Mold cutting tool and manufacture method thereof

A die-cutting knife and cutter body technology, applied in metal processing and other directions, can solve the problems of high production cost and use cost, complicated die-cutting knife processing, and inability to be widely used, so as to prolong the service life, strengthen the strength, and increase the stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the drawings and examples.

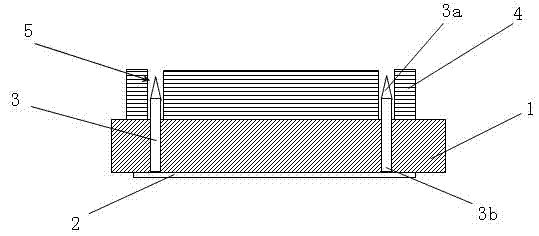

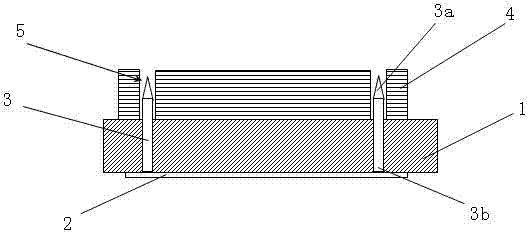

[0025] like figure 1 Shown, die-cutting knife of the present invention comprises: base plate 1, constitutes the main base material of die-cutting knife, supports the knife body of fixed die-cutting knife, and the size of base plate is selected according to the size of die-cutting pattern; Fixed on the bottom plate, the knife body is composed of multiple sections, the blade 3a of the knife body protrudes outward from the front of the bottom plate, and is used as the cutting part in the die-cutting action. The metal with less deformation can be used as the bottom plate, iron plate, copper plate or steel plate can meet the needs very well, and the corresponding selection can be made according to the specific difference in the required strength. Splicing forms the corresponding die-cutting pattern, selects multiple corresponding cutter bodies 3 according to the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com