Automatic scrap clearing die

An automatic cleaning and waste cleaning technology, which is applied in metal processing and other directions, can solve problems such as material jams, concave and uneven cutting surfaces, time-consuming and labor-intensive problems, and achieve the effects of reducing production costs, increasing yields, and beautiful appearance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

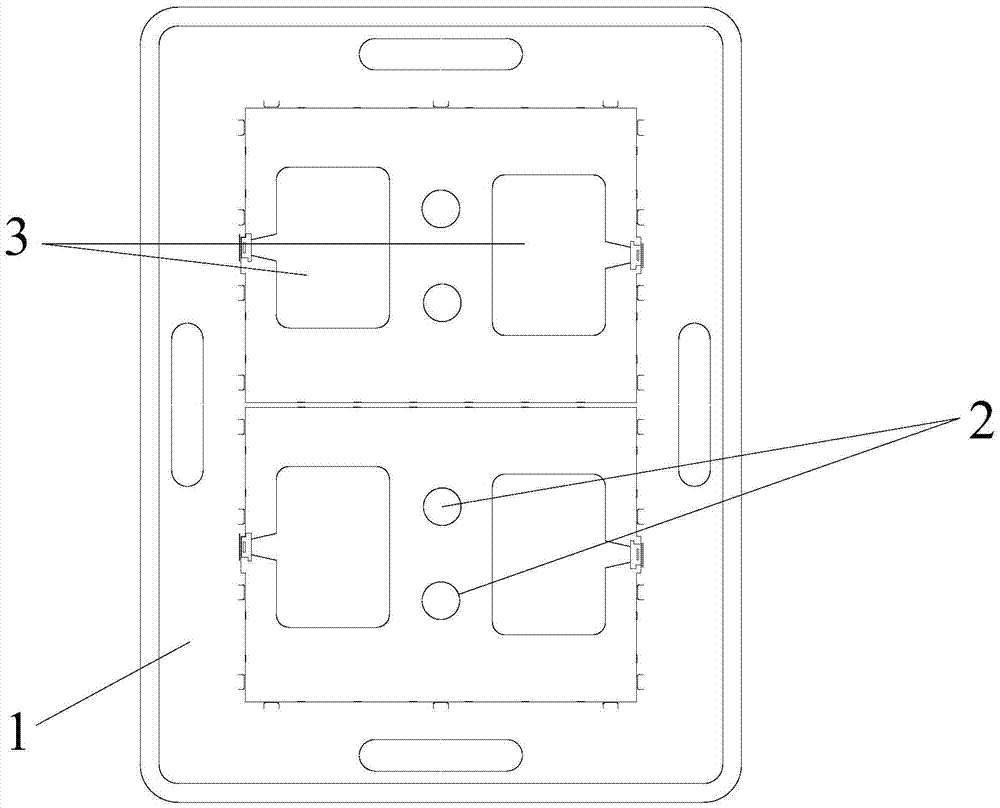

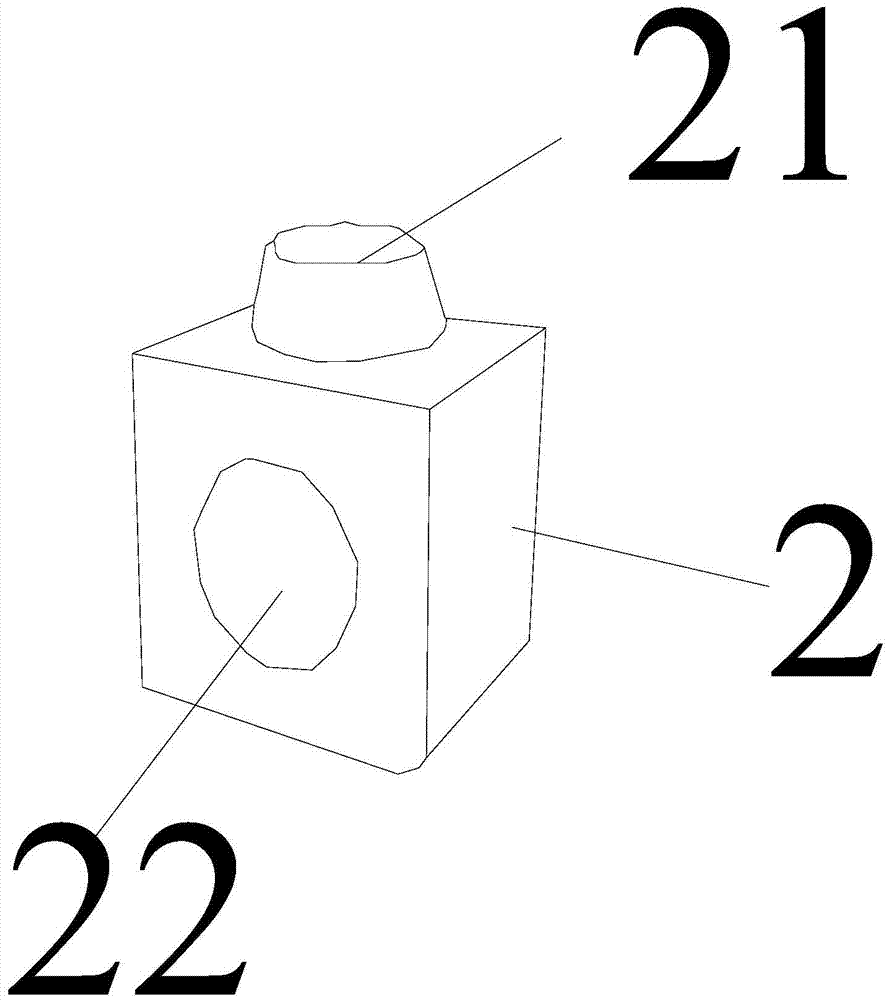

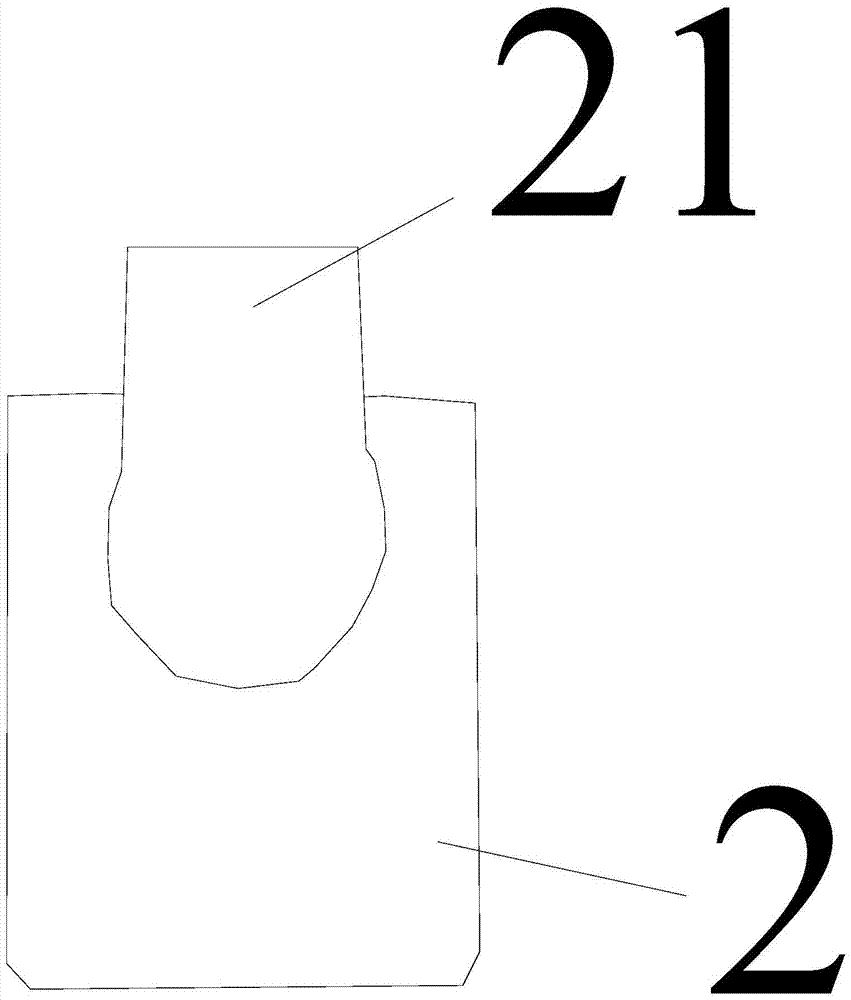

[0019] as attached Figure 1-3 As shown, the automatic stripping mold includes a mold body 1, a number of stripping pieces 2 are provided on the front of the mold body 1, a number of stripping grooves 3 are provided on the back of the mold body 1, and the top surface of the stripping pieces 2 A stripping inlet 21 is provided on the top, and a stripping outlet 22 is provided on the side of the stripping part 2, and the longitudinal section 23 of the stripping part 2 is tapered. During the die-cutting process, the cut waste is discharged through the stripping part 2 and the stripping tank 3. The top surface of the stripping part 2 is provided with a stripping inlet 21, and the cut waste enters through the stripping inlet 21, and then enters from the side. The waste stripping outlet 22 discharges, and the waste material discharged vertically from the side is easy to clean up. The longitudinal section of the waste stripping part 2 is tapered, and the waste material is easy to slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com