Electric connector

A technology for electrical connectors and docking parts, which is applied in the directions of connections, circuits, and parts of connecting devices, can solve the problems of disadvantage, save manufacturing costs, and high difficulty in assembly, so as to reduce manufacturing difficulty, save manufacturing costs, and ensure accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

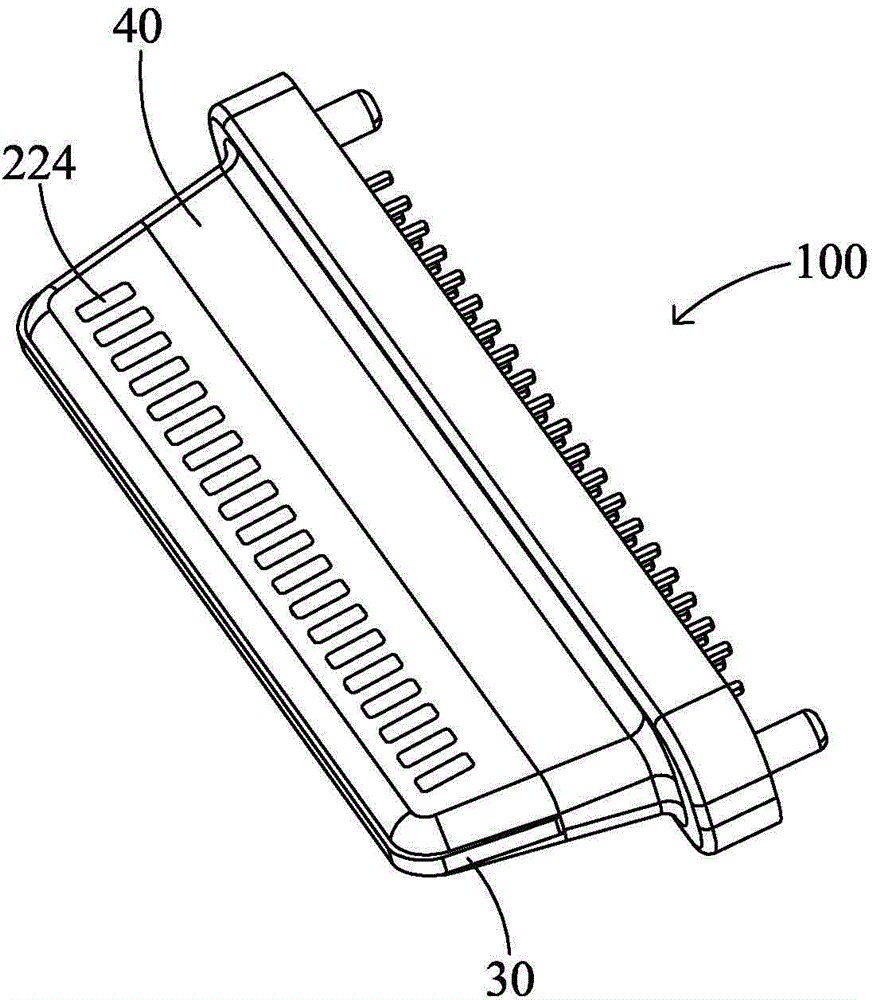

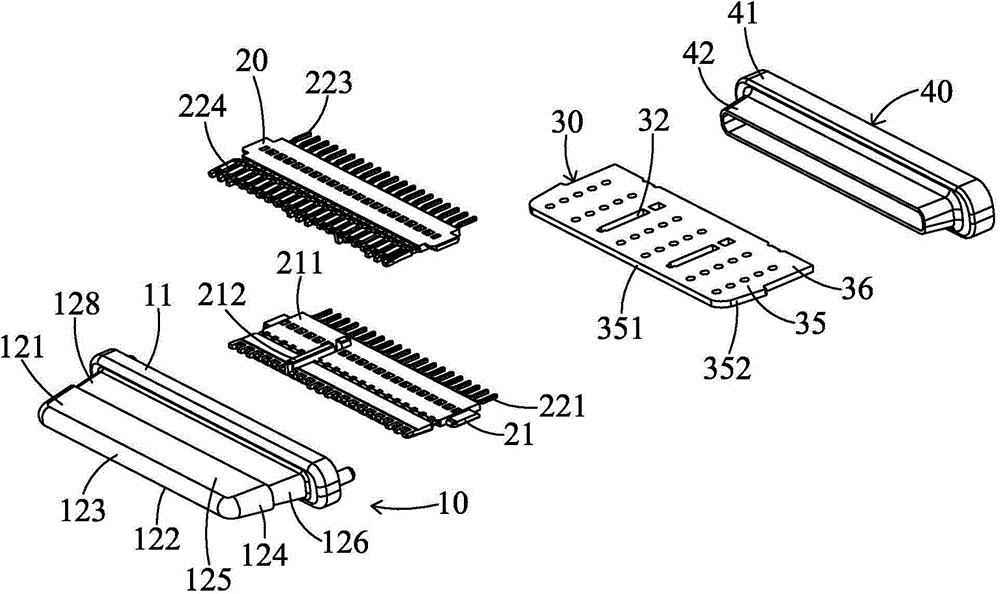

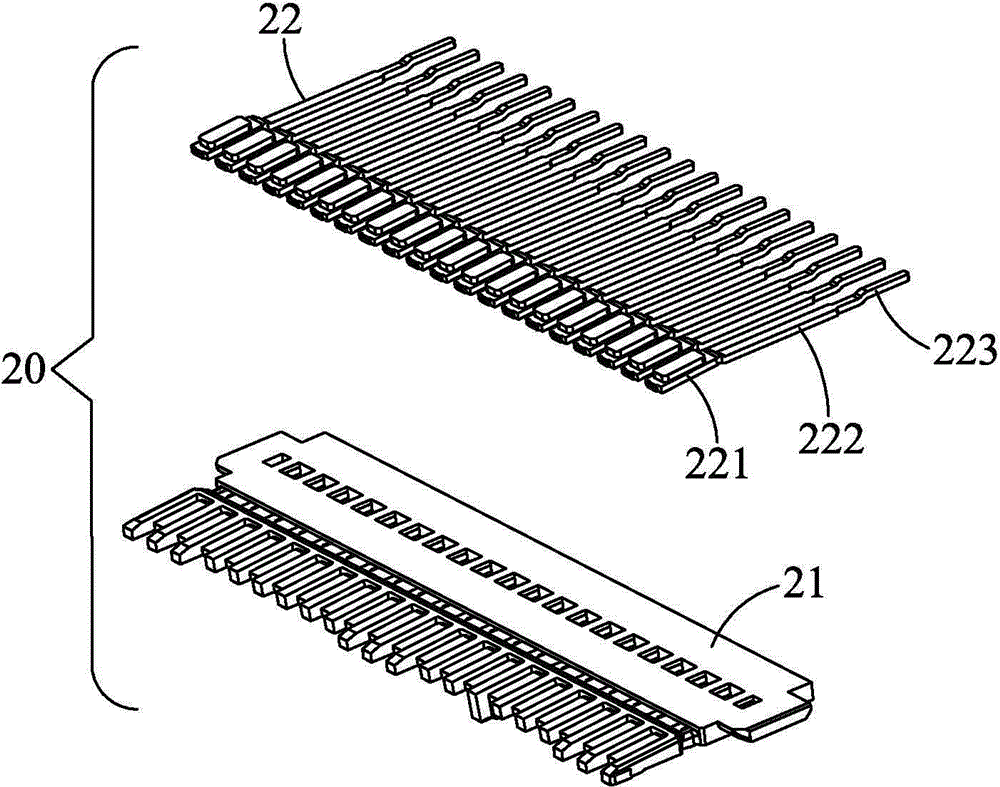

[0016] see Figure 1 to Figure 3 As shown, the electrical connector 100 according to the first embodiment of the present invention is a plug connector, which is used to be inserted into a mating connector (not shown), which includes an insulating body 10, two terminal modules 20, a metal shield Sheet 30 and a metal shell 40.

[0017] The insulating housing 10 includes a main body 11 and a plate-shaped butt joint 12 protruding forward from the middle of the main body 11 . The thickness and width of the main body 11 are larger than the butt joint 12 . The docking portion 12 supports forward and reverse insertion of the electrical connector 100 , and the docking portion 12 is symmetrical up and down, left and right, and its thickness and width gradually increase from front to back. The docking part 12 has opposite upper and lower surfaces 121, 122 and a front end surface 123 between the upper and lower surfaces 121, 122 and opposite side surfaces 124, and the upper and lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com