Method for improving die-cutting quality of carton

A die-cutting and quality technology, which is applied in the direction of papermaking, paper/cardboard containers, rigid/semi-rigid containers, etc., can solve the problems of manual feeding of unit cardboard, easy wear and tear of die-cutting knives, low work efficiency, etc., to achieve work High efficiency, high degree of automation, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

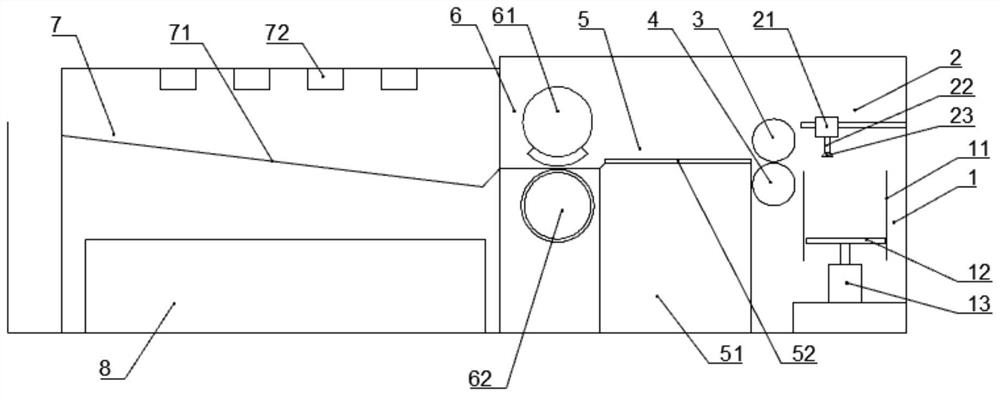

[0024] Such as figure 1 and figure 2 As shown, a method that can improve the quality of carton die-cutting includes the following steps:

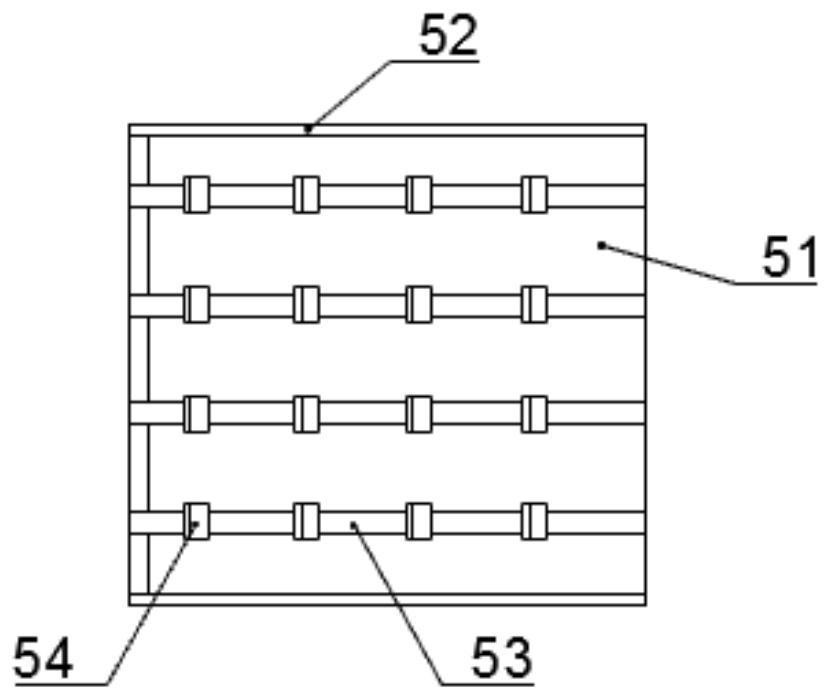

[0025] S1. Send a plurality of neatly stacked unit cardboards to the discharge rack 1, and the discharge mechanism 2 sequentially sends the individual unit cardboards between the first feed roller 3 and the second feed roller 4, and the discharge rack 1 Comprising a frame body 11 with top and bottom openings, the bottom of the frame body 11 is provided with a movable plate 12, and the bottom of the movable plate 12 is provided with a lifting cylinder 13, and the lifting cylinder 13 controls the movable plate 12 to move up and down, and the discharging mechanism includes a mobile base 21, Electric telescopic rod 22 and suction cup 23, suction cup 23 is fixed on the electric telescopic rod 22, electric telescopic rod 22 is fixed on the mobile base 21, and mobile base 21 moves on the slide rail, and the feeding mechanism utilizes suction cup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com