Swing stem shield device for die-cutting machine

A die-cutting machine and shield technology, applied in metal processing and other directions, can solve the problems of low die-cutting accuracy, inaccurate die-cutting position, and high die-cutting scrap rate, and achieves short adjustment time, accurate die-cutting position, High precision die-cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

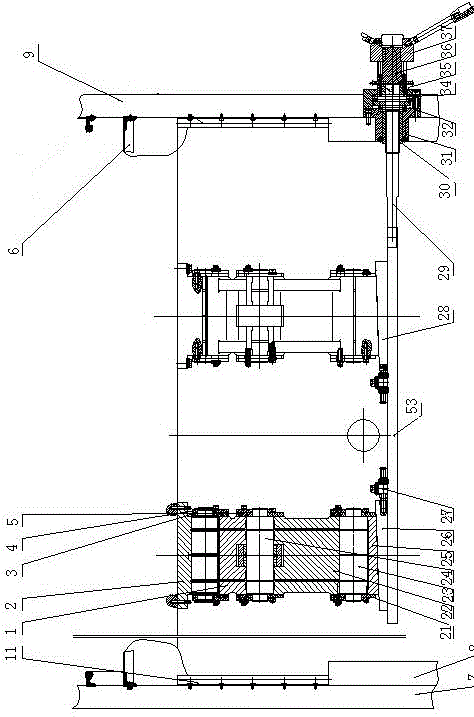

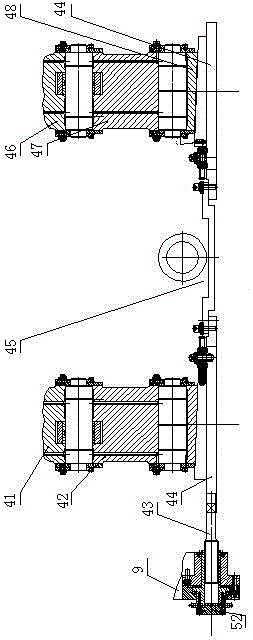

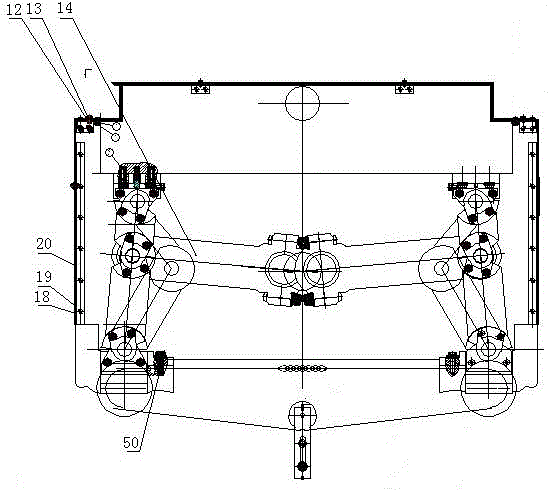

[0012] Die-cutting machine pendulum shield device structure of the present invention is as follows Figure 1-3 As shown, the front part between the transmission surface wallboard 7 and the operation surface blocking plate 9 is installed with a long-drawn main board 53, and the long-drawn main board 53 is installed on the operation surface blocking plate 9 through the second pressure regulating screw 29, and is located on the operation surface blocking plate 9. A pressure regulating sprocket 35 is installed on the external second pressure regulating screw 29, a knob shaft 36 and a knob 37 are installed at the end of the pressure regulating sprocket 35, an adjusting nut 30 is installed on the second pressure regulating screw 29, and a sealing sleeve is installed on the outside of the regulating nut 30 31. A washer 32 is installed at the end of the sealing sleeve 31, and a retaining sleeve 34 is installed at the end of the pressure regulating sprocket 35. Slant iron 26,28 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com