Online defect detection device and method for die-cutting machine

A defect detection and die-cutting machine technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to detect paper position deviation and offset defects of printed matter, mixed batches, and inability to detect the same printed matter production batch. , to achieve the effect of preventing mixed goods, high die-cutting efficiency and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

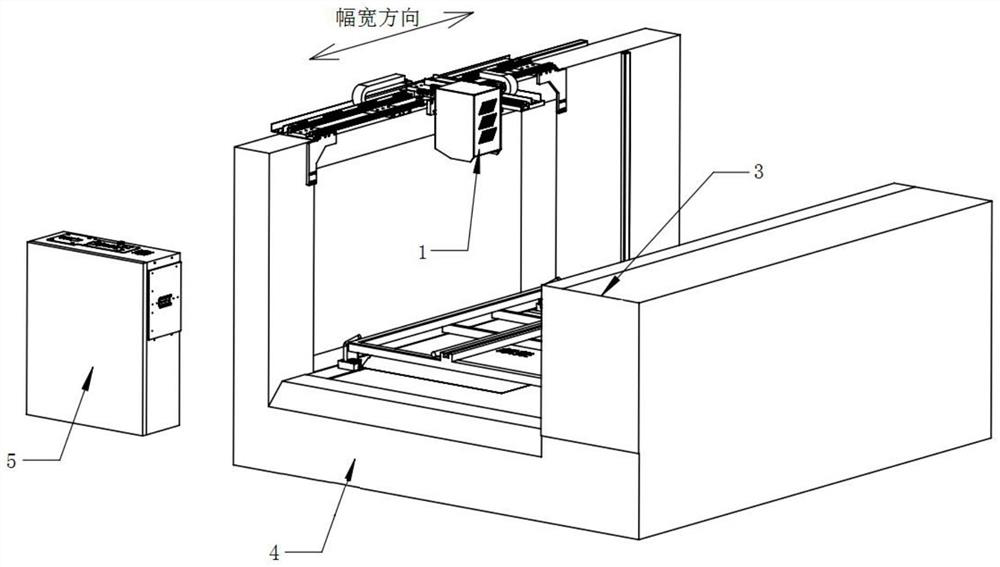

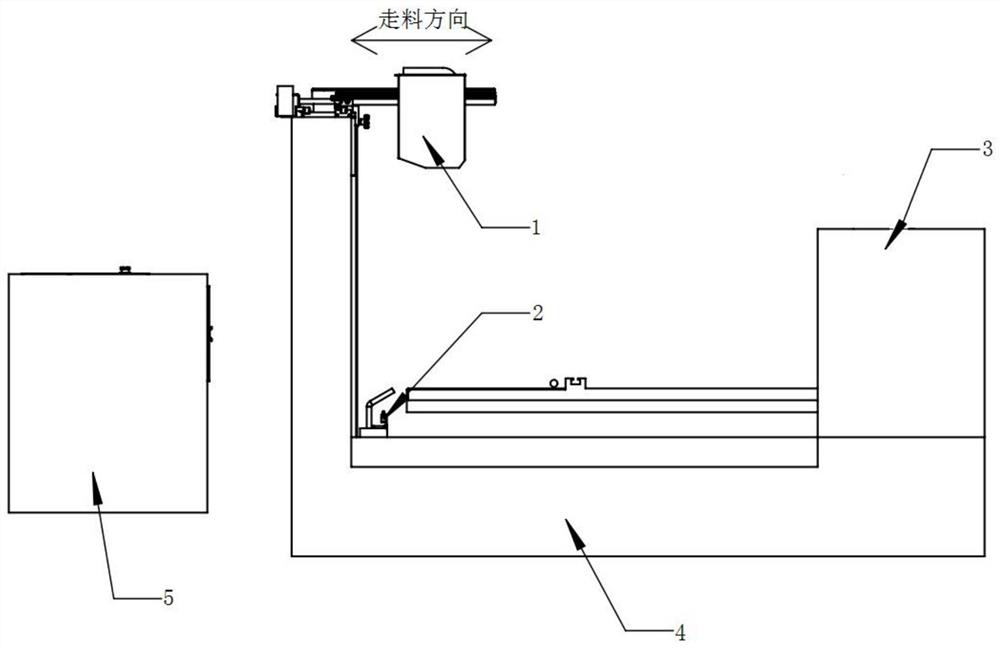

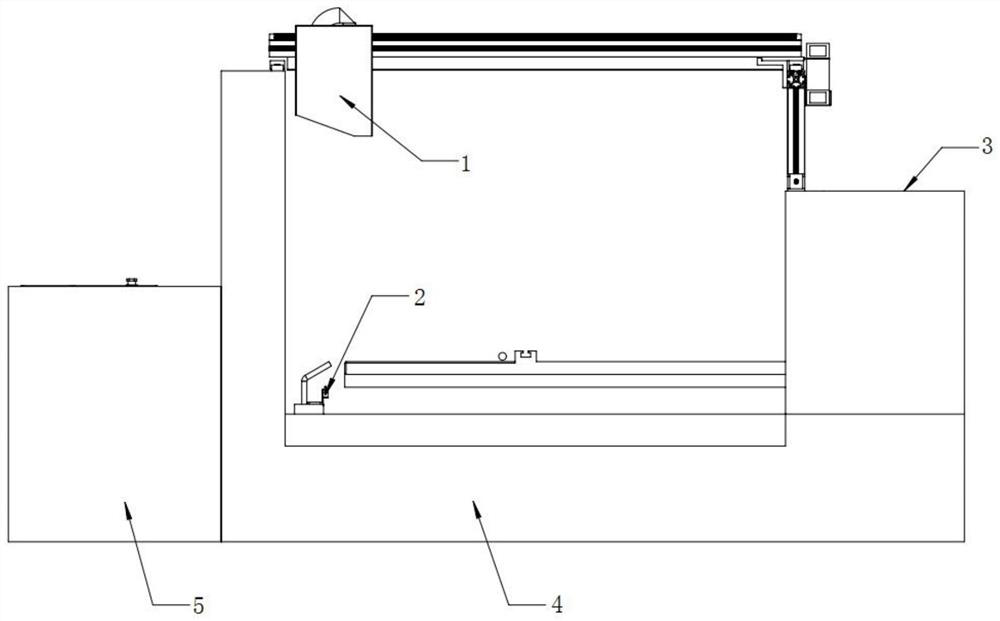

[0075] Such as figure 1 and figure 2 As shown, Embodiment 1 of the present application provides an online defect detection device for a die-cutting machine, including: an acquisition module 1, a sensor module 2, a display module 3, a die-cutting machine 4 and a control processing module 5;

[0076] Wherein, the collection module 1 is arranged at the top of one side of the die-cutting machine 4, and is connected with the control processing module 5 through a cable, and is used to collect the paper image of the printed matter, and transmit the paper image of the printed matter to the Described control processing module 5, described printed matter paper image is collected under the stationary state of printed matter paper;

[0077] The sensor module 2 is arranged at the drawing gauge 6 of the die-cutting machine 4, and communicates with the control processing module 5, and is used to sense whether the printed matter paper passes through, when the printed matter paper passes thr...

Embodiment 2

[0098] Corresponding to the aforementioned embodiment 1 of an online defect detection device for a die-cutting machine, the present application also provides embodiment 2 of an online defect detection method for a die-cutting machine. Such as Figure 4a As shown, the method includes the following steps:

[0099] S101, receiving a trigger signal sent by the sensor module 2, the trigger signal is sent when the sensor module 2 senses that the printed paper passes;

[0100] S102, after delaying according to the preset delay time, send the image acquisition signal to the acquisition module 1, the preset delay time is the time required for the printed paper to move to the preset position after passing the sensor module 2 , and the printed paper is in a static state at the preset position;

[0101] S103, receiving the printed paper image collected by the collection module 1;

[0102] S104, comparing the code type information on the printed matter paper image with the code type inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com