Film laminating machine for easy-to-tear adhesive sticker label

A label laminating machine and frame technology, applied in lamination devices, lamination auxiliary operations, instruments, etc., can solve the problems of low work efficiency, complex self-adhesive label processing technology, etc., to ensure levelness, improve mold The effect of cutting efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

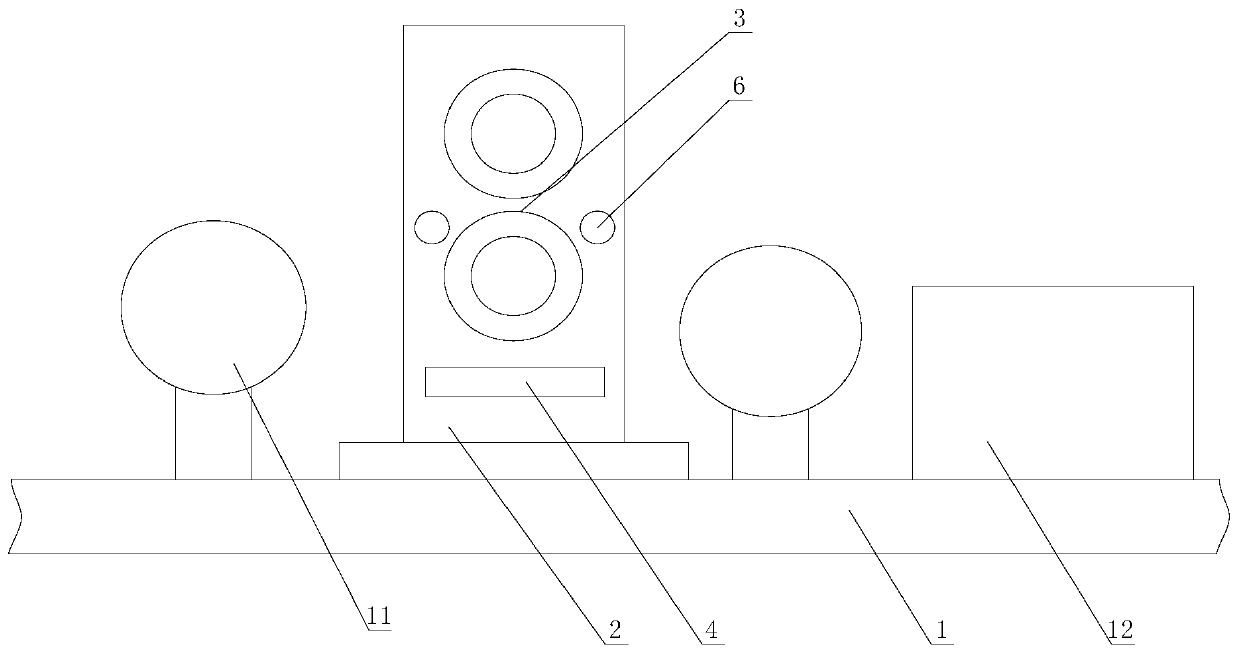

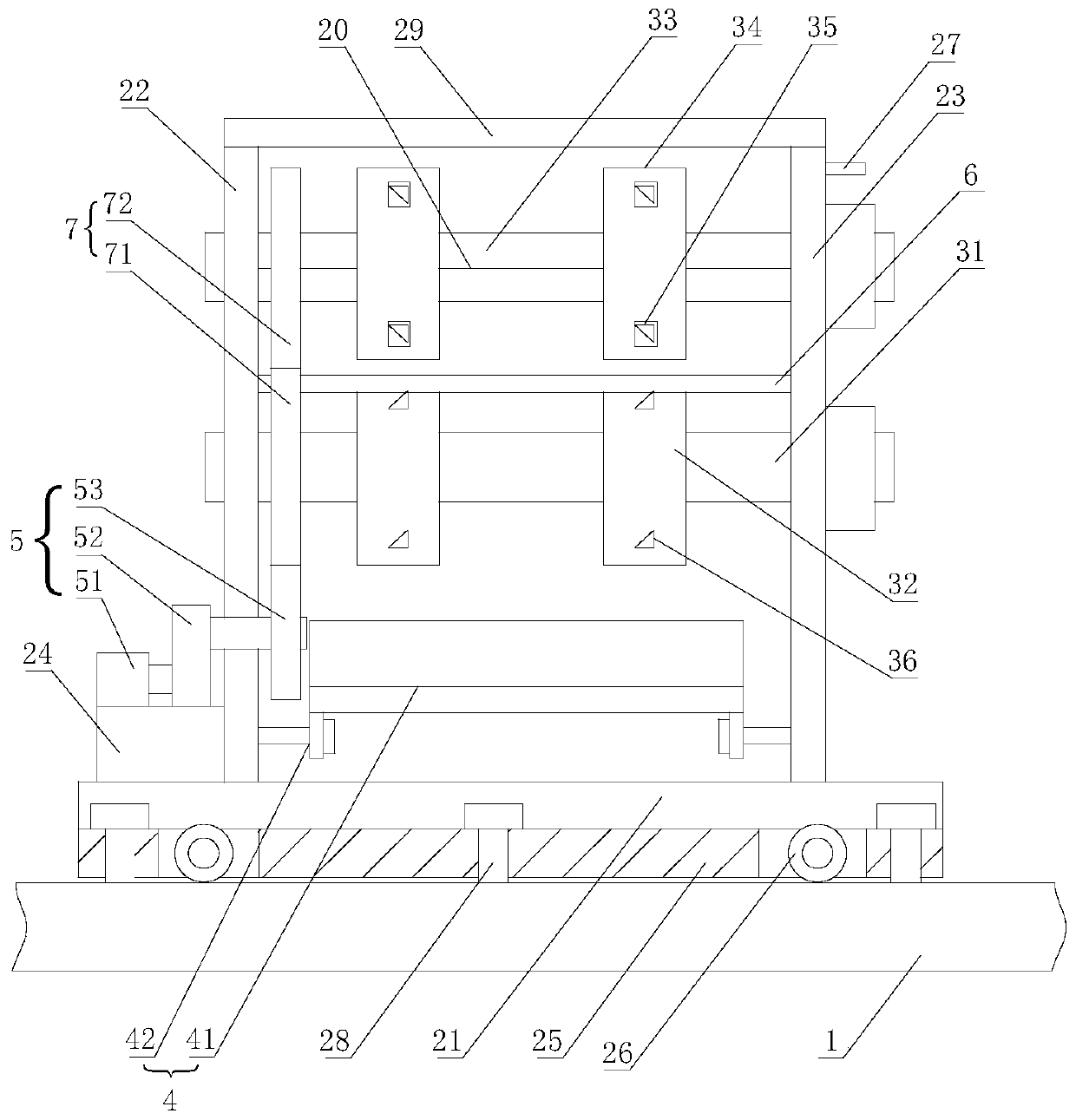

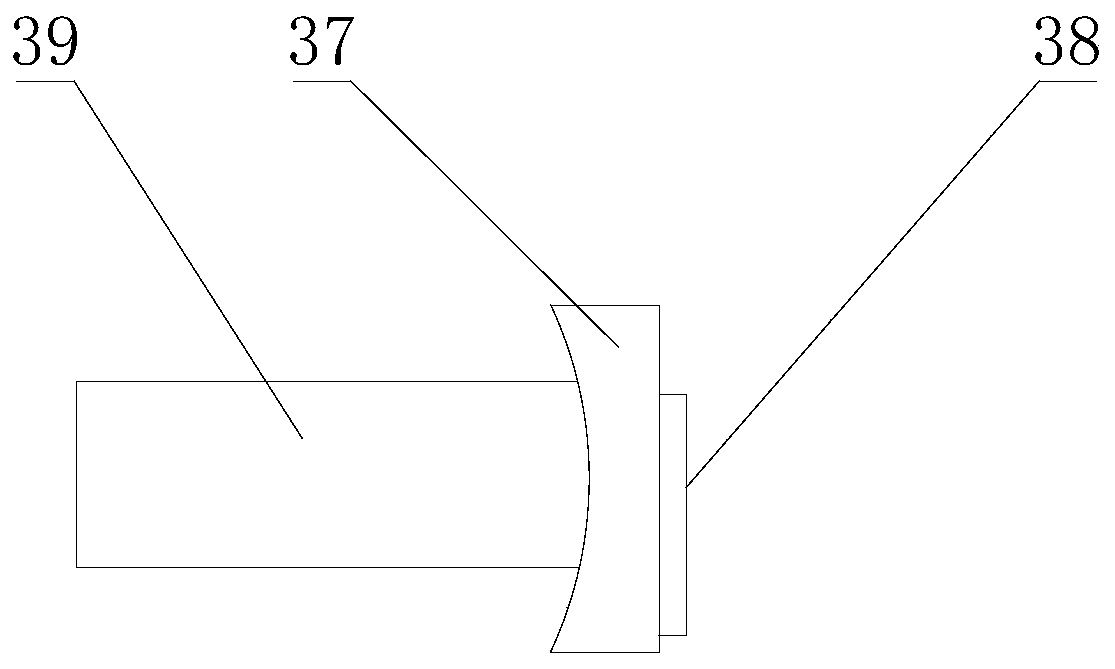

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an easy-to-tear self-adhesive label laminating machine includes a frame 1, and the frame 1 includes a feed drum 11, a gluing device 12 and a base 2, and the feed drum 11 and the base 2 in the present embodiment The gluing device 12 is a prior art, which is not described in detail in this embodiment. The base 2 is arranged between the feed drum 11 and the gluing device 12. The base 2 includes a die-cutting assembly 3 and a waste collection unit. Component 4, the die-cutting component 3 is rotatably connected to the base 2, the waste collection component 4 is detachably installed on the base 2 below the die-cutting component 3, and the base 2 is provided with a die-cutting The drive assembly 5 connected to the assembly 3, the base 2 is also provided with a guide support rod 6.

[0023] By setting the base 2 between the feed roller 11 and the gluing device 12, during the self-adhesive production process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com