Die cutting process for single-sided high-hardness thick copper plate

A technology of high-hardness and thick copper plates, which is applied in the manufacture of printed circuits, electrical components, printed circuits, etc., can solve problems such as waste residues, inability to maintain the stability of single-sided high-hardness thick copper plates, end-face flatness, end-face warpage, etc., to achieve Maintain stability, facilitate centralized recycling and reuse, and avoid end face warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

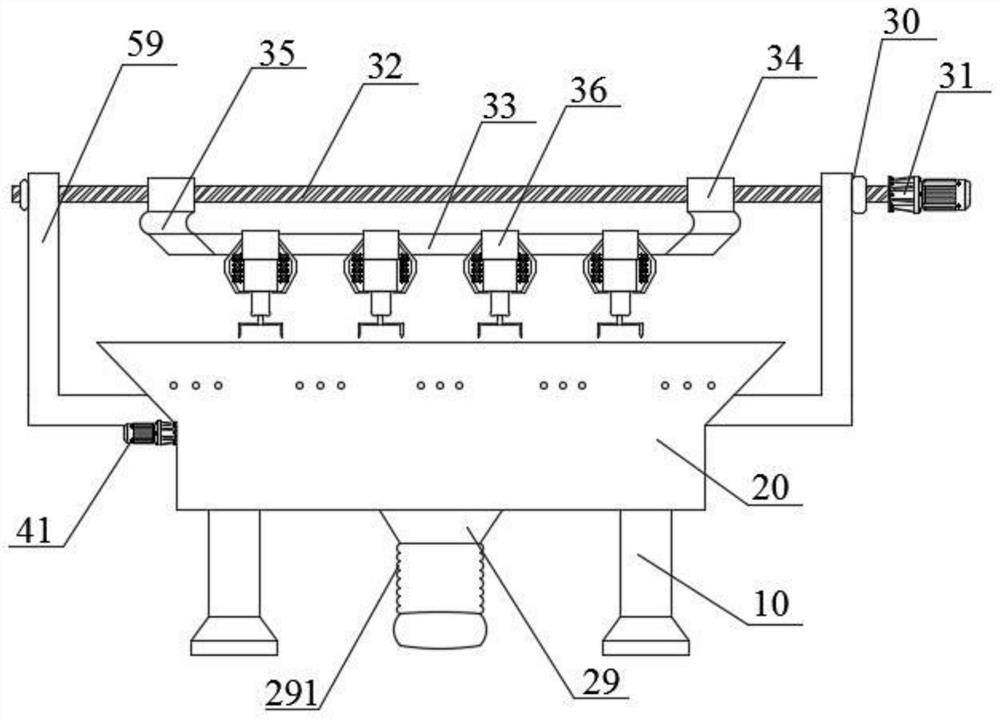

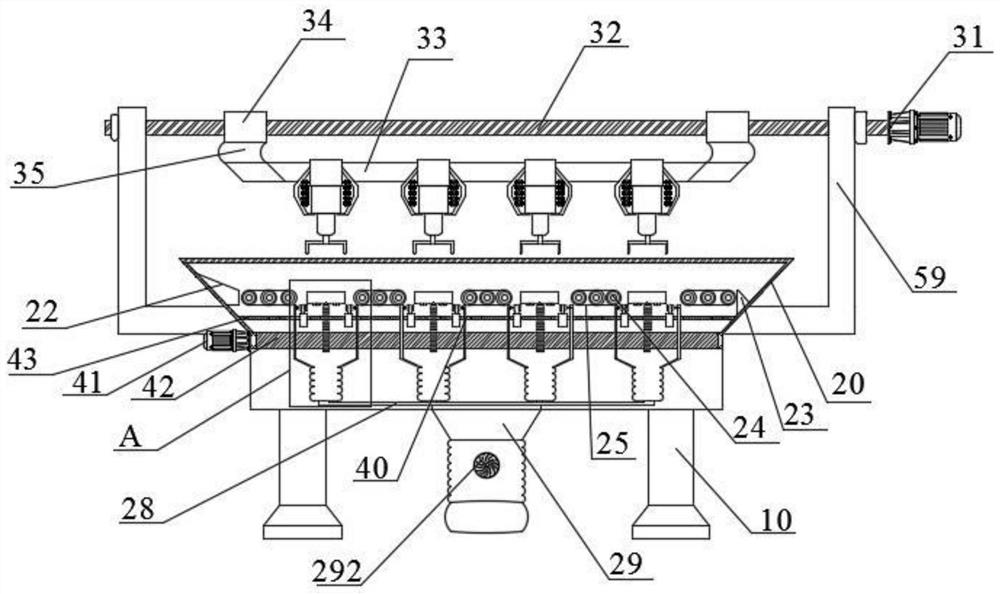

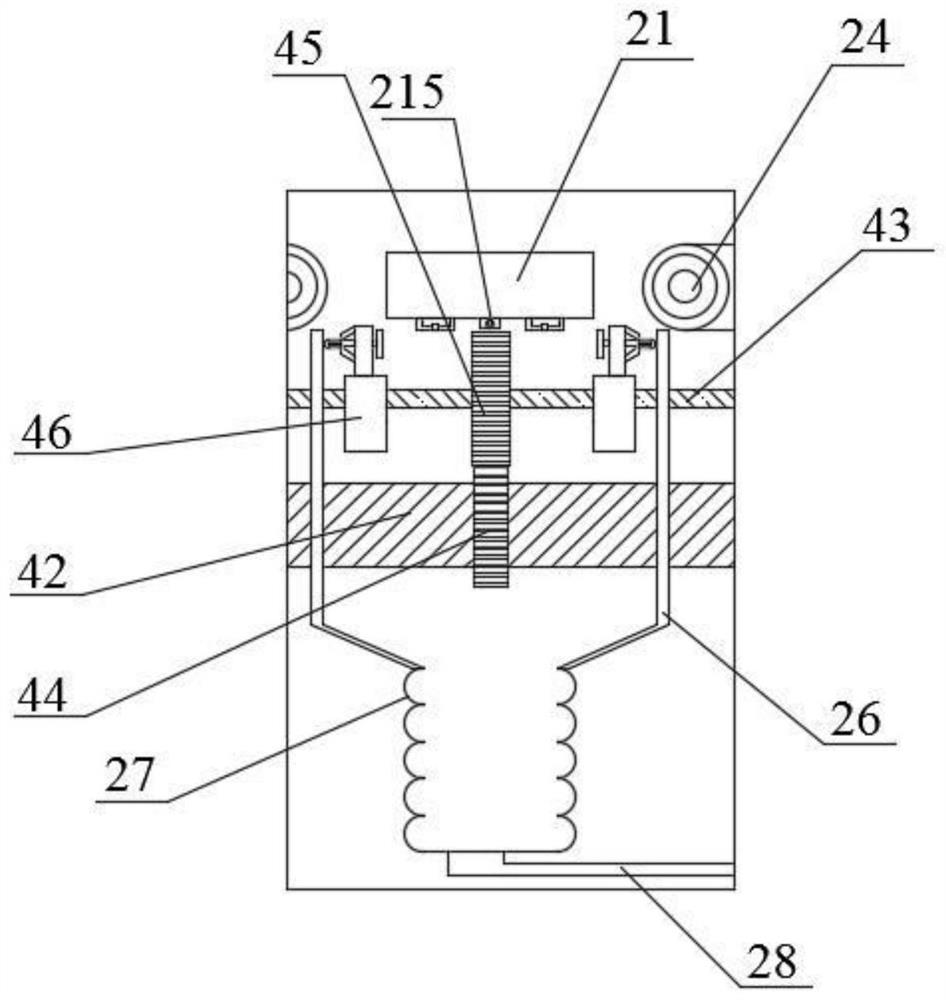

[0036] like Figure 1-3As shown, this embodiment provides a die-cutting device for a single-sided high-hardness thick copper plate, including a bracket 10, a mounting shell 20, and an adjustable die-cutting mechanism 30. The bracket 10 is arranged below the mounting shell 20, and can be The die-adjusting and cutting mechanism 30 is arranged above the installation casing 20, and the installation casing 20 is provided with a fixing device for limiting and fixing the single-sided high-hardness thick copper plate and performing end face milling on the single-sided high-hardness thick copper plate after die-cutting. Milling mechanism 40 . The die-cutting equipment performs adjustable die-cutting on a plurality of single-sided high-hardness thick copper plates through the adjustable die-cutting mechanism 30. The fixed milling and grinding mechanism 40 is limited and fixed during the die-cutting process, and end-face milling is performed after the die-cutting is completed. Maintain ...

Embodiment 2

[0043] like Figure 2-3 , Figure 7 As shown, this embodiment provides a die-cutting equipment for single-sided high-hardness thick copper plates. The difference from Embodiment 1 is that a feeding table 22 is provided on one side of the inner cavity of the mounting shell 20, and the inner cavity is on the other side. A feeding table 23 is provided on one side. The inner cavity of the mounting shell 20 is located between the feeding table 22 and the die-cutting table 21 , between the adjacent die-cutting tables 21 , and between the die-cutting table 21 and the unloading table 23 , and there are multiple parallel roller sets. , the roller set consists of a plurality of parallel rollers 24 and a conveyor belt 25 wound around each roller 24 . The feeding table 22 is used for feeding the single-sided high-hardness thick copper plate, the roller set is used for conveying the single-sided high-hardness thick copper plate, and the unloading table 23 is used for unloading the single...

Embodiment 3

[0050] like Figure 1-7 As shown, this embodiment provides a single-sided high-hardness thick copper plate die-cutting process, which includes the following steps:

[0051] Step 1, after adding the single-sided high-hardness thick copper plate from the feeding table 22 of the die-cutting equipment, place a plurality of single-sided high-hardness thick copper plates in the accommodating groove 211 of the die-cutting table 21 through the roller set;

[0052] In step 2, the first reduction motor 41 drives the driving shaft 42 to rotate forward or reversely, the driving shaft 42 drives the driving gear 44 to rotate, and the driving gear 44 drives the driven gear 45 and the driven shaft 43 meshed with it to rotate, so that the limit milling is performed. The structure rotates to the lower sides of the die-cutting table 21; the second deceleration motor 31 drives the ball screw 32 to rotate, and the screw seat 34 meshing with the ball screw 32 drives the plurality of fixed tables 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com