CCD automatic positioning die cutting machine

An automatic positioning and die-cutting machine technology, applied in metal processing and other directions, can solve the problems of affecting die-cutting efficiency, taking a long time, and failing to meet the accuracy requirements, so as to improve die-cutting accuracy, die-cutting efficiency, and die-cutting. The effect of higher precision and die-cutting efficiency, higher die-cutting precision and die-cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

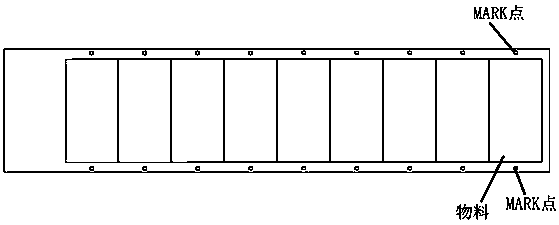

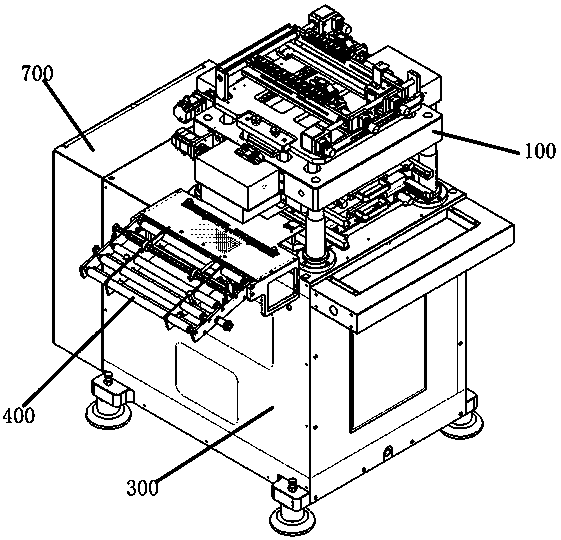

[0044] Please refer to the attached Figures 1 to 22 , the present invention provides a CCD automatic positioning die-cutting machine, including a die-cutting host 300 for providing stamping power, a control box 700 for centralized control, a feeding mechanism 400 for material feeding, and a die-cutting The positioning adjustment mechanism 100 for horizontal adjustment and automatic positioning, the control box 700 is installed behind the die-cutting host 300, the adjustment mechanism 100 is installed on the die-cutting host 300, and the feeding mechanism 400 is installed on the die-cutting host 300. The side of the die-cutting host 300 is described.

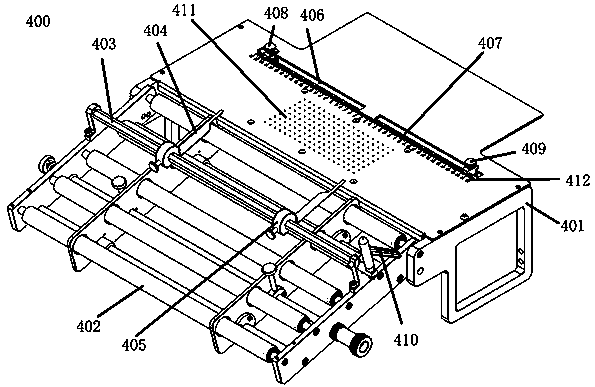

[0045] Specifically, please refer to image 3 , the feeding mechanism 400 includes a feeding frame 401, a drum 402, a width adjustment frame 403, a left adjustment limit arm 404, a right adjustment limit arm 405, a left width measurement slot 406, a left measurement adjustment block 408, a right width measurement Groove 407, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com