Tab die cutting method for inter-coating pole piece

A pole piece, die-cutting technology, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of high difficulty in die-cutting process and low die-cutting efficiency, and achieves reduction of dust and burrs, high die-cutting efficiency, high die-cutting efficiency, etc. Simple effect of die cutting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

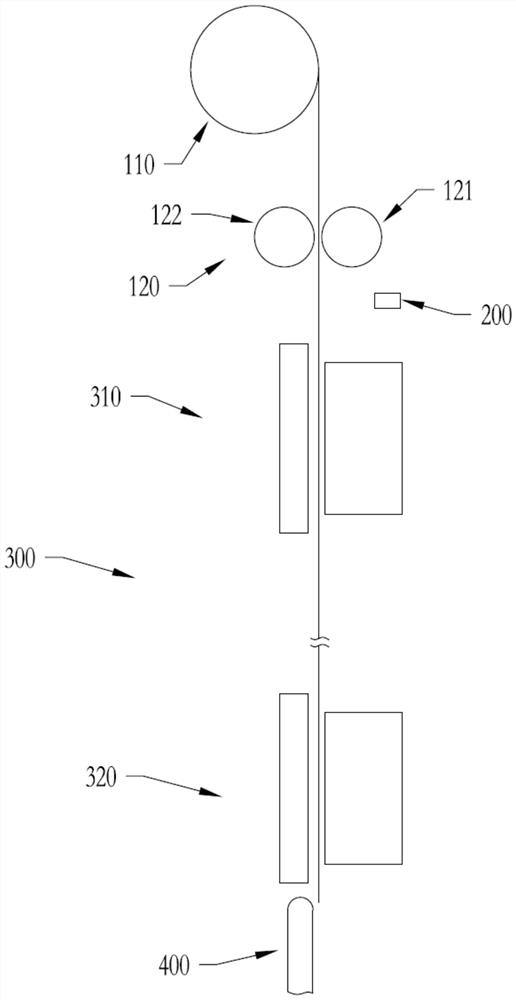

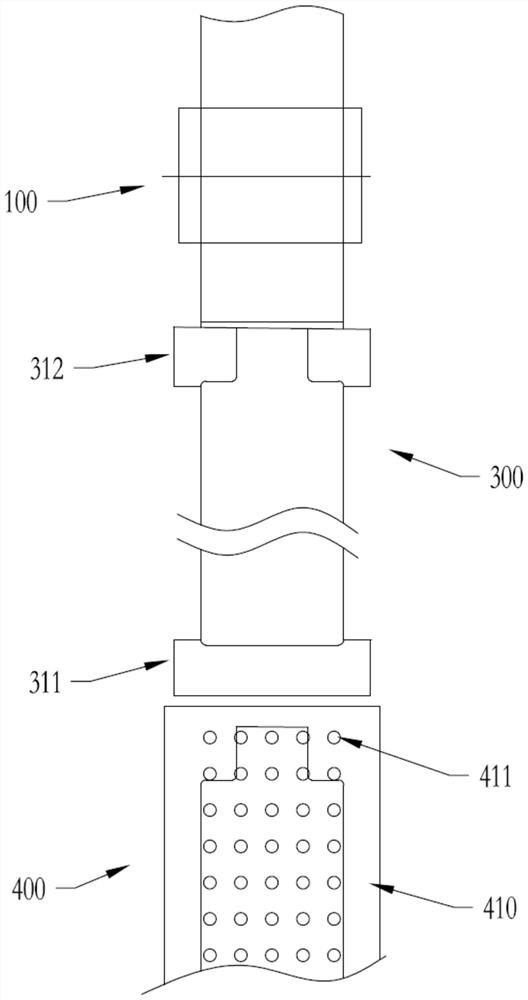

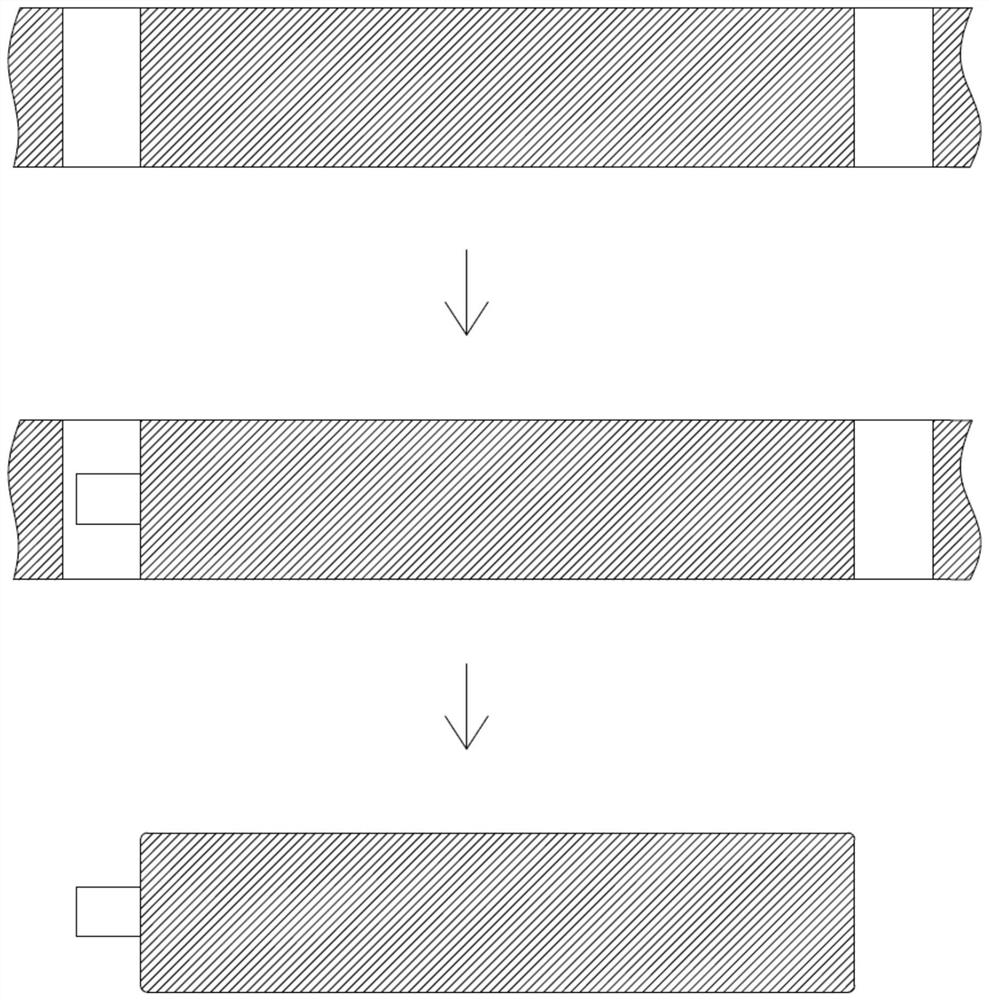

[0032] like Figure 1 ~ Figure 3 As shown, a lug die-cutting method for an intercoated pole piece includes a material guide assembly 100 for pulling the intercoated pole piece coil, a detection assembly 200 for detecting the intercoating position of the intercoated pole piece, A die-cutting assembly 300 for die-cutting the intercoated pole pieces introduced by the material guide assembly 100, and a blanking assembly 400 for pulling and conveying the die-cut pole pieces;

[0033] The tab die-cutting method comprises the following steps:

[0034] S1, conveying the intercoated pole piece correction guide material through the material guide assembly 100;

[0035] S2, after being transported to the designated position, the position detection of the intercoating position of the intercoating pole piece is carried out by the detection component 200;

[0036] S3, transportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com