Method for preparing high-stability mesoporous molecular sieve

A mesoporous molecular sieve, high stability technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of mesoporous structure, reduced interaction, high preparation cost, etc., to achieve high Molecular sieve yield, improve stability, reduce the effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides a method for preparing a high-stability mesoporous molecular sieve, the method comprising the following steps:

[0060] (1), using Y-type molecular sieve precursor 1;

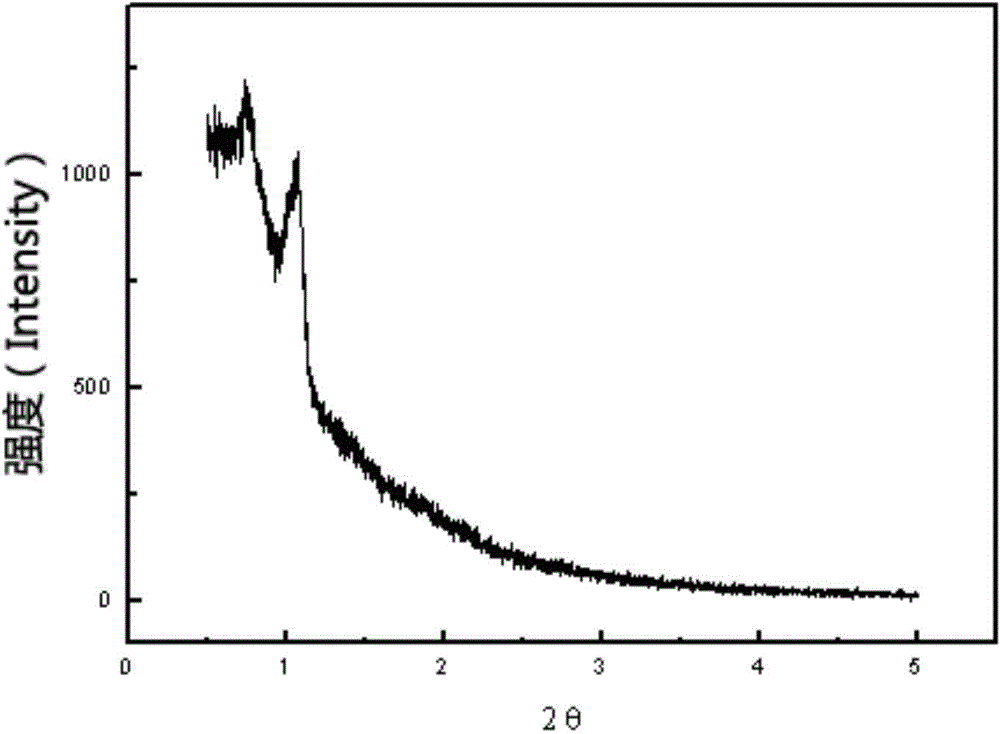

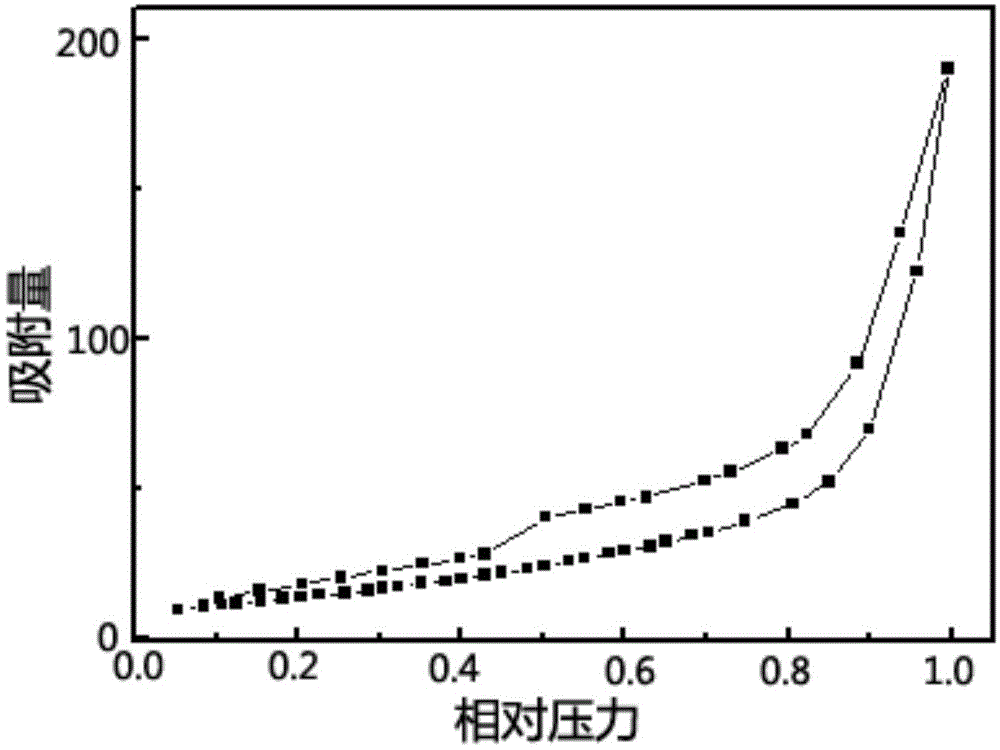

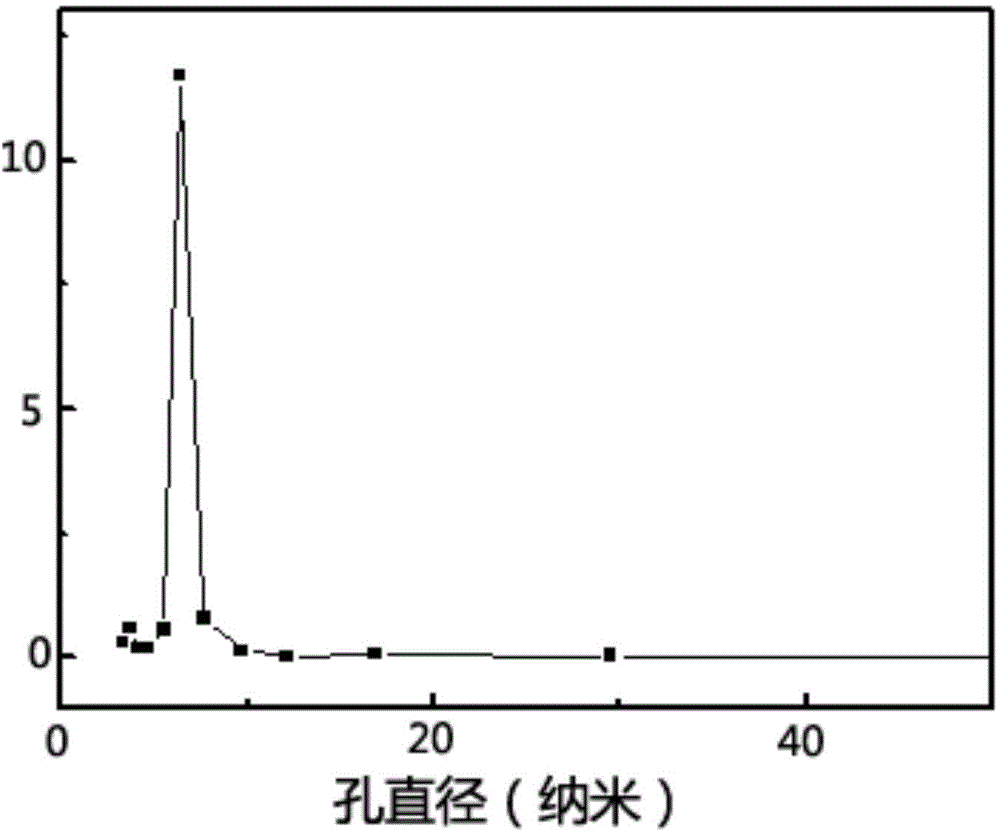

[0061] (2) Crystallization: Take 50g of Y-type molecular sieve precursor 1 solution, add 5g of seed crystals (meso-microporous molecular sieve prepared in Example 1 of CN201110101174.3) to assemble, adjust the pH value to 1, and stir at 30°C for 10 hours. After aging at 30°C for 20 hours, it was transferred to a crystallization tank, and after crystallization at 120°C for 24 hours, it was washed and dried to obtain JZ-1, a highly stable mesoporous molecular sieve. Its physical property is that the specific surface area is 678m 2 g -1 , Mesopore specific surface area 545m 2 g -1 , pore volume 1.08ml·g -1 , with an average pore size of 4.1nm.

Embodiment 2

[0063] This embodiment provides a method for preparing a high-stability mesoporous molecular sieve, the method comprising the following steps:

[0064] (1), using Y-type molecular sieve precursor 1;

[0065] (2) Crystallization: take 50g of the Y-type molecular sieve precursor 1 solution, add 10g of the product JZ-1 of Example 1 as a seed crystal for assembly, adjust the pH value to 1.2, stir at 20°C for 24 hours, and age at 50°C for 10h Move to a crystallization kettle, crystallize at 100°C for 48 hours, wash and dry to obtain high stability mesoporous molecular sieve JZ-2. Its physical property is a specific surface area of 656m 2 g -1 , Mesopore specific surface area 571m 2 g -1 , pore volume 1.01ml·g -1 , the average pore size is 3.9nm.

Embodiment 3

[0067] This embodiment provides a method for preparing a high-stability mesoporous molecular sieve, the method comprising the following steps:

[0068] (1), using Y-type molecular sieve precursor 1;

[0069] (2) Crystallization: Take 30g of the Y-type molecular sieve precursor 1 solution and add 2g of the product JZ-2 of Example 2 as a seed crystal for assembly, adjust the pH value to 1.5, stir at 50°C for 10 hours, and age at 20°C for 24h Move to a crystallization kettle, crystallize at 120°C for 24 hours, wash and dry to obtain high-stability mesoporous molecular sieve JZ-3. Its physical property is that the specific surface area is 612m 2 g -1 , Mesopore specific surface area 402m 2 g -1 , the pore volume is 1.13ml·g -1 , the average pore size is 5.1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com