Method for preparing multi-crystal structure lead-free interconnection welding spot by applying vibration

A technology of polycrystalline structure and solder joints, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of large CTE mismatch, prone to failure of solder joints, and easy failure of interconnected solder joints, etc. Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

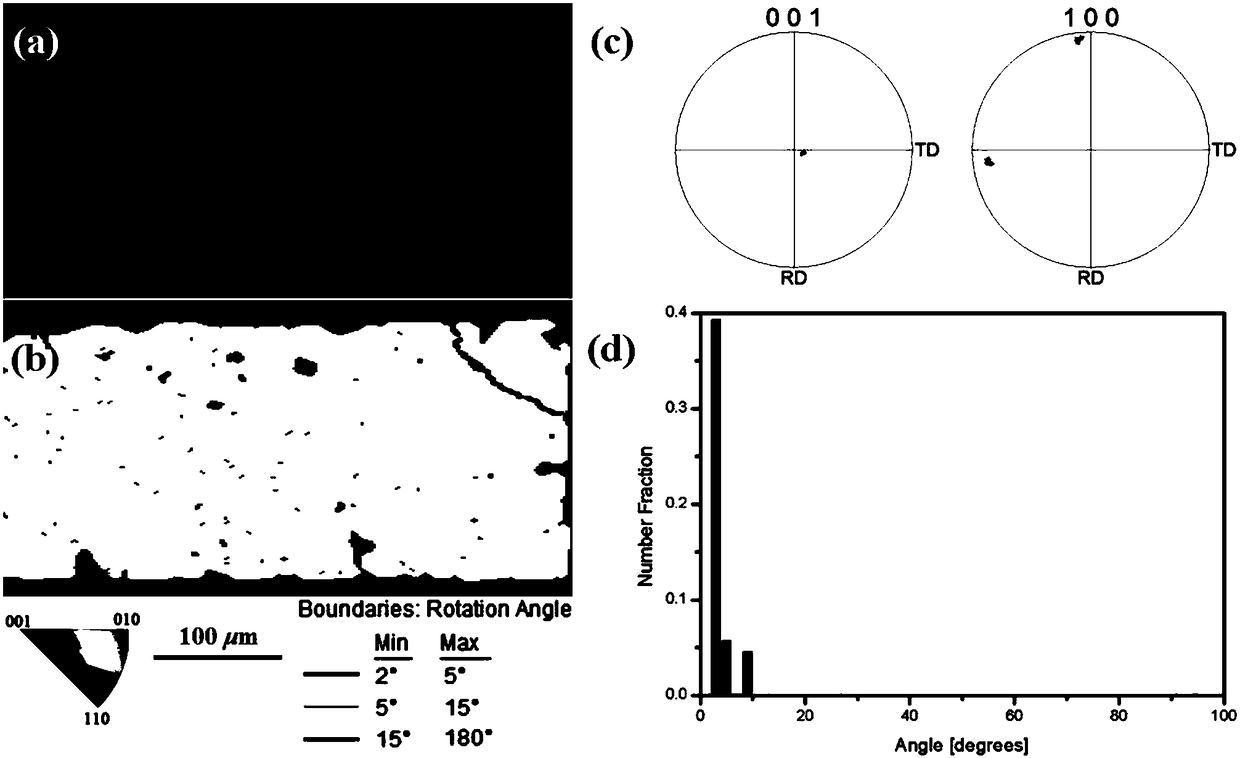

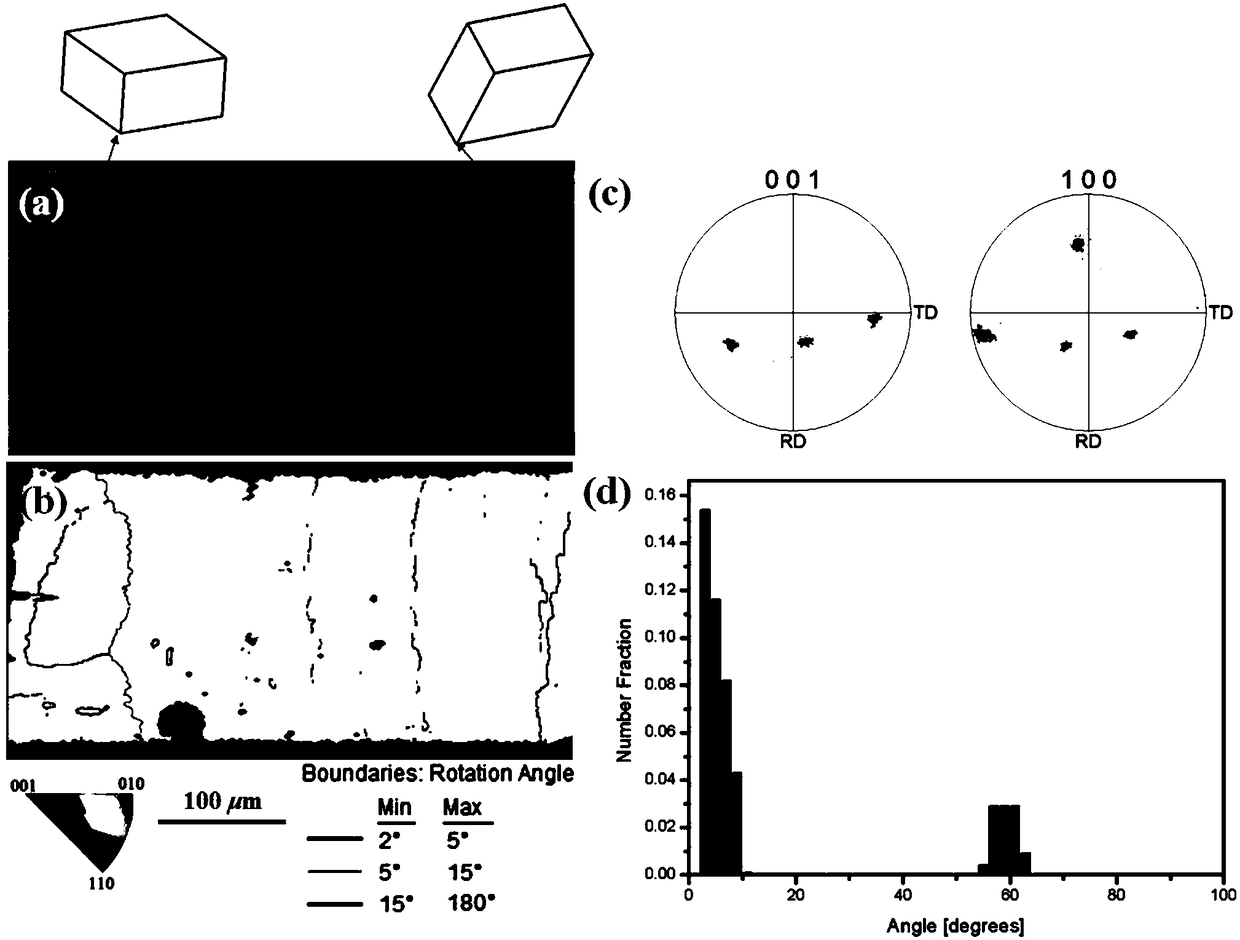

[0040] Example 1: figure 1 with 4 Explain in detail the implementation of the present invention, and combine Figure 5 , 6 , 7, 8, 9 and 10 show that the electromigration reliability of the polycrystalline solder joint structure is better than that of the single crystal solder joint.

[0041] Production of Cu / Sn3.5Ag(wt.%) / Cu linear solder joints with a cross-sectional size of 400μm×400μm and a thickness of 300μm, presenting a polycrystalline structure.

[0042] 1. The copper pad is made by wire cutting, its size is 400μm×400μm×10mm, and its purity is 99.99wt.%. Put the pad into the prepared HNO with a volume fraction of 30% 3 Soak in an aqueous solution for 30s to remove the oxide on the surface, then put the pad in an acetone solution for 60s to remove the contaminants on the surface, and then dry it for later use;

[0043] 2. Paste the double-sided adhesive on printed circuit boards (PCB), the size of the PCB is 10mm×10mm×2mm, the material is FR-4, and the copper pad to be soldered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com