Automatic facial mask die cutting and folding mechanism

A folding mechanism and die-cutting technology, applied in metal processing, packaging and other directions, can solve the problems of high labor intensity of operators, slow die-cutting speed, secondary pollution, etc. Cut and fold quick effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

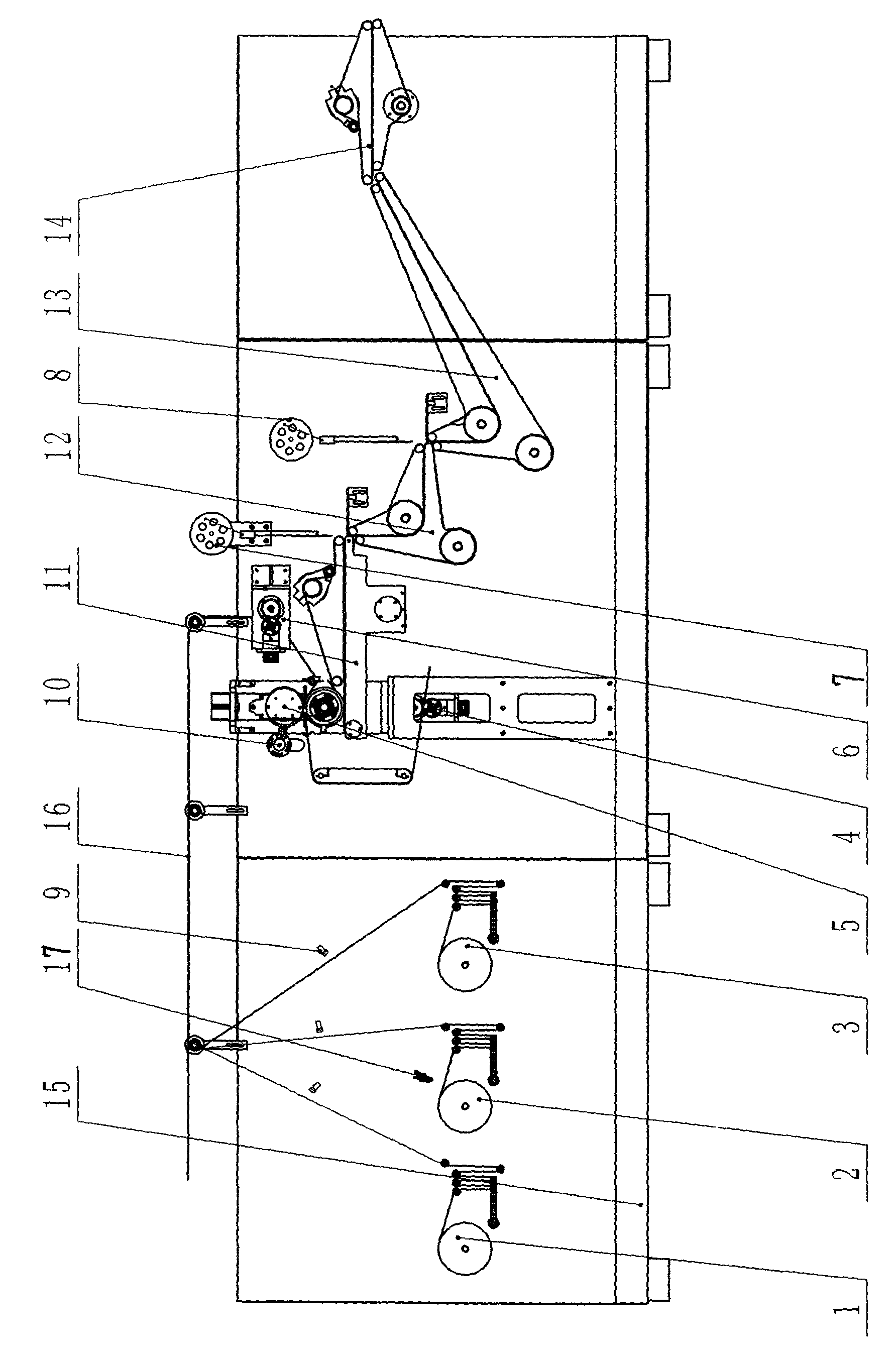

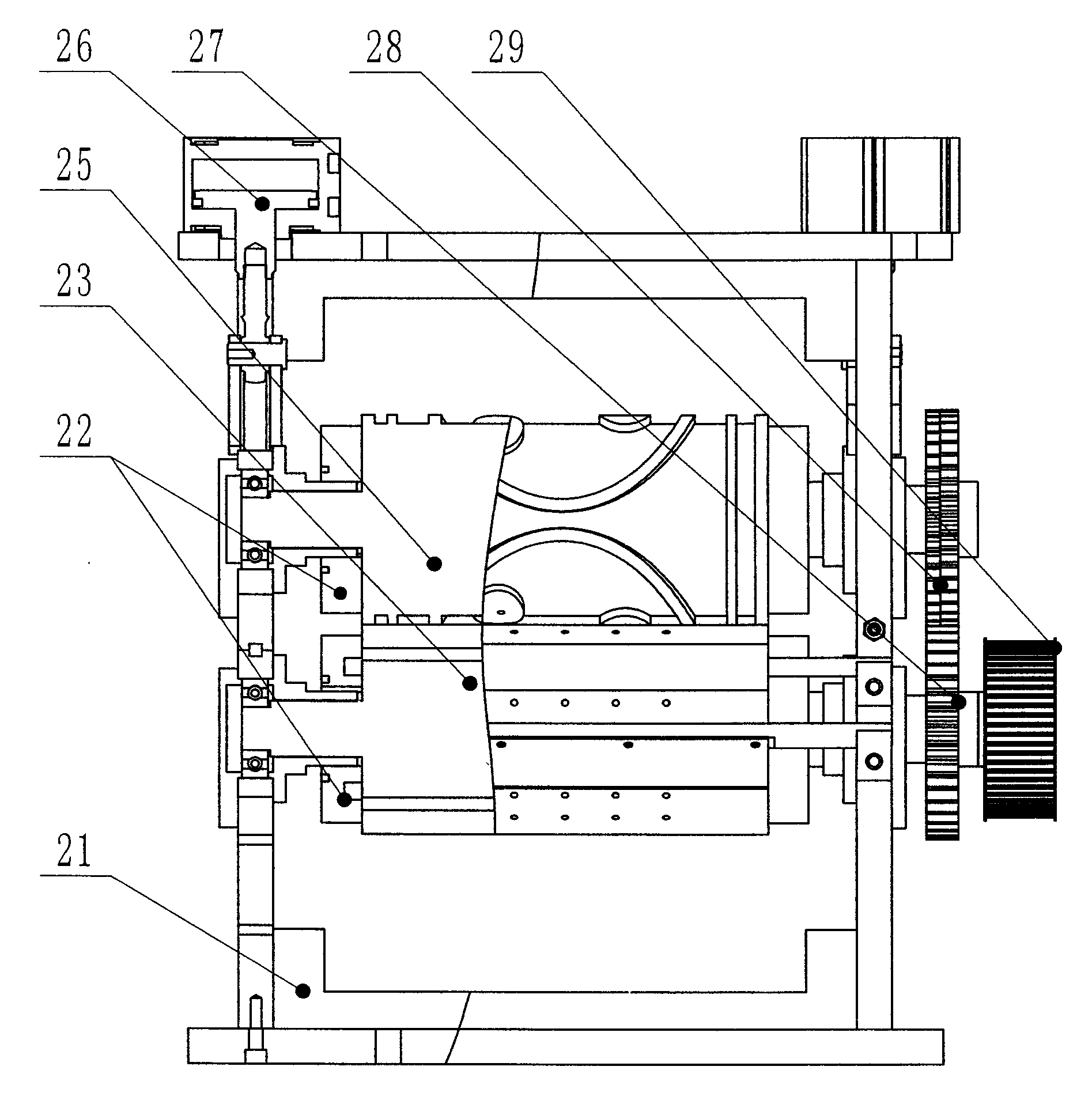

[0009] Reference figure 1 , figure 2 It can be seen that the present invention is applied to the automatic die-cutting and folding mechanism of the face mask of the automatic non-woven face mask packaging machine, including a frame 15, a die-cutting device 5 (and a traction device 6), and the die-cutting device 5 includes a die-cutting frame 21 (installed On the frame 15), the die-cutting bottom roll 23 (on the bottom, is active), and the die-cutting knife roll 25 (on the upper and passive, the two rolls are arranged in a rolling type up and down), on the die-cutting bottom roll 23 , The die-cutting knife roller 25 is equipped with a suction disk 22 (a total of two pieces of upper and lower, which can prevent the three-layer film material from shifting and displacing each other during die-cutting, and it is stable and reliable). A waste collection assembly 10 is installed on the frame 15 and close to the die-cutting knife roller (it uses the negative pressure generated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com