Die cutting machine for printing

A technology of die-cutting machine and die-cutting plate, which is applied in metal processing and other directions, can solve the problems of low die-cutting quality and poor precision, and achieve the effect of improving die-cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached Figure 1-5 The application is described in further detail.

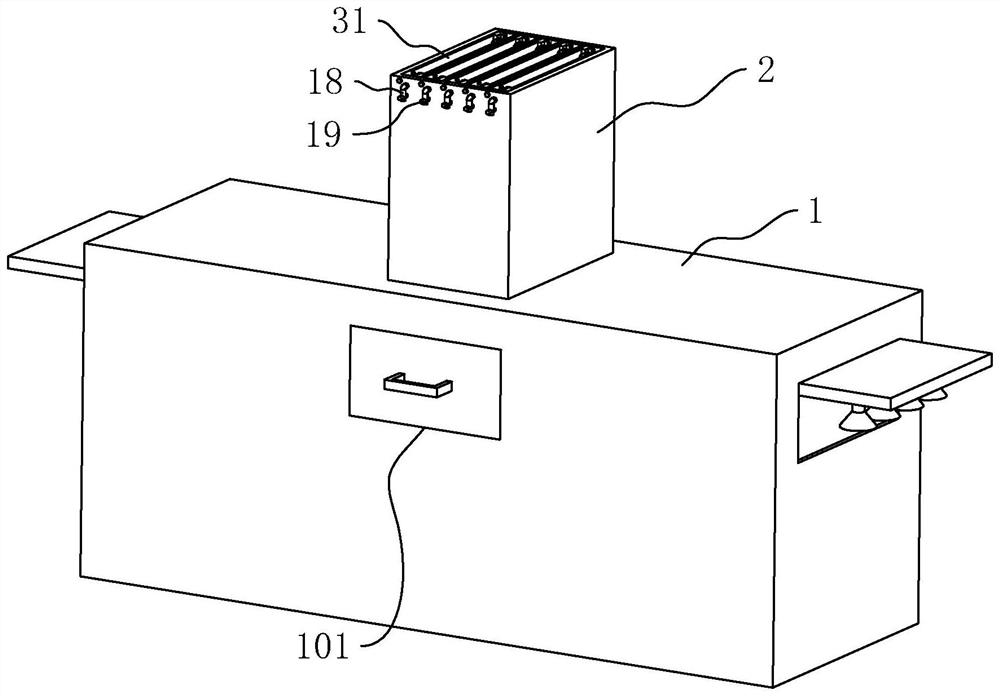

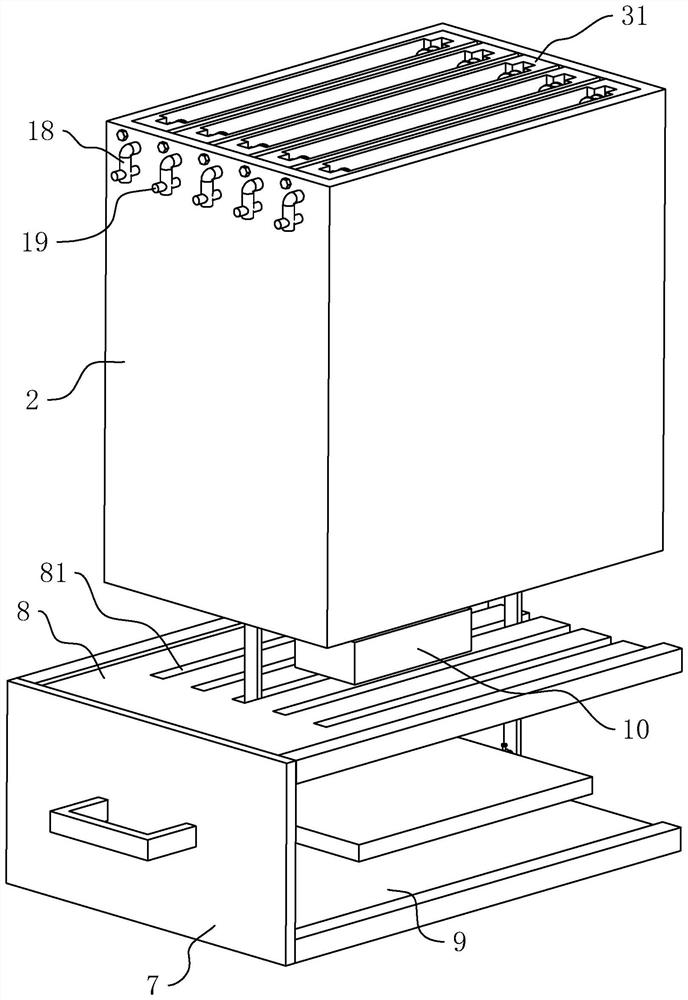

[0032] The embodiment of the present application discloses a printing die-cutting machine. refer to figure 1 , figure 2 and image 3 , The die-cutting machine for printing includes a body 1, one end of the body 1 in the length direction is a feed end, and the other end is a discharge end.

[0033] The top of the machine body 1 is connected with a plate storage box 2 with a hollow interior and an open top. Multiple die-cutting components are arranged in the plate storage box 2, and the multiple die-cutting components are evenly arranged along the direction from the feeding end to the discharging end. , Different die-cutting components are used to die-cut different products.

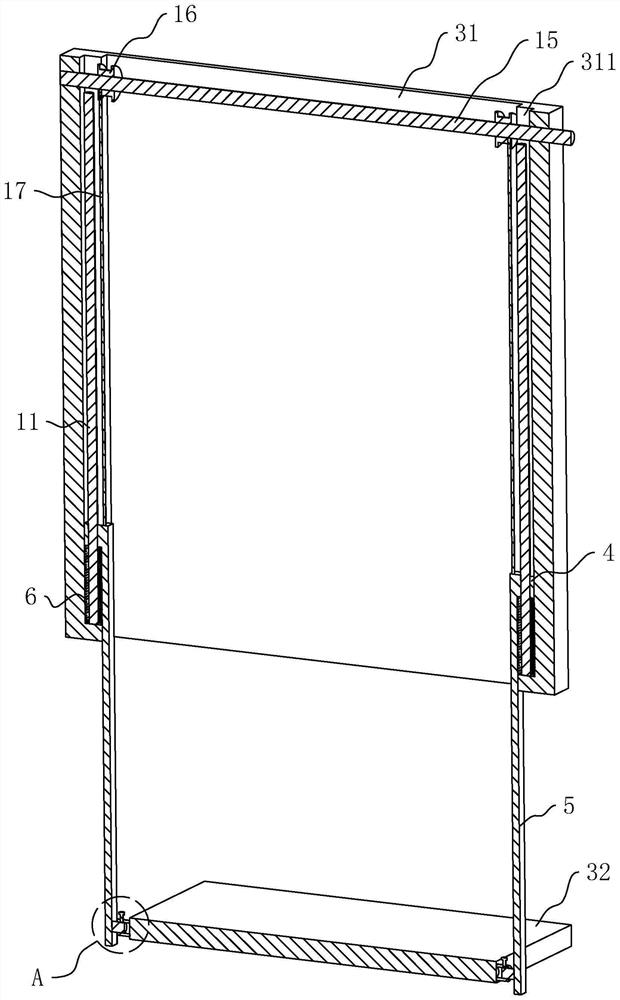

[0034] The die-cutting assembly includes an installation box 31 bolted in the plate storage box 2 , and a die-cutting plate 32 located in the installation box 31 . The inside of the installation box 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com