Cassette positioning device and semiconductor processing device

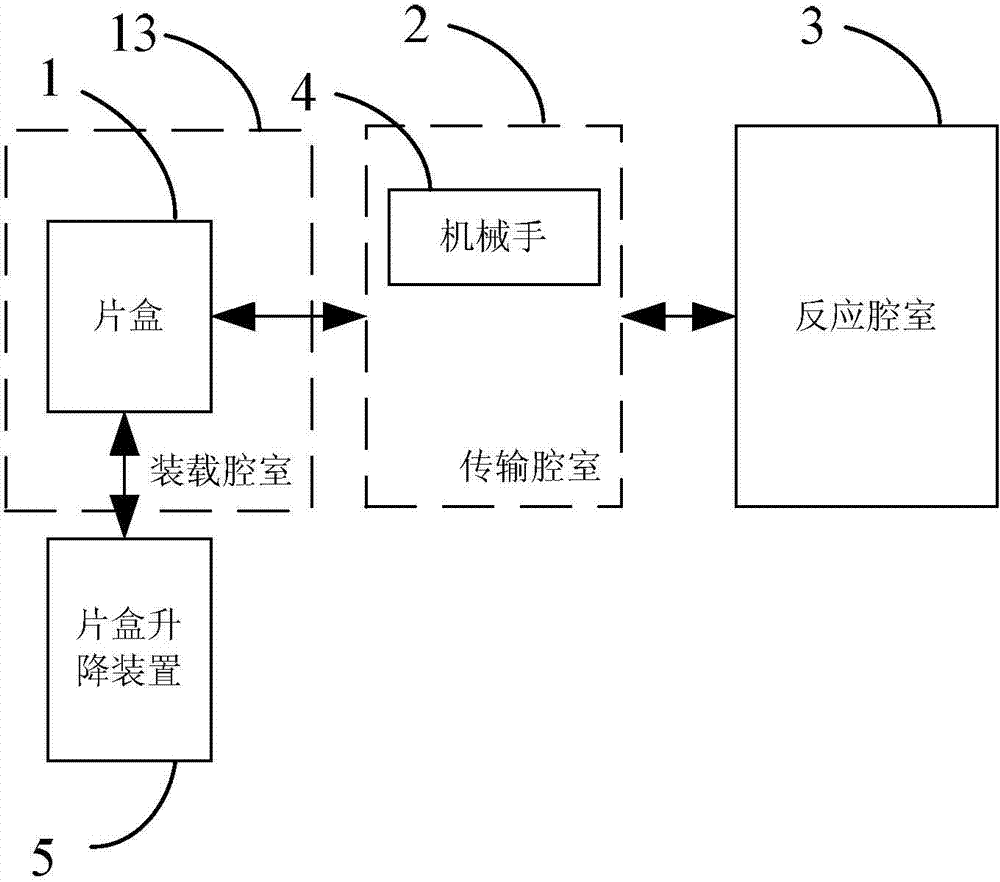

A technology for positioning devices and cassettes, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as non-unique positions, inconvenient maintenance, reduced transmission and process efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

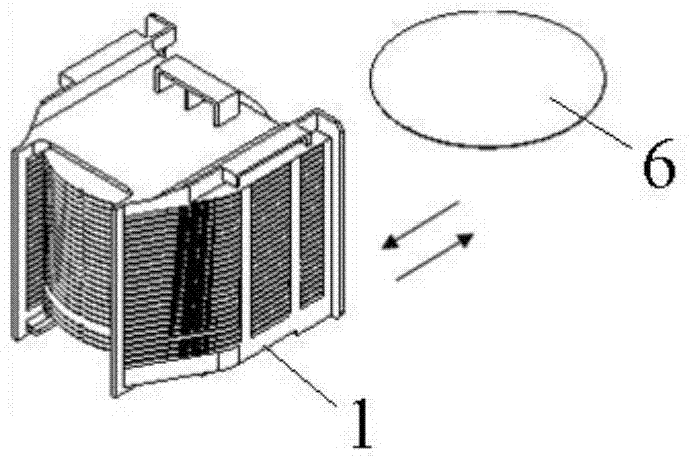

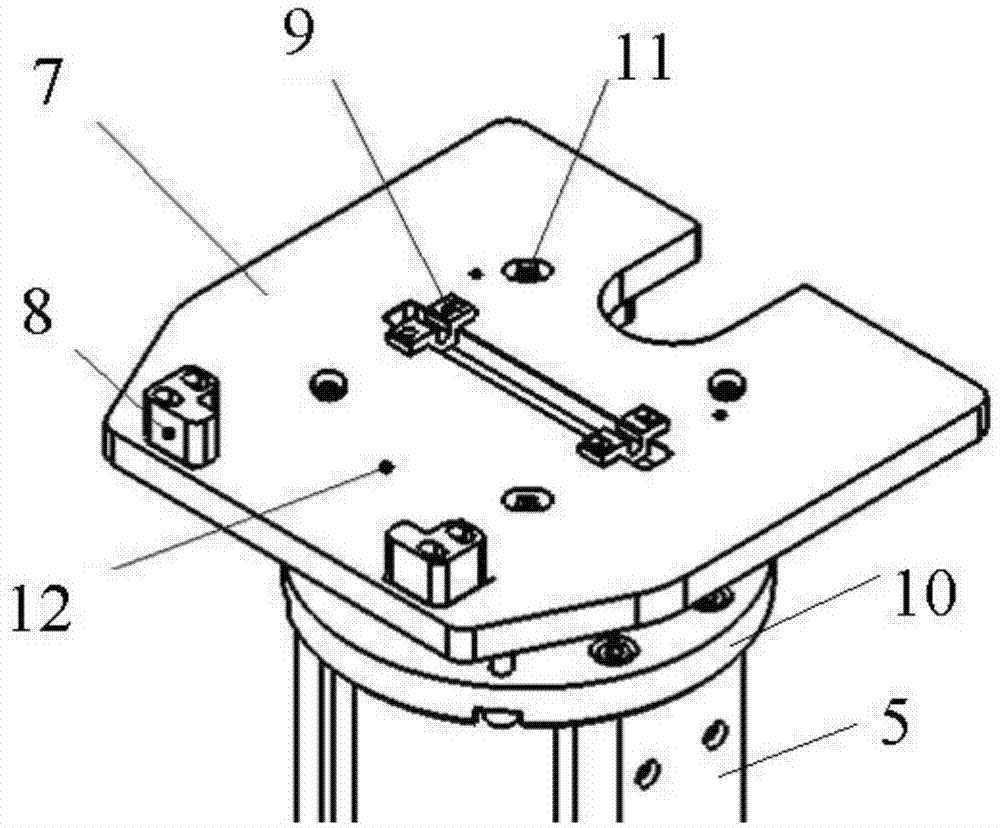

[0041] Please also refer to Figures 5A-5E , the film cassette positioning device provided by the first embodiment of the present invention is located in the loading chamber 20 for accommodating the film cassette 33, and is driven by the lifting device 31 to move linearly in the vertical direction to cooperate with the manipulator (Fig. (not shown in ) completes taking or putting the film from the film box 33.

[0042] The cassette positioning device includes a positioning bottom plate 21 , a rotating positioning plate 22 and a support column 23 . Wherein, the positioning base plate 21 is arranged horizontally, and is connected with the elevating device 31. In the present embodiment, the elevating device 31 has a connecting plate 32 arranged horizontally, and the positioning base plate 21 is screwed on the connecting plate 32 by screws 24 to realize the lifting and lowering. Device 31 connections. Preferably, set screws 25 are also provided on the positioning bottom plate 21...

no. 2 example

[0051] Figure 7A It is a schematic diagram of the cassette positioning device provided by the second embodiment of the present invention. Figure 7B for Figure 7A Enlarged view of region II in middle. Please also refer to Figure 7A and Figure 7B , the cassette positioning device provided in this embodiment also includes a positioning bottom plate 21 , a rotating positioning plate 22 and a support column 23 . The structures and functions of the positioning bottom plate 21 , the rotating positioning plate 22 and the support column 23 are the same as those of the above-mentioned first embodiment, and since they have been described in detail in the above-mentioned first embodiment, they will not be repeated here. Only the differences between this embodiment and the above-mentioned first embodiment will be described in detail below.

[0052] Specifically, the cassette positioning device further includes a support column lifting mechanism 34 for driving the support column 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com