Electric pressure adjusting main machine of die cutting machine

A die-cutting machine, electric technology, applied in metal processing and other directions, can solve the problems of poor versatility of die-cutting machines, insufficient die-cutting thickness, inconvenient replacement of shaft shoulders, etc., and achieves high die-cutting accuracy and versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

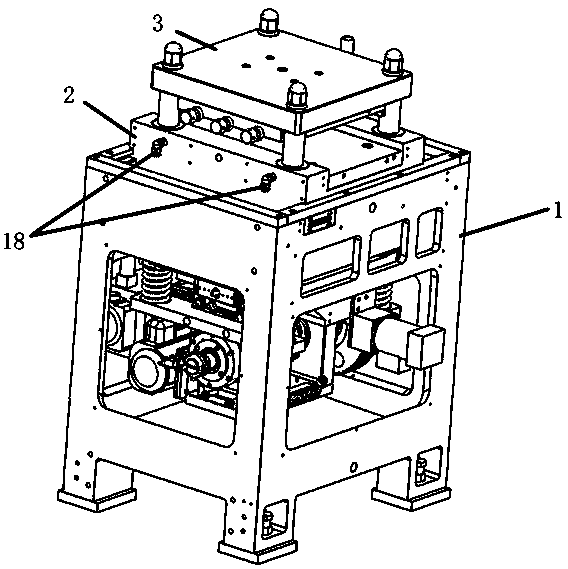

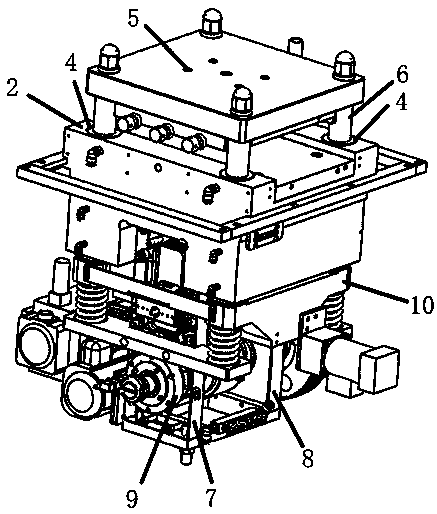

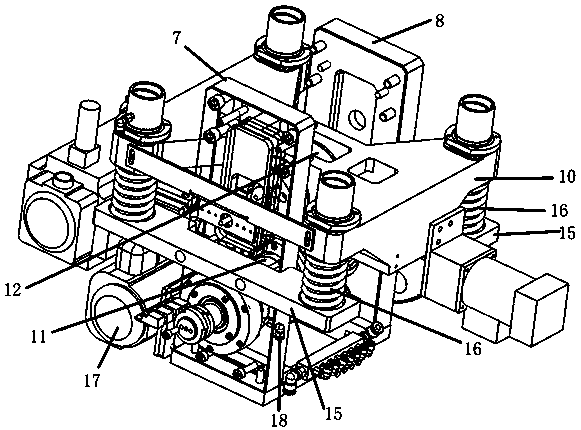

[0029] Please refer to the attached Figures 1 to 4 , the embodiment of the present invention provides an electric voltage regulating main engine of a die-cutting machine, including a frame 1, on which a lower mold base 2 is fixed, and the lower mold base 2 is a fixed mold base, and the lower mold base 2 Guide sleeves 4 are arranged on the four corners, and an upper mold base 3 is arranged parallelly above the lower mold base 2. The upper mold base 3 is a movable mold base, and the upper mold base 3 is provided with a die mounting hole 5 , the cutting die mounting hole 5 can be used to install the cutting die, the upper die base 3 is fixed on four movable guide pillars 6 vertically arranged with the upper die holder 3, the movable guide pillars 6 are movably connected with the guide sleeve 4, That is, the movable guide post 6 can move up and down in the guide sleeve 4, and the lower end of the movable guide post 6 passes through the guide sleeve 4 and is connected to the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com