Die-cutting machine feeding platform with improved structure

A technology for improving the feeding platform and structure, which is applied in metal processing and other directions, can solve the problems of unsteady feeding, unstable tension control, and easy swinging of feeding, and achieve high production efficiency, simple structure, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

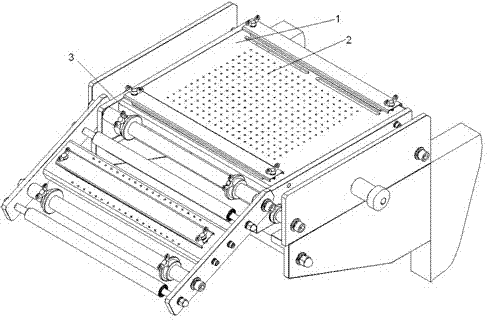

[0013] Embodiment: A structure-improved feeding platform of a die-cutting machine, including a placement table 1, an air pressure chamber 3 and an air extraction device, a cavity structure is formed inside the air pressure chamber, and the placement table 1 is sealed and fixed to cover the opening of the air pressure chamber 3 On the side, there are several perforations 2 connected with the interior of the air pressure chamber on the placing table, and the air pressure chamber 3 is connected with the air suction port of the air suction device.

[0014] When placed on the platform 1, the film just covers all the perforations. At this time, the air pumping device pumps air to the air pressure chamber 3, and the air pressure chamber 3 forms a negative pressure attraction force on the film. At this time, the film is tightly attached to the Placed on the table, it is flattened under the action of strong air pressure, which has a tension effect, avoids damage to film materials, is ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com