Method for protecting seed crystal layer during production of cast single crystal

A seed crystal layer and single crystal technology is applied in the field of protection of the seed crystal layer during the production of cast single crystals, which can solve the problems affecting the quality of cast single crystals, easy nucleation, etc., so as to reduce the probability of nucleation and growth, and reduce the number of nuclei. crystal, the effect of reducing the probability of dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

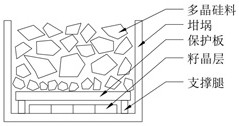

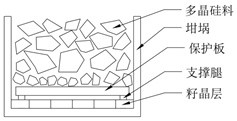

[0035] refer to figure 2 , when producing cast single crystal, provide a kind of seed crystal layer protection method, comprise the following steps:

[0036] Step a Prepare a protection plate, the size of the protection plate is 950mm×950mm×20mm, which matches the size of the G6 crucible, and the material of the protection plate is silicon material.

[0037] Step b Prepare support legs in the shape of a small cuboid, the size of the support legs is 30mm×30mm×10mm, and the material of the support legs is silicon material.

[0038] Step c: pull the single crystal ingot to remove the skin, and then cut to obtain a cuboid-shaped seed crystal. The size of the seed crystal is 158mm×158mm×20mm.

[0039] Step d: laying the seed crystal on the bottom of the crucible to form a complete seed crystal layer.

[0040] In step e, place the support legs in the shape of a small cuboid around the seed crystal layer. Only the four corners of the seed crystals are subjected to compressive stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com