Probe cleaning sheet and cleaning method

a technology of cleaning sheet and probe, which is applied in the direction of instruments, semiconductor/solid-state device testing/measurement, manufacturing tools, etc., can solve the problems of affecting the cleaning effect of the probe tip end, and affecting the cleaning effect of the probe. , to achieve the effect of soft and efficient cleaning and sufficient cushioning property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

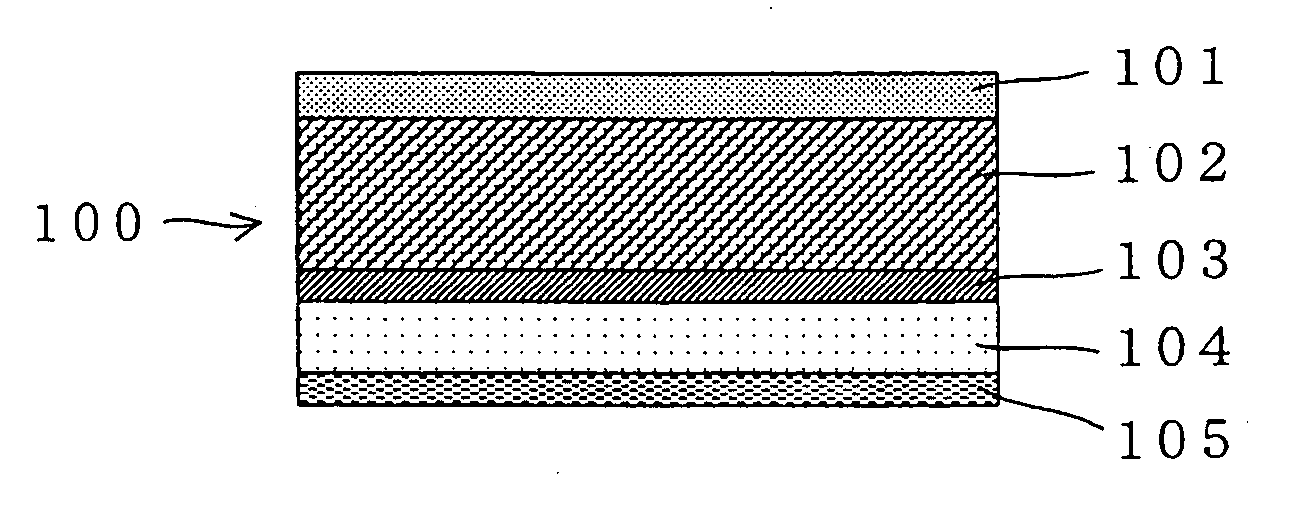

example 1

[0069] A coating liquid (solid content concentration: 50 mass %) was prepared by dispersing 40 mass % of silicon carbide (#4000: grain size 3 μm) in aqueous suspension (PFA concentration: 10 mass %) of tetrafluoro-ethylene-perfluoroalkyl vinyl ether copolymer (PFA). On one surface of a drawn PTFE porous body film having porosity of 70%, average pore diameter of 0.3 μm and thickness of 800 μm, a PET film (thickness: 10 μm) was provided by thermal fusion, to form a laminated body. On the surface of drawn PTFE porous film opposite to the PET film, the coating liquid was applied and dried, to form a polishing layer having the thickness of 50 μm. On a surface of the PET film, an epoxy-based adhesive was applied and dried, to form an adhesive layer (thickness: 90 μm). The adhesive layer was semi-cured by heating at 80° C. for 5 minutes. On the adhesive layer, releasing paper (polyethylene-coated quality paper) was placed, and the resulting body was cut to a cleaning sheet A (thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com