Packing box punching tool plate

A packaging box and punching technology, used in metal processing and other directions, can solve the problems of arching and burrs of printed matter, die-cutting failure, increased contact surface and friction, etc., and achieve the effect of improving die-cutting quality and die-cutting stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments,

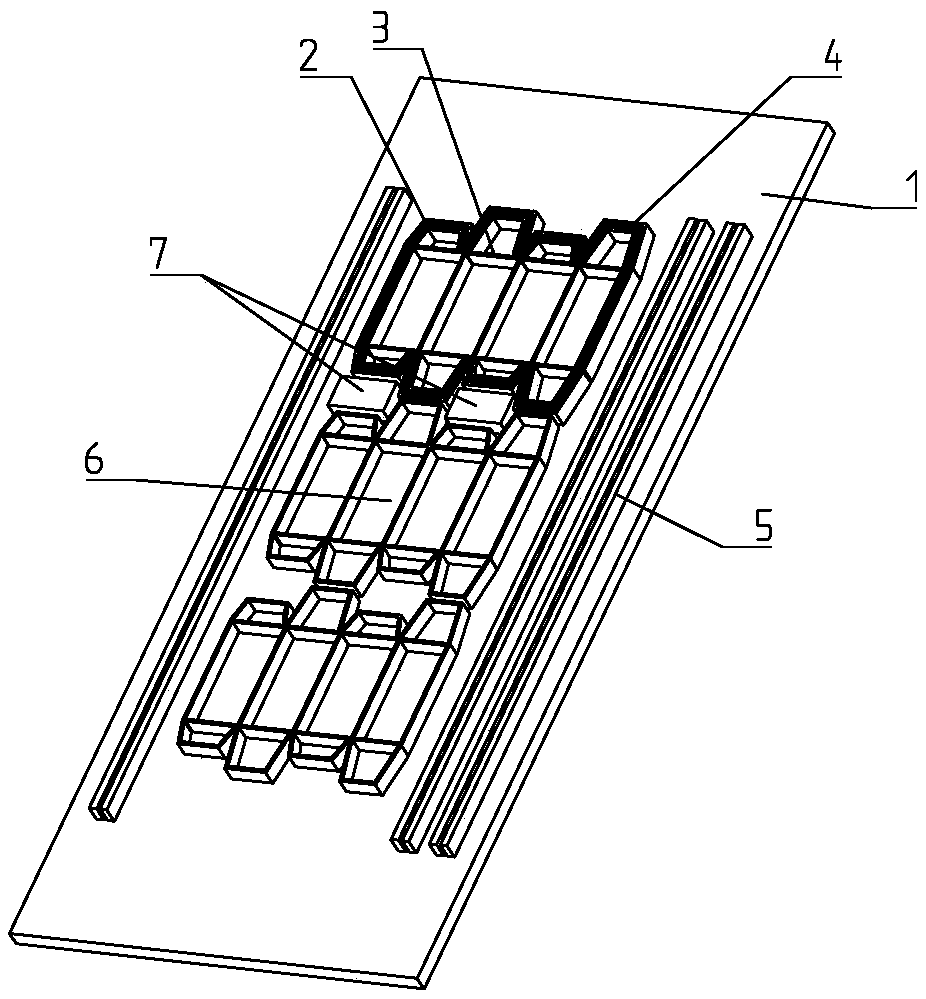

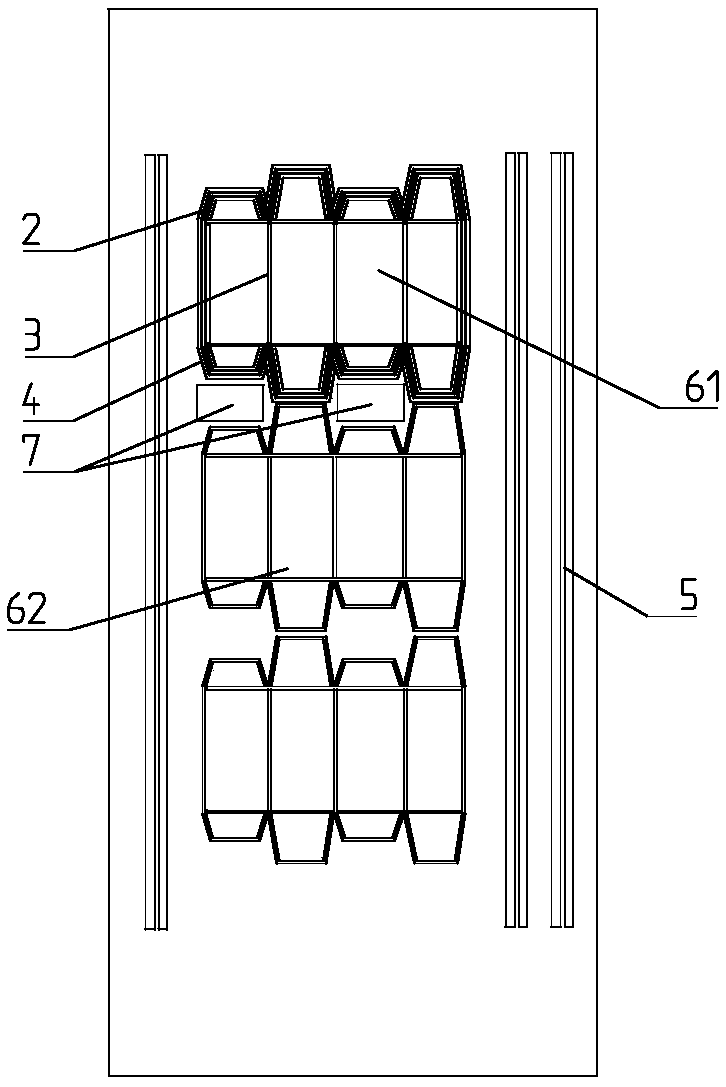

[0020] A packaging box stamping knife plate, including a plate body 1, a plurality of die-cut blocks according to the typesetting of the packaging box, the die-cut blocks include a cutting knife body 2 and an indentation knife body 3 fixed on the plate body 1, this embodiment Among them, the die-cutting block is divided into a first die-cutting block 61 and a second die-cutting block 62 (the second die-cutting block 62 is a cutting knife body 2 and an indentation knife body 3 without an elastic pad 4 in the prior art, so as to facilitate Compared with the strokes of the cutting knife body 2 and the creasing knife body 3 placed with elastic pads), the arrangement of the cutting knife body 2 and the creasing knife body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com