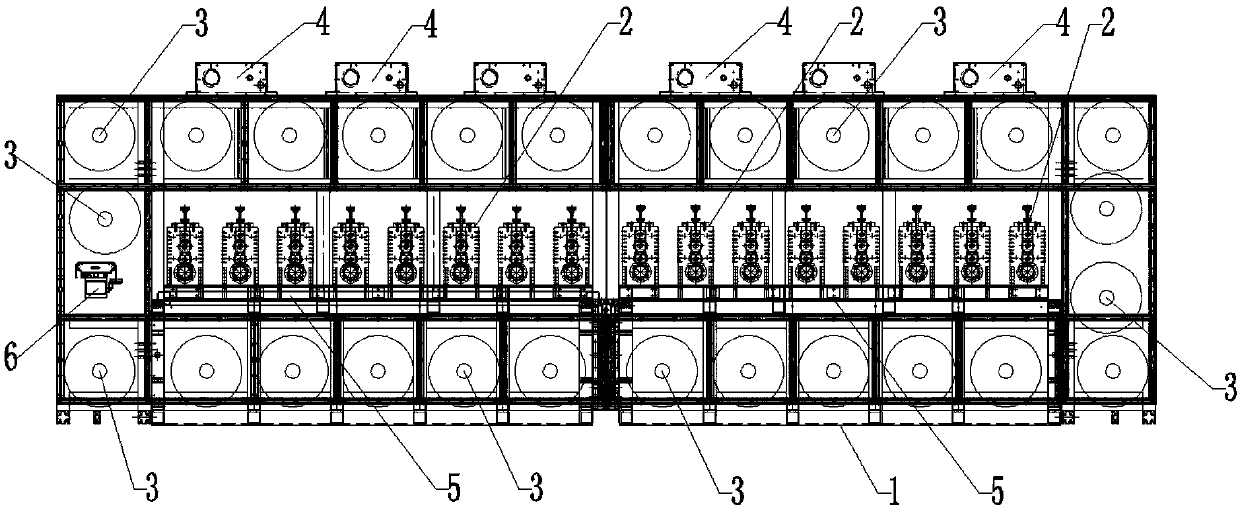

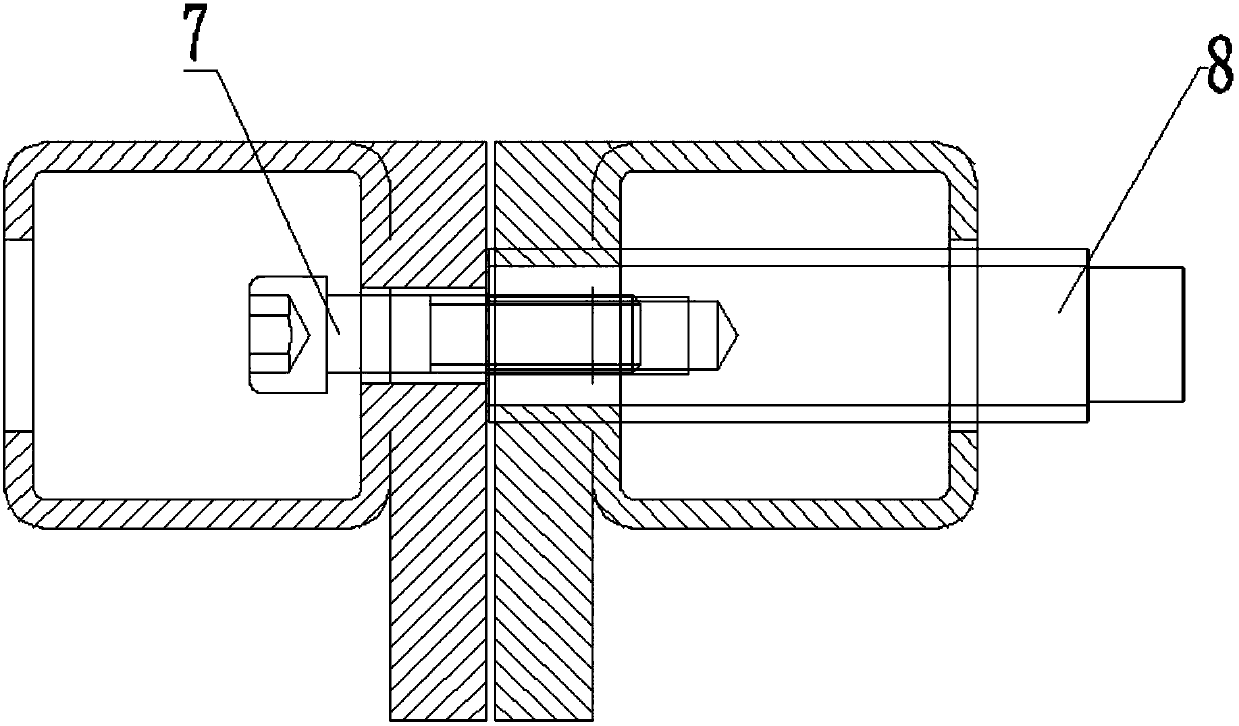

Multilayer structure flexible electronic continuous compounding system

ActiveCN106671551AClosely connectedMeet functional requirements such as tension controlLamination ancillary operationsControlling laminationFlexible electronicsCompound system

The invention belongs to the field of multilayer structure flexible electronic compound machining, and discloses a multilayer structure flexible electronic continuous compounding system. The multilayer flexible electronic continuous compounding system comprises four coiling-uncoiling modules, a primary lamination die cutting module, a rotation step pitch module, a secondary lamination die cutting module, a waste rejection module and a tag coiling module, and the internal constitutions and mutual connection manners of the modules are designed. Moreover, an optimal research result is given for the process principles of lamination die cutting control, tension control and the like of the system. By adopting the multilayer flexible electronic continuous compounding system, free switching among a plurality of working condition modes can be realized according to required working conditions, meanwhile single compounding, yield detection, waste rejection, rectification, high-accuracy die cutting and continuous feeding can be satisfied effectively, and the functions of good tension control and the like are ensured.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Laser die cutting machine

PendingCN109514098AAvoid the problem of poor cuttingEffective tension controlMetal working apparatusLaser beam welding apparatusMechanical engineeringLaser

The invention provides a laser die cutting machine. The laser die cutting machine is a combined type multifunctional laser die cutting machine, the laser die cutting machine comprises any one or any two or combination of more than two of a reciprocated feeding system, a lower recombining and peeling off system, an upper waste discharge system, a slicing system, a flattening system, and a waste gasexhaust system. The laser die cutting machine can improve the laser die cutting finished product yield, the automatic waste discharge, automatic winding and automatic slicing of the die cutting flowcan be achieved, and related function modules of a die cutting device are simple in structure and convenient to maintain.

Owner:SHANGHAI DIZI PAPER PLASTIC TECH CENT +1

Bright enhancement film and light shading glue integrated die cutting process

InactiveCN106863463AImprove fitImprove die-cutting accuracyPackagingMetal working apparatusEngineeringTectorial membrane

The invention discloses a bright enhancement film and light shading glue integrated die cutting process. An angle-adjustable sheet transferring pasting mechanism is installed at the specific position of a round cutter die cutting machine to be independently controlled, a bright enhancement film with an outer frame subject to die cutting according to a specific angle through the mechanism is set right to be subject to transferring pasting to an adhesive protective film, then marker chasing is carried out through an electric eye (namely an industrial camera, the same below), an inner frame of light shading glue is cut off, and the light shading glue is centered and pasted to the bright enhancement film; and then marker chasing is carried out through the electric eye to enable the light shading glue and the outer frame of the bright enhancement film to be subject to integrated die cutting molding. By means of the integrated die cutting method, the light shading glue and the bright enhancement film are better attached, and the die cutting accuracy is improved.

Owner:GUANGZHOU JINGSAI PRECISION MACHINERY CO LTD

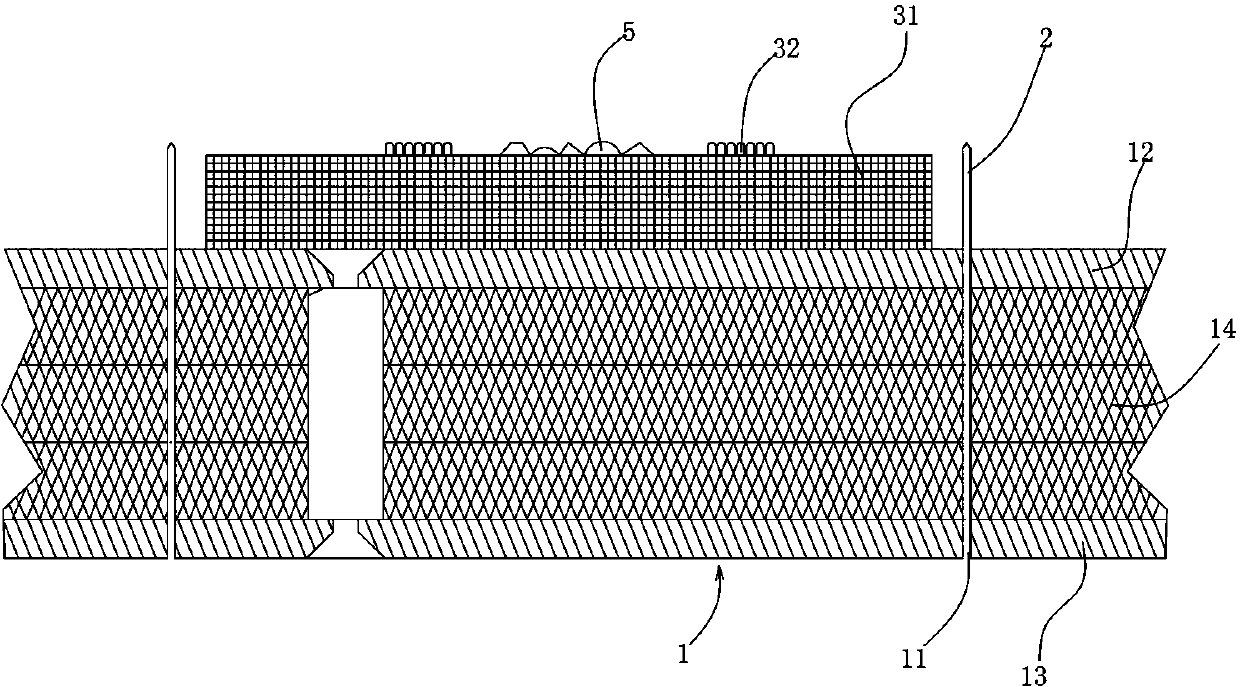

Die-cutting upper cutting die and manufacturing method thereof

InactiveCN104191652AGuaranteed accuracySolve the problem of different sizesBox making operationsPaper-makingEngineeringKnife blades

The invention discloses a die-cutting upper cutting die and a manufacturing method of the die-cutting upper cutting die. The upper cutting die comprises a die-cutting upper cutting die carrier plate, wherein forming blades used for forming the periphery of an object to be cut are embedded into the die-cutting upper cutting die carrier plate, at least a creasing line die block used for generating creases on the object to be cut and angle die cutters are arranged in a peripheral encirclement defined by the forming blades, the creasing line die block comprises a metal substrate with a defined shape, creasing lines directly machined on the metal substrate are arranged on the surface of the metal substrate, and protrude out of the metal substrate for the preset height and in the preset shape, and the metal substrate is fixedly connected with the die-cutting upper cutting die carrier plate through fasteners. The die-cutting upper cutting die and the manufacturing method of the die-cutting upper cutting die have the advantage that relative positions of transverse creasing lines and longitudinal creasing lines exactly meet the design standard.

Owner:HUIXINLEI DIE CUTTER TECH CO LTD

Die-cutting machine feeding platform with improved structure

InactiveCN103029162AAvoid damageSimple structureMetal working apparatusAtmospheric pressureFilm material

The invention discloses a die-cutting machine feeding platform with an improved structure. The platform comprises a placing platform, a pneumatic cavity and an air extractor, wherein a cavity structure is arranged on the inner side of the pneumatic cavity; the placing platform is covered on the opening side of the pneumatic cavity in a sealing fixing manner, and is provided with a plurality of through holes communicated with the interior of the pneumatic cavity; the pneumatic cavity is communicated with an exhaust opening of the air extractor; and the air extractor can extract out air in the pneumatic cavity. The platform realizes the fixation and the flattening of a film material through pneumatic attraction force, and keeps the film material in a tension state through friction force between the film material and the placing platform to enable the film material to generate a predetermined tension force; and the platform has the advantages of simple structure, stability in operation, convenience in operation, avoidance of surface damage of the film material, high die-cutting precision and high production efficiency.

Owner:SUZHOU CHUANRI PRECISION MACHINERY

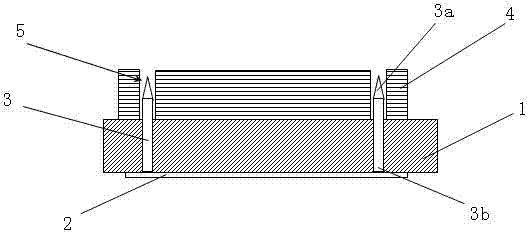

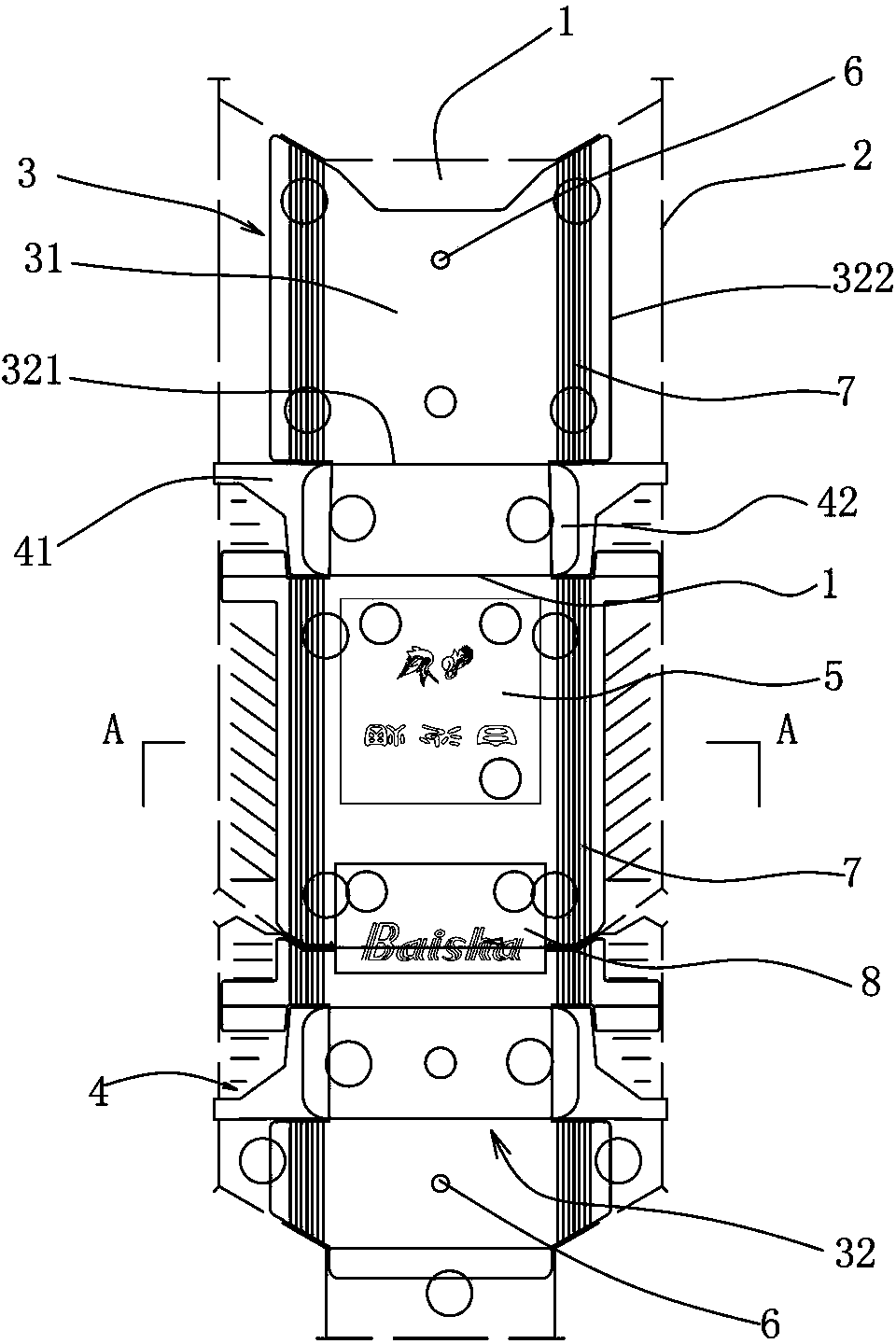

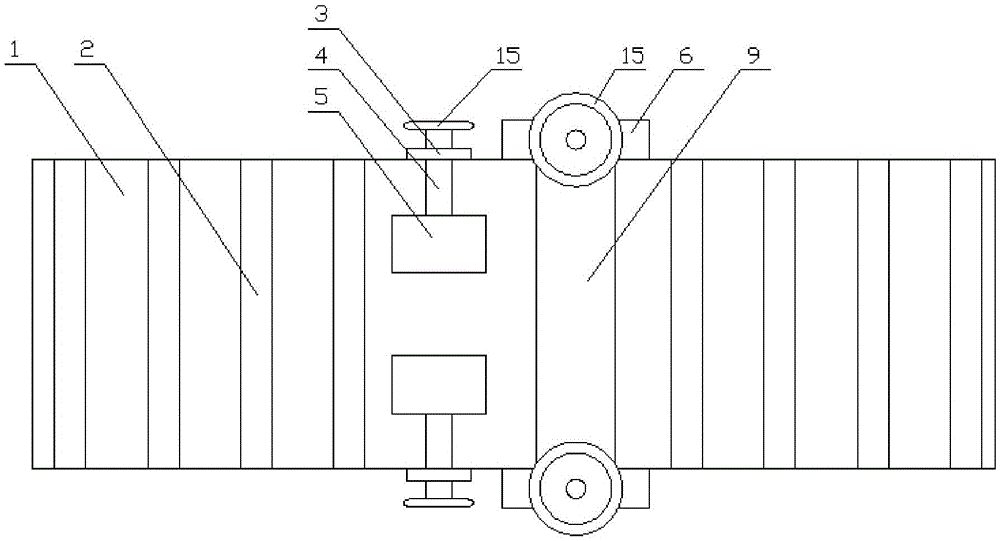

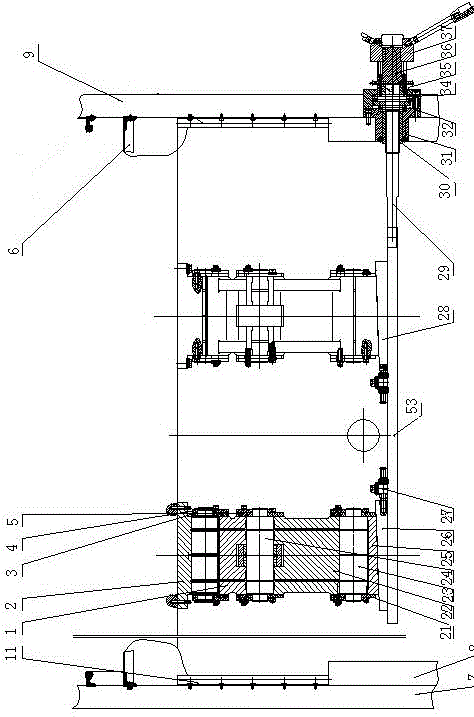

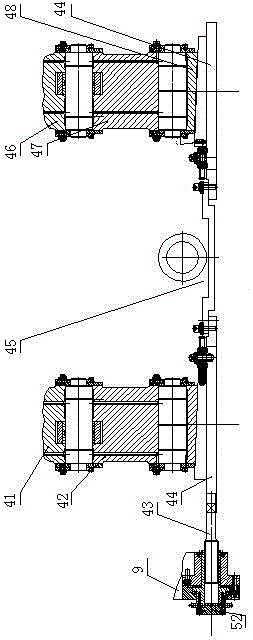

Mold table device of uncoiling die cutting machine

InactiveCN108789638AStable torque characteristicsEnsure smoothnessMetal working apparatusFeed driveEngineering

The invention relates to an all-servo mold table device of an uncoiling die cutting machine. The device comprises a mold table main body frame, an upper die cutting platform, a lower die cutting platform, a feed driving mechanism for guiding products to enter a die cutting station, and a discharge driving unit for guiding the products to shift out of the die cutting station; the feed driving mechanism and the discharge driving mechanism are both fixedly mounted on the lower die cutting platform; the lower die cutting platform is connected with a mold table driving unit; the die table driving unit controls the lower die cutting platform to move up and down; and the lower die cutting platform and the upper die cutting platform are pressed for die cutting of the products. Compared with the prior art, the device adopts an all-servo control and stick clamping mode to simplify mechanical structure and to improve the die cutting speed and the production efficiency; and through arrangement ofthe lower die cutting platform capable of moving, a lower mold is always bonded with the products during die cutting, and conveyed papers and the mold table are always maintained on the same plane, sothat the floating in the mold table is reduced, the up-down travel of the mold table is reduced, and the die cutting frequency can be greatly improved.

Owner:SHANGHAI ZIDAN FOOD PACKAGING & PRINTING CO LTD

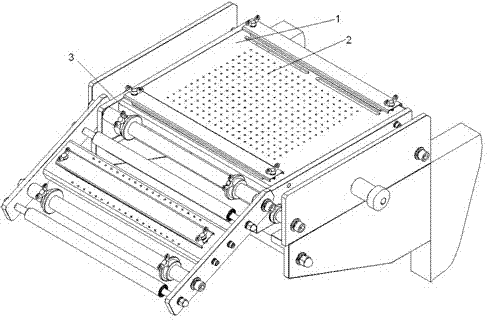

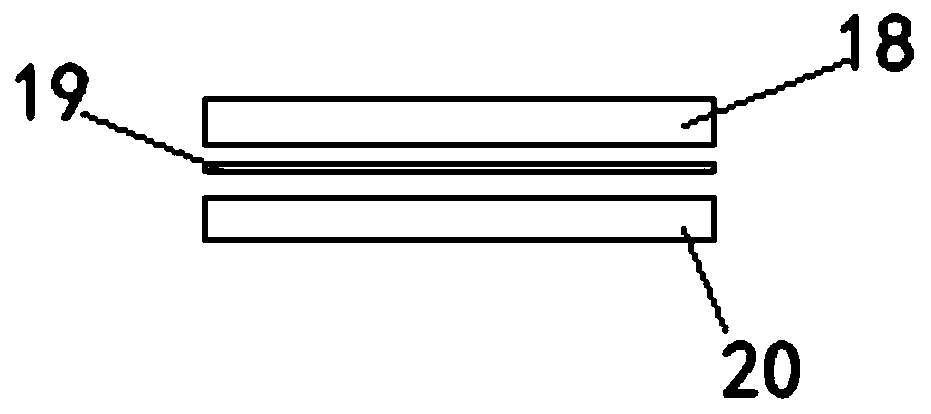

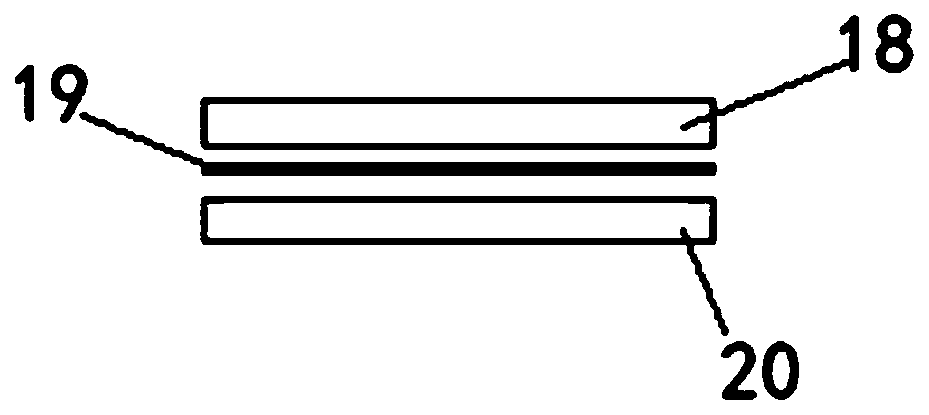

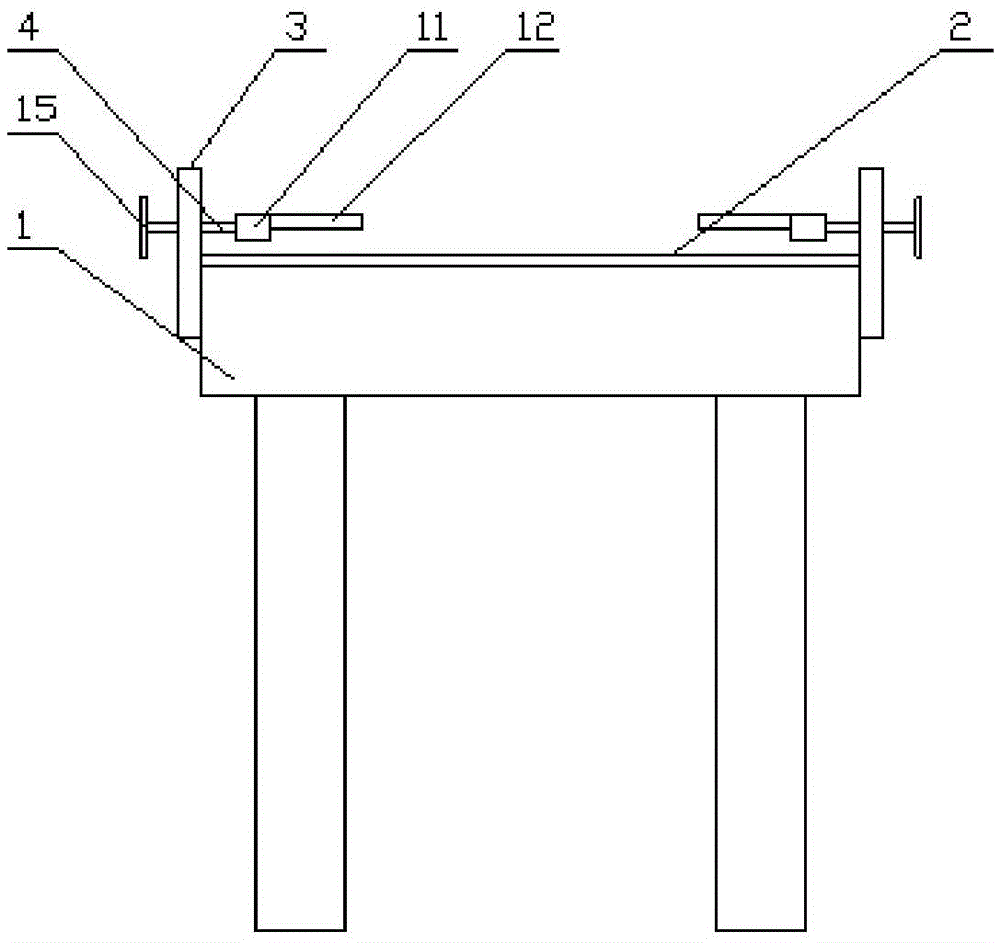

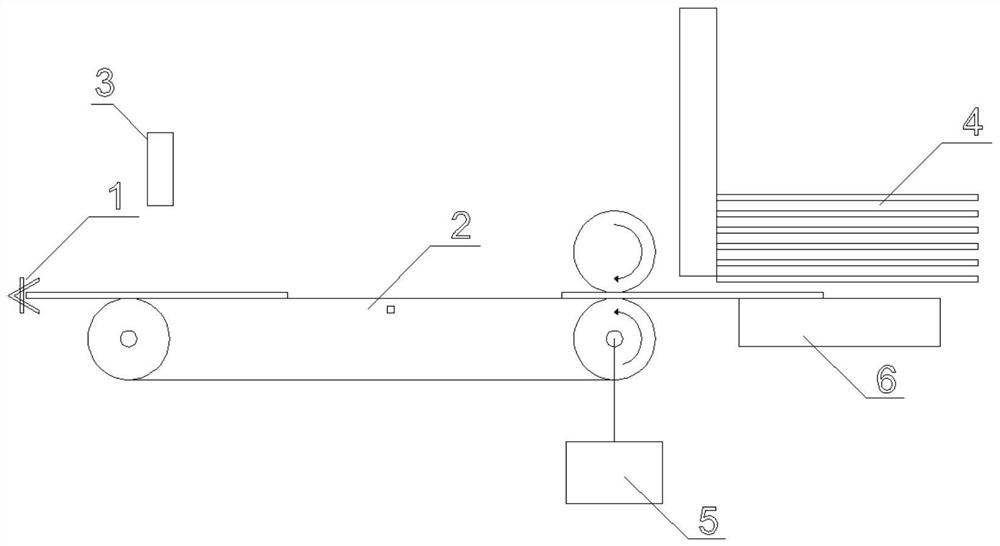

Feeding device of die cutting machine

InactiveCN105014730AStable tension controlNot easy to swingMetal working apparatusBiochemical engineeringTension control

The invention discloses a feeding device of a die cutting machine. The feeding device comprises support arms on the two sides and a connecting rod for connecting the support arms. A first round rod, a second round rod, a third round rod, a fourth round rod and an auxiliary rod are arranged between the two support arms. The auxiliary rod is provided with an externally-arranged pressing plate. The pressing plate is provided with a pressing trough. The feeding device of the die cutting machine is arranged on one side of a feeding table, and a die cutting device is arranged on the other side of the feeding table. The first round rod is provided with two slideable first fixing rings. The third round rod is provided with two slideable second fixing rings. The first fixing rings are fixed to the first round rod through bolts, and the second fixing rings are fixed to the third round rod through bolts. The lower side of the pressing plate is in a smooth arc shape, and the pressing plate is fixed to the auxiliary rod through bolts. The feeding device of the die cutting machine is simple, applicable and convenient to use. The tension of die-cutting raw materials is controlled stably, the die-cutting raw materials are not prone to swinging, and the die cutting precision is high.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

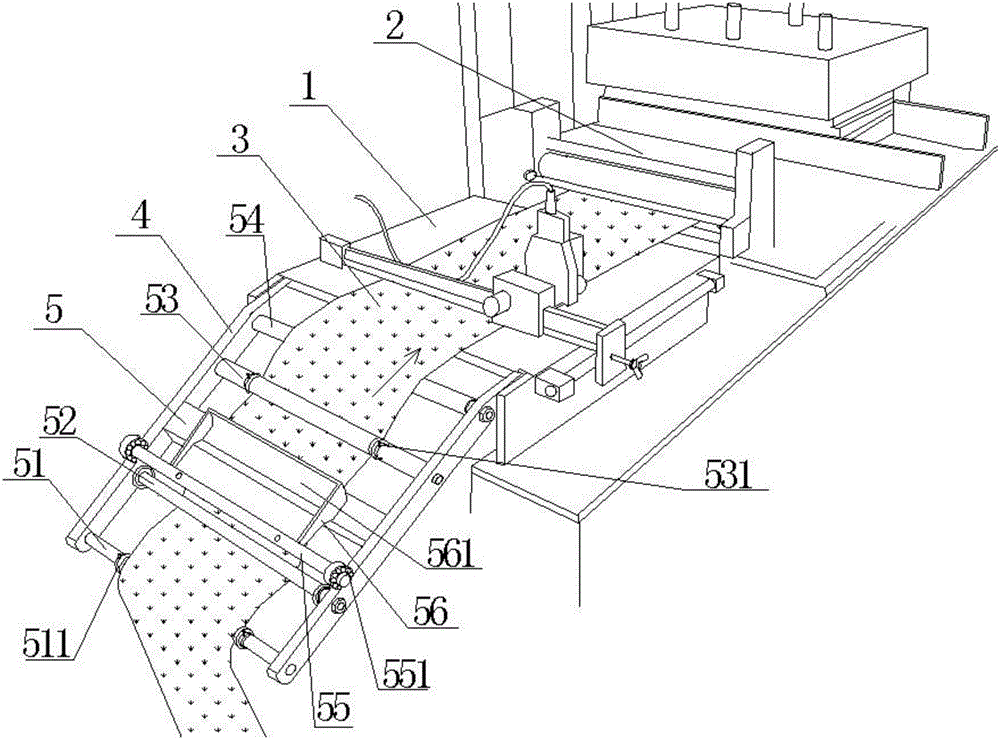

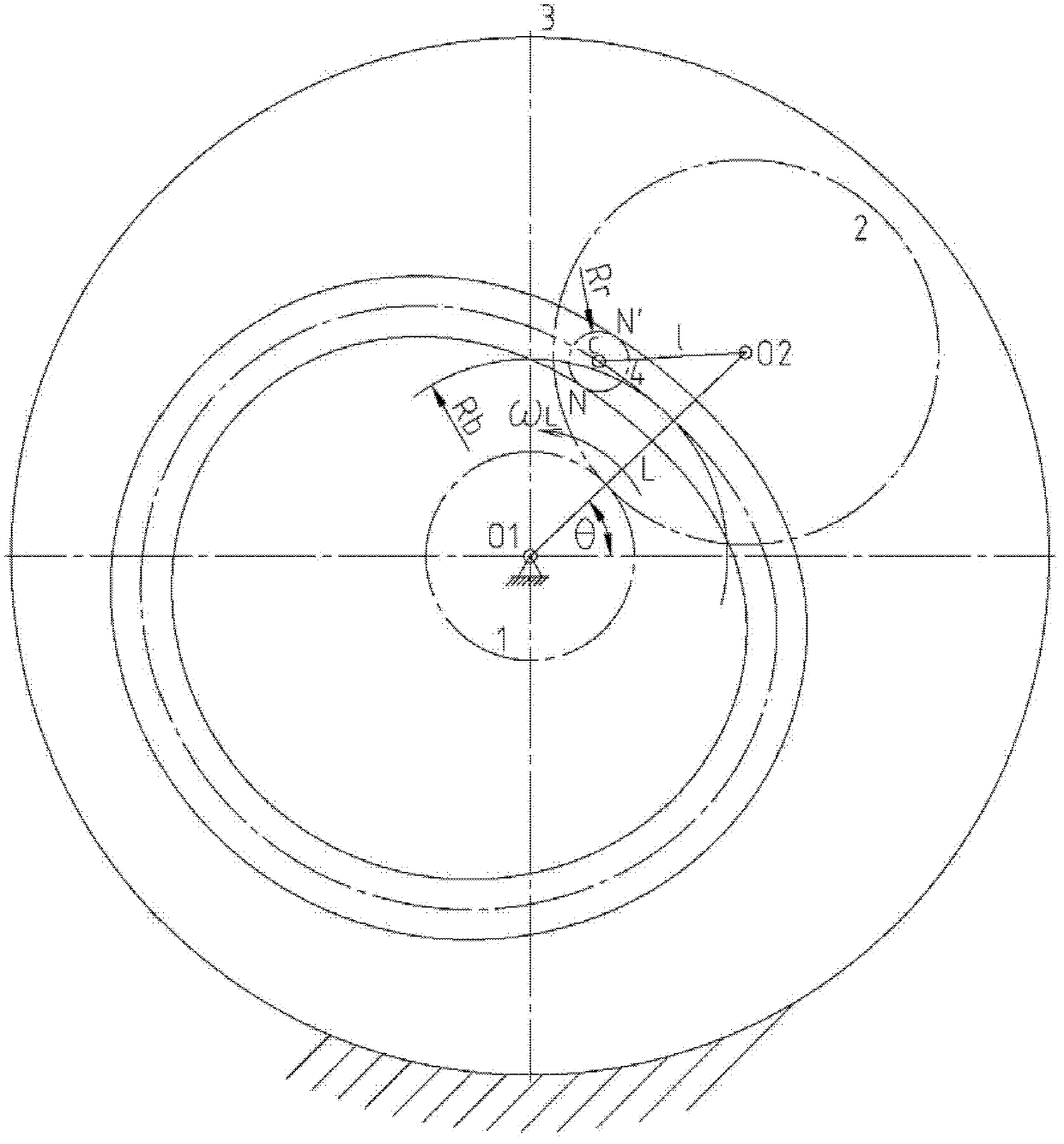

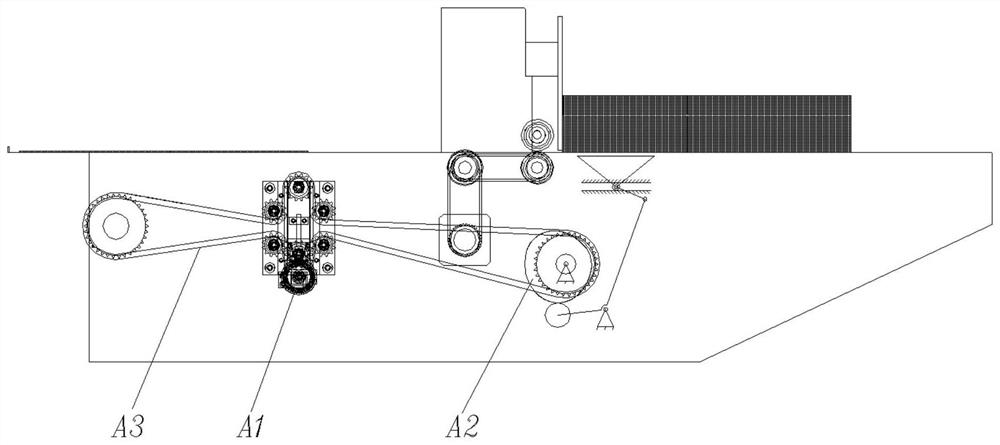

Variable transmission paper feed mechanism for die-cutting machine

The invention relates to a variable transmission paper feed mechanism for a die-cutting machine. The paper feed mechanism comprises a cam-planetary gear epicyclic train component, a speed-increasing gearbox, a synchronous belt, a paper feeding roller and a paper feeding belt roller, wherein the cam-planetary gear epicyclic train component is connected with the speed-increasing gearbox, and the speed-increasing gearbox is connected with the paper feeding roller and the paper feeding belt roller through the synchronous belt. Compared with the prior art, the paper feed mechanism is stable and reliable in movement and high in paper feeding accuracy, large-stroke high-speed smooth paper feeding can be realized, manufacturing cost can be controlled, and later maintenance and service costs are low.

Owner:SHANGHAI ETERNAL MACHINERY

Cardboard die cutting device

InactiveCN108127968AAvoid offsetGuaranteed accuracyBox making operationsPaper-makingCardboardEngineering

The invention discloses a cardboard die cutting device. The device is composed of a machine box, a base, a dust collecting device, a conveying device and a die cutting device, wherein an organic box is arranged at the upper end of the base, the machine box is internally provided with a die cutting device, a conveying device is arranged on one side of the die cutting device, and clamping plates arearranged on the two sides of the conveying device; the lower end of the clamping plate is fixedly connected with the lower end of the clamping plate through a connecting rod, a pushing motor is arranged in the middle of the lower end face of the connecting rod, and a rotating shaft is arranged at the lower end of the pushing motor; rotating teeth are arranged on the rotating shaft, and a dust collecting device is arranged at the upper end of the machine box; the dust collection device is composed of a dust holding box, a dust suction pipe and a dust suction motor; and the dust storage box isconnected with the dust suction pipe, the dust collecting motor is arranged at the upper end of the dust containing box, and debris generated in the die cutting process can be cleared away in time, sothat the sanitation in the device is guaranteed, meanwhile the die cutting precision is improved, and the dust collecting box is internally provided with a dust removing drawer which can be used forconveniently cleaning chippings.

Owner:方杨军

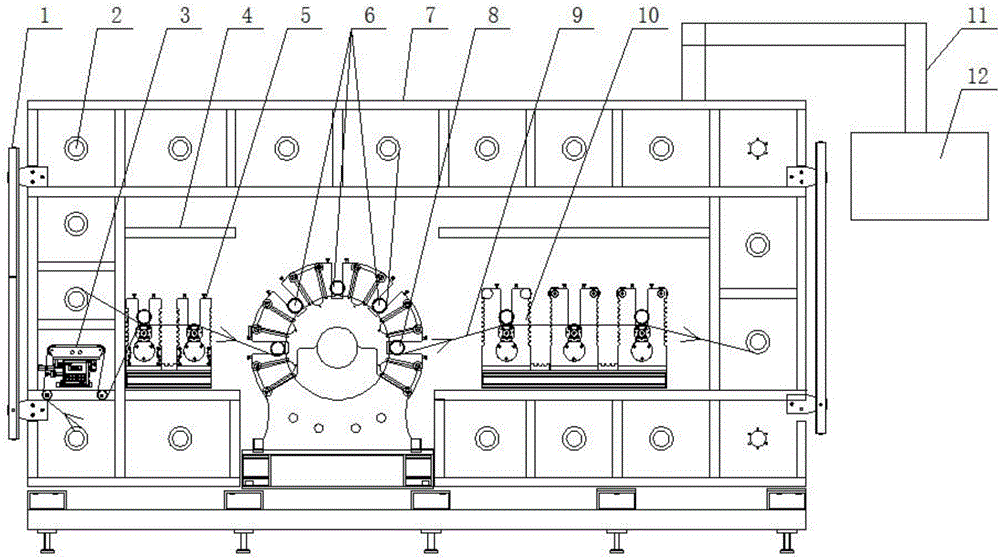

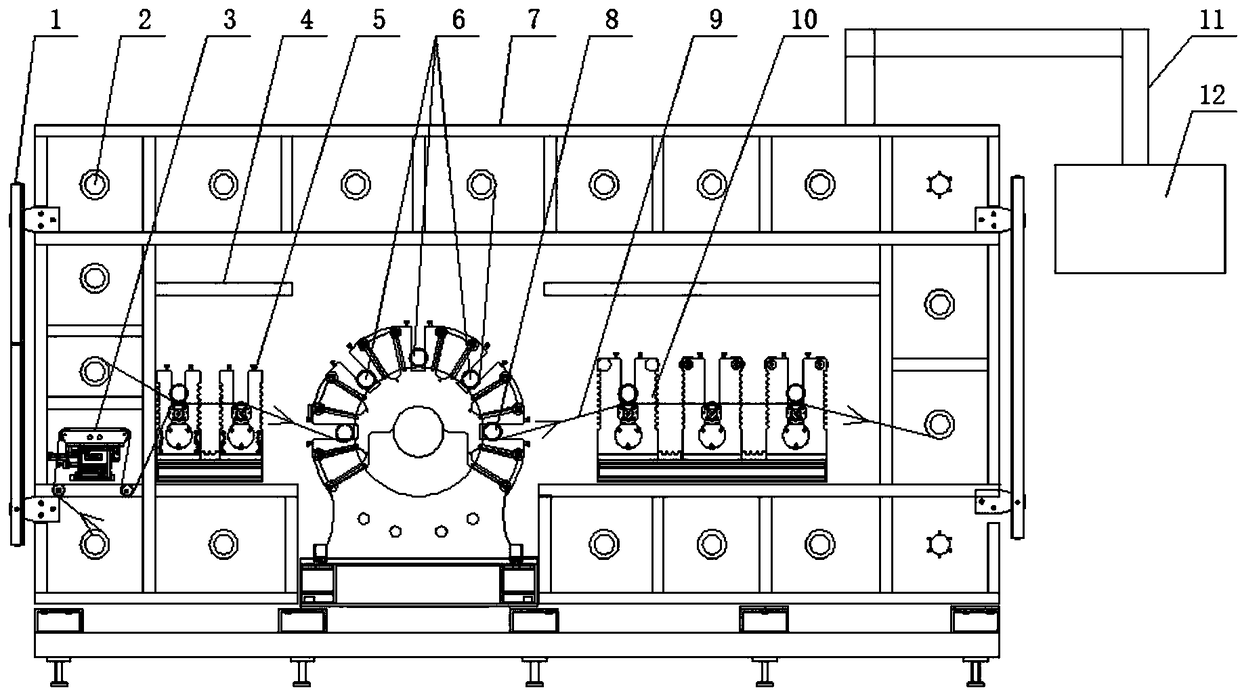

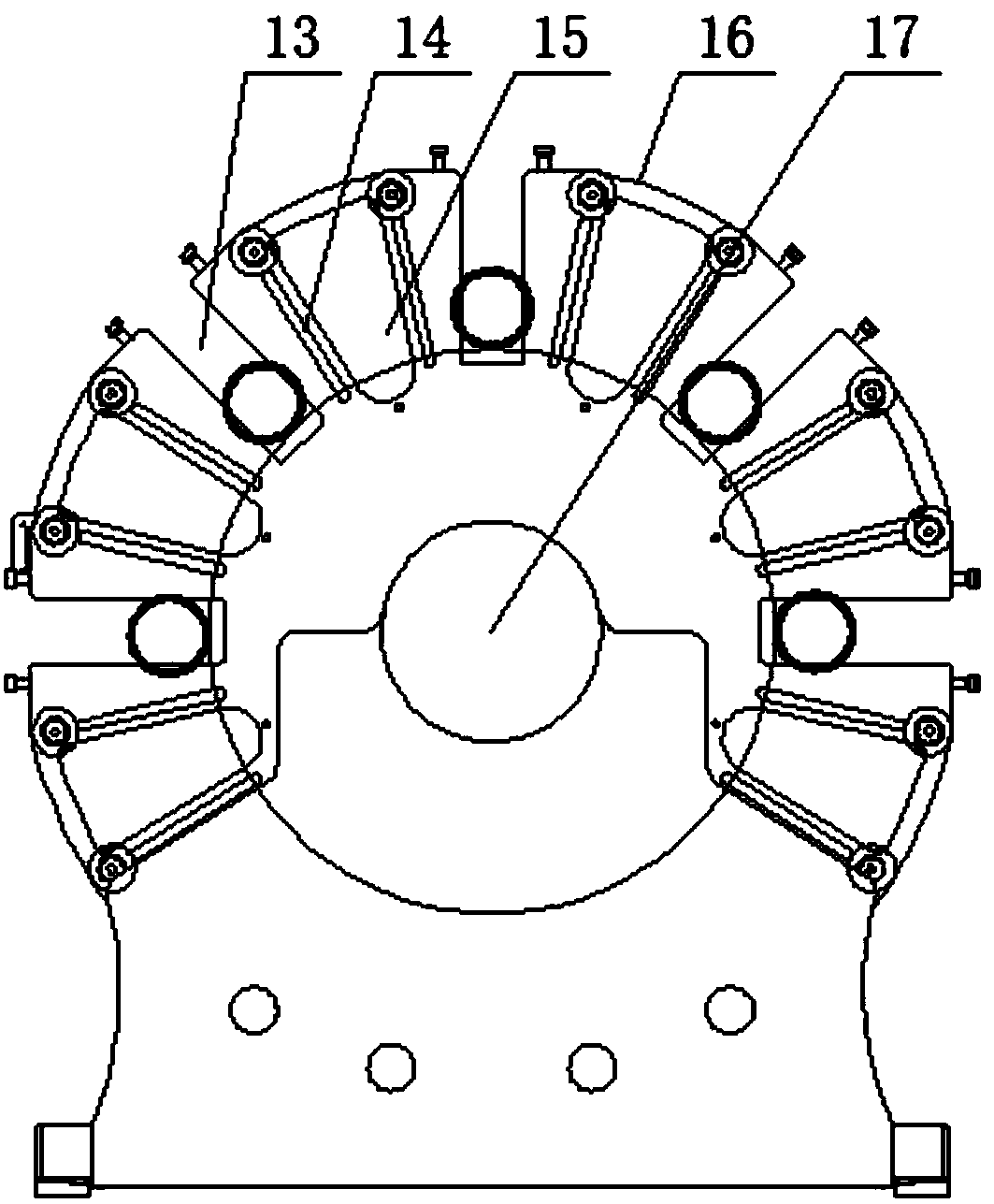

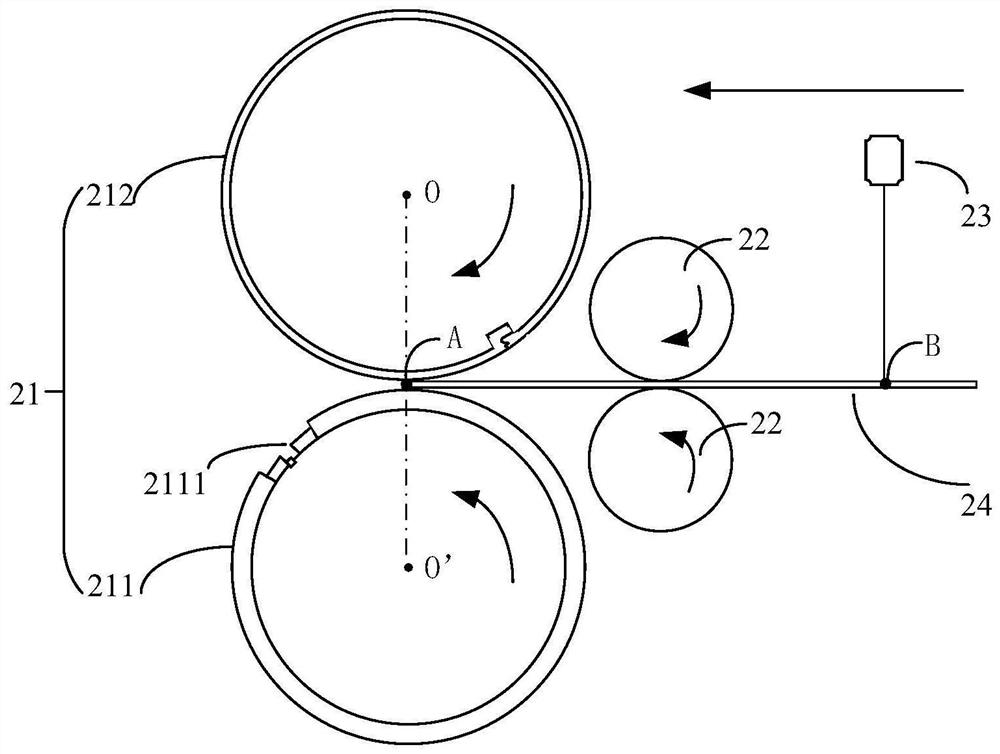

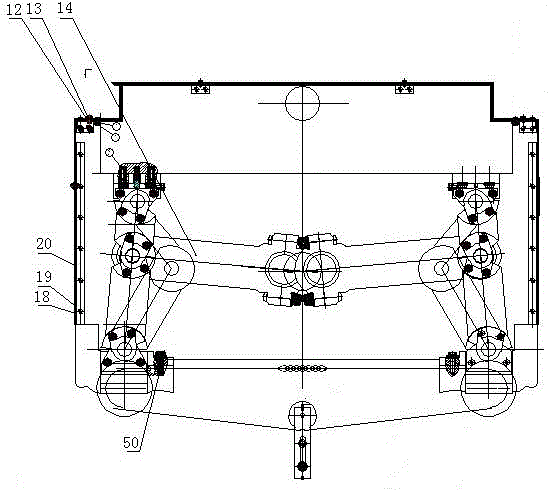

Satellite type column-to-column rotary die cutting device

ActiveCN106738044AImprove performanceSmooth in and outMetal working apparatusWorkstationGas expansion

The invention relates to a satellite type column-to-column rotary die cutting device. The device includes an equipment main frame, an electrical cabinet, a gas expansion shaft and a console; the back side of the equipment main frame is provided with the electrical cabinet, an outer ring of the front side of the equipment main frame is provided with the gas expansion shaft, and the console is installed on the equipment main frame; the device is characterized by further comprising a deviation correcting device, a front auxiliary workstation, a satellite type column-to-column workstation and a rear auxiliary workstation; the front side of the equipment main frame is provided with the deviation correcting device, the front auxiliary workstation, the satellite type column-to-column workstation and the rear auxiliary workstation in sequence from left to right. The device has the advantages of being scientific and reasonable in structure design, high in processing efficiency, high in die cutting precision, high in process yield, low in die cutting cost, stable in operation, safe, reliable, capable of conducting function extension and saving space and easy to achieve, and is a highly innovative satellite type column-to-column rotary die cutting device.

Owner:中融飞腾(北京)科技有限公司

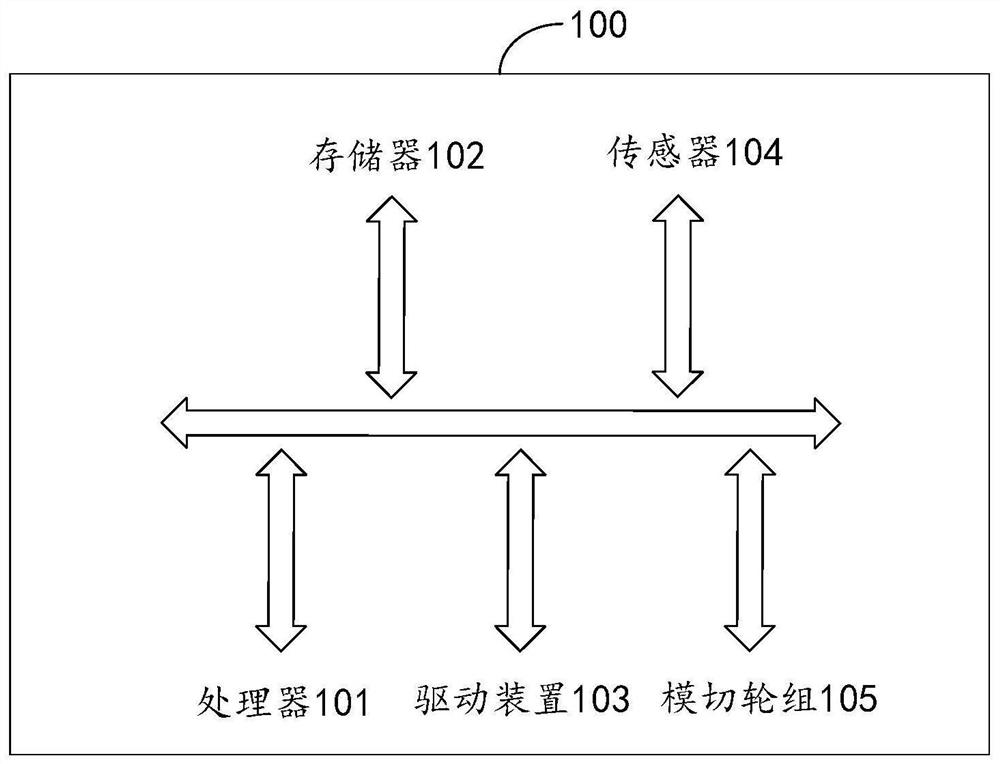

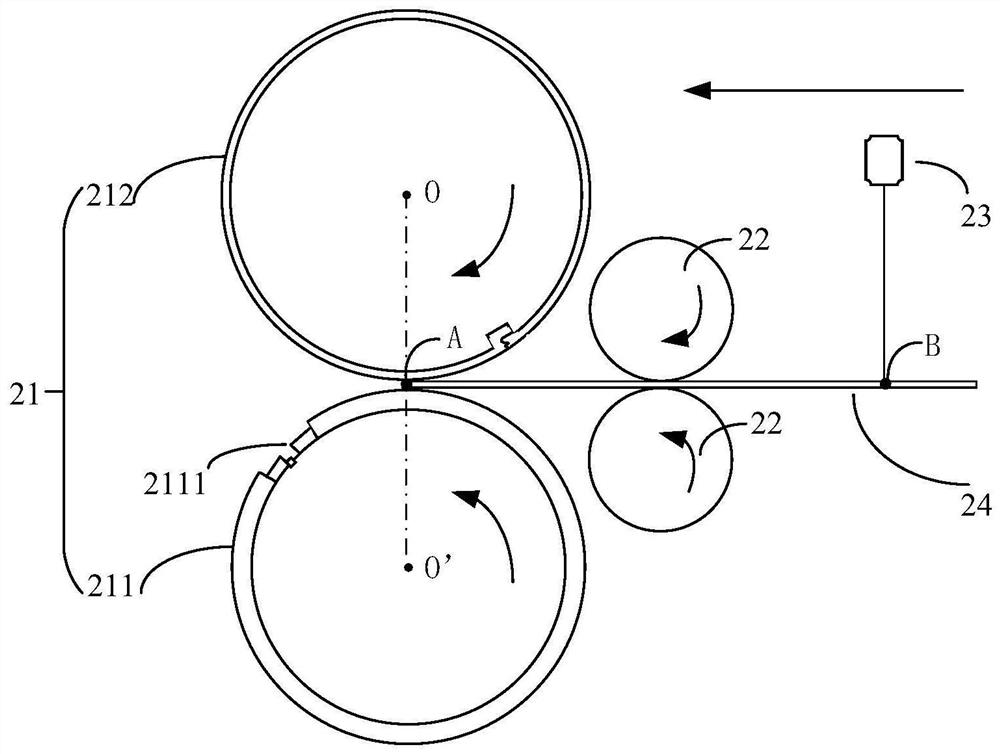

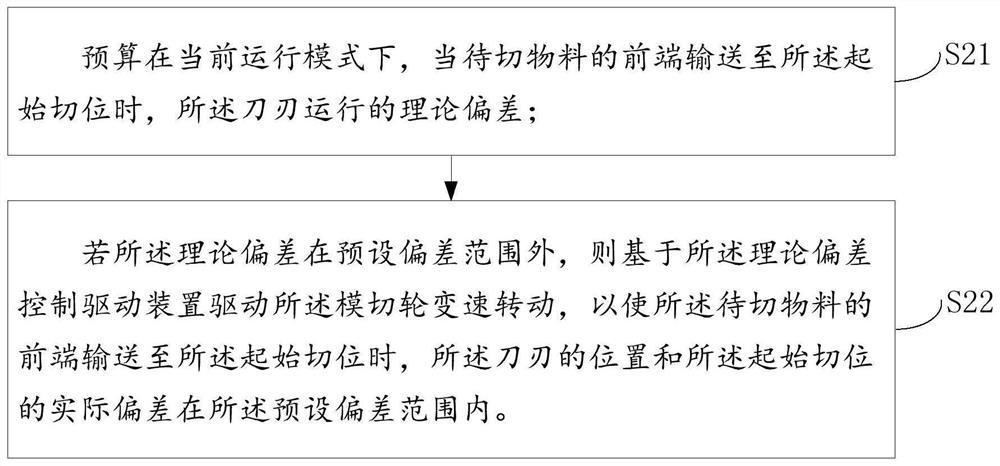

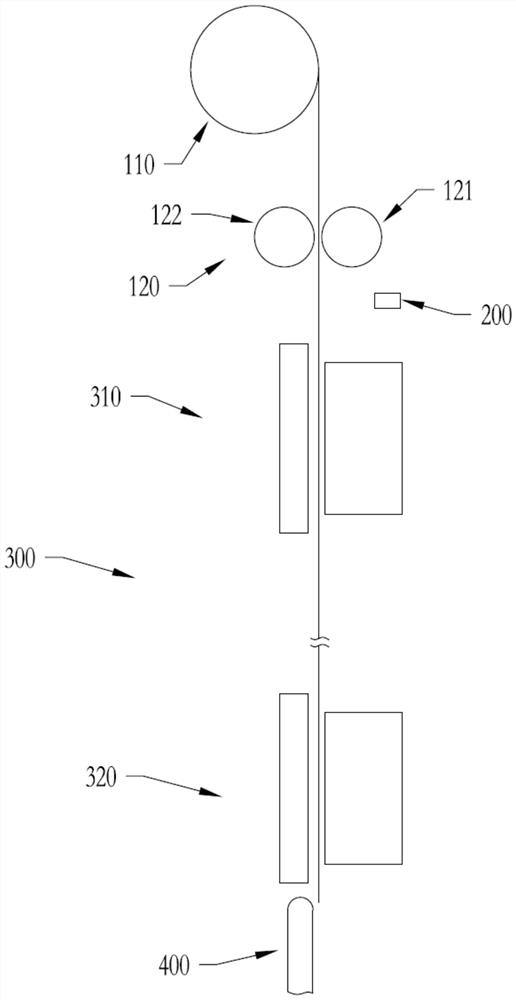

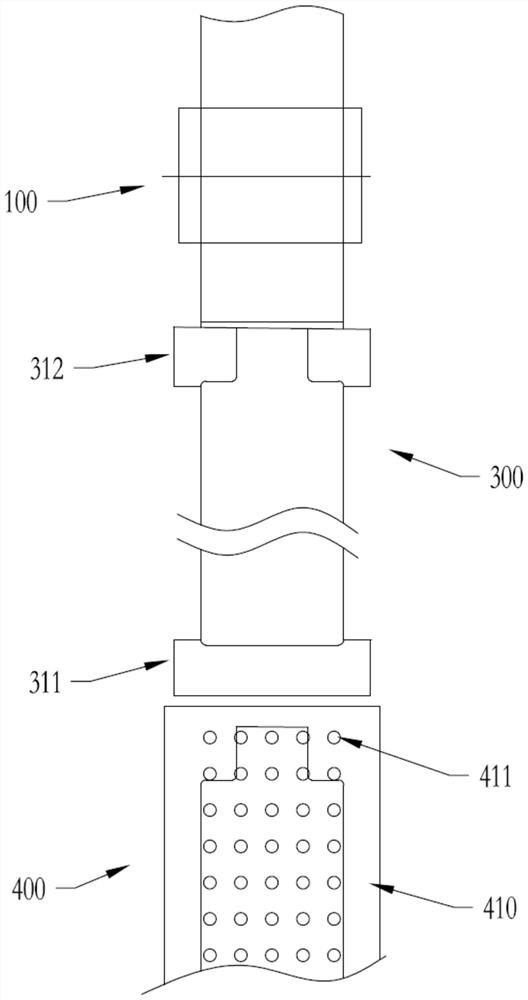

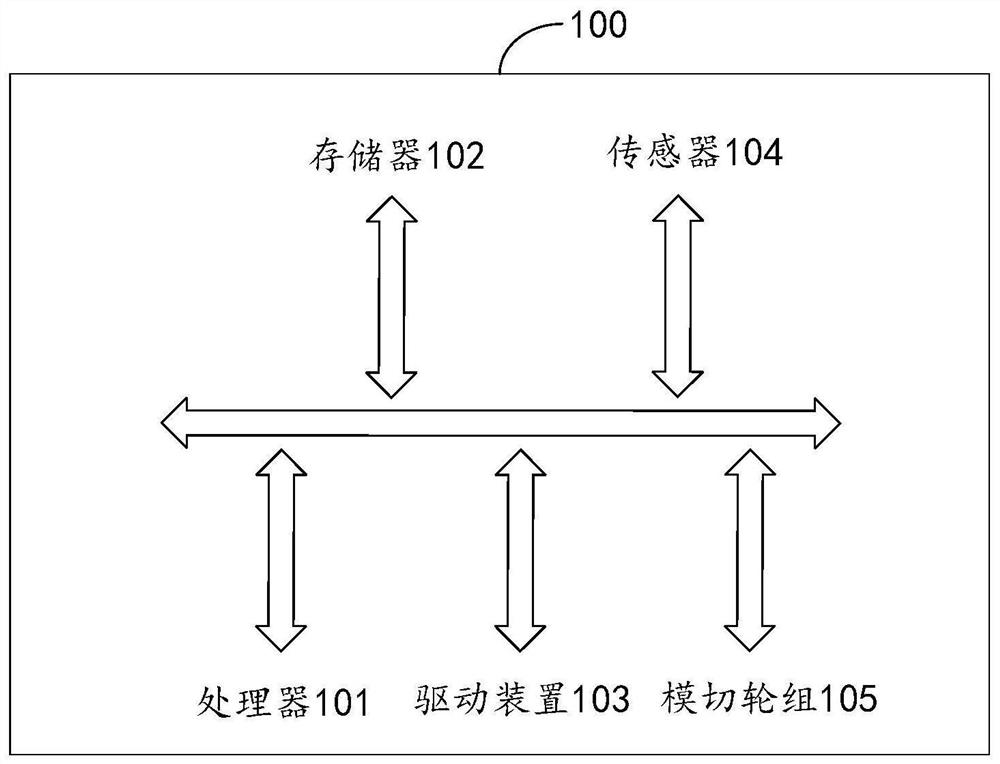

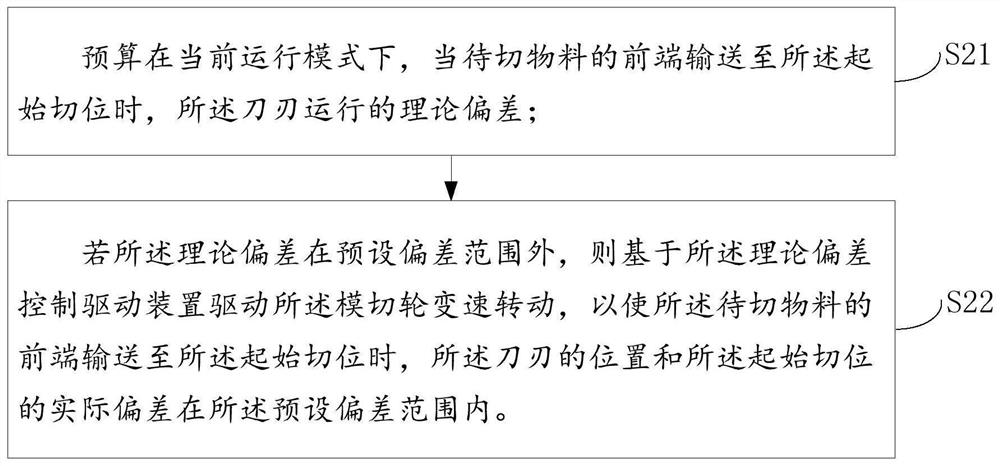

Position correction method, die cutting method, position correction device and die cutting machine

The invention relates to the technical field of die cutting, in particular to a position correction method, a die cutting method, a position correction device and a die cutting machine. According to the position correction method, the die cutting method, the device and the die cutting machine provided by the embodiment, theoretical deviation of a blade of a cutter arranged on a die cutting wheel relative to operation of the front end of a material to be cut when the front end of the material to be cut is conveyed to an initial cutting position in the current operation mode can be estimated; and if the estimated theoretical deviation is out of a preset deviation range, a driving device is controlled to drive the die cutting wheel to rotate at a variable speed based on the theoretical deviation, so that when the front end of the material to be cut is conveyed to the initial cutting position, actual deviation between the position of the blade and the initial cutting position is within the preset deviation range. Therefore, according to the embodiment, the blade and the front end of the material to be cut can reach the initial cutting position at the same time by controlling the variable speed motion of the die cutting wheel, so that the die cutting precision is improved.

Owner:SHENZHEN HANDWAY IND DIGITAL EQUIP CO LTD

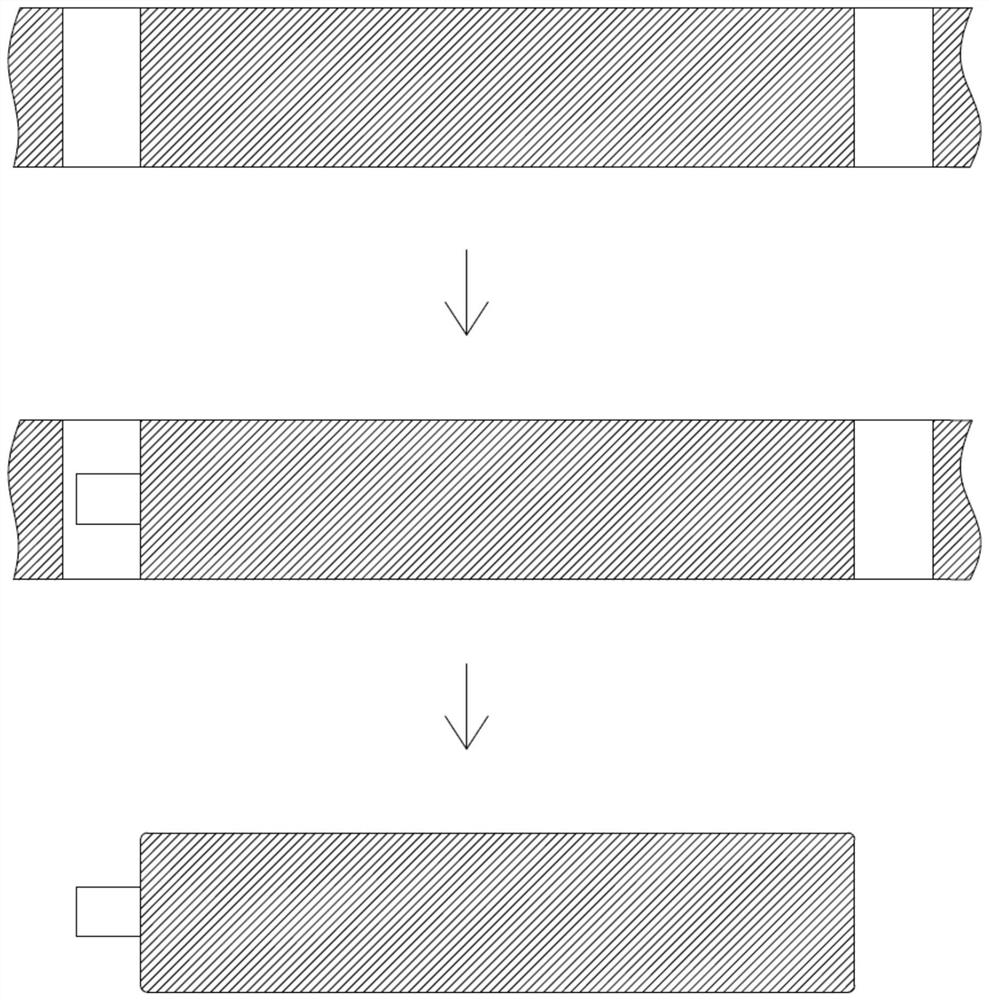

Tab die cutting method for inter-coating pole piece

ActiveCN112692152AImprove die-cutting efficiencyImprove die-cutting accuracyMetal-working feeding devicesMetal working apparatusPole pieceMechanical engineering

The invention relates to the technical field of pole piece die cutting, in particular to a tab die cutting method for an inter-coating pole piece. A material guide assembly used for pulling an inter-coating pole piece roll material, a detection assembly used for detecting the inter-coating position of the inter-coating pole piece, a die cutting assembly used for carrying out die cutting on the inter-coating pole piece introduced by the material guide assembly, and a discharging assembly used for pulling and conveying the die-cut pole piece are involved in the tab die cutting method. According to the tab die cutting method, a large-compaction-density process can be adopted, so that the capacity of a single battery cell is improved; a large-size cutter mechanism is omitted, so that dust and burrs are reduced, the quality of the pole piece is effectively improved, and the safety performance of a battery is improved; and the large-size cutter mechanism is omitted, so that the use cost of equipment is remarkably reduced, thereby greatly reducing the manufacturing cost of a battery cell.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

Composite and multi-station full-die-cutting ultrahigh-frequency tag antenna machining equipment and method

PendingCN111185961AReduce pollutionDoes not affect the processing effectPretreated surfacesCoatingsTag antennaElectronic tagging

The invention provides composite and multi-station full-die-cutting ultrahigh frequency tag antenna machining equipment and method, and relates to an ultrahigh frequency tag antenna. An antenna body is provided with a chip binding positioning point formed in a die cutting mode and a chip binding point formed in the die cutting mode. A second base material layer or a first base material layer and the second base material layer are pasted on one side of an antenna layer of the antenna body. The machining equipment is characterized by comprising a first die cutting mechanism, a second die cuttingmechanism and a traction mechanism. The machining equipment and method solve the problem of, in the prior art, 1, how to avoid the problem of using an etching process to produce a chip binding pointand a chip binding positioning point of an ultra-high frequency electronic tag antenna; 2, how to completely avoid the use of an etching process in the production process of the ultra-high frequency electronic tag antenna; 3, how to prevent the antenna layer from shifting during movement or driving in the machining process; and 4, how to help the antenna layer to move or drive better while maintaining the tension.

Owner:黄光伟

A satellite-type circular pressing circular die-cutting device

The invention relates to a satellite type column-to-column rotary die cutting device. The device includes an equipment main frame, an electrical cabinet, a gas expansion shaft and a console; the back side of the equipment main frame is provided with the electrical cabinet, an outer ring of the front side of the equipment main frame is provided with the gas expansion shaft, and the console is installed on the equipment main frame; the device is characterized by further comprising a deviation correcting device, a front auxiliary workstation, a satellite type column-to-column workstation and a rear auxiliary workstation; the front side of the equipment main frame is provided with the deviation correcting device, the front auxiliary workstation, the satellite type column-to-column workstation and the rear auxiliary workstation in sequence from left to right. The device has the advantages of being scientific and reasonable in structure design, high in processing efficiency, high in die cutting precision, high in process yield, low in die cutting cost, stable in operation, safe, reliable, capable of conducting function extension and saving space and easy to achieve, and is a highly innovative satellite type column-to-column rotary die cutting device.

Owner:中融飞腾(北京)科技有限公司

Composite and multi-station full-die-cutting ultrahigh-frequency antenna processing device and method

PendingCN111275155AReduce pollutionDoes not affect the processing effectLiquid surface applicatorsLamination ancillary operationsTag antennaElectronic tagging

The invention provides a composite and multi-station full-die-cutting ultrahigh-frequency antenna processing device and method. An antenna body of an ultrahigh-frequency tag antenna is provided with achip binding positioning point formed in a die cutting mode and a chip binding point formed in a die cutting mode. The processing equipment is characterized by comprising a first die cutting mechanism, a second die cutting mechanism and a floating roller device. The invention solves the following problems in the prior art: 1, problems in the prior art are solved; the problem of how to produce a chip binding point and a chip binding positioning point of an ultrahigh-frequency electronic tag antenna by using an etching process is solved. Problem 2: how to completely avoid the application of anetching process in the production process of the ultrahigh frequency electronic tag antenna. 3, how to prevent the position of the antenna layer from deviating during movement or transmission in the machining process; 4, how to help the antenna layer to better move or transmit while maintaining tension; and 5, how to help the chip binding point and the chip binding positioning point to be accurately machined.

Owner:黄光伟

Automatic rotating die-cutting machine

The invention discloses an automatic rotating die-cutting machine. The automatic rotating die-cutting machine comprises a mounting rack; a plurality of die-cutting stations are sequentially mounted onthe mounting rack; a plurality of winding and unwinding shafts are sequentially disposed on the mounting rack around the die-cutting stations; each winding and unwinding shaft is driven through a motor to rotate; an automatic deviation rectification device which rectifies deviation of the die-cutting process is further disposed at one end of the mounting rack; die-cutting cutters are connected with die-cutting motors; the die-cutting motors are connected with a control switch; and upper auxiliary shafts used for material winding and unwinding are mounted on the upper portion of the mounting rack. Unwinding and winding are driven through the motors, and then the whole unwinding and winding action is finished; the die-cutting stations are disposed in the middle, the die-cutting cutters on the die-cutting stations are cylindrical die-cutting cutters, and die-cutting of different products is achieved by replacing the die-cutting cutters on the different die-cutting stations; and the automatic deviation rectification device is used for calibrating the unwinding process during material unwinding, so that reject products caused by material deviation are avoided and then the ratio of qualified products is increased.

Owner:SHENZHEN HADESHENG PRECISION TECH

A position correction method, a die cutting method, a position correction device and a die cutting machine

Owner:SHENZHEN HANDWAY IND DIGITAL EQUIP CO LTD

Flat pressing die cutting machine

InactiveCN106799772APrevent deviation from movementImprove die-cutting accuracyMetal working apparatusWebs handlingEngineeringMechanical engineering

The invention provides a flat pressing die cutting machine which comprises a rack. Rollers are arranged on the rack. The rack is further sequentially provided with a straightening mechanism and a die cutting mechanism. The straightening mechanism comprises side supporting plates which are oppositely arranged on the two sides of the rack. The side supporting plates are in threaded connection with drive rods. The front ends of the drive rods are rotationally connected with straightening blocks. The die cutting mechanism comprises side supports oppositely arranged on the two sides of the rack, and a moving plate and a fixed plate which are correspondingly arranged are arranged at the upper portion and the lower portion of the interior of each side support. An upper roller is rotationally connected between the moving plates, and a lower roller is rotationally connected between the fixed plates. The flat pressing die cutting machine has the beneficial effects that a die cut piece material is prevented from running leftwards and rightwards, and the die cutting accuracy is improved.

Owner:TIANJIN WANGUO POLYMER MATERIALS CO LTD

Automatic control method and system for sheet conveying

The invention provides an automatic control method and system for sheet conveying, a detection unit matched with a conveying belt to work is arranged between a feeder part and a gripper edge of a gripper bar, and the detection unit is used for detecting whether a sheet reaches the position or not; the distance between the detection unit and the input end of the conveying belt is a known fixed value; the conveying belt provides power through a servo motor, the actual operation angle of the servo motor is collected from the time when a sheet enters the input end of the conveying belt to the time when a detection unit detects a sheet signal, the angle is converted into longitudinal displacement to serve as a theoretical displacement value, a fixed value is compared with the theoretical displacement value, and a difference value is obtained; and the servo motor is adjusted based on the difference value. According to the automatic control method and system for sheet conveying, the adjusting effect can be achieved without adjusting a mechanical structure, meanwhile, the paper feeding effect of each sheet can be adjusted in real time, the die cutting precision is improved, alarms are reduced, and the production efficiency is improved.

Owner:MASTERWORK GROUP CO LTD

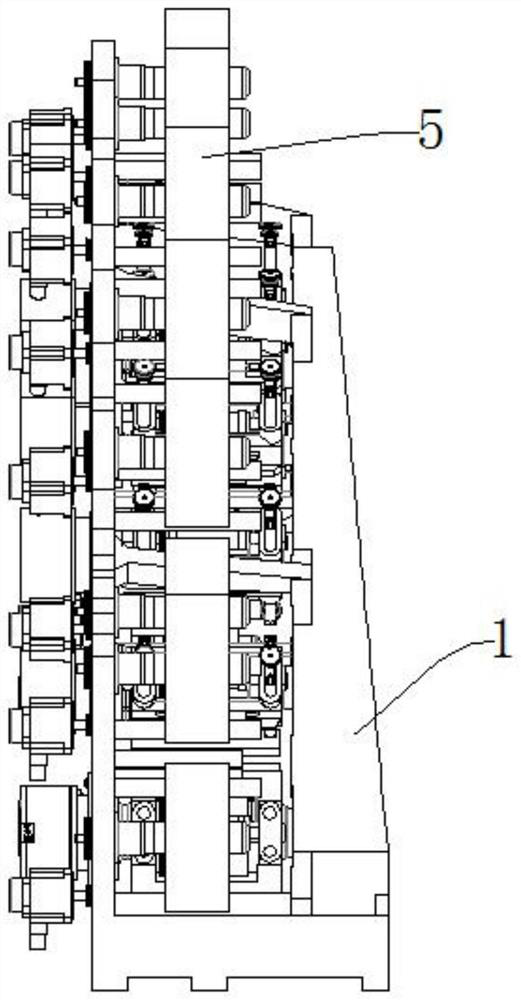

Roller type tool apron

PendingCN112895005AImprove convenienceAchieve axial adjustmentMetal working apparatusLinear motionDevice Plate

The invention discloses a roller type tool apron which comprises a roller type tool apron body and rib plates, a flange plate is installed at one end of the roller type tool apron body, a guide rod installation hole is formed in the roller type tool apron body, a guide rod is installed in the guide rod installation hole, and stepped grooves and screw holes are formed in the upper side and the lower side of the roller type tool apron body. According to the roller type tool apron, the exterior of the roller type tool apron is of a cylindrical structure, and the roller type tool apron is installed in an installation hole of a die-cutting machine base equipment plate and can do rotary motion and axial linear motion, so that a lower tool shaft can be conveniently rotated to the upper portion to be installed, the tool installation convenience is improved, and overall axial adjustment of a tool apron assembly is achieved. The adjustment and alignment convenience and accuracy of tools of the tool apron assemblies are improved. Eight installation holes are machined in the tool apron body and used for installing guide rods and guaranteeing accurate positioning of a tool shaft sliding block, so that the installation accuracy of a tool shaft is improved, and due to the fact that the tool apron is an integrally-machined part, the installation accuracy of a motor and a speed reducer can be improved.

Owner:廊坊纽特科技有限公司

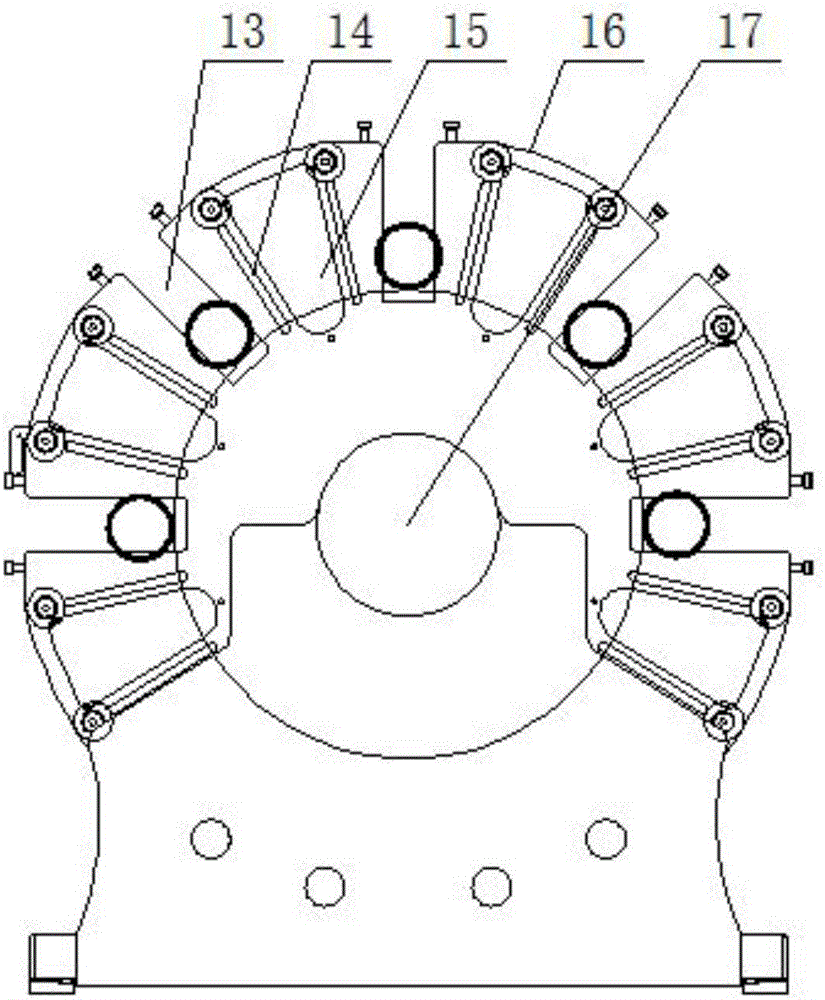

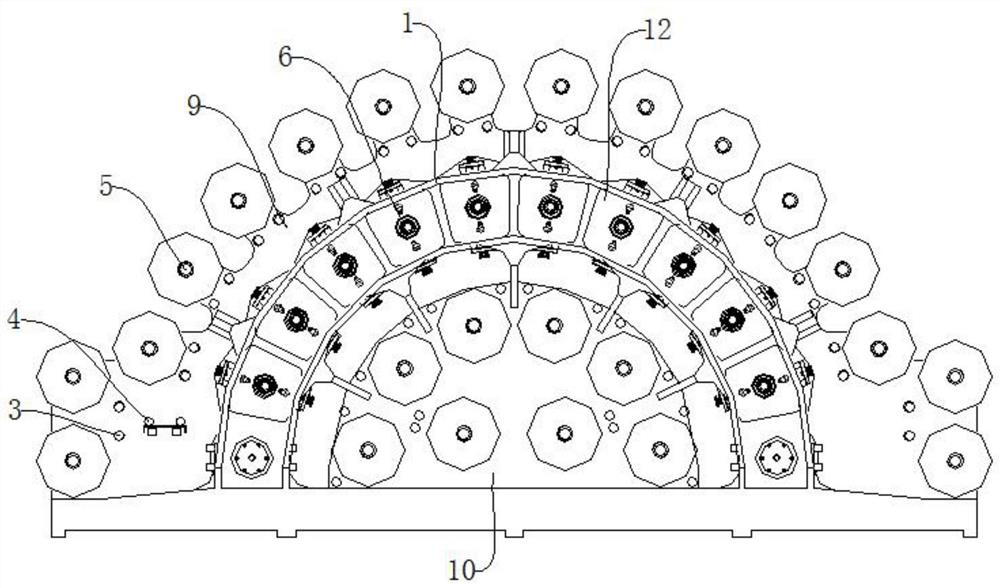

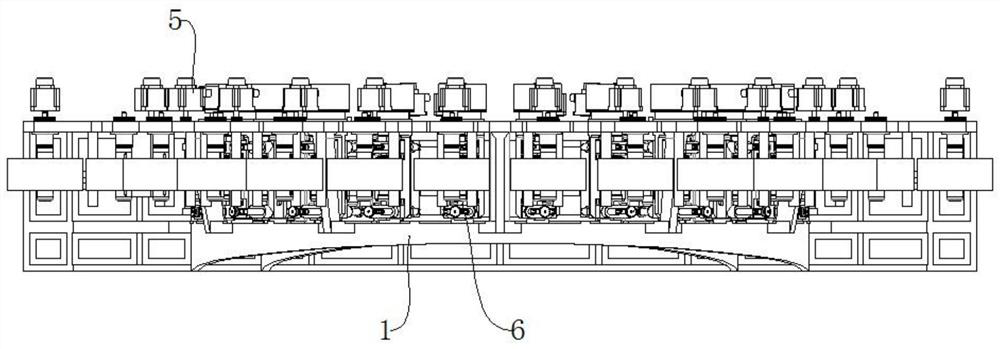

Die-cutting machine with tool aprons arranged in arc shape

PendingCN112917578AAvoid disturbanceMovement speed is stableMetal working apparatusStructural engineeringDevice Plate

The invention discloses a die-cutting machine with tool aprons arranged in an arc shape. The die-cutting machine comprises an arc-shaped base, roller type tool apron assemblies, traction roller assemblies, guide shafts and a deviation rectifying mechanism, an arc-shaped base front equipment plate and an arc-shaped base rear equipment plate are both installed on the front face and the back face of the arc-shaped base through bolts, the roller type tool apron assembly is installed on the arc-shaped base front equipment plate, the traction roller assemblies are installed on two sides of the bottom edge of the arc-shaped base, the guide shafts are installed at corners of two sides of a rear equipment plate outer ring vertical plate, and the deviation rectifying mechanism is installed on one side of the rear equipment plate outer ring vertical plate. According to the die-cutting machine with the tool aprons arranged in the arc-shaped mode, the roller type tool apron assemblies are distributed and installed on the arc-shaped base in the arc-shaped mode, a material belt is wound around bottom rollers of the roller type tool apron assemblies, a fixed wrap angle is formed, disturbance of a cutting edge on a cutter shaft to the material belt can be avoided, the stability of the movement speed of the material belt is guaranteed, and therefore, the die-cutting precision of products is improved.

Owner:廊坊纽特科技有限公司

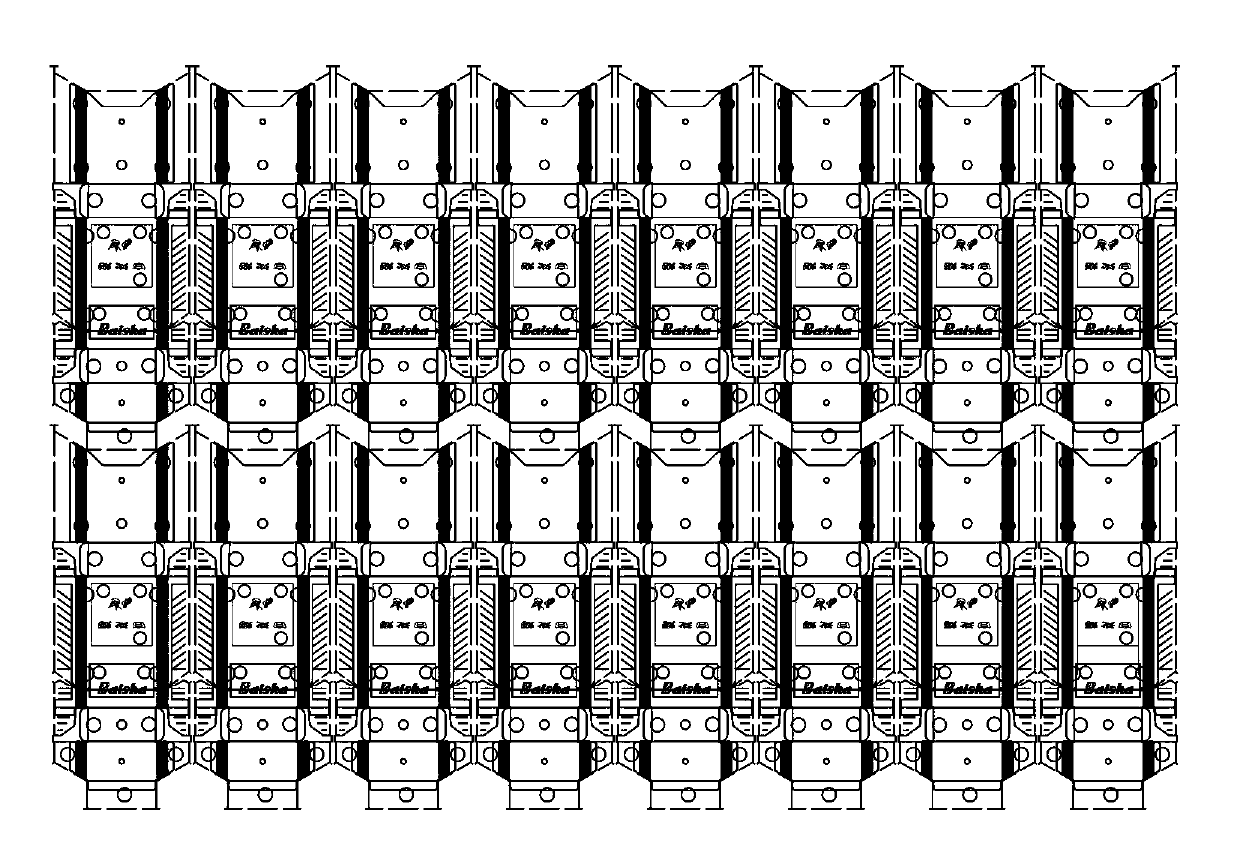

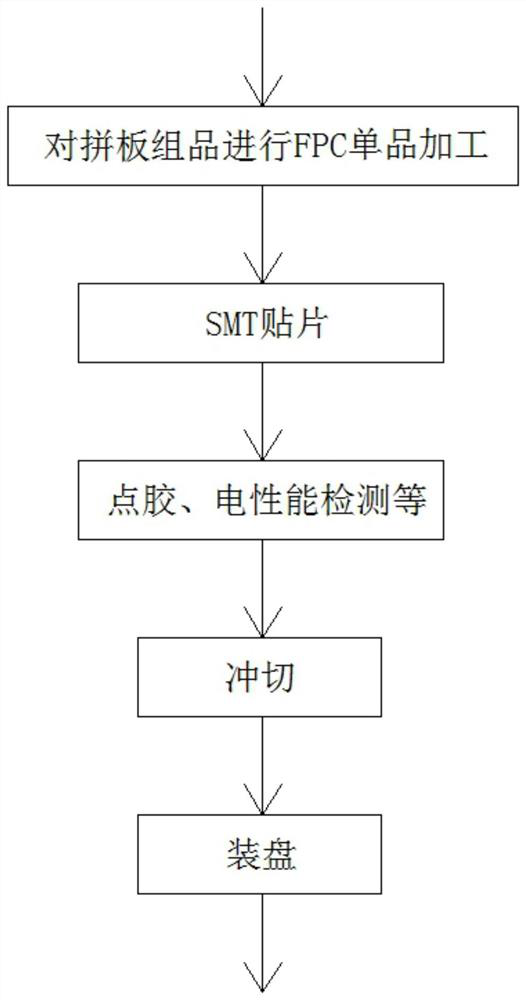

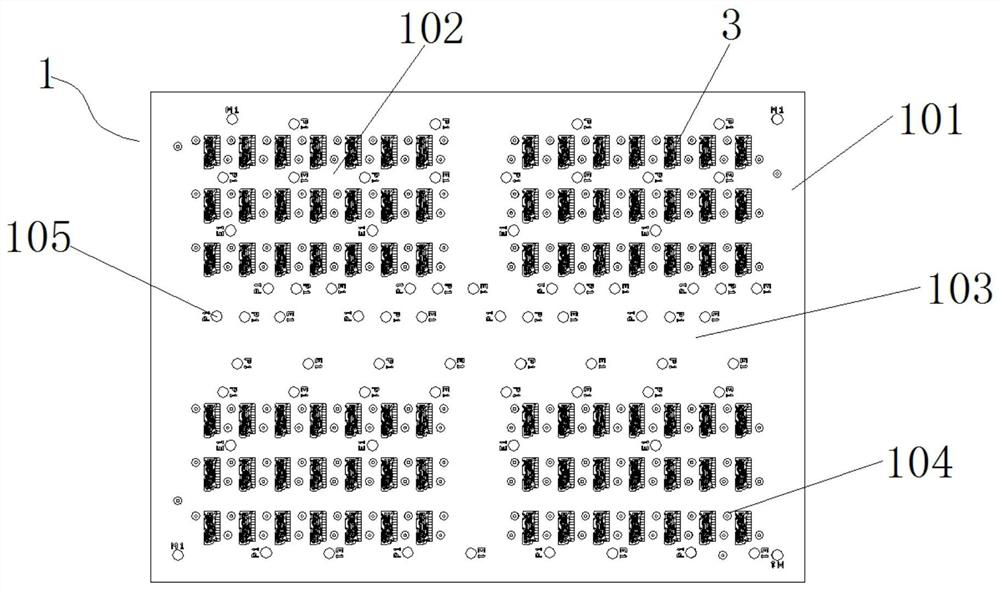

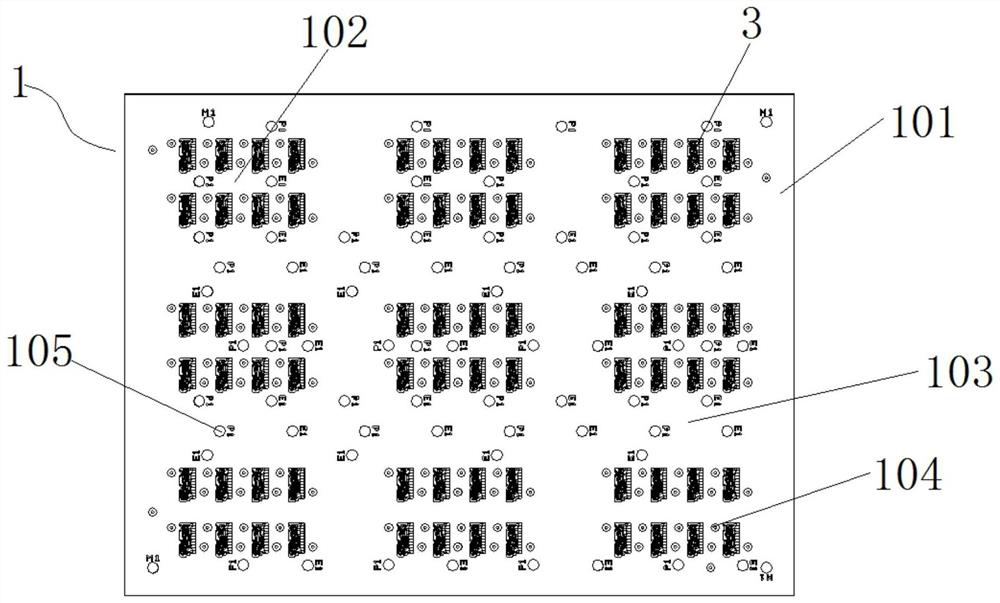

High-precision forming method of vcm flexible circuit board

ActiveCN111712043BHigh strengthFlatness is not affectedInsulating layers/substrates workingFlexible circuitsProcess engineering

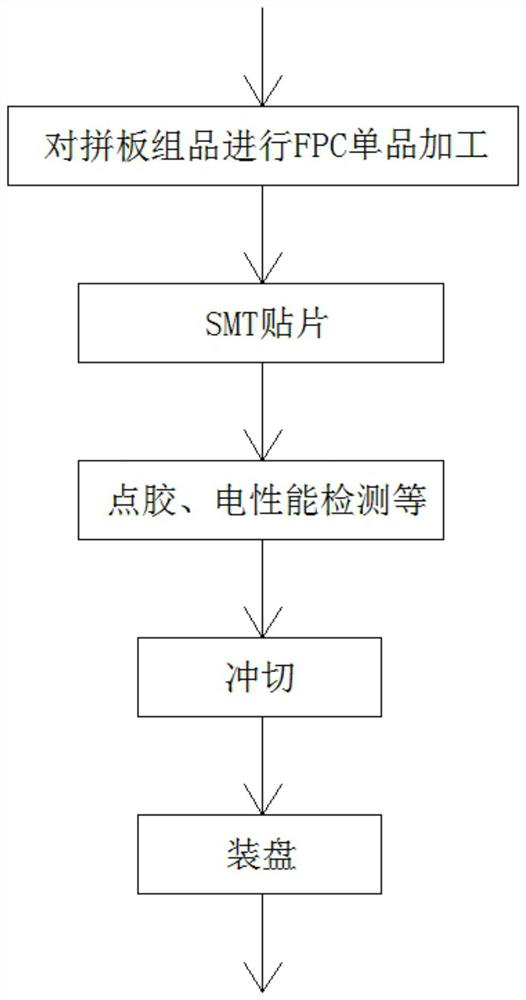

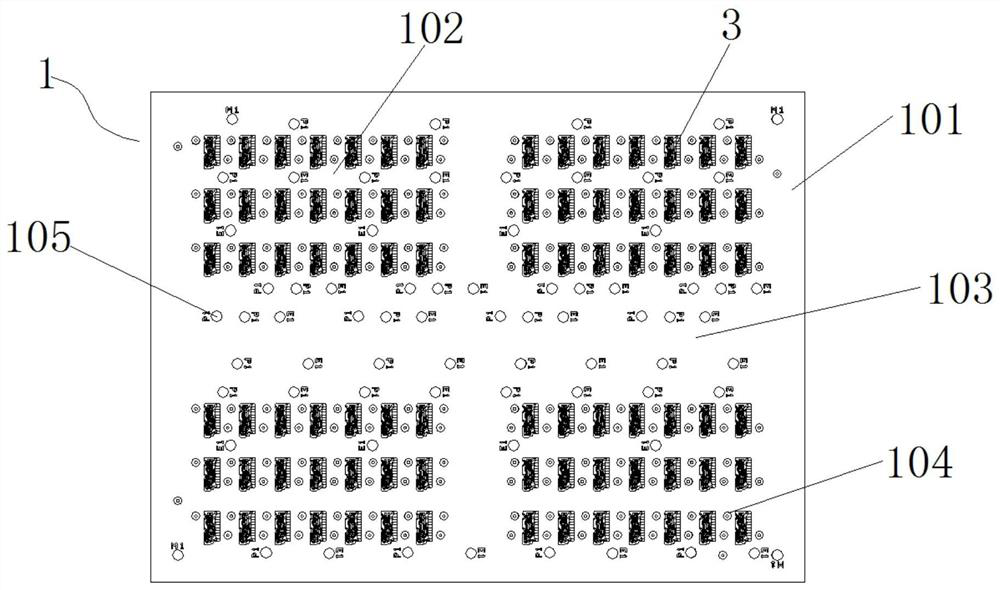

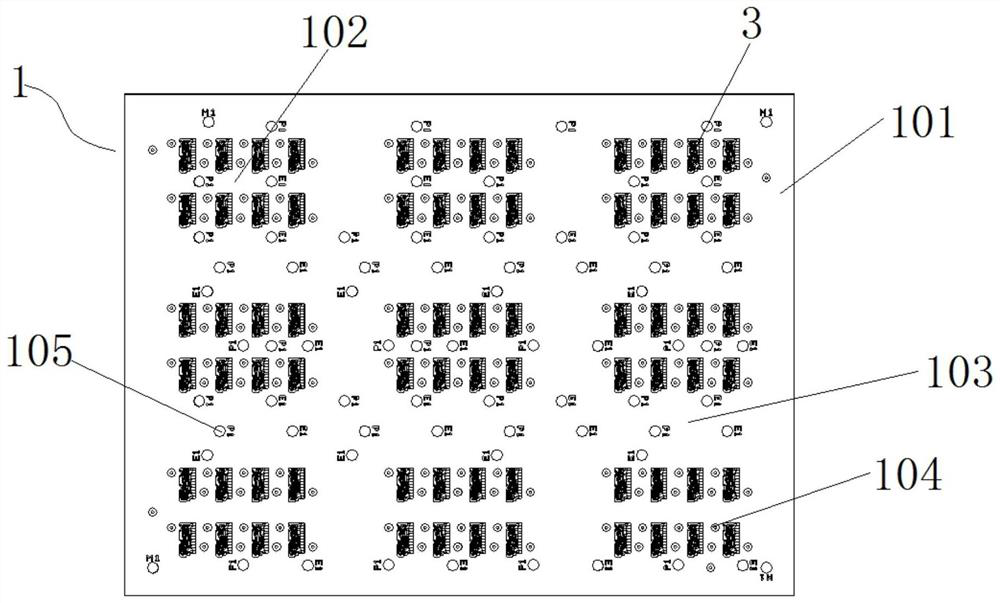

The invention discloses a high-precision forming method for a VCM flexible circuit board. The specific operation method is as follows: step 1, provide FPC flexible board assembly, and perform FPC single product processing on the FPC flexible board assembly, and the FPC flexible board assembly It includes a jigsaw body, an effective area and an invalid area are set on the jigsaw body, and there are multiple effective areas, and the multiple effective areas are arranged in a matrix, so that the invalid areas are distributed in a cross shape or a well shape, and the effective areas are There are multiple FPC items arranged in a matrix; step 2, SMT patching of multiple FPC items on the entire panel; step 3, dispensing, Electrical performance testing and other operations; step 4, punching the entire panel into a single product with a punching die; step 5, loading into a plate. The invention has the advantages of improving the dimensional accuracy of FPC processing, high die-cutting accuracy and meeting the assembly requirements of VCM components.

Owner:WUXI HAOBANG HIGH TECH CO LTD

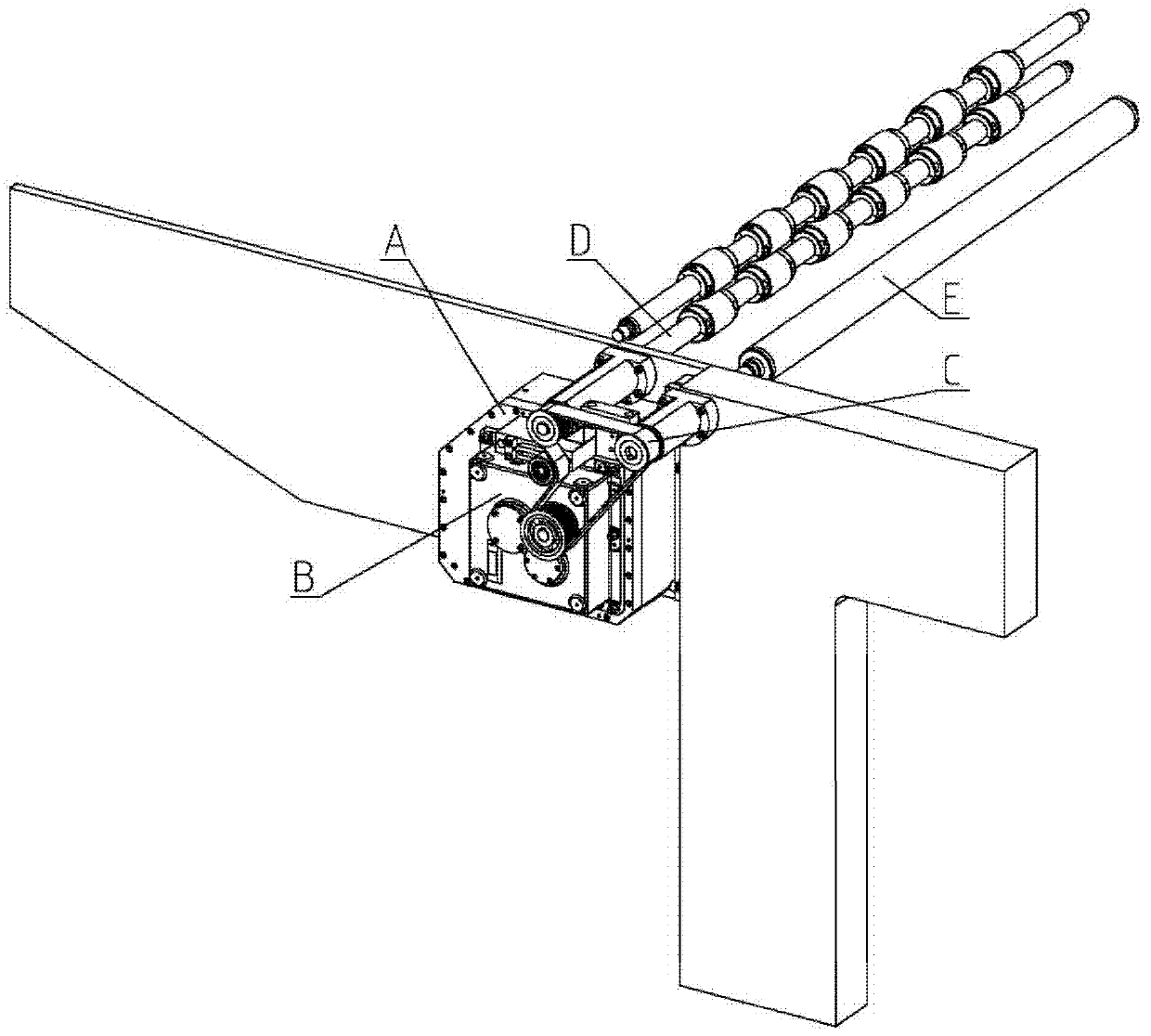

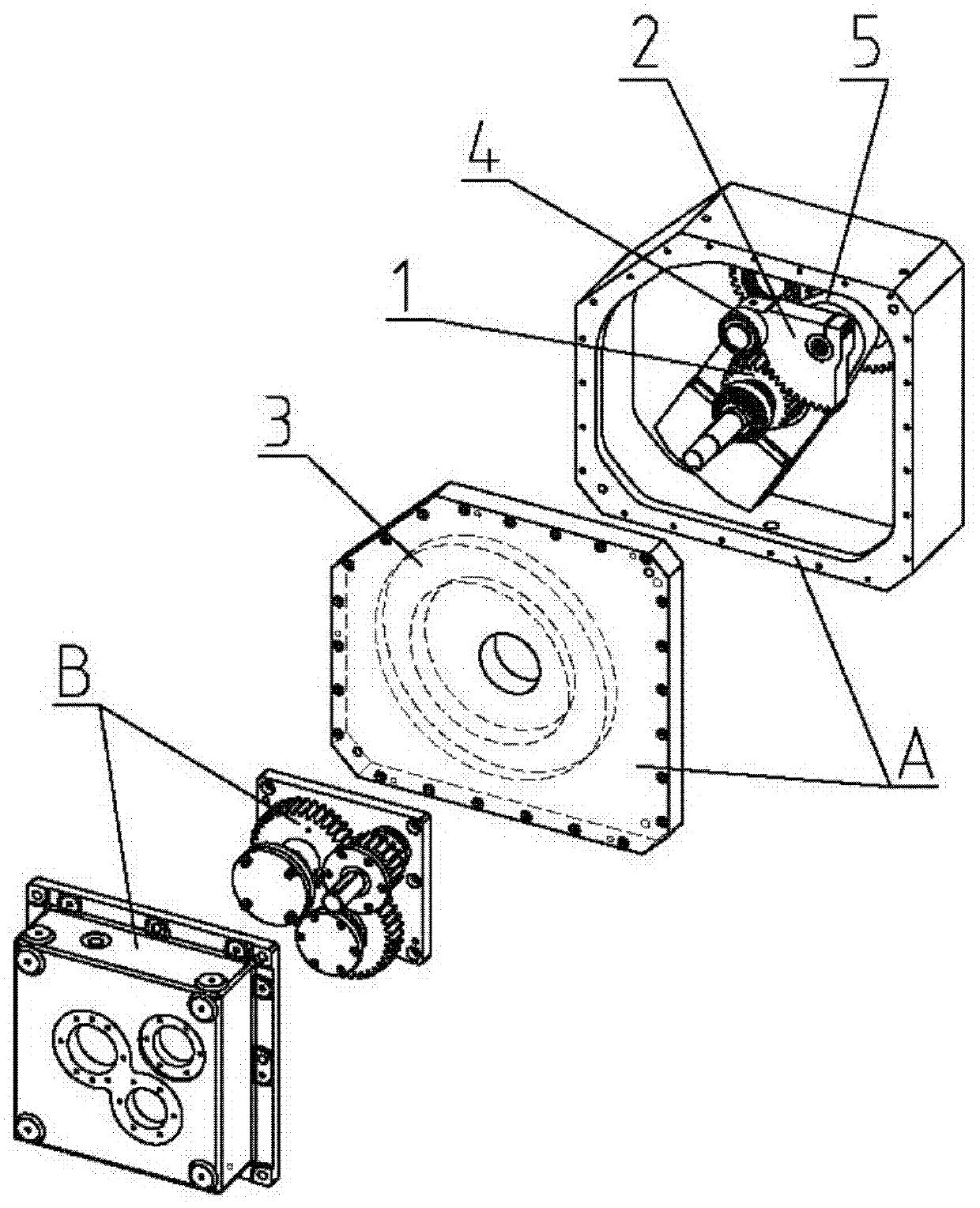

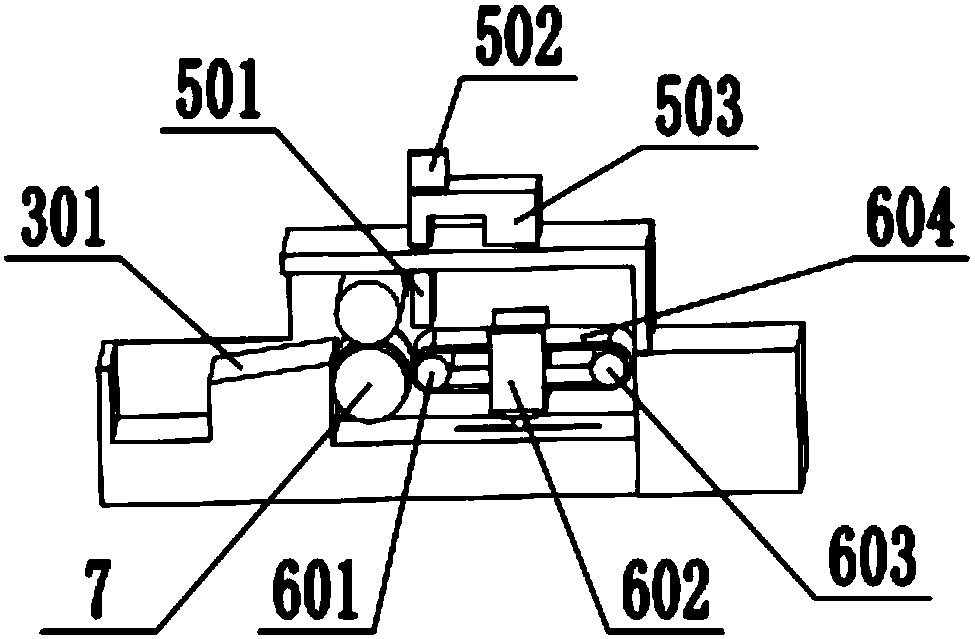

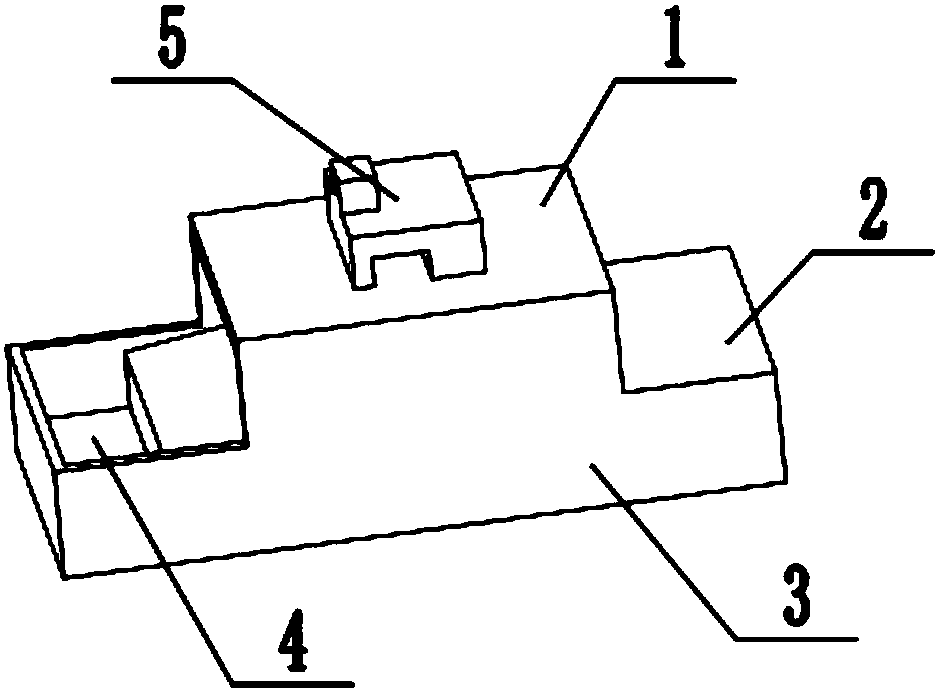

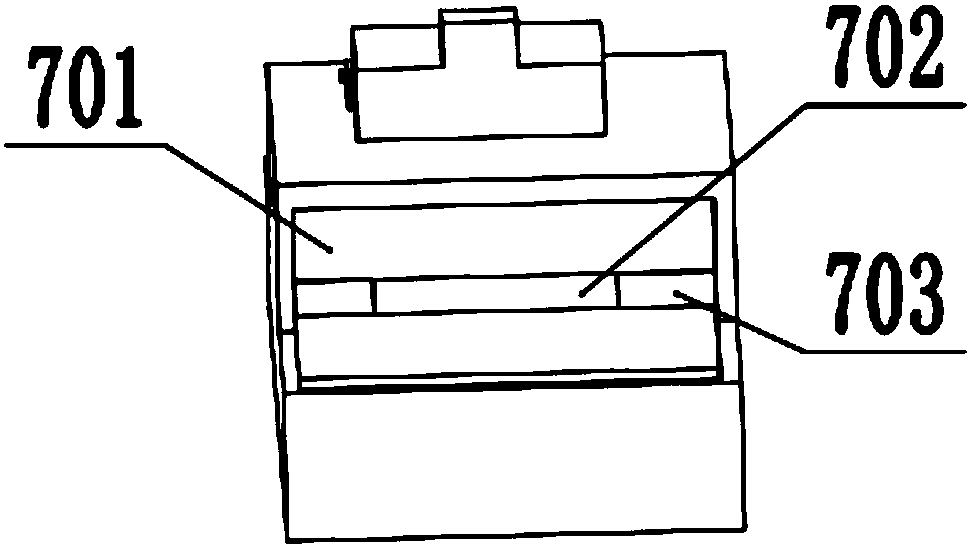

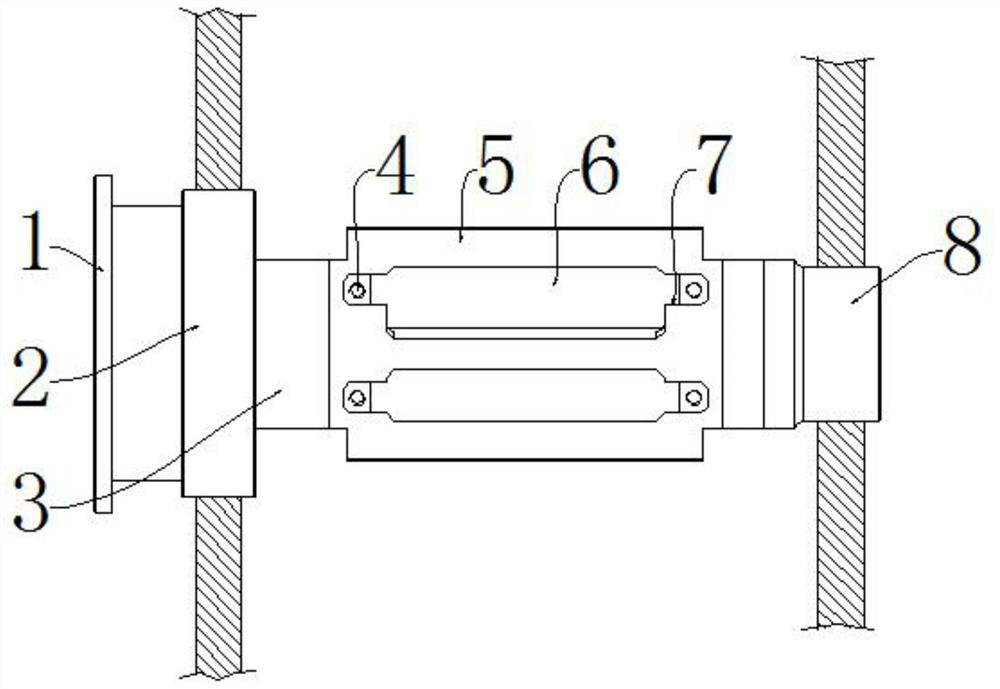

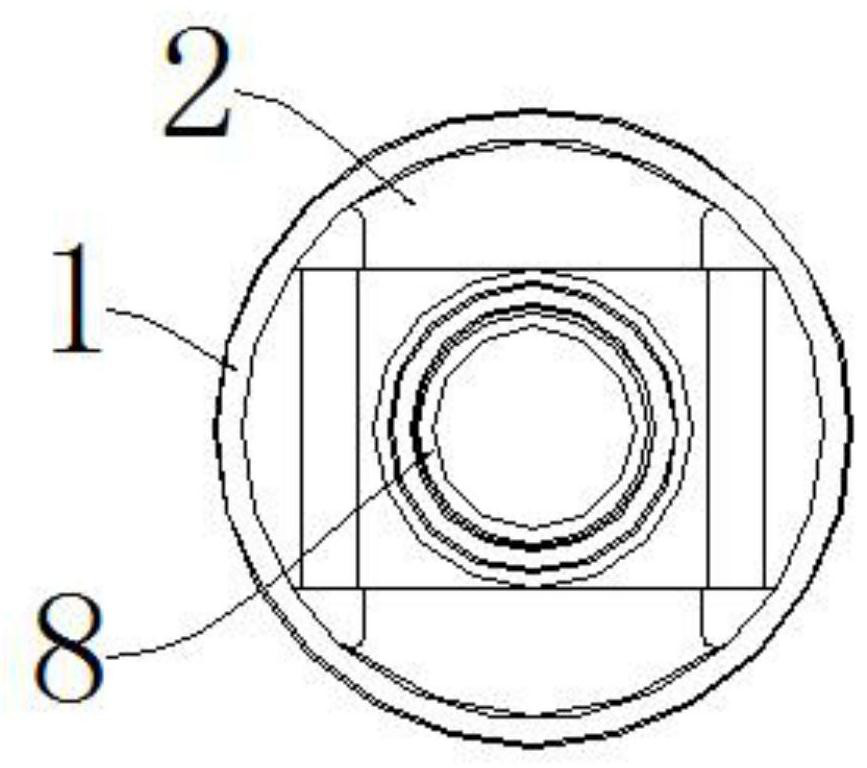

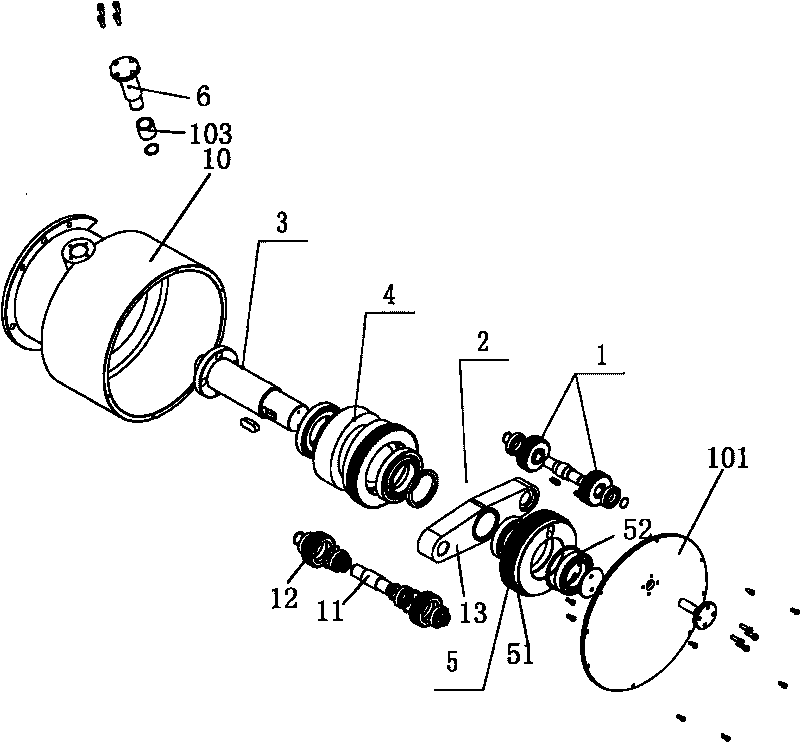

Automatic translation mechanism of die-cutting rubber pad roller

InactiveCN101712211AEasy to moveExtended service lifeBox making operationsPaper-makingGear wheelEngineering

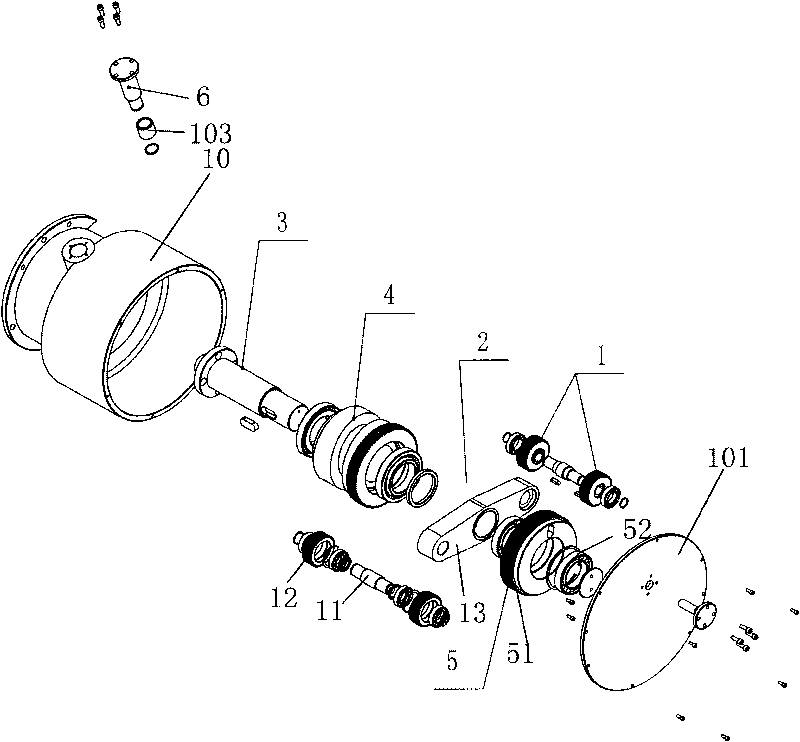

The invention discloses an automatic translation mechanism of a die-cutting rubber pad roller, comprising a planetary gear, a planet carrier, a die-cutting rubber pad roller, a movable center wheel, a fixed center wheel and a positioning shaft. The planet carrier is fixed on the die-cutting rubber pad roller; the planetary gear is mounted on the planet carrier and comprises a gear and a shaft; the fixed center wheel is provided with a cam and a separator sleeve; the planet carrier is fixed on the die-cutting rubber pad roller; and the planetary gear is mounted on the planet carrier and connected with the movable center wheel, the fixed center wheel and the positioning shaft which are assembled, mounted and fixed in a gearbox; the gear box is dustproof by a gearbox cover and is locked by the positioning shaft and the shaft sleeve. The invention has simple and practical structure and extremely convenient maintenance in the use process, balances translation by rotating the die-cutting rubber pad roller along, effectively prolongs the service life of the die-cutting rubber pad roller and improves the die-cutting precision thereof.

Owner:深圳市科发机械制造有限公司

High-precision corrugated paper die cutting device based on rigid contact

ActiveCN113400413AImprove die-cutting accuracySolve the problem that it is difficult to achieve high-precision die-cuttingMetal working apparatusStructural engineeringDie cutting

The invention discloses a high-precision corrugated paper die cutting device based on rigid contact. The high-precision corrugated paper die cutting device comprises a die cutting roller and a cushion roller which are matched with each other, a die cutting plate is installed on the die cutting roller, outwards-protruding cutter lines and pressing lines are distributed on the die cutting plate, a rigid cushion plate is installed on the cushion roller, and a plurality of die cutting grooves are distributed in the rigid cushion plate. When a corrugated board is subjected to die cutting, the cutter lines and the surface of the rigid cushion plate are correspondingly located on the upper side and the lower side of the corrugated board for die cutting operation, the pressing lines and the die cutting grooves are correspondingly located on the upper side and the lower side of the corrugated board for indentation operation, and the cutter lines and the pressing lines on the die cutting board are in rigid contact with the rigid cushion plate. The rigid cushion plate is installed on a cushion roller to replace a traditional rubber cushion roller for use, the die cutting grooves are formed in the rigid cushion plate, in the application process, on one hand, rigid contact is formed between the cutter lines and the rigid cushion plate, the phenomena of deviation, dislocation and the like of corrugated boards can be effectively avoided, on the other hand, the die cutting grooves are matched with the pressing lines, and the indentation with accurate positioning can be ensured to be formed.

Owner:GUANGZHOU KESHENGLONG CARTON PACKING MACHINE

Paper pre-stacking device and method for full-automatic die-cutting machine

The invention relates to the technical field of post-press finishing, and particularly relates to a paper pre-stacking device and method for a full-automatic die-cutting machine. The paper pre-stacking device comprises a bottom plate, wherein a baffle plate I is in bolt connection to the top of the bottom plate; two baffle plates II are arranged at one side of the baffle plate I; a through slot is formed in the top of the bottom plate; two slide plates which are in bolt connection to the baffle plates II are arranged inside the through slot; and a transmission mechanism is arranged inside the bottom plate. According to the paper pre-stacking device disclosed by the invention, the transmission mechanism drives the two baffle plates II and the baffle plate I to arrange three sides of a paperboard, and a cylinder drives a baffle plate III to arrange the fourth side of the paperboard, so that the purpose of arranging in all directions is achieved. The device arranges the four sides of the paperboard, so that the paperboard does not deflect, and therefore, arranging precision, on the paperboard, of the device and die-cutting precision, on the paperboard, of the later period are improved; and moreover, the paperboard does not have a folding condition as a result of manual pushing, so that integrity of the paperboard is greatly improved.

Owner:GUANGDONG NEW GRAND LONG PACKING CO LTD

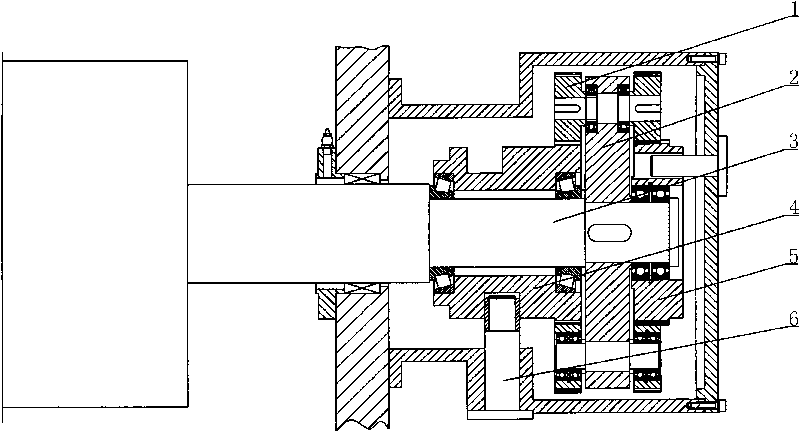

Electric pressure adjusting main machine of die cutting machine

InactiveCN110757556AImprove die-cutting accuracyVersatileMetal working apparatusEngineeringDie cutting

The invention provides an electric pressure adjusting main machine of a die cutting machine, and belongs to the field of die cutting equipment. The electric pressure adjusting main machine of the diecutting machine comprises a machine frame. A lower die holder is fixed to the machine frame and is a fixed die holder. Guide sleeves are arranged at the four corners of the lower die holder. An upperdie holder is further arranged above the lower die holder in a parallel mode, cutter die installation holes are formed in the upper die holder, and the upper die holder is fixed to four moving guide columns which are arranged in the mode of being perpendicular to the upper die holder. The moving guide columns are movably connected with the guide sleeves, and the lower ends of the moving guide columns pass through the guide sleeves and are connected to a lifting base. A left support and a right support are connected with the side of the lower die holder, bearings are fixed to the left support and the right support, and a lifting mechanism which is used for adjusting the lifting base to ascend and descend is arranged on the bearings. A pressure adjusting mechanism which is used for adjustingthe pressure of die cutting is arranged at the bottom of the lifting base, and the lifting mechanism and the pressure adjusting mechanism are connected in a transmission mode. compared with the priorart, the electric pressure adjusting main machine of the die cutting machine has the advantages that the pressure formed by a cutter to a product can be adjusted so as to guarantee the die cutting accuracy, part replacement is not required, and the universality is higher.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

Swing stem shield device for die-cutting machine

InactiveCN102975231AIt takes less time to adjust the machineSimple structureMetal working apparatusEngineeringRejection rate

The invention discloses a swing stem shield device for a die-cutting machine. A long pulling main plate is arranged on a front part between a driving face wall plate and an operating face plugging plate; the long pulling main plate is arranged on the operating face plugging plate through a second pressure-regulating screw rod; wedges are arranged on the long pulling main plate; lower shaft seats are arranged on the upper part of the wedge; upper and lower connecting shafts are arranged on the upper parts of the lower shaft seats; lower swing arms are arranged on the upper parts of the upper and lower connecting shafts; middle connecting shafts are arranged on the upper parts of the lower swing arms; upper swing arms are arranged on the upper parts of the middle connecting shafts; the upper parts of the upper swing arms are connected with upper shaft seats; and connecting rod combinations are arranged among the front and back four swing arms. The swing stem shield device for the die-cutting machine disclosed by the invention is simple in structure, and is reasonable in layout, so that the die-cutting machine has the advantages of easiness for installing as a whole, convenience in operating, high die-cutting accuracy, low time consumption on debugging, accurate die-cutting position, high accuracy and low windowing and die-cutting rejection rates.

Owner:DALIAN XINKE MACHINERY

High-precision forming method for VCM flexible circuit board

ActiveCN111712043AHigh strengthFlatness is not affectedInsulating layers/substrates workingFlexible circuitsMechanical engineering

The invention discloses a high-precision forming method for a VCM flexible circuit board. The specific operation method is as follows: step 1, providing an FPC flexible board jointed board, performingFPC single product processing on the FPC flexible board jointed board; the FPC flexible board jointed board comprising a jointed board body, a plurality of effective areas and a plurality of invalidareas being arranged on the jointed board body, the plurality of effective areas being arranged in a matrix, so that the invalid areas are distributed in a cross shape or a # shape, and a plurality ofFPC single products arranged in the matrix are arranged in the effective areas; step 2, performing SMT pasting on the plurality of FPC single products on the whole jointed board; step 3, performing operations such as dispensing and electrical property detection on the plurality of FPC components of the whole jointed board; fourthly, the whole jointed board is punched into a single product througha punching die; step 5, loading into a tray. The method has the advantages that the FPC machining size precision is improved, the die cutting precision is high, and the assembling requirement of theVCM assembly can be met.

Owner:WUXI HAOBANG HIGH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com