High-precision forming method for VCM flexible circuit board

A technology of flexible circuit boards and forming methods, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as low die-cutting accuracy, low dimensional accuracy, and unsatisfactory products, so as to improve die-cutting accuracy and strength , shrink the effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

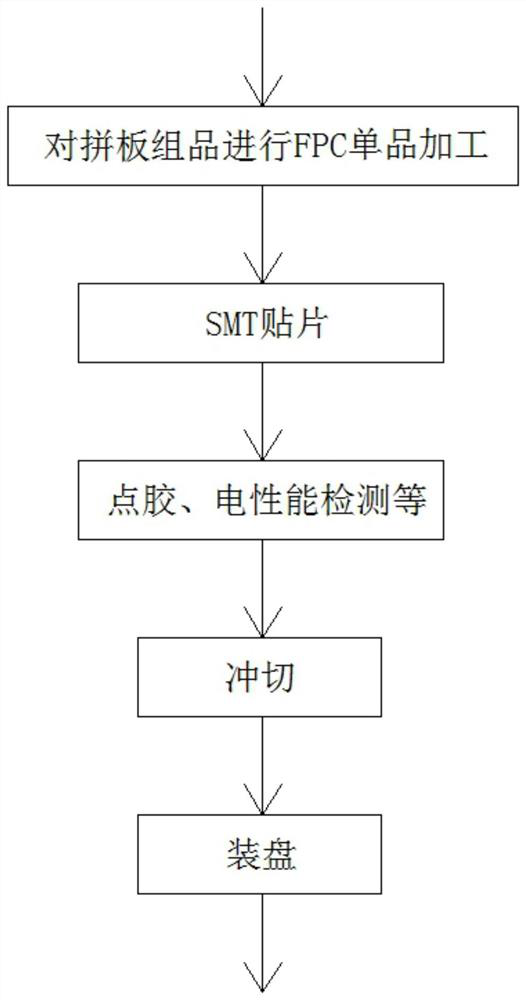

[0041] A VCM flexible circuit board high-precision forming method, the specific operation method is:

[0042] Step 1. Provide FPC flexible board assembly 1, and perform FPC single product processing on FPC flexible board assembly 1;

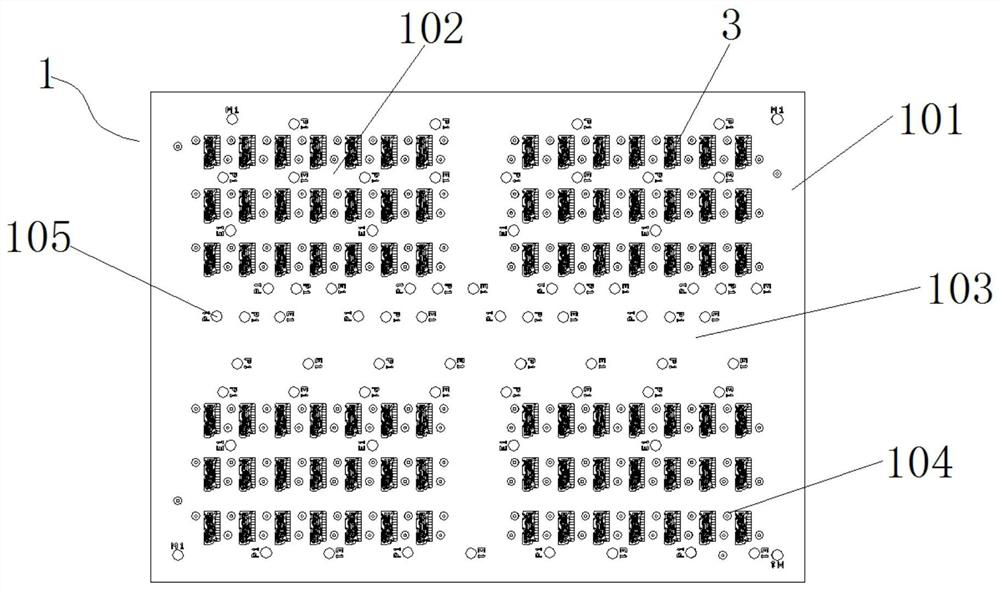

[0043] The FPC flexible board panel 1 includes a panel body 101, the panel body 101 is provided with an effective area 102 and an invalid area 103, and the effective area 102 is provided with four, and the four effective areas 102 are arranged in a matrix, The invalid area 103 is distributed in a cross shape;

[0044] A plurality of FPC items 3 arranged in a matrix are arranged in the effective area 102, and one side of the FPC items 3 is provided with an optical positioning point 104;

[0045]The invalid area 103 adopts a full-panel normal mode structure;

[0046] A plurality of positioning holes 105 are arranged in the invalid area 103;

[0047] Step 2. Perform SMT patching on multiple FPC single products on the entire FPC flexible board pan...

Embodiment 2

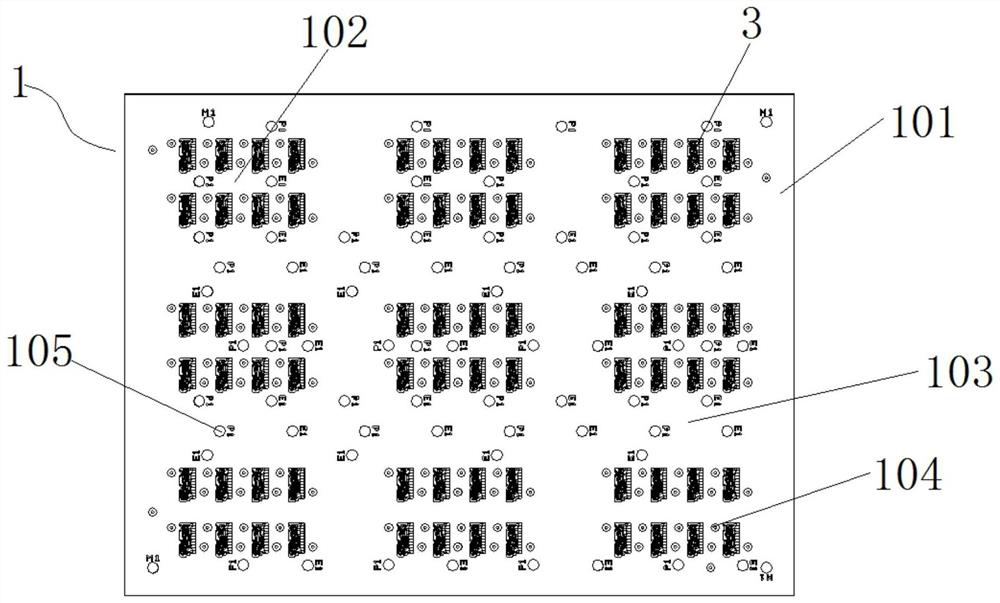

[0063] The difference between this embodiment and Embodiment 1 is that the FPC flexible board panel 1 in step 1 includes a panel body 101, and the panel body 101 is provided with an effective area 102 and an invalid area 103, and the effective area There are six 102, and the six effective areas 102 are arranged in a matrix, so that the invalid areas 103 are distributed in a well shape.

[0064] The difference between the above-mentioned FPC flexible board assembly (including six effective areas, each with 2×4 matrix-arranged FPC items) and the original FPC flexible board assembly (8×16 matrix-arranged FPC items) The comparison table of expansion and contraction coefficient and process capability index (cpk) is as follows:

[0065] Panel specification Expansion coefficient Process Capability Index 6×(2×4) ±0.029 1.4 8×16 ±0.048 0.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com