High-precision corrugated paper die cutting device based on rigid contact

A rigid contact, high-precision technology, applied in metal processing and other directions, can solve problems such as the inability to effectively improve die-cutting accuracy, corrugated cardboard misalignment, offset, affecting product quality, etc., to achieve stable molding effect, avoid offset, use The method is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

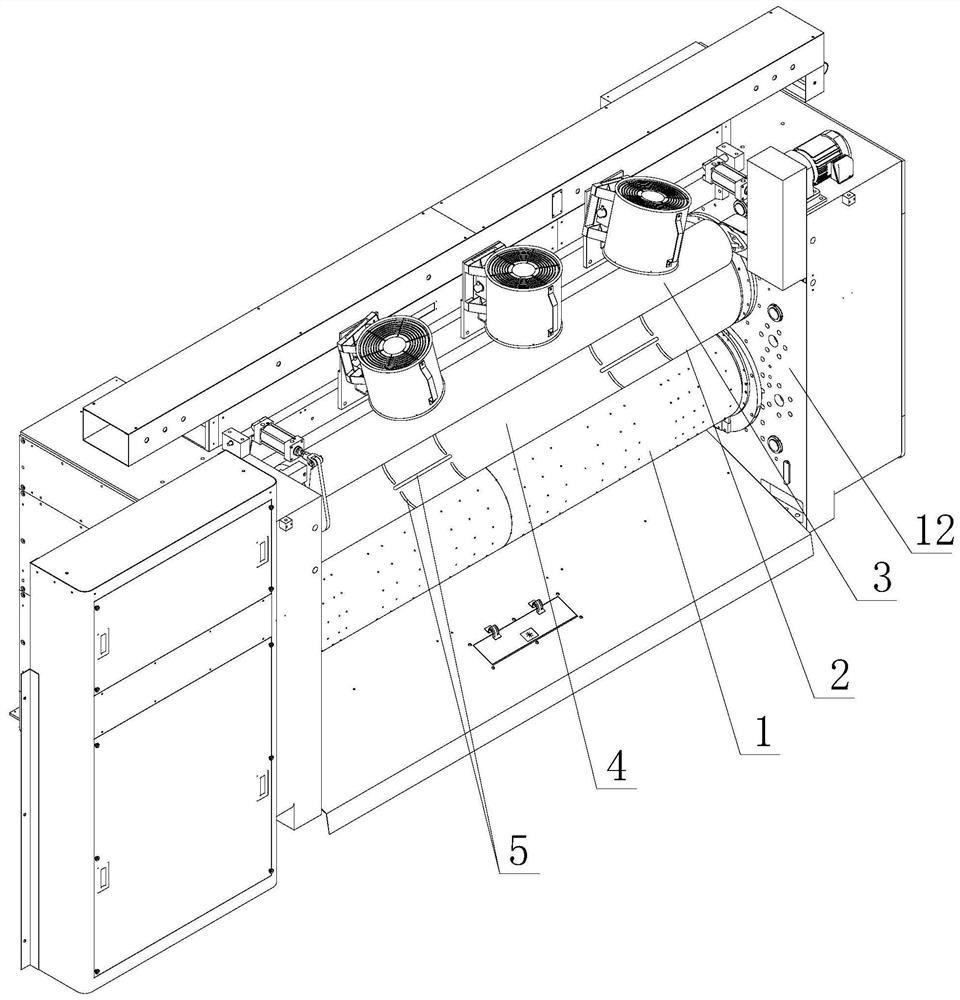

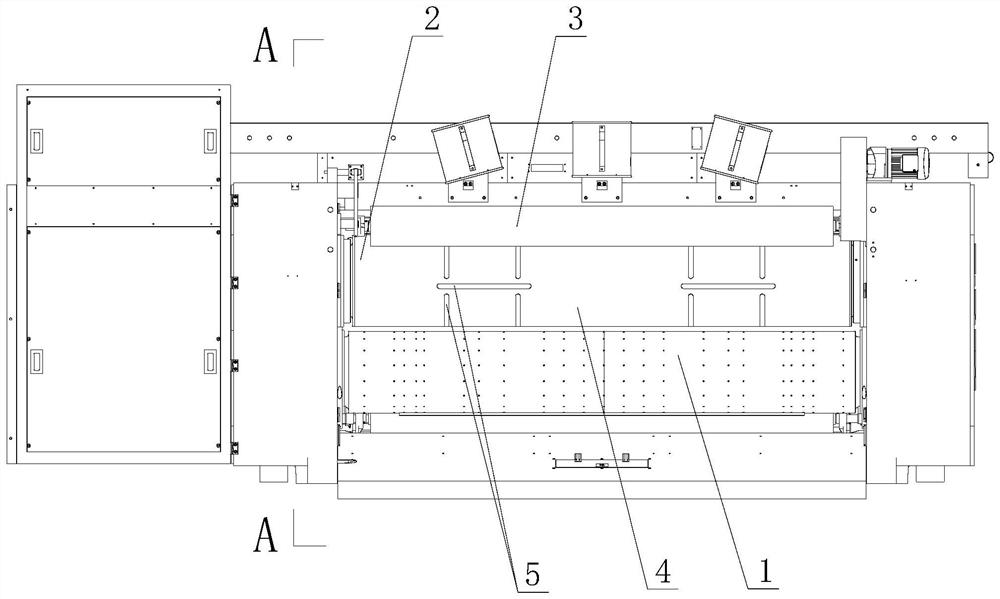

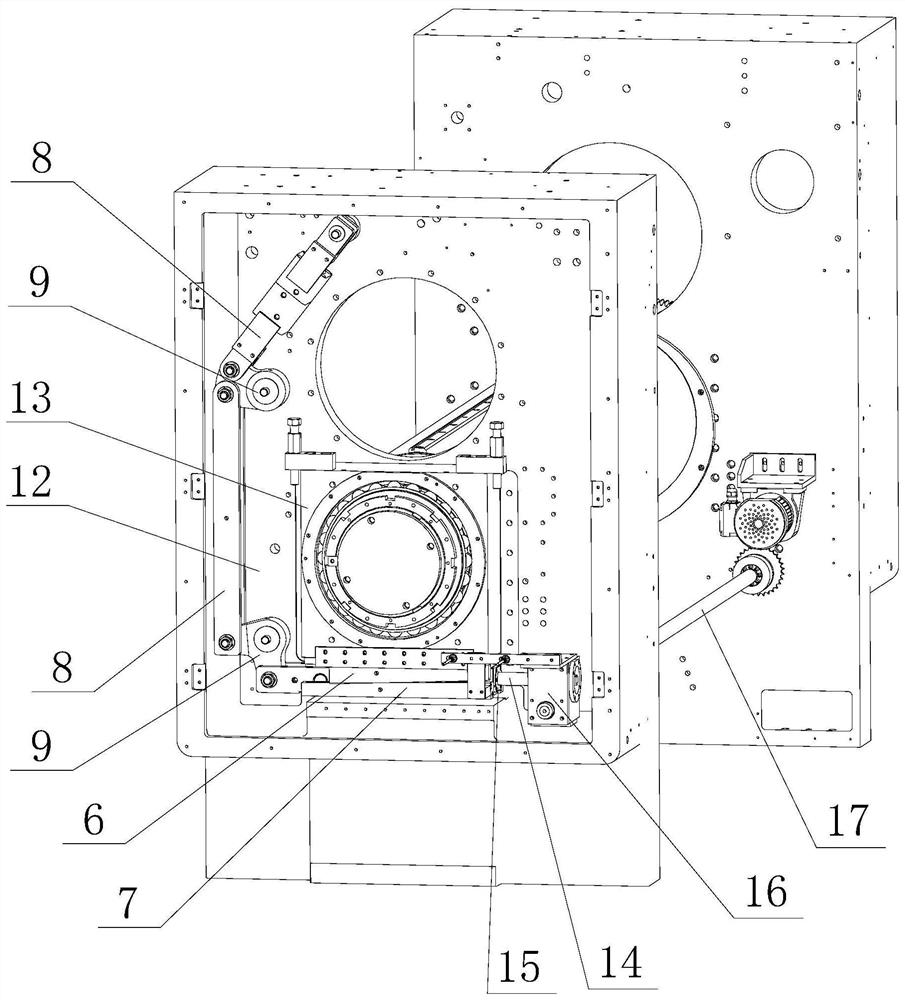

[0033] In this embodiment, a high-precision corrugated paper die-cutting device based on rigid contact, such as figure 1 or figure 2 As shown, it includes a die-cutting roller 1 and a backup roller 2 that cooperate and form a die-cutting roller group (in this embodiment, one side of the backup roller is also provided with a waste cleaning brush roller 3), and a die-cutting plate is installed on the die-cutting roller (not shown in the figure), protruding knife lines and pressure lines are distributed on the die-cutting board, a rigid backing plate 4 is installed on the backup roller, and several die-cutting grooves 5 are distributed on the rigid backing plate; When cutting, the knife line and the surface of the rigid backing plate are correspondingly located on the upper and lower sides of the corrugated cardboard for die-cutting operations, and the crimping line and die-cutting grooves are correspondingly located on the upper and lower sides of the corrugated cardboard for i...

Embodiment 2

[0038]This embodiment is a high-precision corrugated cardboard die-cutting device based on rigid contact. Compared with Embodiment 1, the difference is that: in the fixing structure on both sides of the rigid backing plate, the fixing structure includes axial fixing strips and keyholes. , elastic fixing strips and lock buckles; one side of the rigid backing plate is provided with fixed installation holes, and each fixed installation hole is pressed and fixed on the backing roller by the axial fixing strip, and the other side of the axial fixing strip and the rigid backing plate There are one-to-one corresponding lock holes on the sides, and the two ends of the elastic fixing strips are respectively equipped with lock buckles. connect. When installing the rigid backing plate, press and fix one side of the backing roller along the axial direction of the backing roller through the axial fixing strip, and then roll the rigid backing plate to cover the surface of the backing roller...

Embodiment 3

[0040] This embodiment is a high-precision corrugated cardboard die-cutting device based on rigid contact, which is suitable for die-cutting processing of large or super-large corrugated cardboard. Compared with Example 1, the difference is that there are also Auxiliary installation holes, when in use, can further strengthen the installation stability of the rigid backing plate on the backing roller through the auxiliary installation holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com