A high-efficiency die-cutting device for release paper

A release paper and die-cutting technology, applied in the field of machinery, can solve the problems of high cost, high maintenance cost, limited use by small and medium-sized enterprises, etc., and achieve the effect of reducing replacement cost and convenient later maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

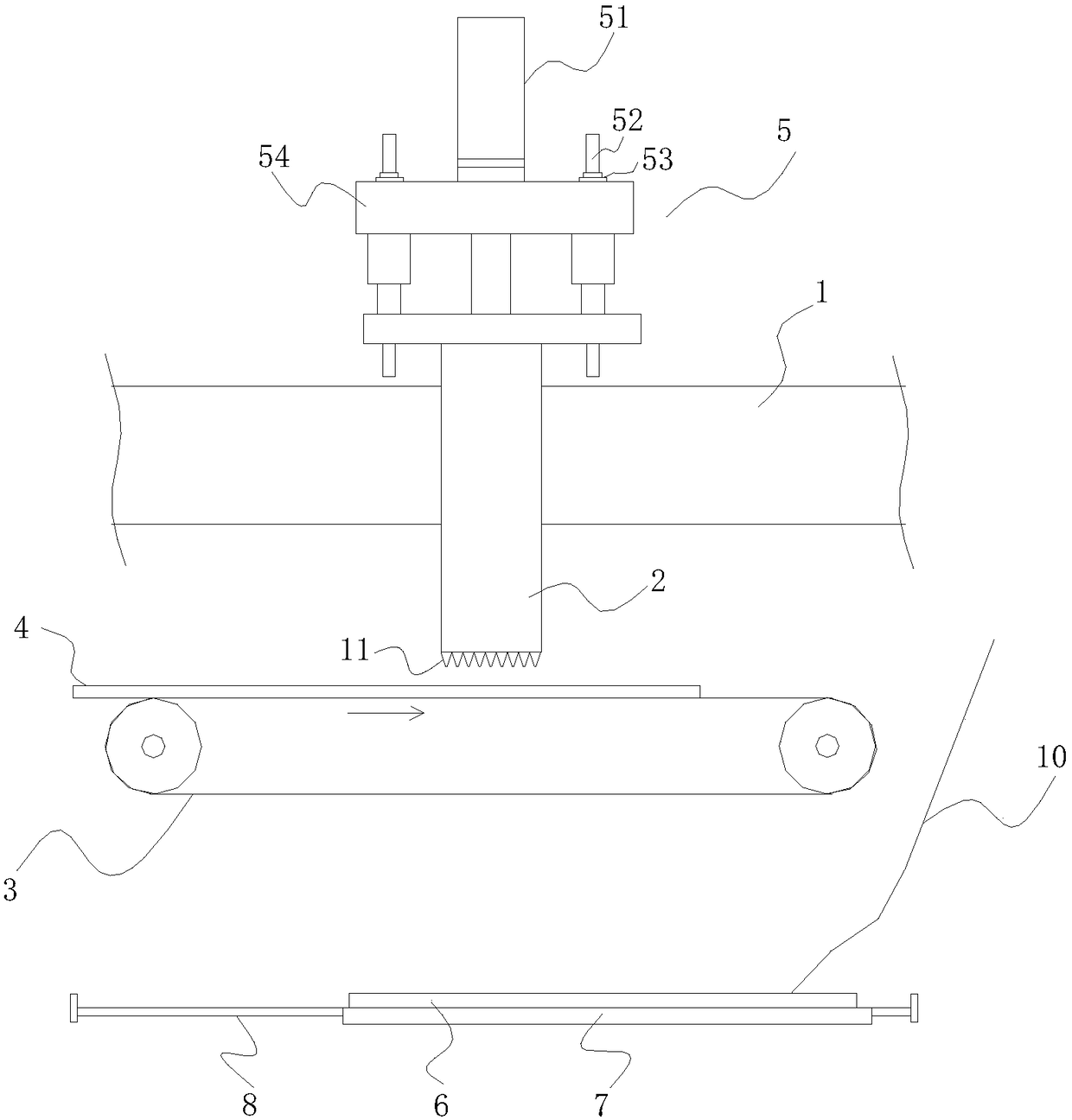

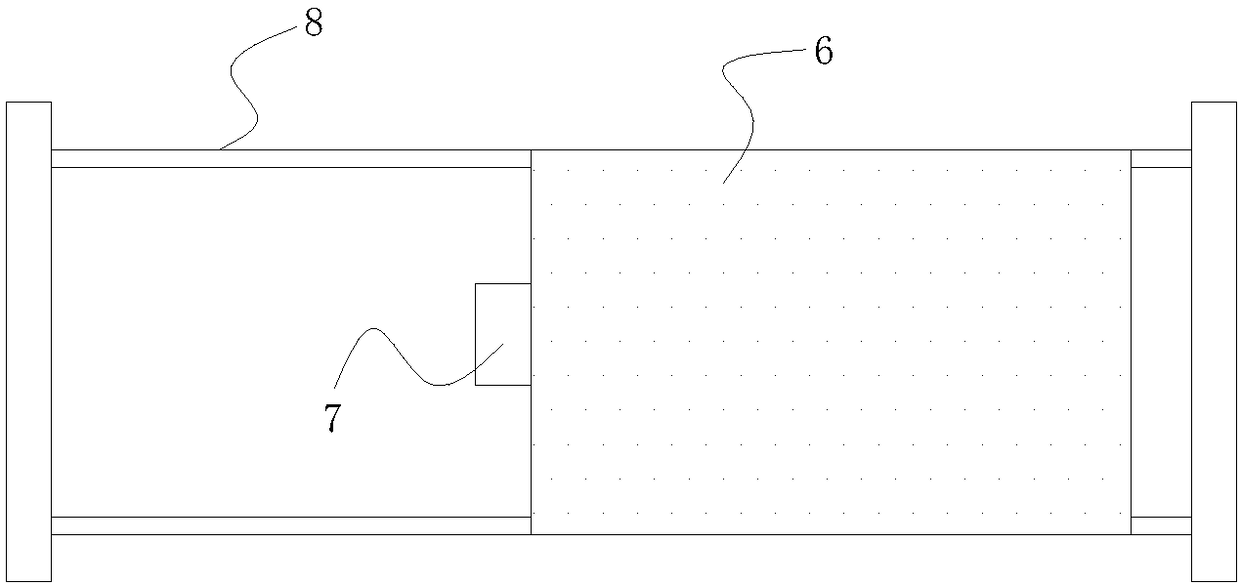

[0031] like figure 1 , image 3 as shown, figure 1 is a schematic diagram of the structure of the high-efficiency die-cutting device, image 3 It is a top view of the feeding mechanism.

[0032] A high-efficiency die-cutting device for release paper, comprising a die-cutting board 1 and a die-cutting knife cylinder 2, the die-cutting knife cylinder 2 runs through the die-cutting board 1 and the top and bottom ends of the die-cutting knife cylinder 2 are corresponding The upper and lower end faces of the die-cutting plate 1 protrude out, and the bottom of the die-cutting knife barrel 2 is equipped with a blade 11. The die-cutting device also includes a driving cylinder 5, a transmission mechanism 3 and a feeding mechanism,

[0033] The driving cylinder 5 is connected to the top of the die-cutting knife cylinder 2, and drives the die-cutting knife cylinder 2 to reciprocate up and down; the driving cylinder 5 includes a booster cylinder 51, a cylinder guide rod 52, a guide bas...

Embodiment 2

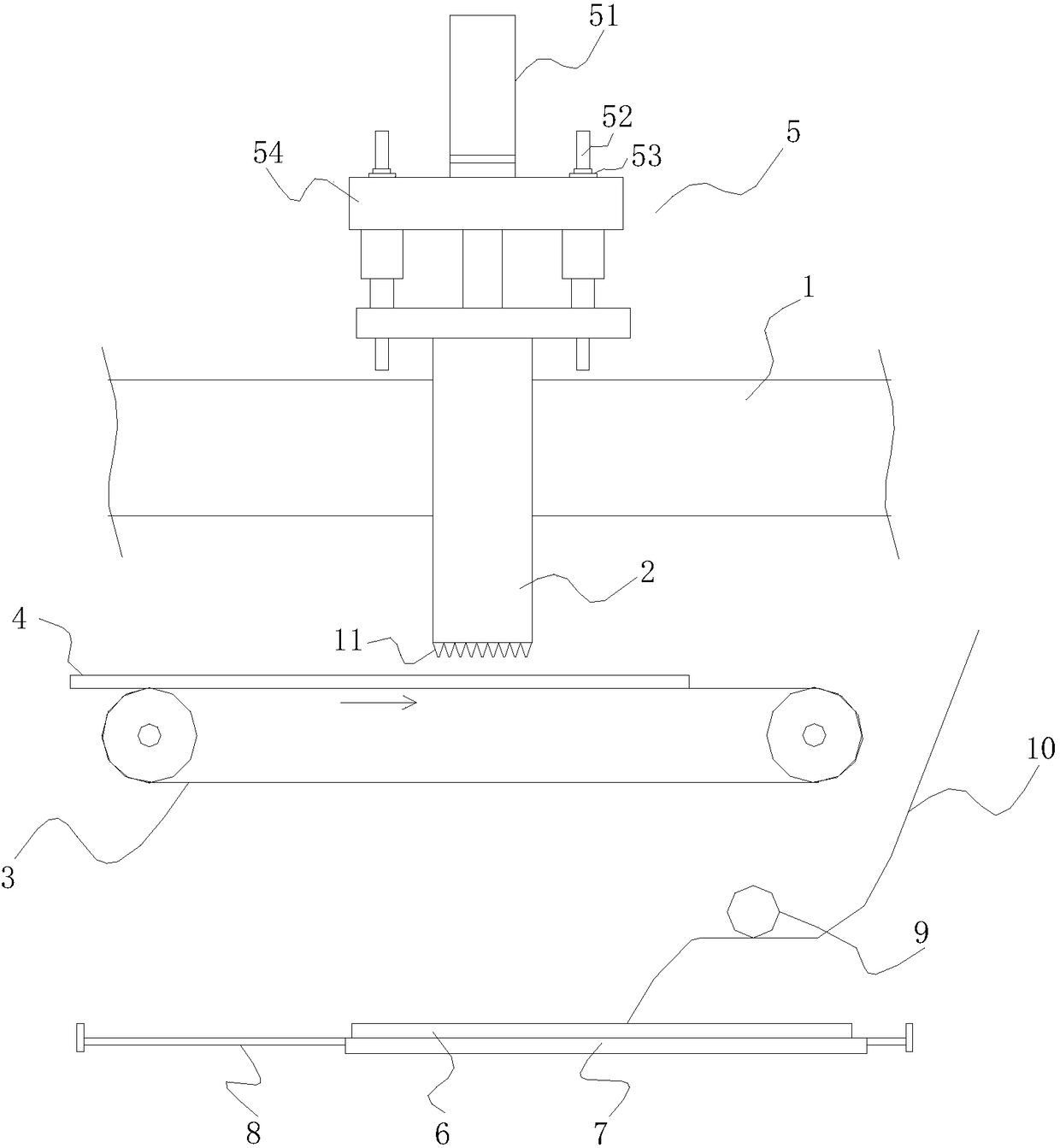

[0042] like figure 2 , image 3 as shown, figure 2 is a schematic diagram of the die-cutting device; image 3 It is a top view of the feeding mechanism.

[0043] A high-efficiency die-cutting device for release paper according to the embodiment of the present invention includes a die-cutting board 1 and a die-cutting knife cylinder 2, the die-cutting knife cylinder 2 runs through the die-cutting board 1 and the die-cutting knife cylinder 2 The top and bottom ends of the die-cutting plate 1 protrude from the upper and lower end surfaces of the die-cutting plate 1 accordingly, and the bottom of the die-cutting knife barrel 2 is equipped with a blade 11. The die-cutting device also includes a driving cylinder 5, a transmission mechanism 3 , auxiliary processing part 9 and feeding mechanism,

[0044]The driving cylinder 5 is connected to the top of the die-cutting knife cylinder 2, and drives the die-cutting knife cylinder 2 to reciprocate up and down; the driving cylinder 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com