Constant-speed closed-loop photo electrically controlled mask discharging mechanism

A speed closed-loop, photoelectric control technology, applied in the direction of thin material processing, winding strips, transportation and packaging, etc., can solve the problems of poor accuracy, difficult mask die-cutting height synchronization, affecting the quality and efficiency of mask die-cutting and folding, etc. , to achieve high precision, improve die-cutting quality and efficiency, and synchronously discharge the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

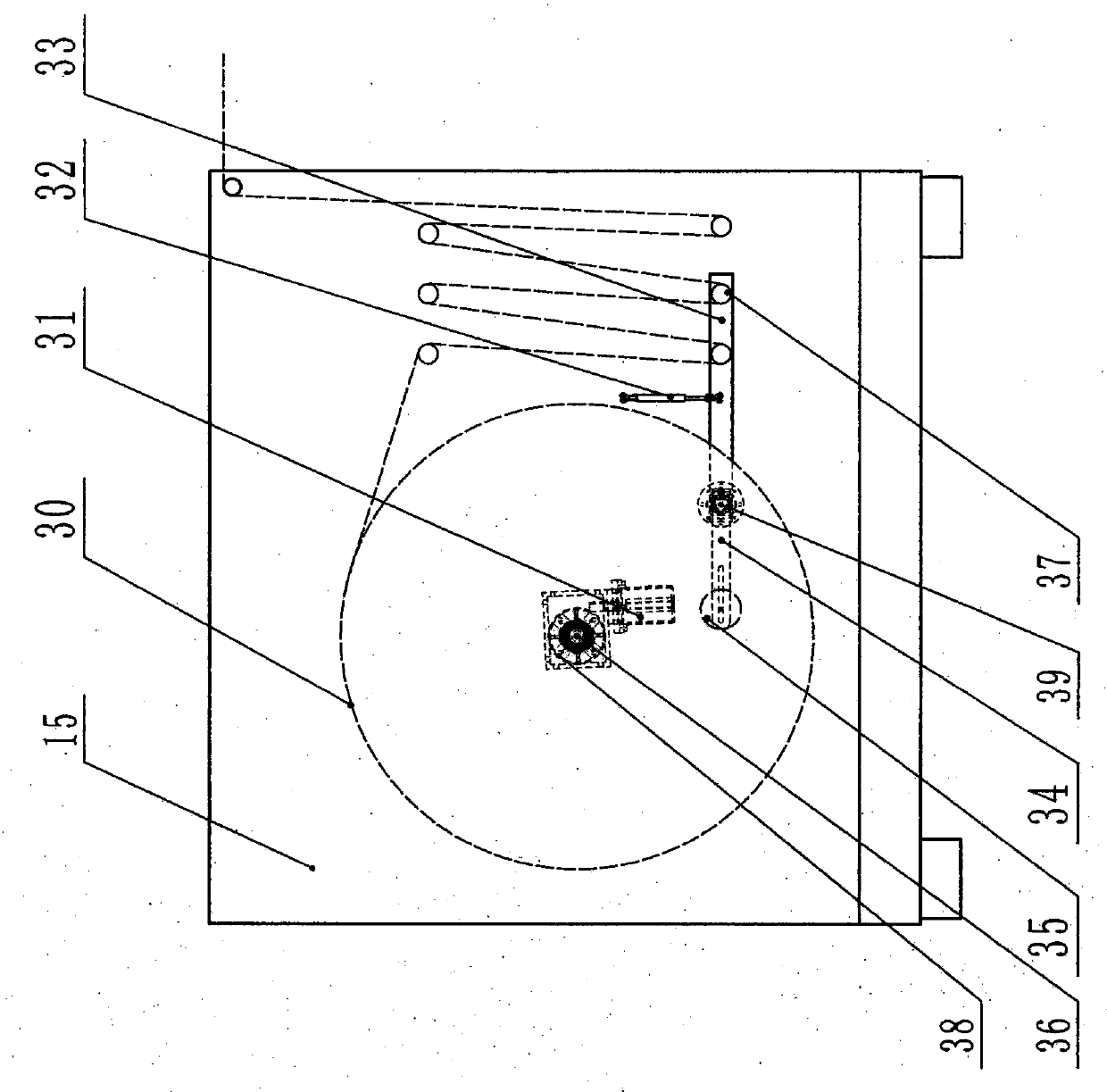

[0008] refer to figure 1 It can be seen that the present invention is applied to the constant speed closed-loop photoelectric control mask discharge mechanism of the automatic non-woven facial mask packaging machine, including the frame 15, the material bearing shaft 36, and the guide roller 37, and the material bearing shaft 36 passes through the intermediate transmission assembly 38 Link to each other with discharging motor 31 (comprising deceleration function), described frame 15 is equipped with swing arm mandrel 39 (it is corresponding with the guide roller position of frame bottom), in this swing arm mandrel 39 (as fulcrum) One end is equipped with a floating balance assembly (it is composed of a counterweight swing arm 34 and a counterweight 35 on the counterweight swing arm 34, which plays a balancing role), and the other end of the swing arm mandrel 39 is equipped with a floating swing arm 33, so The guide roller 37 (generally the guide roller at the bottom of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com