Automatic control method and system for sheet conveying

An automatic control system and sheet material technology, applied in the direction of object supply, pile separation, thin material processing, etc., can solve problems that affect work efficiency, cannot be solved, and die-cutting accuracy is reduced, so as to improve die-cutting accuracy and increase production efficiency , Reduce the effect of adjusting the frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

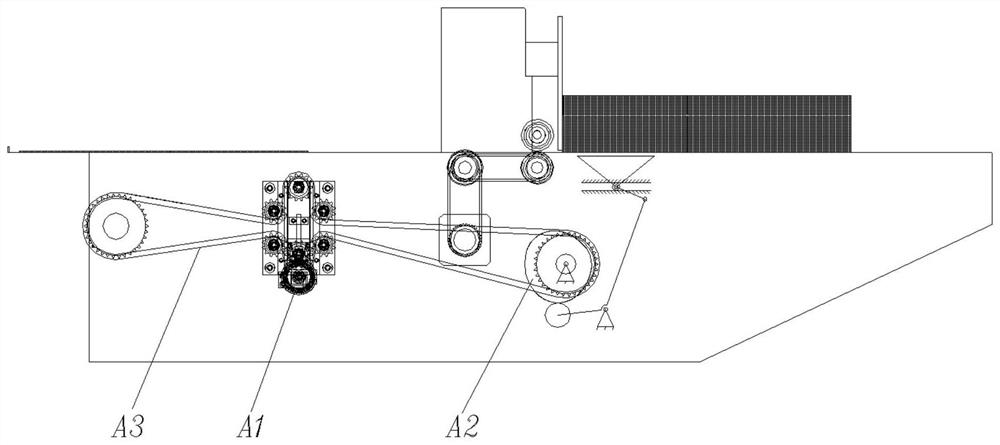

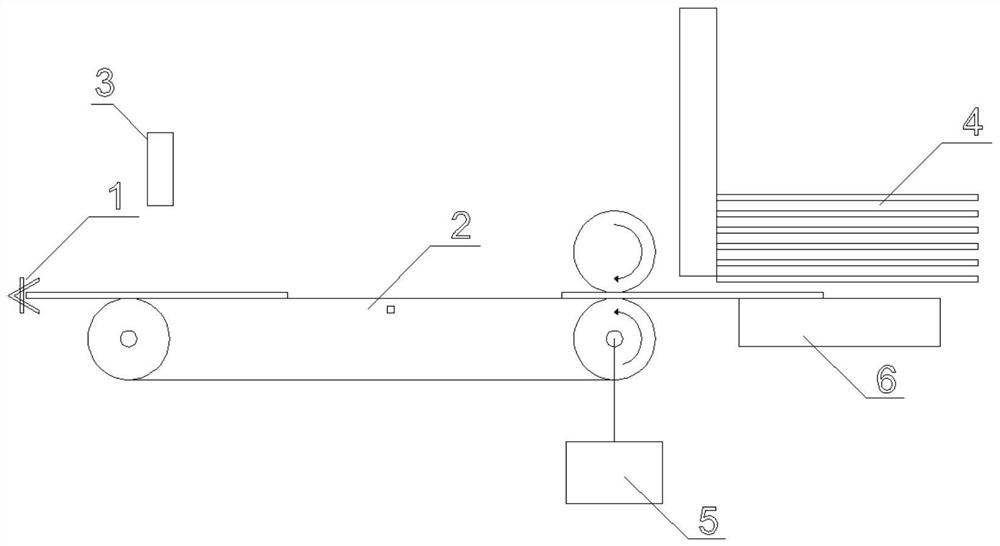

[0067] This embodiment provides an automatic control method for sheet material conveyance. A detection unit 3 that cooperates with the conveying belt 2 is provided between the feeder part 6 and the gripper 1 of the tooth row. The detection unit 3 is used to detect whether the sheet material 4 is Reach this position; the distance between the detection unit 3 and the input end of the conveyor belt 2 is a known fixed value; the conveyor belt 2 is powered by the servo motor 5, and the collection sheet 4 starts from entering the input end of the conveyor belt 2 until the detection unit 3 detects the sheet The actual running angle of the servo motor 5 between the end of the material 4 signal, convert the angle into a longitudinal displacement as a theoretical displacement value, compare the fixed value with the theoretical displacement value to obtain a difference, and adjust the servo motor 5 based on the difference.

[0068] The detection unit 3 adopts but is not limited to one or ...

Embodiment 2

[0093] This embodiment provides an automatic control system for conveying sheet 4, including:

[0094] Detection unit 3: set between the jaws 1 of the tooth row and the feeder part 6, used to detect whether the sheet 4 reaches the position;

[0095] The measuring unit is used to measure the distance between the detection unit 3 and the input end of the conveyor belt 2, and the distance is a fixed value; the measuring unit can use electronic measurement such as a laser sensor, or can use a ruler for manual measurement;

[0096] The servo motor 5 is used to provide power for the conveyor belt 2;

[0097] The main control unit is connected to the detection unit 3 and the servo motor 5, and is used to collect the actual running angle of the servo motor 5 between the sheet 4 entering the input end of the conveying belt 2 and the detection unit 3 detecting the end of the sheet 4 signal, and The angle is converted into a longitudinal displacement as a theoretical displacement value,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com