Variable transmission paper feed mechanism for die-cutting machine

A technology of variable speed transmission and paper feeding mechanism, applied in metal processing and other directions, can solve the problems of inability to realize large stroke and high speed controllable motion law, uncontrollable motion law during paper feeding, high maintenance and use costs, reducing impact, The effect of low maintenance and use costs in the later period and controllable manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

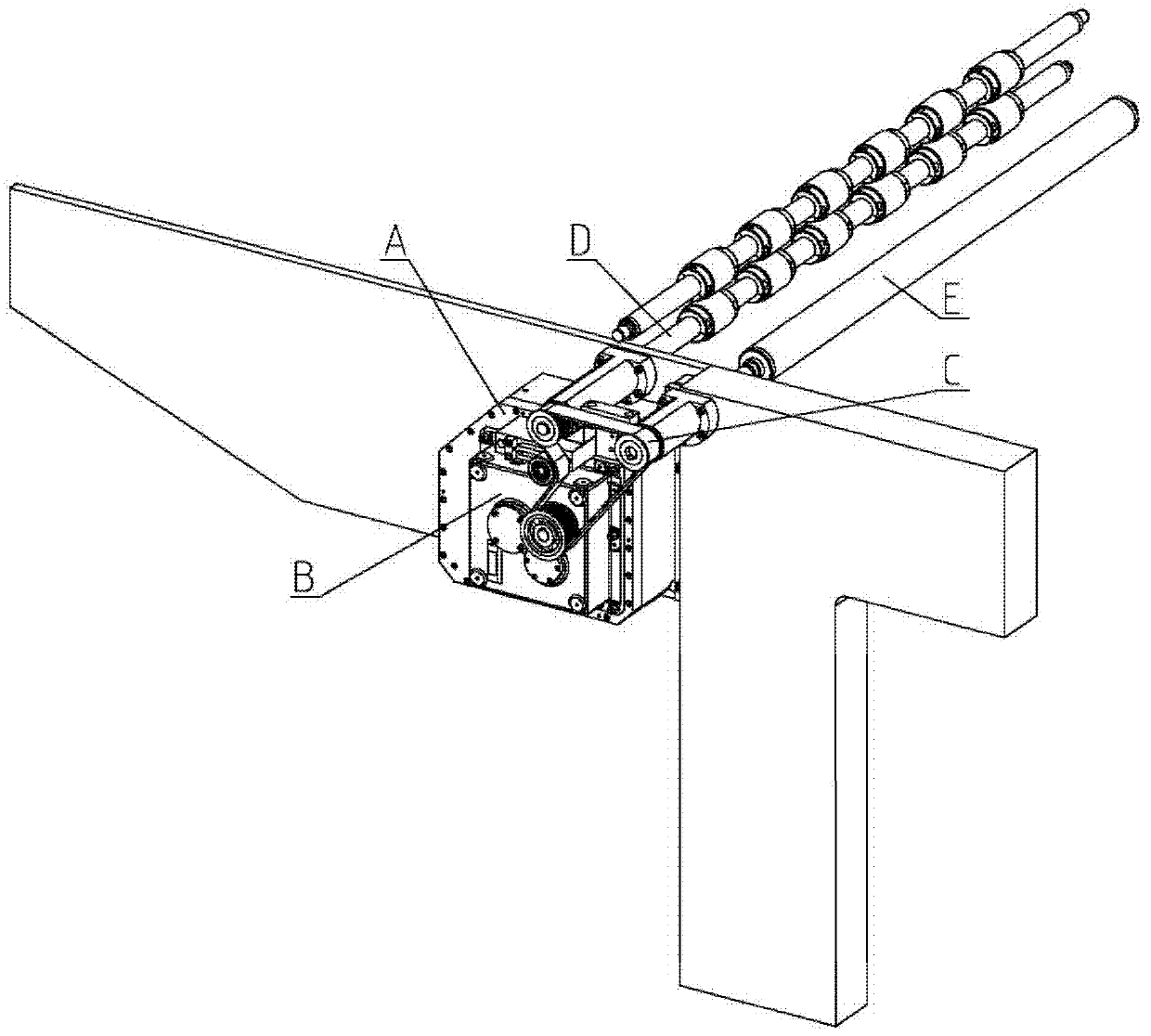

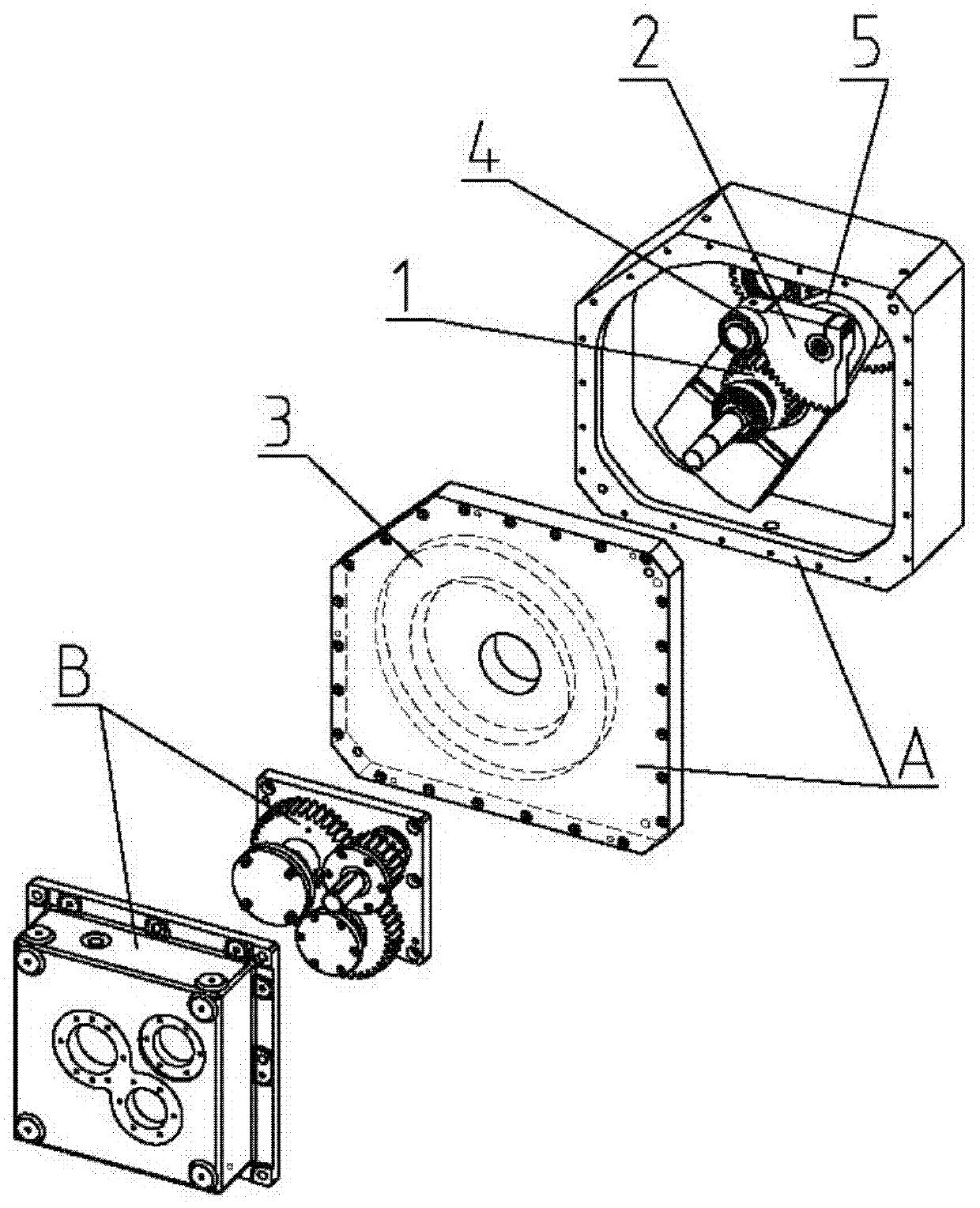

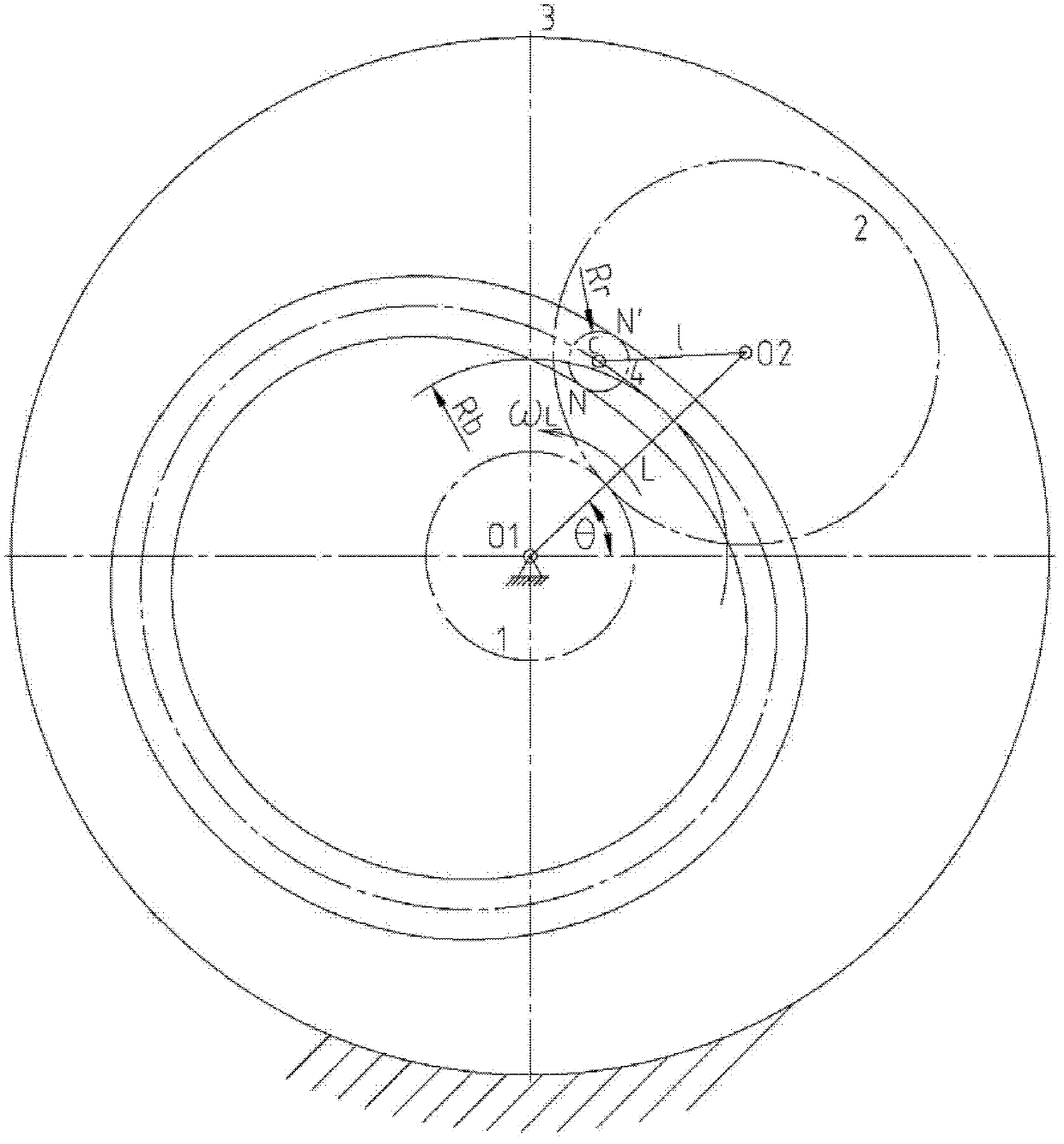

[0015] Such as figure 1 and figure 2 As shown, a die-cutting machine variable speed transmission paper feeding mechanism, including speed-increasing gear box B, timing belt C, paper feeding roller D, paper feeding belt roller E and center wheel 1, planetary wheel 2, grooved cam 3, roller The cam-planetary gear epicyclic train assembly A composed of sub-4 and epicyclic pendulum 5. The epicyclic pendulum 5 is connected to the power mechanism and drives the planetary wheel 2 to input power to the entire variable speed transmission paper feeding mechanism. The roller 4 is eccentrically arranged on the planetary wheel 2 and extends into the curved groove of the grooved cam 3. The center wheel 1 and the The planetary gear 2 meshes, connects the speed-up gearbox B through the transmission shaft, and outputs power to the speed-up gearbox B, then adjusts and matches the paper feeding stroke through the speed-up gearbox B and the synchronous belt C, and finally drives to the paper fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com