Automatic translation mechanism of die-cutting rubber pad roller

A technology of traversing mechanism and die-cutting glue, applied in the field of mechanical parts, can solve the problems of fast wear of die-cutting rubber pad roller, high cost, affecting die-cutting accuracy, etc., so as to improve die-cutting accuracy, prolong service life and facilitate maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

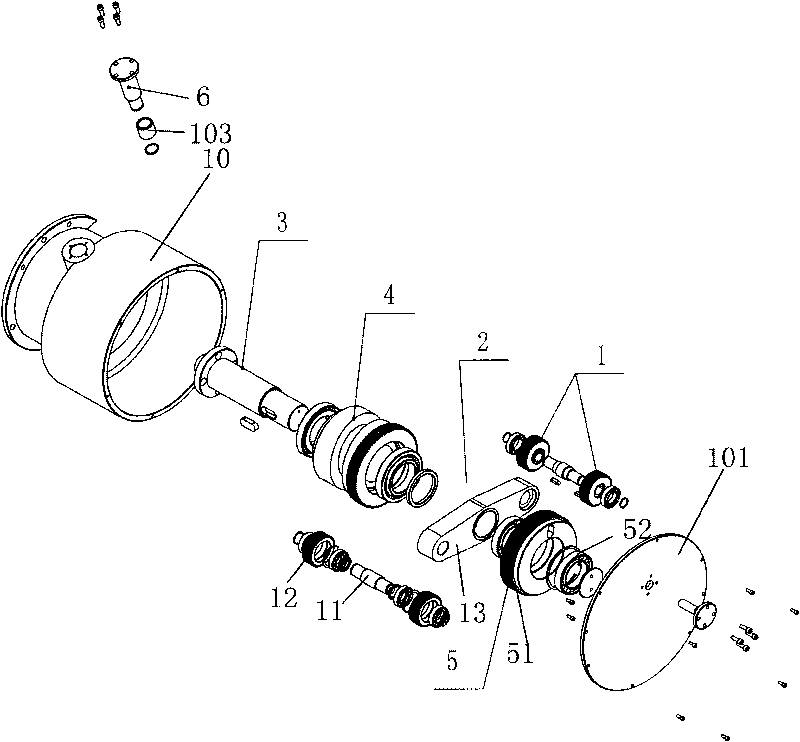

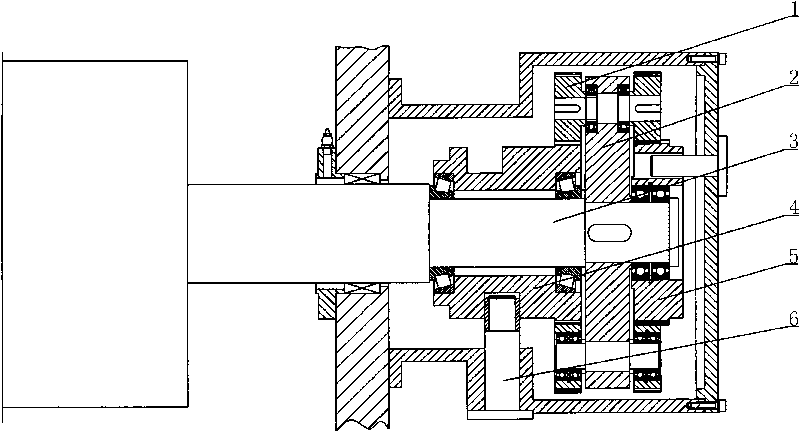

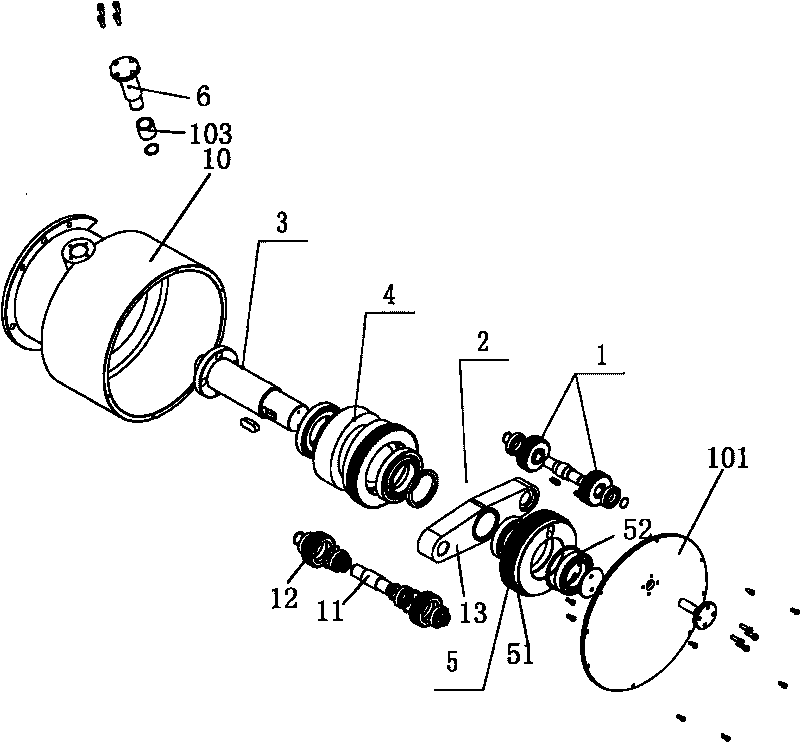

[0021] Such as Figure 1-2 As shown, a die-cutting rubber pad roller automatic traverse mechanism, which consists of a planetary gear 1, a planetary carrier 2, a die-cutting rubber pad roller 3, a movable center wheel 4, a fixed center wheel 5, and a positioning shaft 6. The planetary carrier 2 Fixed on the die-cut rubber pad roller 3, the planetary gear 1 is installed on the planet carrier 2. The planetary gear 1 is composed of a gear 11 and a shaft 12 . The fixed center wheel 5 is provided with a cam 51 and a spacer 52 . There are two planetary gears 1 installed on the planet carrier 2 through a connecting rod 13 . When the present invention is installed, the planet carrier 2 is fixed on the die-cutting rubber pad roller 3, the planetary gear 1 is installed on the planet carrier 2, and connected to the movable center wheel 4, the fixed center wheel 5, and the positioning shaft 6, and the above-mentioned assembly is completed Afterwards, it is installed and fixed in a gear c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com