Packaging box production technology

A production process and packaging box technology, applied in the field of cardboard boxes, making cartons, envelopes or paper bags, can solve the problem that the cardboard cannot be completely cut, and achieve the effect of increasing the feed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

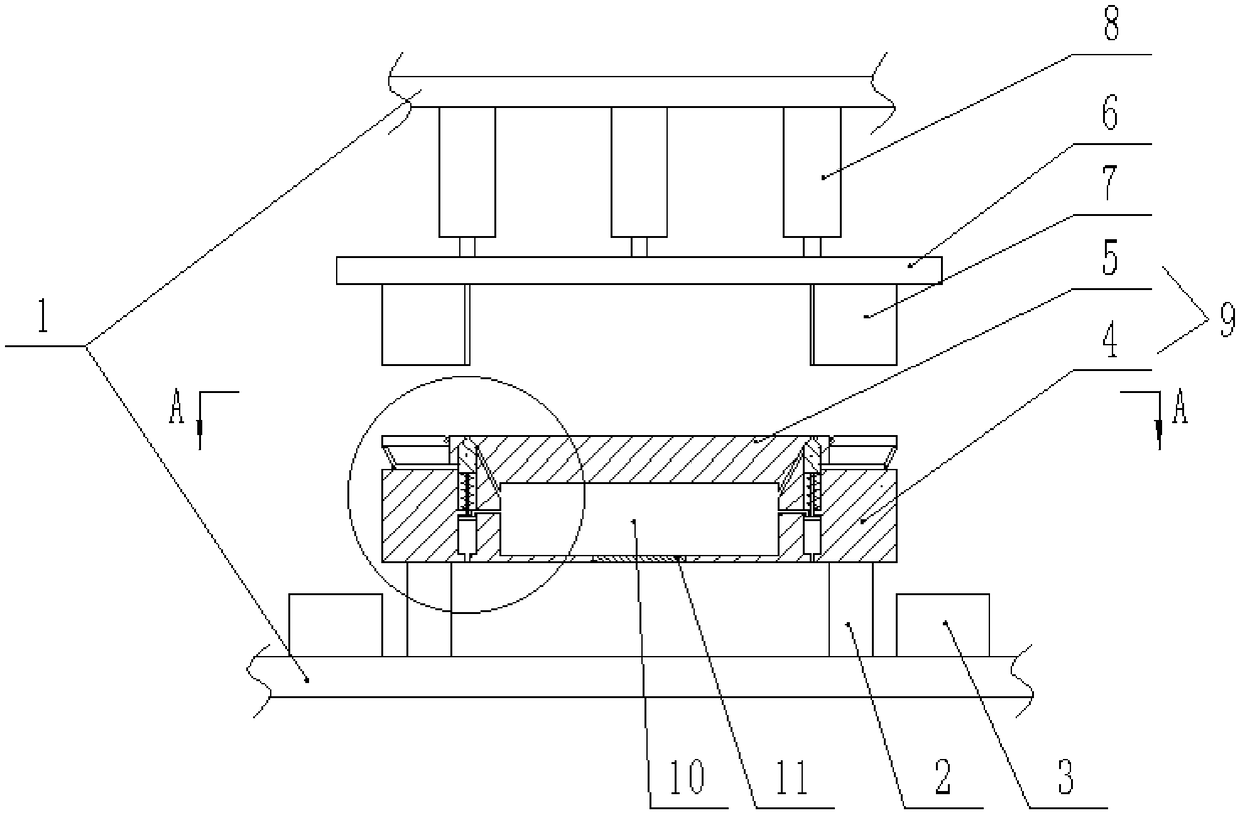

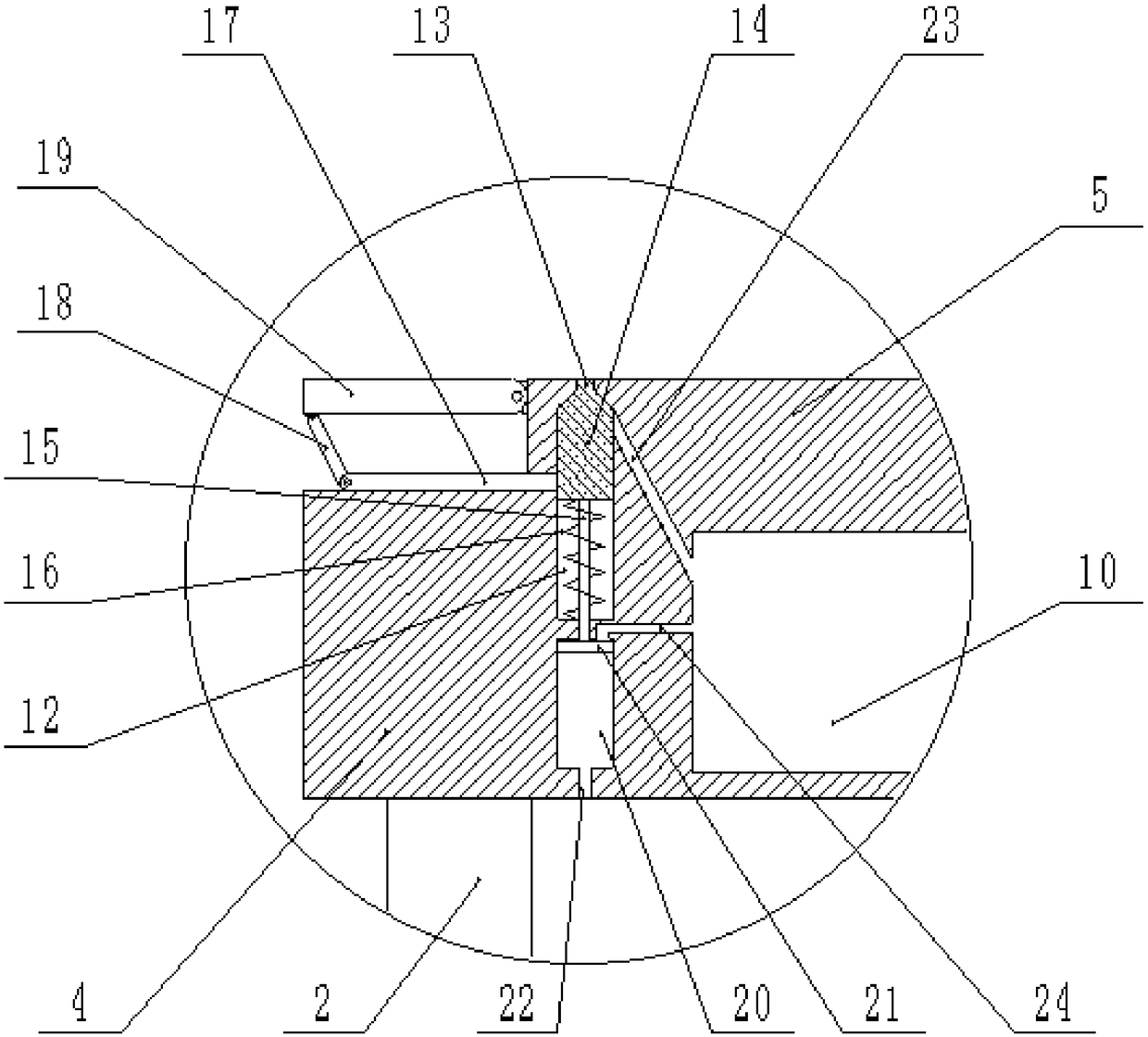

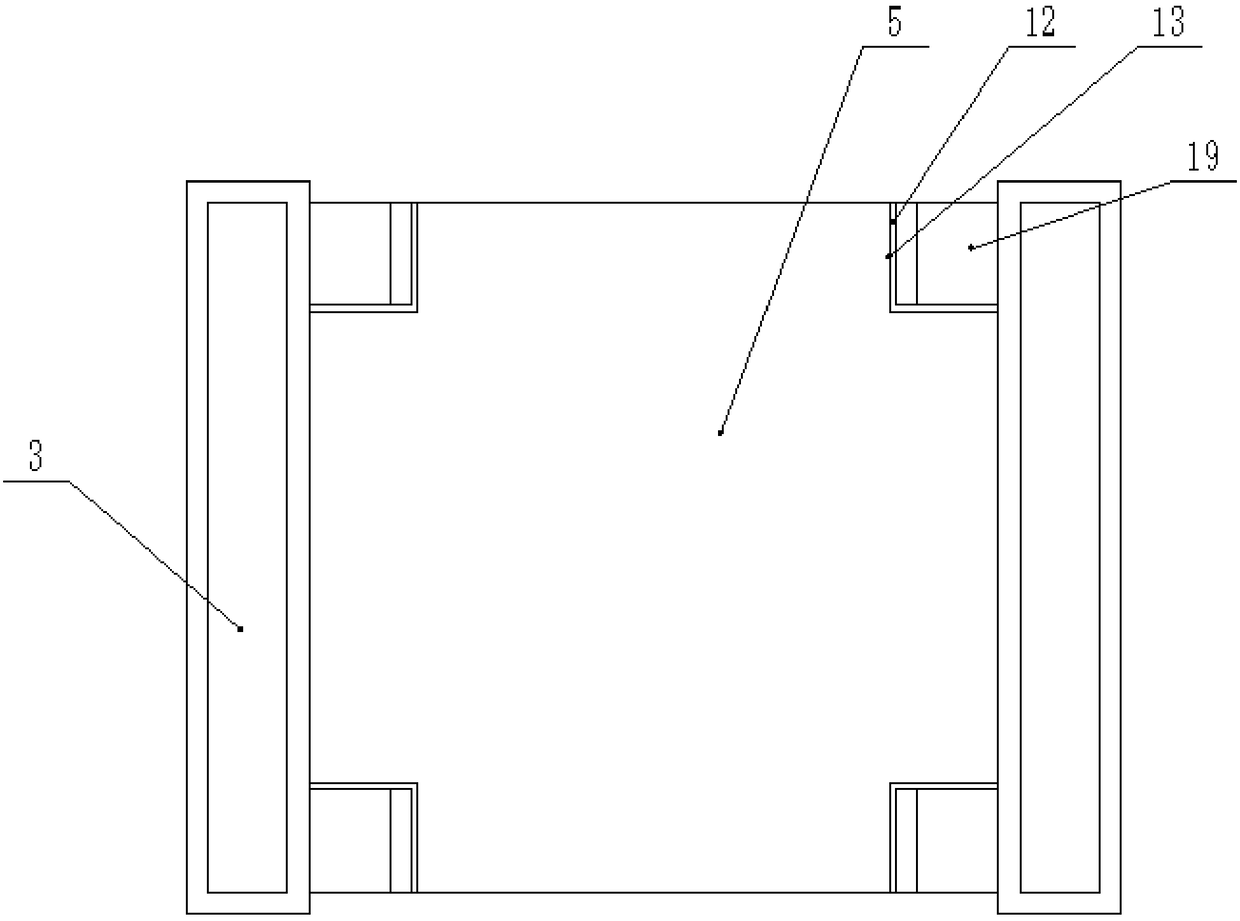

[0020] The reference signs in the drawings of the description include: frame 1, support column 2, collection tank 3, base 4, boss 5, connecting plate 6, die cutter 7, hydraulic cylinder 8, placing table 9, paper scrap collection Cavity 10, sealing door 11, groove 12, filling part 13, sliding part 14, piston rod 15, compression spring 16, second connecting rod 17, first connecting rod 18, support plate 19, cylinder barrel 20, piston plate 21 , Exhaust channel 22, paper dust collection channel 23, suction channel 24.

[0021] The embodiment is basically as attached figure 1 Shown: a packaging box production process, including the following steps:

[0022] Step 1: Prepare a hydraulic die-cutting device;

[0023] Step 2: The hydraulic die-cutting device includes a frame 1, a support column 2 is fixedly installed on the frame 1, a placement platform 9 is fixedly installed on the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com