Die cutting equipment capable of separating electrostatic paper

A belt separation, paper technology, applied in the direction of pile separation, thin material processing, metal processing, etc., can solve the problems of paper waste, equipment stoppage, unqualified die-cut products, etc., to avoid paper waste, improve work efficiency, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

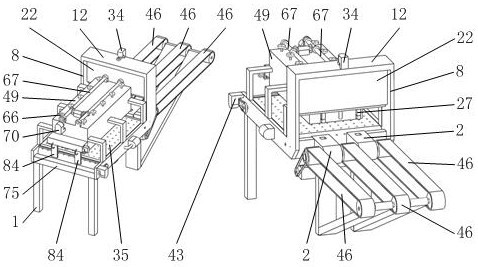

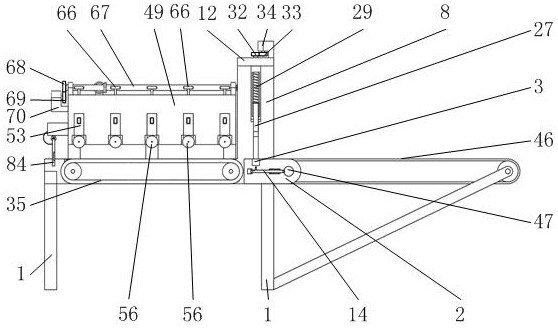

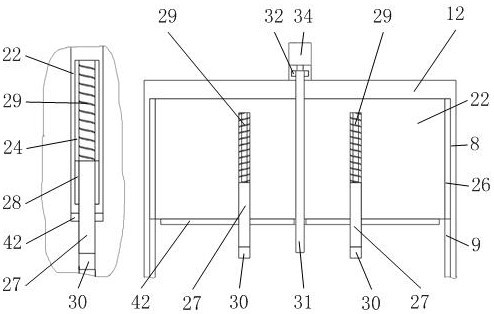

[0031] The accompanying drawings are schematic diagrams of the implementation of the present invention, so as to facilitate the understanding of the operation principle of the structure. The specific product structure and proportions can be determined according to the use environment and conventional techniques.

[0032] like figure 1 , 2 As shown, it includes support block 2, conveyor belt A46, conveyor belt B35, pressure seat 22, motor A34, motor B43, rotating shaft D83, baffle 84, sensor 85, leaf spring 86, separation rod 89, motor D92, motor E96 , where as figure 1 , 2 As shown, there is a support block 2 for connecting and transitioning between the conveyor belt A46 driven by the motor E96 and the conveyor belt B35 driven by the motor B43 and with its own suction cup structure; the fixed seat A49 above the conveyor belt B35 has a paper The structure that presses the paper when it is completely moved to the conveyor belt B35 and automatically resets after separating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com